Contents

42/14-42-EN Sensyflow FMT700-P 3

1Safety.............................................................................................................................................................5

1.1 Intended use...................................................................................................................................................5

1.2 Target groups and qualifications ....................................................................................................................5

1.3 Warranty provisions........................................................................................................................................6

1.4 Note symbols..................................................................................................................................................6

1.5 Name plates ...................................................................................................................................................6

1.6 Safety instructions for electrical installation ...................................................................................................7

1.7 Returning devices...........................................................................................................................................7

1.8 Integrated management system.....................................................................................................................8

1.9 Disposal..........................................................................................................................................................8

1.9.1 Information on WEEE Directive 2002/96/EC (Waste Electrical and Electronic Equipment)...................8

1.9.2 RoHS Directive 2002/95/EC ...................................................................................................................8

2Device description .......................................................................................................................................9

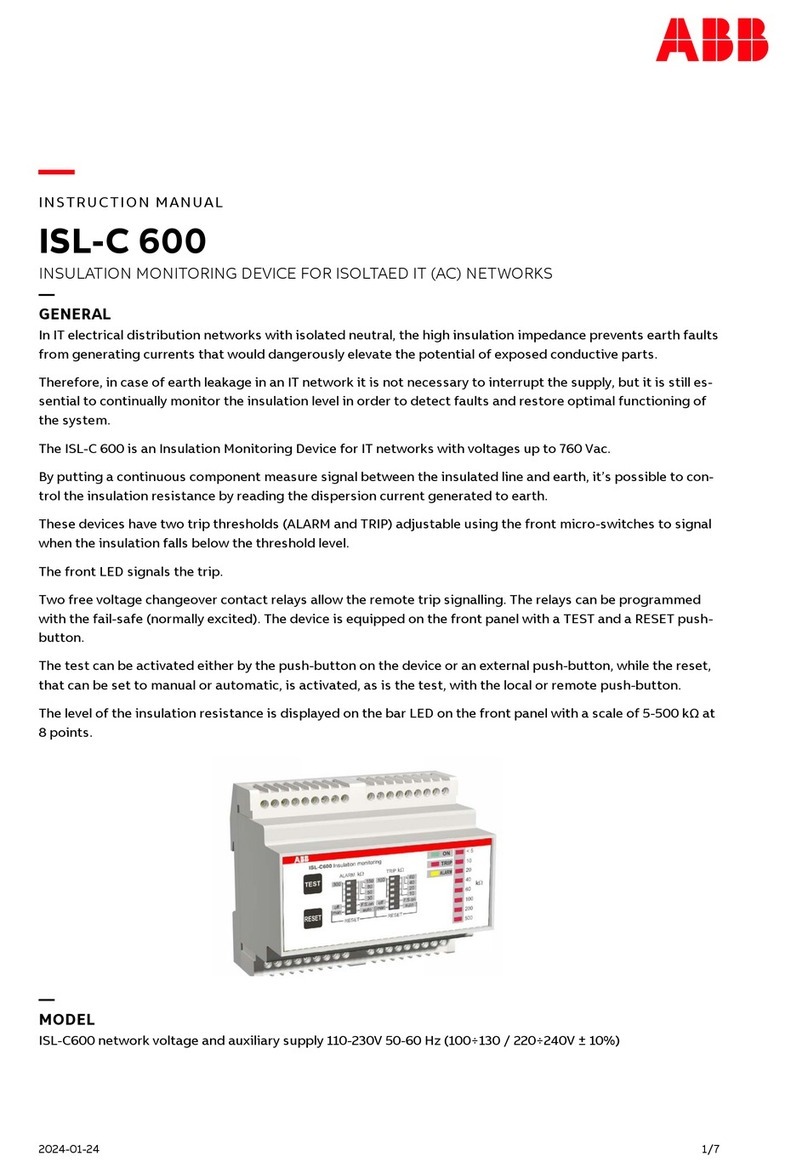

2.1 Front view.......................................................................................................................................................9

2.2 Rear view........................................................................................................................................................9

2.2.1 Supply power ........................................................................................................................................10

2.2.2 D-SUB connector ..................................................................................................................................10

2.2.3 BNC outputs and sensor connection ....................................................................................................11

3Electrical connections ...............................................................................................................................12

3.1 BNC outputs and flowmeter sensor connection...........................................................................................12

3.2 SLOT 1: D-SUB connection „Serial Output“.................................................................................................12

3.3 SLOT 3: D-SUB connection „Totalizer“ ........................................................................................................13

3.4 SLOT 4: D-SUB connection „Analog Outputs“ .............................................................................................14

4Commissioning ..........................................................................................................................................16

5Operation.....................................................................................................................................................17

5.1 Supply / evaluation unit ................................................................................................................................17

5.2 Display unit (Display)....................................................................................................................................18

5.3 Options .........................................................................................................................................................18

5.3.1 Adjustable measuring rate ....................................................................................................................18

5.3.2 Fast measuring rate ..............................................................................................................................19

5.3.3 Analog outputs ......................................................................................................................................20

5.4 Temperature measurement..........................................................................................................................22

5.5 Operation with two flowmeter sensors .........................................................................................................23

6Communication ..........................................................................................................................................24

6.1 Digital interfaces...........................................................................................................................................24

6.1.1 Serial interface ......................................................................................................................................24

6.1.2 Totalizer (integrator function) ................................................................................................................30

7Measuring setup and installation .............................................................................................................33

8Specifications .............................................................................................................................................35

9Dimensions .................................................................................................................................................37

9.1 Flowmeter sensor Sensyflow FMT700-P, DN 25.........................................................................................37

9.2 Flowmeter sensor Sensyflow FMT700-P, DN 50 ... DN 200........................................................................38

9.3 Supply / evaluation unit ................................................................................................................................39

9.4 Accessories ..................................................................................................................................................39

10 Appendix .....................................................................................................................................................46

10.1 Decommissioning and packaging ................................................................................................................46

10.2 Additional documents ...................................................................................................................................46