6.0 MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

6.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

6.2 System Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

6.3 Static Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

6.3.1 Magnet Coil Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

6.3.2 Electrode Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

6.3.3 Flowmeter Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-6

7.0 PARTS LIST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

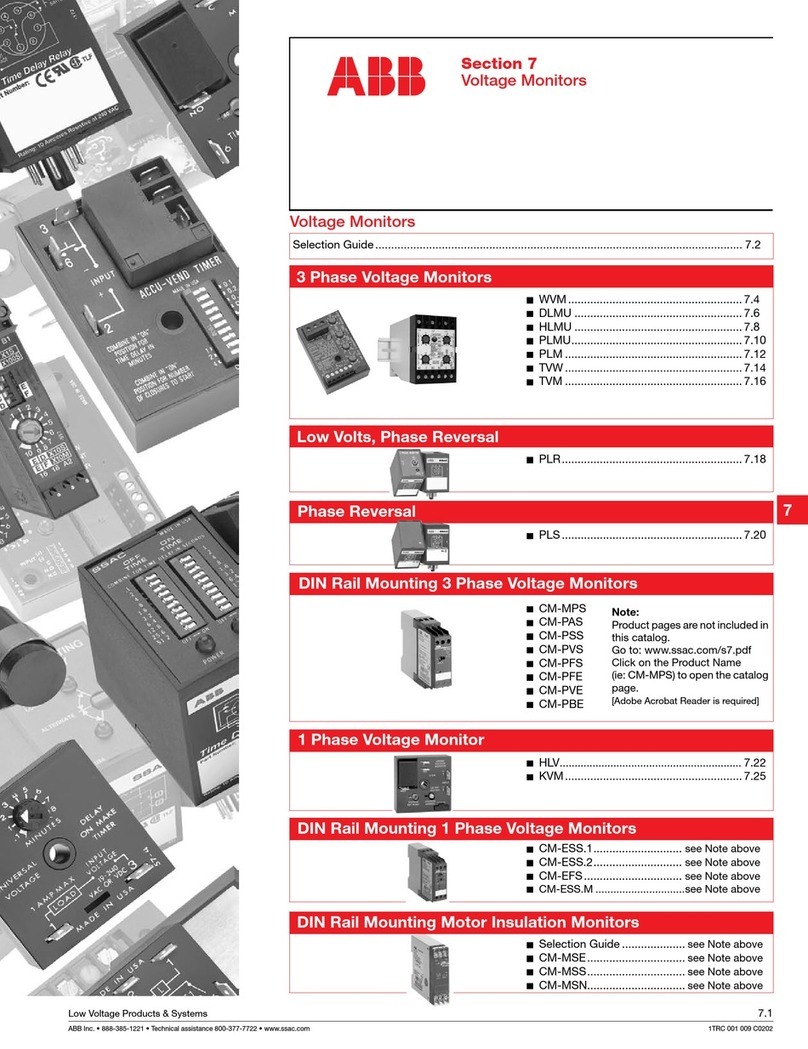

Figure List

FIGURE 1-1. TYPICAL FLOWMETERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

FIGURE 1-2. ELECTRONICS COMPARTMENT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

FIGURE 2-1. OUTLINE DIMENSIONS, SIZES 1/25" THROUGH 1-1/2" . . . . . . . . . . . . . . . . . . . . . . . . 2-2

FIGURE 2-2. OUTLINE DIMENSIONS, SIZES 2" THROUGH 4" . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

FIGURE 2-3 OUTLINE DIMENSIONS, WITH SANITARY FITTINGS, SIZES 1/25" THROUGH 1-1/2" . 2-6

FIGURE 2-4 OUTLINE DIMENSIONS, WITH SANITARY FITTINGS, SIZES 2" THROUGH 4" . . . . . . 2-7

FIGURE 2-5. RECOMMENDED PIPING DIAGRAM. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

FIGURE 2-6. FLANGE BOLT TIGHTENING SEQUENCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

FIGURE 2-7. MOUNTING DIAGRAM FOR 1- 40 mm (1/25 - 1-1/2") SIZES . . . . . . . . . . . . . . . . . . . . 2-10

FIGURE 2-8. MOUNTING DIAGRAM FOR 50 - 100 mm (2 - 4") SIZES. . . . . . . . . . . . . . . . . . . . . . . . 2-12

FIGURE 2-9. MOUNTING DIAGRAM, SANITARY FITTINGS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-13

FIGURE 2-10. OUTLINE DIMENSIONS, GROUNDING RINGS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-15

FIGURE 2-11. GROUNDING PROCEDURE, NON-INSULATED PIPE . . . . . . . . . . . . . . . . . . . . . . . . 2-16

FIGURE 2-12. GROUNDING PROCEDURE, INSULATED PIPE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-17

FIGURE 2-13. 10D1476S REMOTE CUSTOMER CONNECTION BOX . . . . . . . . . . . . . . . . . . . . . . . 2-18

FIGURE 3-1. TYPICAL INSTRUMENT TAG . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

FIGURE 3-2. ADDITIONAL TAG FOR FM APPROVED METER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

FIGURE 3-3. PRIMARY MOUNTED PC ASSEMBLIES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

FIGURE 4-1. BASIC OPERATING PRINCIPLE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

FIGURE 5-1. SCHEMATIC for PRIMARY WIRING, REMOTE CONVERTER . . . . . . . . . . . . . . . . . . . . 5-2

FIGURE 5-3. SCHEMATIC for CMF BOARD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

FIGURE 7-1. EXPLODED VIEW, BASIC FLOWMETER PARTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

Table List

TABLE 1-1. CAL FACTOR and CAPACITY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

TABLE 2-1. RECOMMENDED BOLT TORQUE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

TABLE 6-1. PRIMARY COIL RESISTANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

TABLE 7-1. ANSI CLASS 150 GROUNDING RINGS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

TABLE 7-2. GASKETS FOR ANSI CLASS 150 GROUNDING RINGS. . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

TABLE 7-3. GASKETS FOR METER BODY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

TABLE 7-4. BASIC METER PARTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-3

10D1476 K-MAG MAGNETIC FLOWMETER INSTRUCTION MANUAL

ii