ABB SmartMedia SM2000 Installation instructions

Other ABB Measuring Instrument manuals

ABB

ABB MT series User manual

ABB

ABB SM1000 User manual

ABB

ABB VA Master FAM540 Training manual

ABB

ABB AnalyzeIT AX460 User manual

ABB

ABB AX410 User manual

ABB

ABB SR100A User manual

ABB

ABB CEMcaptain GAA610-M User manual

ABB

ABB Advance Optima magnos206 User manual

ABB

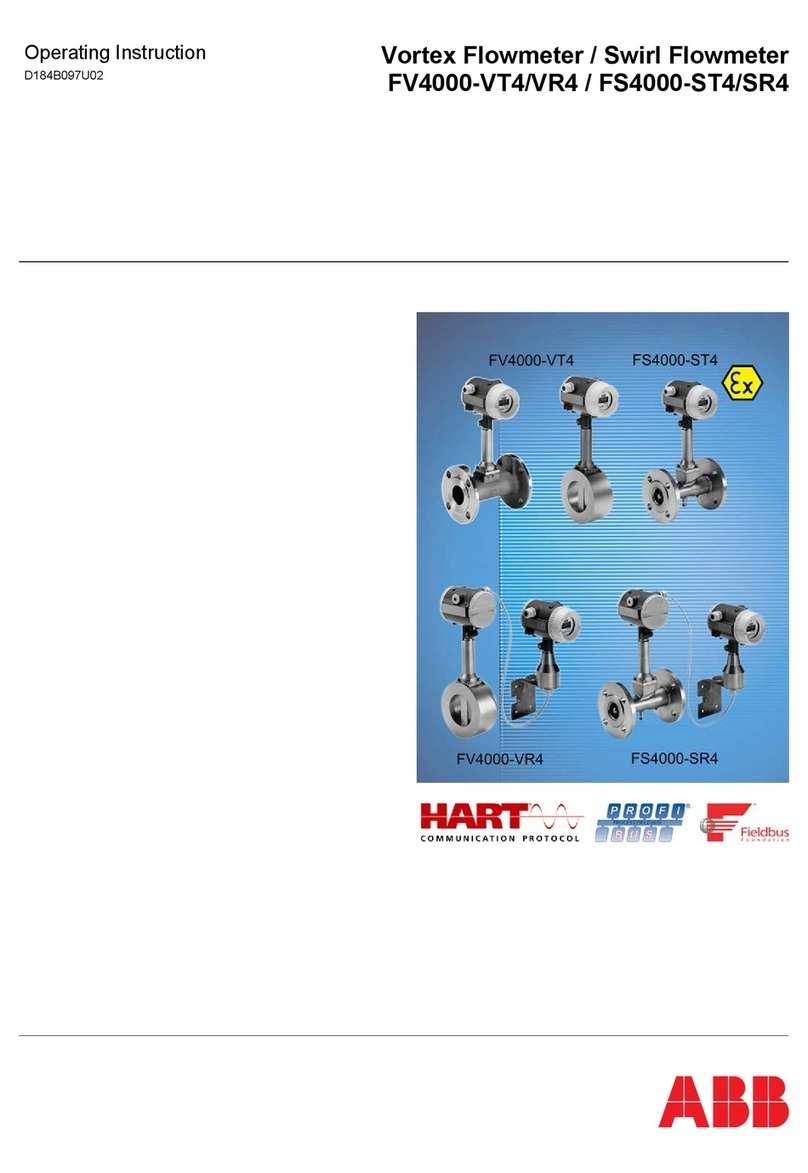

ABB FV4000-VT4 User manual

ABB

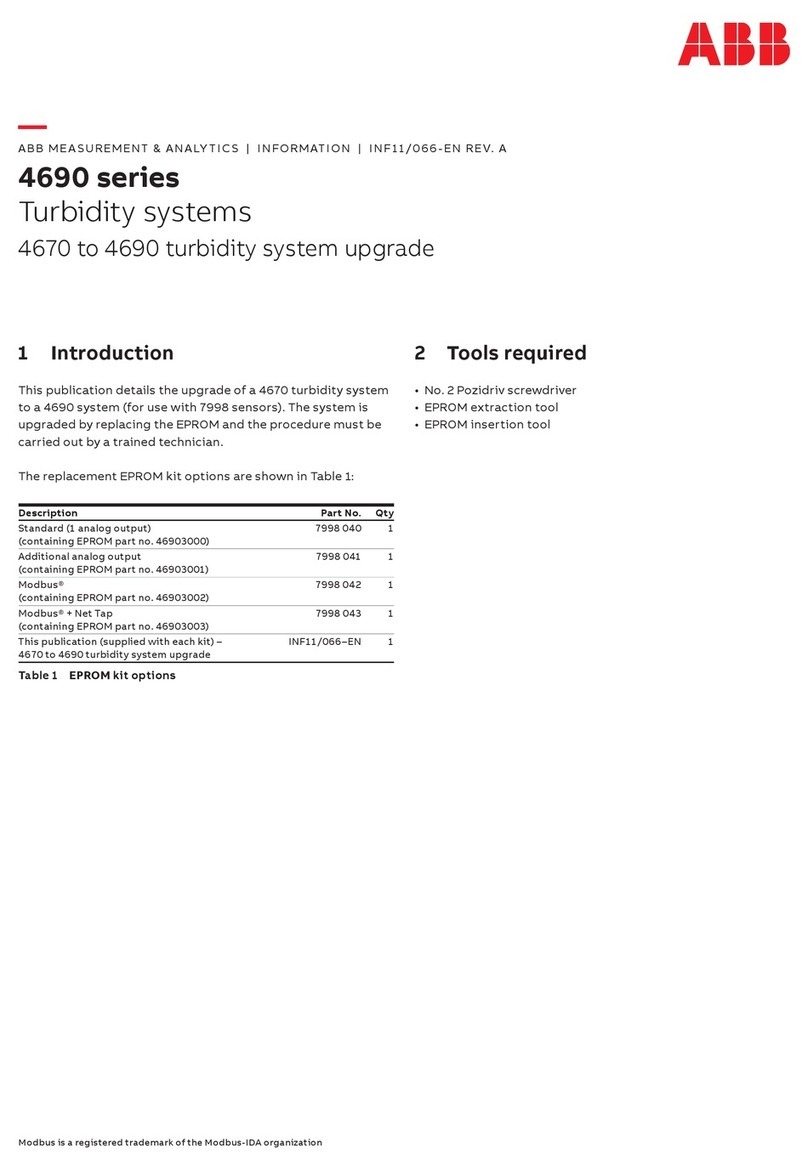

ABB 4690 Series Manual

ABB

ABB MagMaster Instruction sheet

ABB

ABB NGC8206 User manual

ABB

ABB 8037 User guide

ABB

ABB AX411 User manual

ABB

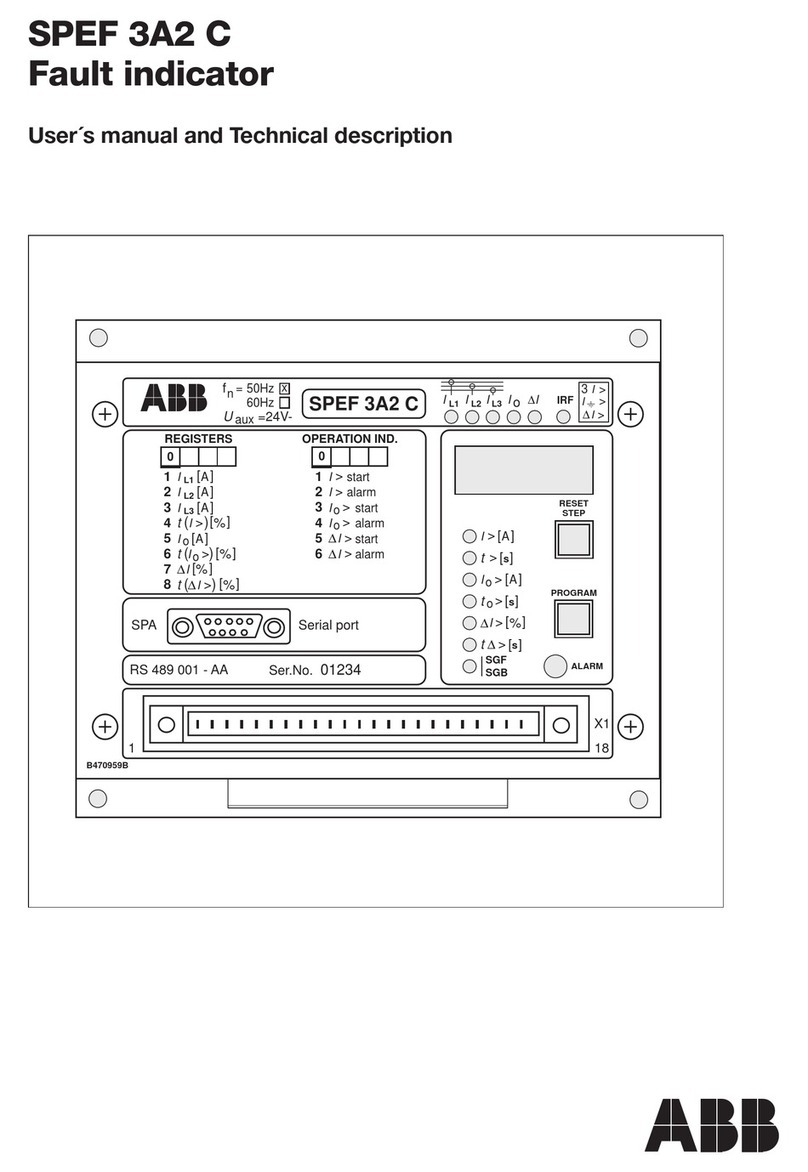

ABB SPEF 3A2 C Parts list manual

ABB

ABB Navigator 550 Training manual

ABB

ABB 8241 User manual

ABB

ABB COPA-XM 3000 Series User manual

ABB

ABB ProcessMaster FEM630 User manual

ABB

ABB 7651 User manual