5SUMMARY

—

1 Summary

1.1 General

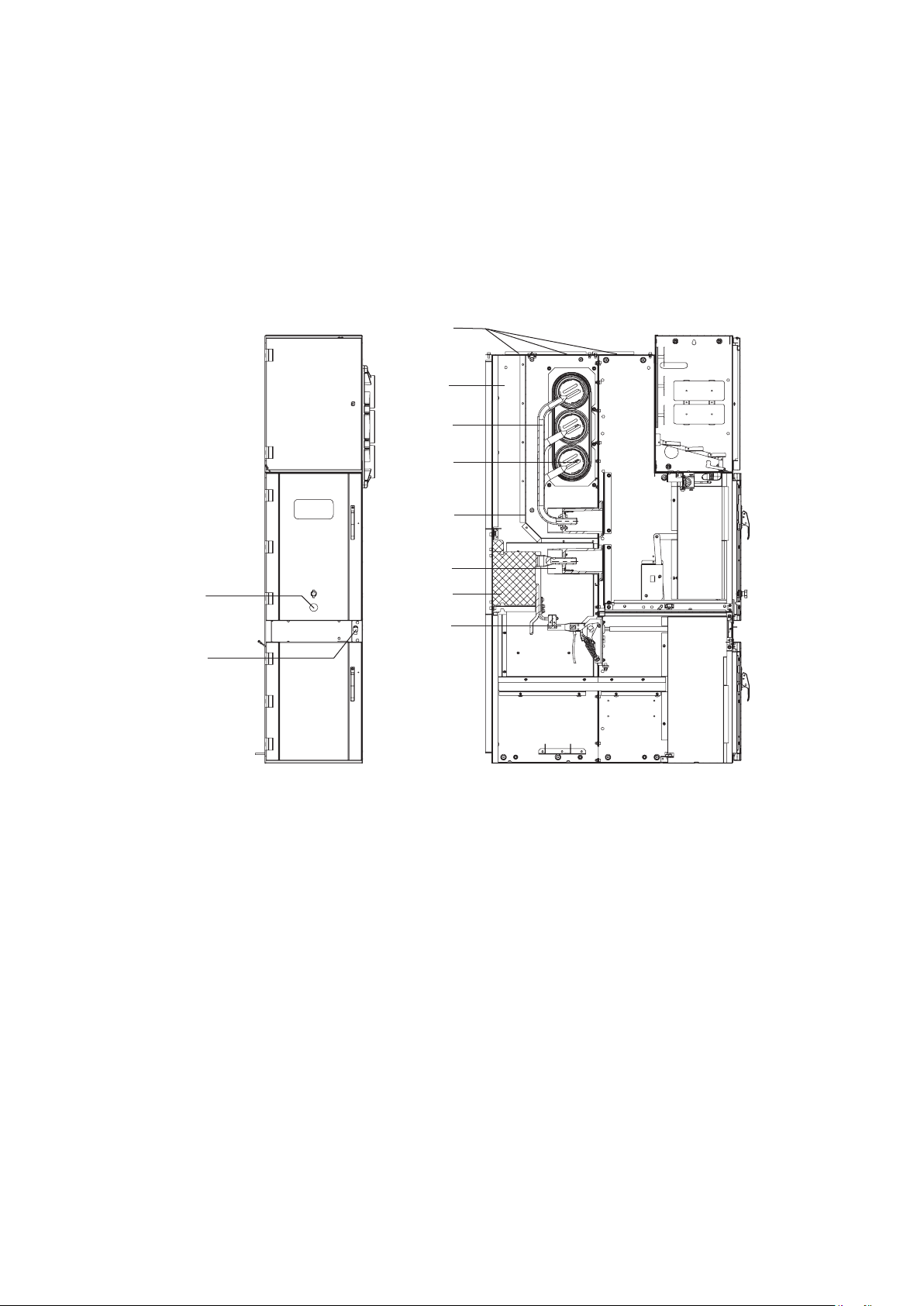

UniGear ZS1 is a three-phase, metal-enclosed, air

insulated switchgear that is factory-assembled,

type tested and suitable for indoor applications up

for 12 kV. The units are designed to accommodate

withdrawable modules and are fitted with a

single busbar system. The withdrawable parts

are equipped with circuit-breakers. Details of the

technical design and configuration of individual

switchgear, including detailed equipment lists

for the individual panels and comprehensive

circuit documentation etc. can be found in the

relevant order documents.

1.2 Standards and specifications

UniGear ZS1 switchgear panels comply with the

standards and specifications for factory-

assembled, metal-enclosed and type-tested high

voltage switchgear, i.e. IEC publications 62271-200

and 62271-1. In addition, in accordance with IEC

60529, the switchgear panels have the following

degrees of protection: IP4X for the enclosure and

IP2X for the partitions.

All other corresponding IEC publications, national

or local safety at work regulations and safety

regulations for production materials must be

followed during the installation and operation of

these systems. Above and beyond this, the order-

related data from ABB must be taken into account.

1.3 Operating conditions

1.3.1 Normal operating conditions

The switchgear is basically suitable for normal

operating conditions for indoor switchgear in

accordance with IEC 62271-200. Among other

considerations, the following limiting values

apply.

The normal operational altitude is up to 1,000 m

above sea level.

The indoor ambient conditions are free of

significant pollution, such as dust, smoke,

corrosive and/or flammable gases, vapors or

salt, etc.

1.3.2 Special operating conditions

The switchgear is suitable for operation in the

WDa type of climate according to IEC 60721-2-1.

Special operating conditions must be discussed

with ABB in advance. For example:

• At site altitudes above 1,000 m, the effects of

the reduction in dielectric strength of the air on

the insulation level must be taken into account

(please refer to the diagram in Figure 1)

• Increased ambient temperatures must be

compensated in the design of the busbars and

branch conductors, otherwise the current

carrying capacity will be limited

Note on special climatic operating conditions:

When switchgear is operated in areas with high

humidity and/or major rapid temperature

fluctuations, there is a risk of dew deposits

which must be excluded under normal operating

conditions for indoor switchgear.

Preventive action (e.g. suitable ventilation and

proper air conditioning of the building or housing,

use of dehumidifying equipment, etc.) must be

taken into consideration with ABB to avoid this

condensation phenomenon and any resulting

corrosion or other adverse effects.

Ambient temperature:

• Maximum +40 °C

• Maximum 24 h average +35 °C

• Minimum (according to “minus indoor class”) -15 °C

Ambient humidity:

Maximum 24 h average of relative humidity 95% RH

Maximum 24 h average of water vapour pressure 2.2 kPa

Maximum monthly average of relative humidity 90% RH

Maximum monthly average of water vapour pressure 1.8 kPa

k 1,0

0,8

0,6

0,4

1000 2000 3000 4000 m 5000 H