In addition to what is explained below, the safety and installation information provided in the

installation manual must be read and followed. The technical documentation and the interface

and management software for the product are available at the website.

The device must be used in the manner described in the manual. If this is not the case the

safety devices guaranteed by the inverter might be ineffective.

Quick Installation Guide

REACT-BATT-AP1

ABB Solar inverters

1.

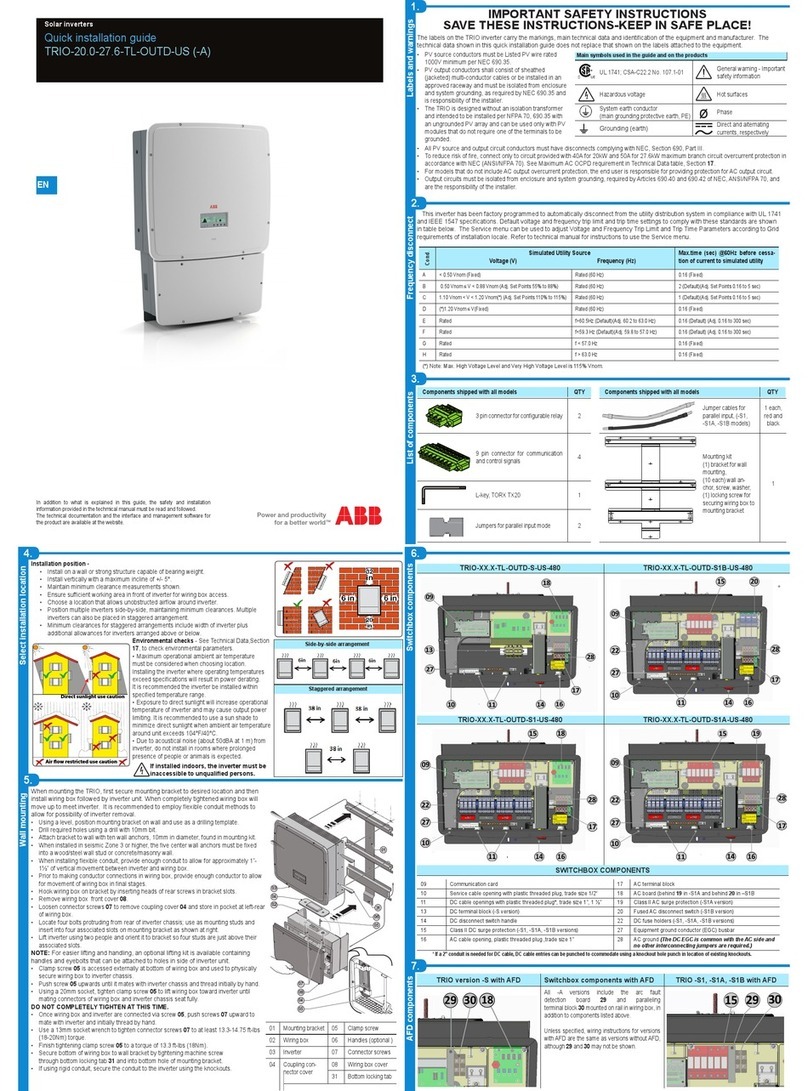

Labels and SymbolsEquipment Models and Components

2.

EN

Safety precautions

4.

Lifting and transport

5.3.

List of supplied components

The labels on the equipment have the Agency marking, main technical data and identication of the equipment and manufacturer

HAZARD. The hazard warnings (set out below) are used to indicate risks or unsafe practices that CAN cause serious injury or death.

• DO NOT dismantle or disassemble the parts of the battery pack (REACT-BATT-AP1). The battery pack has safety functions and protection circuits which could

be compromised by improper use.

• DO NOT set light to or heat the battery pack. Possible damage or melting of the insulation with consequent loss of the safety conditions due to the release of

gas or burning of electrolyte material. The battery pack could produce heat, smoke, breakages or ames.

• DO NOT use or leave the battery pack near a naked ame, boiler or heated places (beyond the temperature range indicated in the technical data).

• DO NOT immerse or wet the battery pack with fresh or salt water. The battery pack could produce heat, smoke, breakages or ames.

• DO NOT break into, strike or stamp on the battery pack; this could deform, damage or short-circuit the battery pack. The battery pack could produce heat,

smoke, breakages or ames.

• DO NOT create damaging impacts or drop the battery pack. The battery pack could be damaged.

• DO NOT use the battery pack for other equipment. The battery pack REACT-BATT-AP1 must be used solely with the inverter REACT-UNO-XX

• DO NOT touch the battery pack directly if there is a leak of electrolyte material. Should the electrolyte material come into contact with the eyes, wash the eyes

with plenty of fresh water as soon as possible, without rubbing them. Then consult a doctor. If no treatment is applied, there could be problems for the eyes.

• DO NOT touch the battery pack if it shows any breaks in the plastic cover where any parts under voltage are visible.

• DO NOT use the battery pack should a fault or any anomaly (such as in smell, heat, colour, smoke, shape or noise) be found. The battery pack could produce

heat, smoke, breakages or ames.

WARNING. The warnings (set out below) are used to indicate risks or dangerous actions which COULD cause serious personal harm or

damage to the product or property.

• DO NOT use the battery pack REACT-BATT-AP1 with other battery models if not expressly indicated by ABB.

• DO NOT use a battery pack that is leaking electrolyte material. The electrolyte material which has leaked from the battery could burn or catch re and cause

smoke, breakages or ames.

• DO NOT use the battery pack if it shows anomalies. Should the battery pack have a bad smell, changes in colouring, deformation or other anomalous condi-

tions during use (including charging and storage), do not use it. If an anomalous battery pack is used, it may produce heat, smoke, breakages or ames.

CAUTION. The caution messages (set out below) are used to indicate risks or dangerous actions which could cause serious harm to people

or damage to property.

• DO NOT use or leave the battery pack exposed to direct sunlight (or in a vehicle which is exposed to the sun). The battery pack could produce heat, smoke,

breakages or ames. In addition, its performance might deteriorate and/or it might have a shorter lifespan.

• If the battery pack has signs of rust, a bad smell or any anomaly on rst being used, do not use the equipment.

• If the skin or clothes come into contact with electrolyte material which has leaked from the battery pack, wash them in plenty of fresh water as soon as possi-

ble, otherwise it might cause inammation of the skin.

Final installation of the equipment must not hinder access to any externally located disconnection devices.

Please refer to the warranty terms and conditions to evaluate any possible warranty exclusions due to improper installation.

The model of equipment to which this guide refers is REACT-BATT-AP1.

The principal components of the REACT-BATT-AP1 are shown in the gure and described in the following table:

3837

394041

424344453635131411

Main components

11 Front cover

14 Battery unit (REACT-BATT-AP1)

13 Battery pack

35 Ground connection points

36 Cabling bypass male ange

45 Internal battery communication (cable to left unit)

44 Switch for setting the termination resistance of the internal battery communication

43 Internal battery communication (cable from right unit)

42 Rotary switch (RS485 internal line address)

41 Communication connector (cable to left unit)

40 Smoke sensor

39 Communication and control connector (cable from right unit)

37 Power connector (cable to left unit)

38 Power connector (cable from right unit)

Transport and handling

Transport of the equipment, especially by road, must be carried out with by suitable ways and means for protecting the components (in particular, the electronic

components) from violent shocks, humidity, vibration, extreme temperatures, etc.

The REACT-BATT-AP1, as it falls within the category of dangerous goods (UN 3480 lithium-ion battery, class 9, group II), must comply with the rules of the

ADR (European Agreement concerning the International Carriage of Dangerous Goods by Road) as regards packaging, transport and marking.

For more information, consult the website of the Ministry of Infrastructure and Transport on page http://www.mit.gov.it/mit/site.php?o=vc&lm=2&id_cat=207).

Exemptions from the provisions:

• the “Ancillary rule” (1.1.3.1 c ADR)

• the “1,000 Units rule” (1.1.3.6 ADR)

-End of life battery unit transportation

Besides complying with the general application of the ADR, Battery Units which are transported for disposal must comply with the following guidelines:

- Be packed in accordance with packing instruction P909 of 4.1.4.1

- Packages that need to be marked: “LITHIUM BATTERIES FOR DISPOSAL”, in addition to other labels and indications provided for in the ADR.

For further details, please refer to the ADR document: “European Agreement concerning the International Carriage of Dangerous Goods by Road”, special

regulation 377.

Storage of REACT-BATT

The storage of REACT-BATT starts from the moment of delivery by ABB. In order to guarantee the full operation of the system, REACT-BATT must be put into

service within 1 year at most of the date of production.

In order to reduce risks during storage of the REACT-BATT it must be considered that:

• In the case of damage to the REACT-BATT there is a high risk of re.

• Keep the REACT-BATT in a dry place.

• Relative humidity, not condensing: 5% … 95%

• Handle and treat packages carefully.

• Avoid unnecessary movements of the REACT-BATT.

• Ambient temperature allowed during storage: -5°C...+40°C

• Maximum height above sea level (a.s.l.): = 2 000 m

For the rules on storing the battery, refer to the regulations in force in the country concerned

- Handling of damaged batteries

Should damage or visible deformation of the cover be found, or should it be noted that the batteries have overheated during operation, immediately contact the

ABB technical assistance service.

Lifting

Risk of injury due to the weight of the equipment.

Where indicated and/or where there is a provision, eyebolts or handles, which can be used as anchorage points, are

inserted and/or can be inserted.

The ropes and means used for lifting must be suitable for bearing the weight of the equipment.

- Equipment weight

Model Weight (kg/lb) Lifting points

REACT-BATT-AP1 37kg / 81.5lb 4 (2 people)

Unpacking and checking

Bear in mind that the packaging elements (cardboard, cellophane, staples, adhesive tape, straps, etc.) may cause cuts and/or injuries if not handled with care.

They should be removed by suitable means and not left in the hands of individuals who are not responsible (e.g. children).

The packaging components must be disposed of in accordance with the regulations in force in the country of installation.

When you open the package, check that the equipment is undamaged and make sure all the components are present.

If any defect or damage is detected, please stop, contact the carrier and also promptly inform the ABB Service

Disposal of battery unit

ABB is responsible for the battery unit disposal. Contact the local ABB service for further details.

At the end of its life cycle, Battery Unit can be packed and transported by trained personnel in accordance with Chapter 1.3 ADR - See section “Transport of

batteries at end of life”.

In case the original packing of the Battery Unit is no longer available, you may request a new one by contacting the ABB service.

In the manual and/or in some cases on the equipment, the danger or hazard zones are indicated with

signs, labels, symbols or icons.

Always refer to instruction manual General warning - Important safety

information

Positive pole and negative pole of

the input voltage (DC)

Temperature range

Hazardous voltage Hot surfaces

Always use safety clothing and/or

personal safety devices

Point of connection for grounding

protection

The labels attached to the equipment must NOT be removed, damaged, dirtied,

hidden,etc...

Components available for battery unit Quantity

Cabling bypass male ange

1

Inadditiontowhatisexplained in thisguide, the safetyand installationinformation providedin the installationmanualmustbe read and followed.

Thetechnicaldocumentationandtheinterfaceandmanagement softwarefor the productare availableat the website.

XXXXXXXXXXXXXXXXXXX

XXXXXXXXXXXXXXXXXXX

ABBsolarinverters

Technical documentation 1

REACT

POWER ALARM GFI ESC UP DOWN ENTER

REACT-UNO

REACT-BATT