- 5 -

3002TC

Contents

Introduction and safety ...................................................................................................................... 7

Warnings in this document ...................................................................................................................7

Equipment safety warnings.................................................................................................7

General installation warnings..............................................................................................8

Assembly warnings ..............................................................................................................8

Electrical connection warnings...........................................................................................8

Safety instructions .................................................................................................................................9

General information..............................................................................................................9

Thermal and voltage hazard ................................................................................................9

Clothing and protective devices .......................................................................................10

Location of safety notices and labels...............................................................................10

Appropriate usage................................................................................................................................10

Environmental conditions..................................................................................................10

Improper or prohibited use................................................................................................10

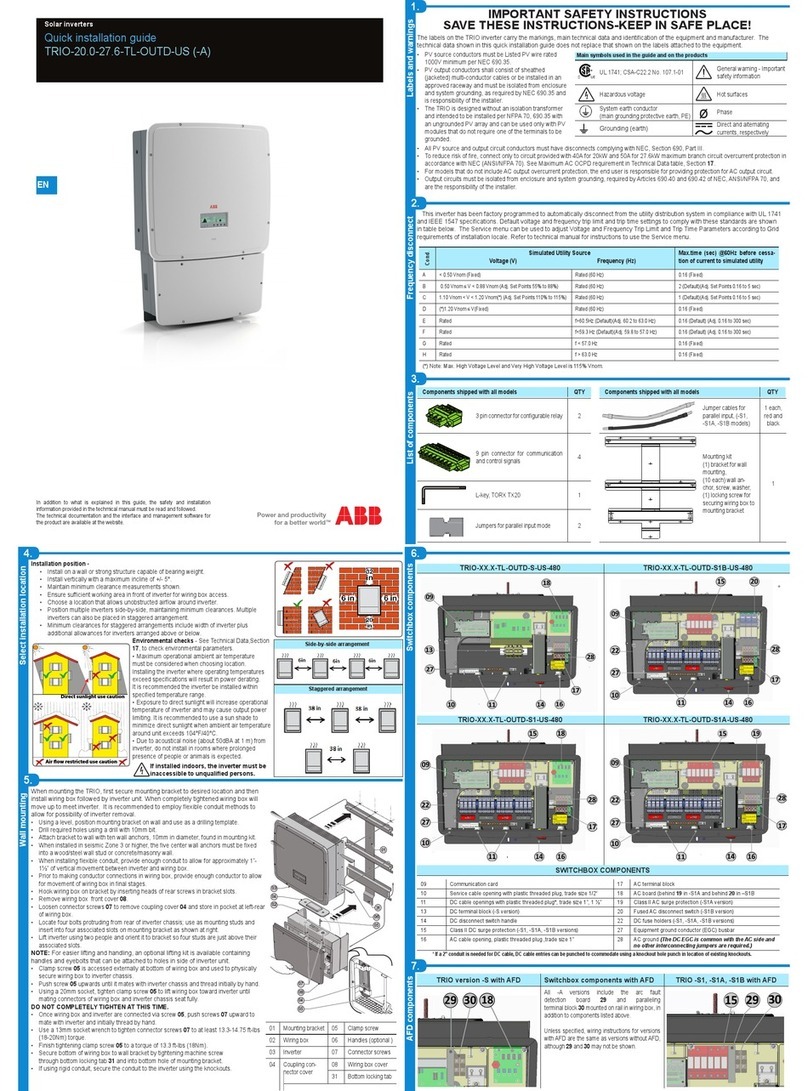

Arc fault detection (AFD) .....................................................................................................................11

Available versions ................................................................................................................................11

Regulatory label ..................................................................................................................12

Installation location .......................................................................................................................... 13

Transportation and handling...............................................................................................................13

Lifting ...................................................................................................................................13

Incoming inspection...........................................................................................................13

Select the installation location............................................................................................................14

Environmental check..........................................................................................................14

Installation position ............................................................................................................15

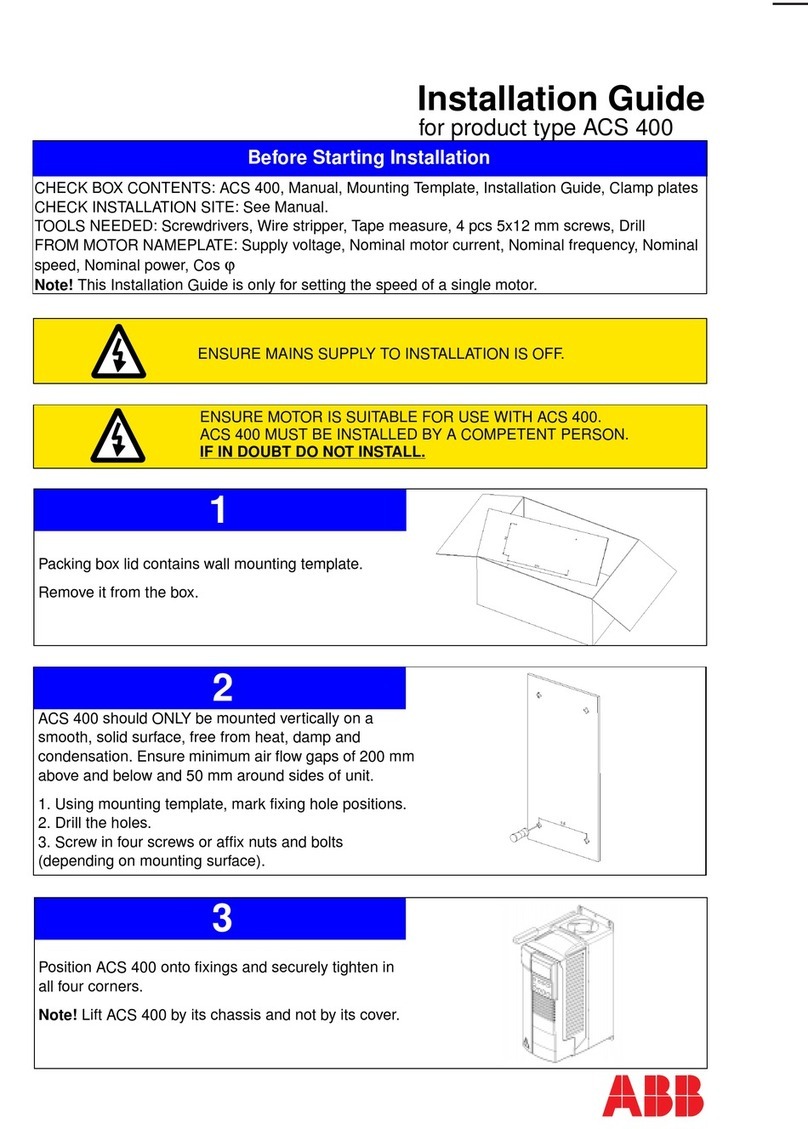

Mounting and wiring ....................................................................................................................... 17

Wall mounting .......................................................................................................................................17

Wiring details ........................................................................................................................................19

Wiring box components.....................................................................................................19

Wiring connections.............................................................................................................22

DC array connections ..........................................................................................................................23

Independent or parallel configuration of inputs..............................................................24

Setting the input mode switch S1 .....................................................................................25

Parallel mode front switch wiring box –S versions only without AFD .........................25

Parallel mode bottom switch wiring box and -S version with AFD...............................26

AC grid connection ..............................................................................................................................26

Serial communication (RS-485).........................................................................................29

Daisy chain multi unit configuration ................................................................................29

Addressing each inverter...................................................................................................30

Configurable relay connection (Alarm) ............................................................................31

Remote control connection ...............................................................................................31

Monitoring system via serial (RS-485)..............................................................................31