Release Notes for RobotStudio 2022.1

General

The release name is RobotStudio 2022.1 and the build number is 22.1.9826.0. The release date is March

29, 2022.

User documentation

The RobotStudio Operating Manual is available in all languages except Czech, i.e. English, German,

French, Korean, Chinese, Japanese, Spanish. A selected set of RobotWare manuals are available. Each of

them is available in two versions, one for IRC5 and one for OmniCore.

Tutorials

Tutorials are available at the RobotStudio product pages at http://www.abb.com/roboticssoftware.

System Requirements

Required Software

Microsoft Windows 10 Anniversary Edition or later, 64-bit edition, is required.

The Windows AppInstaller is a pre-requisite for the virtual OmniCore FlexPendant software, see

https://www.microsoft.com/en-us/p/app-installer/9nblggh4nns1. The App Installer is a default built-in

app in Windows 10, but may have been removed on some PCs.

Sideloading of apps must be enabled on Windows 10 to install the virtual OmniCore FlexPendant.

To enable sideloading follow these steps:

1. Open Settings.

2. Click Update & Security > For developers.

3. Under Use developer features, select Sideload apps or Developer mode.

Recommended Hardware

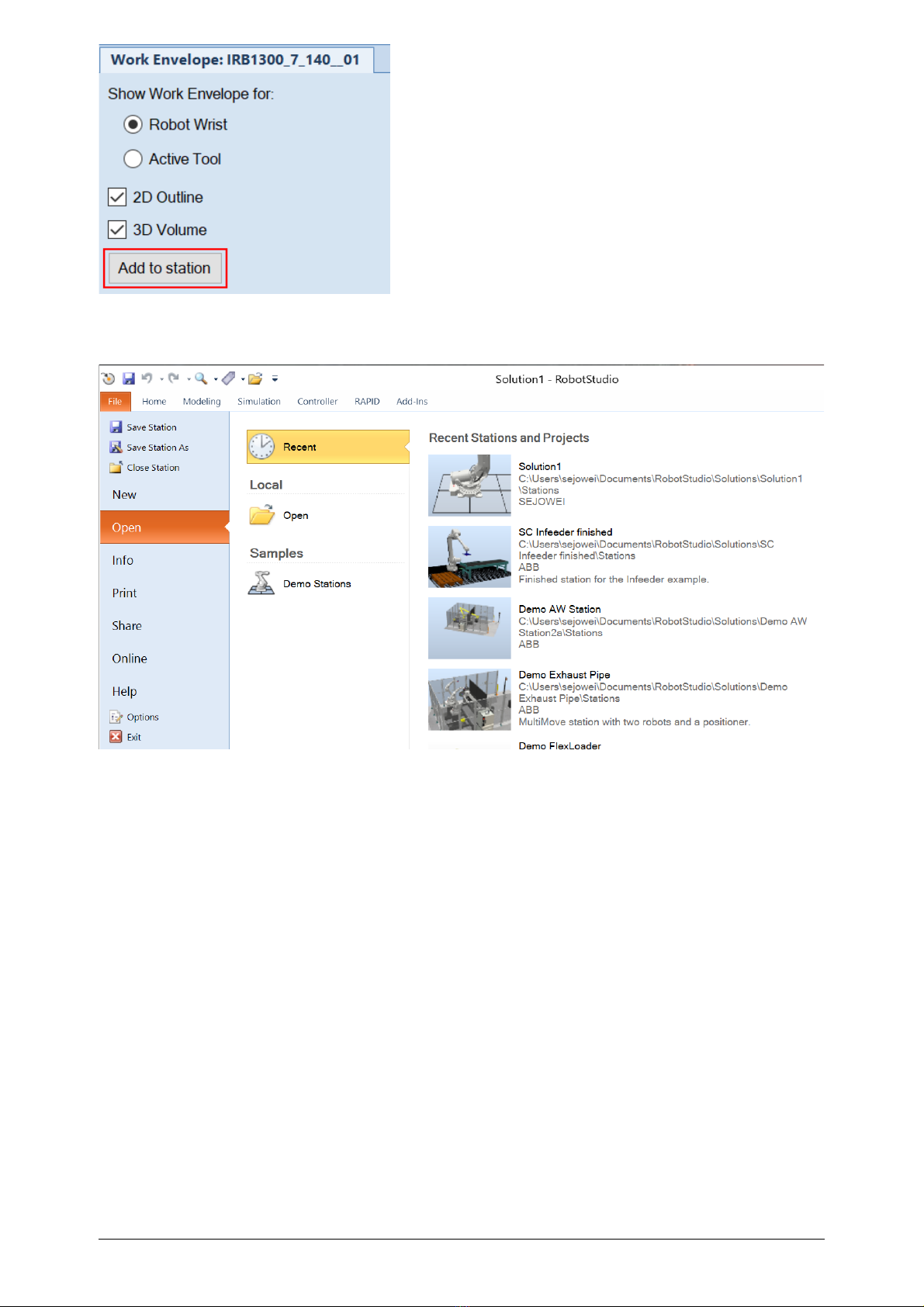

ITEM RE QUIRE ME NT

CPU 2.0 GHz or faster processor, multiple cores recommended

Memory 8 GB minimium

16 GB or more if working with large CAD models

Disk 10+ GB free space, solid state drive (SSD)

Graphics

Card¹

High-performance, DirectX 11 compatible, gaming graphics card from any of the leading vendors.

For the Advanced lightning mode Direct3D feature level 10_1 or higher is required.

Screen

Resolution 1920 x 1080 pixels or higher is recommended

Mouse Three-button mouse

3D Mouse Any 3D mouse from 3DConnexion, see http://www.3dconnexion.com.