4CI/ADS550–EN Rev. D

1Sample requirements

1. Ensure the sampling point is as close as possible to the

wet-section and provides a thoroughly-mixed representative

sample.

2. Sample must contain <10 ppm suspended solids with a

particle size no greater than 60 µm. (If particle sizes exceed

60 µm, use a 60 µm filter.)

3. Sample temperature must be within the range 5 to 55 °C

(41 to 131 °F).

4. Sample flow rates must be within the range 100 to

300 ml/min. (6.10 to 18.30 cu in./min.) – recommended

150 ml/min (9.15 cu in./min.).

5. Sample pressure must not exceed 2 bar gauge (29 psi).

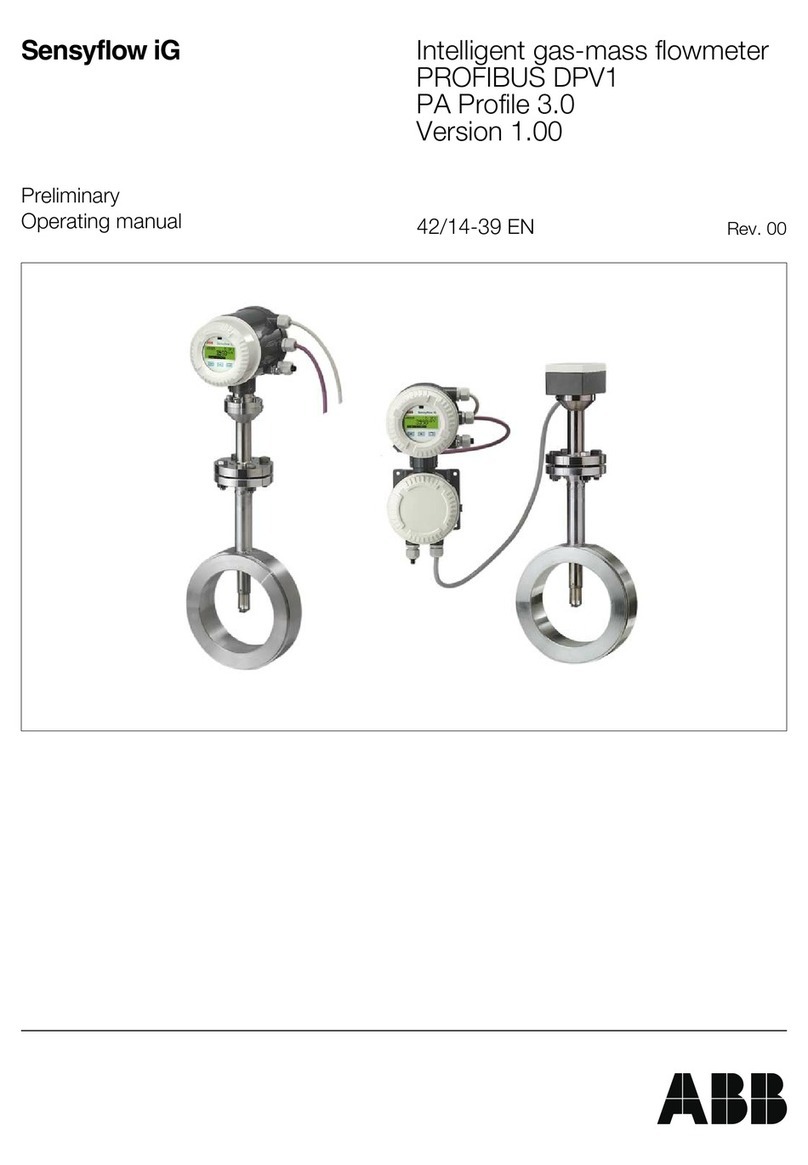

2Locating the wet-section

Referring to Fig. 1:

1. Locate the wet-section / transmitter indoors in a clean, dry,

well-ventilated, easily-accessible area.

2. Do not locate in rooms containing corrosive gases or vapors –

for example, with chlorination equipment or chlorine gas

cylinders.

3. Select a location not subject to strong electrical and magnetic

fields. If this is not possible (for example, where mobile

communications equipment is present), use screened cables

within flexible, earthed, metal conduit.

Note. If the measured sample temperature exceeds

55 °C (131 °F), the calibration valve opens automatically

to protect the dissolved oxygen sensor from thermal

overload. The valve closes after 30 minutes, but if the

sample temperature still exceeds 55 °C (131 °F) the valve

re-opens.

Fig. 1 Locating the wet-section

Maximum cable distance

to transmitter

30 m (98 ft.)

IP54

55 °C

(131 °F)

Max.

0 °C

(32 °F)

Min.

0 to 95 %

Humidity Avoid

vibration