1. Description

PML630 is a power management device that provides

comprehensive load-shedding solution for the power network

in an industrial plant. It protects the plant against blackouts and

power source outages due to system disturbances. PML630 is

a member of ABB’s Relion® product family and a part of its 630

series characterized by their functional scalability and flexible

configurability.

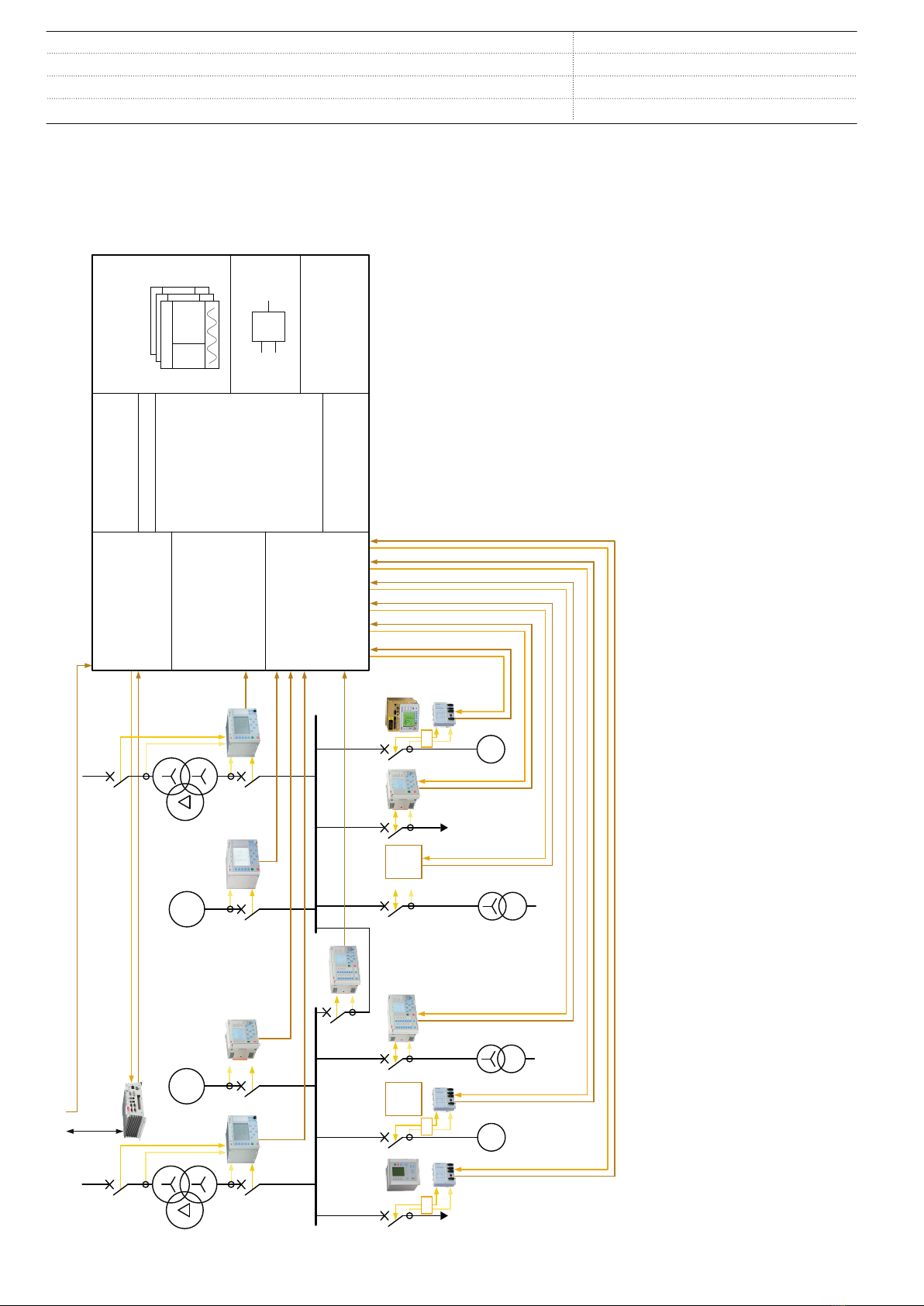

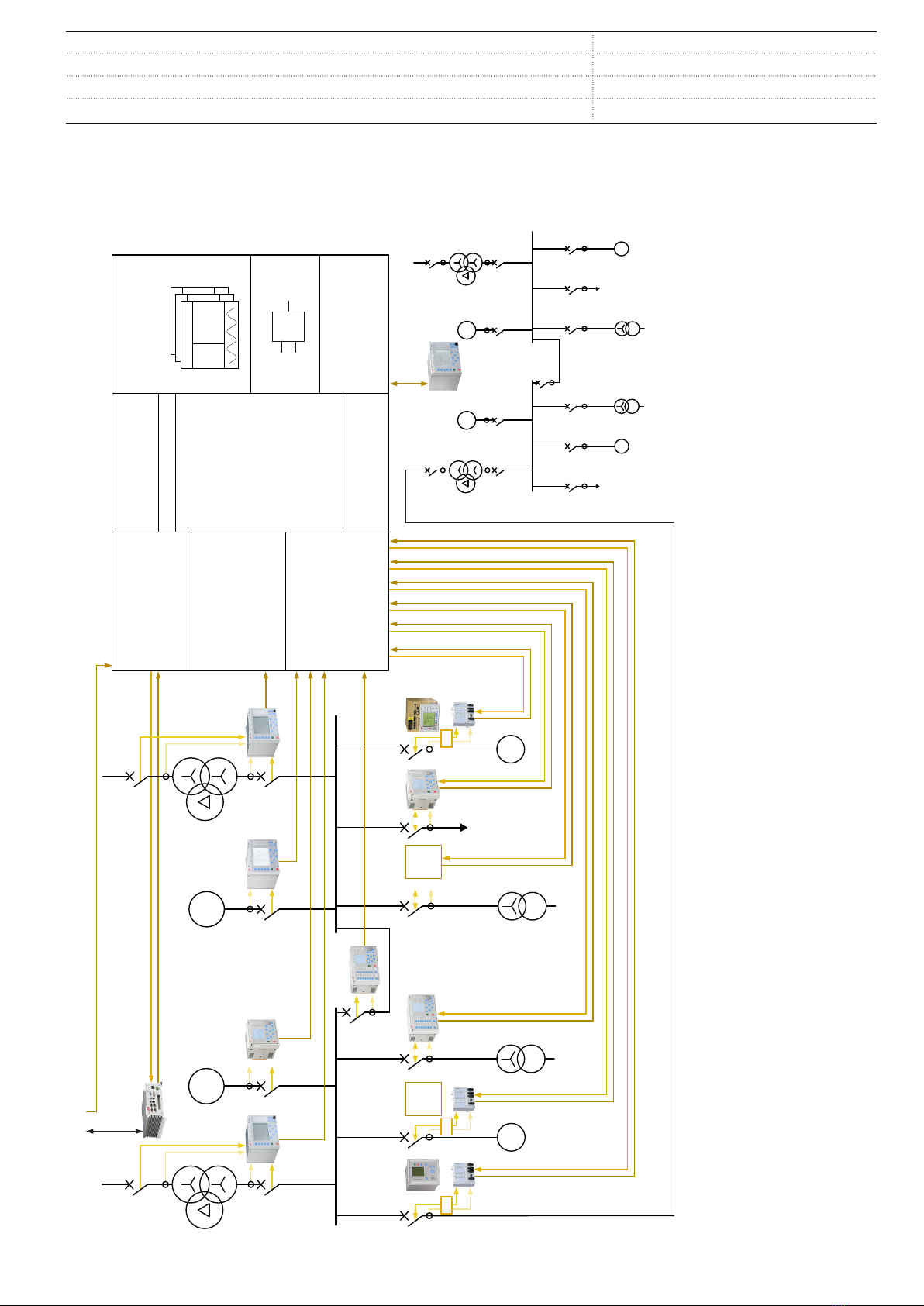

PML630 complies to IEC 61850 and offers seamless

connectivity with Relion 630, 620 and 615 series protection

relays, RIO600 IO units and COM600 to realize the load-

shedding functionality. The device uses GOOSE and MMS

communication profiles for I/O data exchange with other Relion

product family protection relays and COM600 series products.

2. Power management systems

Power Management Systems (PMS) is essential for a safe,

efficient and reliable operation of a power system within an

industrial complex. The PMS functionality suite includes load-

shedding, generator control, power sharing, network

synchronization and power restoration.

PMS solutions protect and optimize the stability of industrial

systems against disturbances by ensuring power sharing

between generators when the industrial power system is

islanded from the grid. These solutions also ensure that the

generators meet the required power demand when the network

is grid-connected. By ensuring fast acting load-shedding

action, generator tripping can be avoided and thereby

facilitating possible islanding of the network.

PMS solutions are suitable for industrial power networks.

• With captive power generation - islanded or grid-

connected

• With substantial and critical loads

• With unstable grid connectivity

• Without grid connectivity

The PMS functionality suite is applicable in various industrial

segments. Some of the industrial segments are Oil and Gas,

Marine, Pulp and Paper, Metals, Minerals, Building automation,

Infrastructure, Food and Beverage. In power utilities, load-

shedding application is particularly relevant.

3. Load-shedding

Load-shedding is required when the electrical load demand

exceeds the capacity of available power sources subsequent to

the loss of power sources or network disintegration. The load-

shedding system has to ensure the availability of electrical

power to all essential and, most importantly, critical loads in the

plant. This is achieved by switching off the non-essential loads

in case of a lack of power in the electrical network or parts of the

electrical network (subnetwork or island).

The load-shedding functionality can also be deployed in

industrial power networks with sole dependency on the utility

networks.

The lack of electrical power can be caused by a loss of

generation capacity or power grid connectivity or the tie line

feeding power to the plant.

Based on the shortfall of available power in the power network,

the load-shedding action initiated by the system ensures that

only identified loads are shed, system is stable after load-

shedding and impact on the associated plant operation is

minimal. The system allows flexibility to select or deselect the

load feeders to be load-shed at any point in time during plant

operation.

Furthermore, the load-shedding function should not operate if

the situation in the power network does not necessitate such an

action. Thus, it has to be accurate and selective.

4. Application

PML630 provides system level protection to small or medium-

sized industrial systems from the system disturbances. The

device supports different modes of load-shedding functions.

• Fast load-shedding

• Slow (overload or maximum demand violation-based)

load-shedding

• Manual load-shedding

• Underfrequency load-shedding as a backup to fast and

slow load-shedding

A network power deficit occurs when a power source such as a

generator or a grid transformer trips. There could also be a

power shortage when a network becomes isolated due to trip of

a bus coupler or a bus tie breaker. The fast load-shedding

function protects the power network during a power deficit.

The fast load-shedding function takes corrective action before

the system frequency [1] drop and provides faster and accurate

load-shedding action based on the power balance calculations

and defined priorities. Thus, the function also contributes

towards faster improvement of the frequency profile of the

system.

The slow load-shedding function prevents the tripping of a

power source during an overload condition. The slow (overload)

load-shedding function triggers the load-shedding and resets

the overload condition by acting faster than the dedicated

overload protection function for the power sources. The

overload situation can arise due to the overcurrent detection in

a generator or grid transformer, or maximum demand violation

at the power grid incomer for a specified period of time. Based

on the amount of the overload, the slow load-shedding function

determines the required load to be shed and uses the power

[1] A frequency-based load-shedding scheme, at the feeder level, acts based on the frequency drop caused by a power deficit. It triggers the shedding of loads based on the preset rate of

change of the frequency or the discreet frequency value settings in their respective devices. It can sometimes result in excessive load-shedding.

1MRS757334 E

PML630/Compact Load-Shedding Solution

Product version: 1.2.1 Issued: 2019-08-27

Revision: E

ABB 3