Motor Overcurrent Relay

PLACING

1HE

RELAY INTO SERVICE

1.

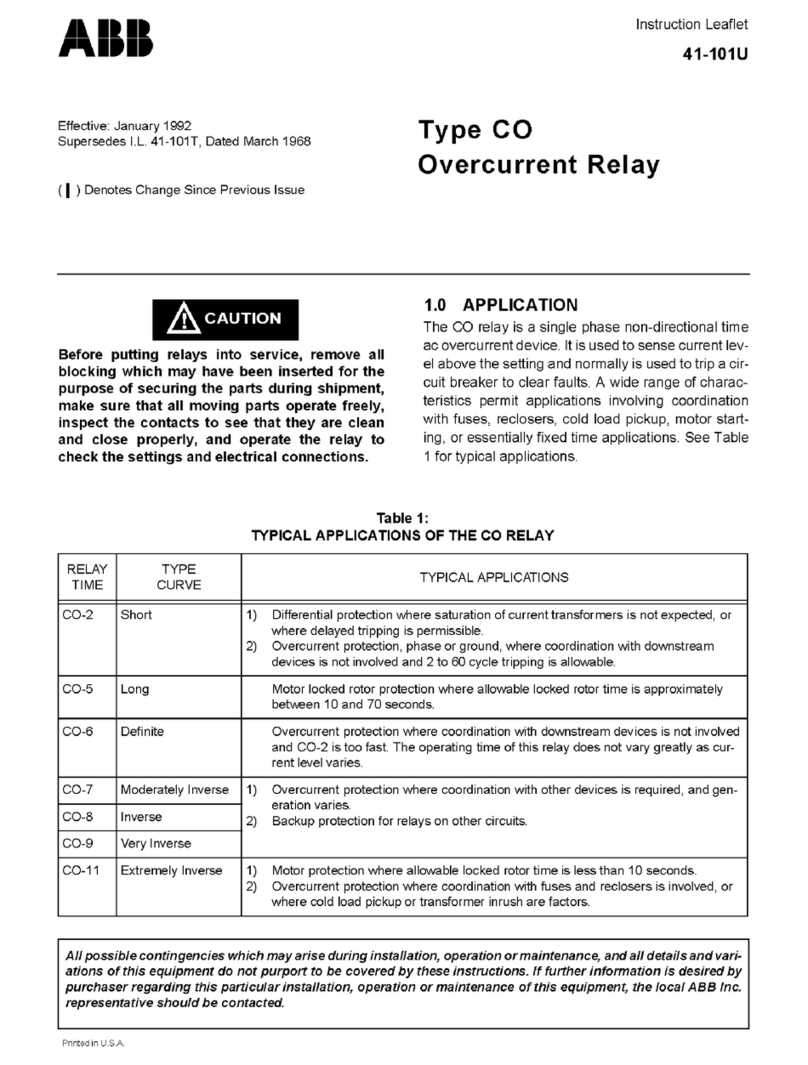

RECEIVING. HANDLING. STORAGE

IB 7.2.1.7-4

Page3

Upon receipt

of

the relay (when not included

as

part

of

a switchboard) examine for shipping damage.

If

damage or loss is evident file a claim at

once and promptly notify the nearestAsea Brown Boveri office. Use normal care in handling to avoid mechanical damage. Keep clean and

dry.

2. INSTALLATION

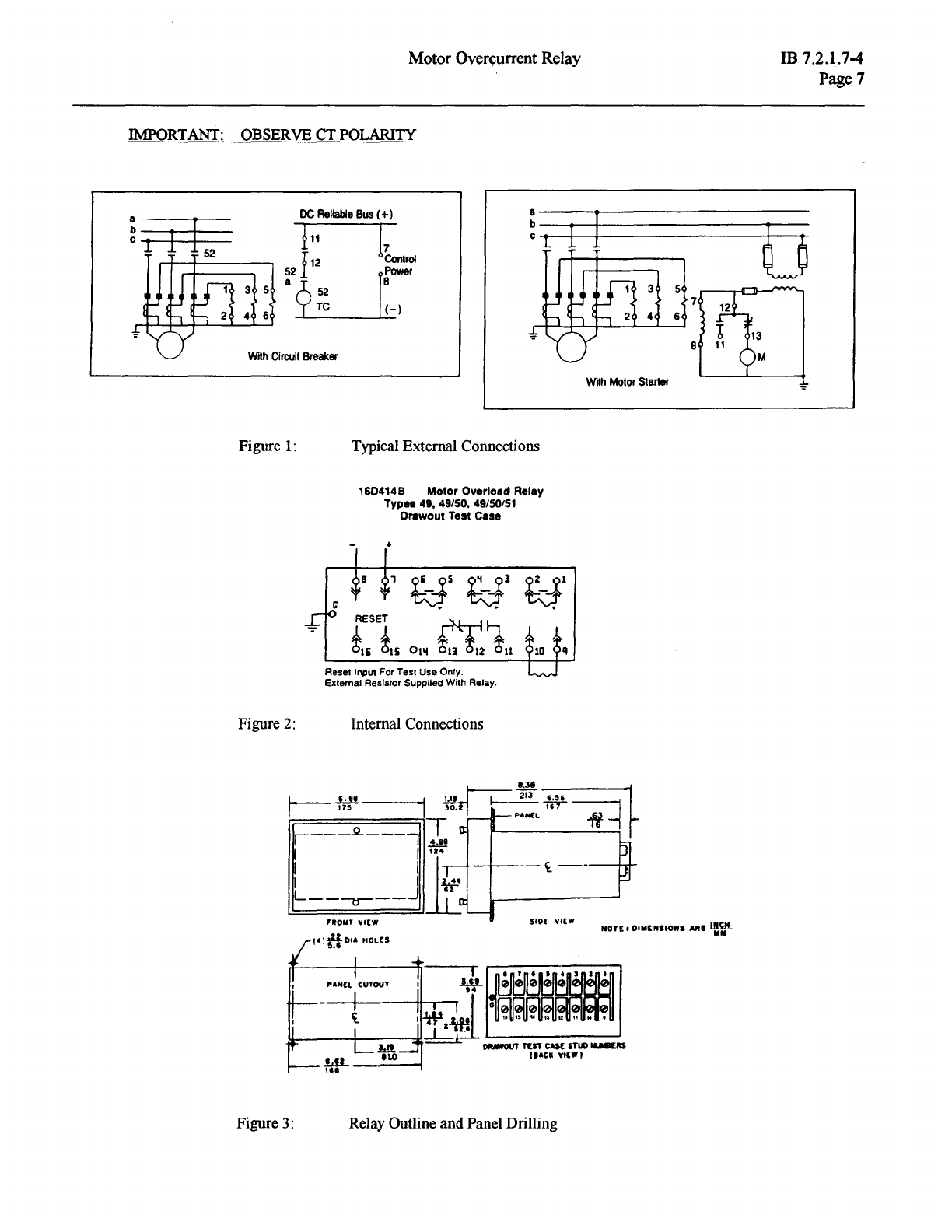

Mounting- The outline dimensions and panel drilling and cutout information is given in Fig.

3.

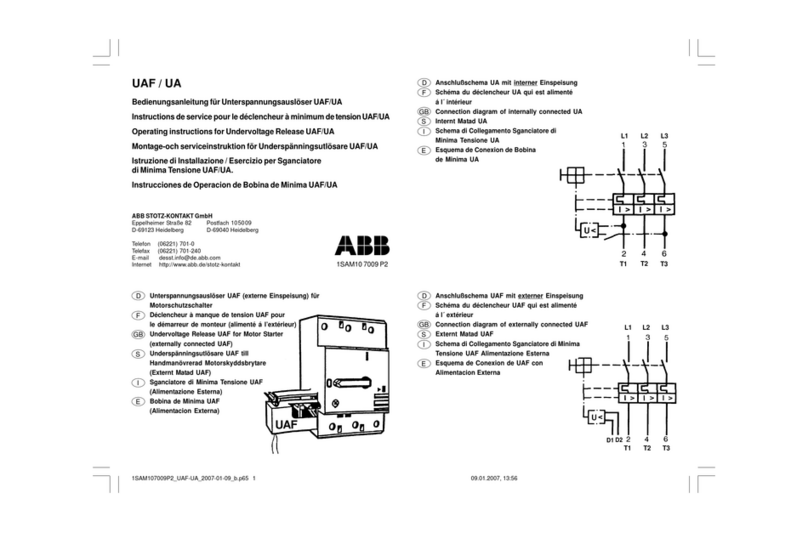

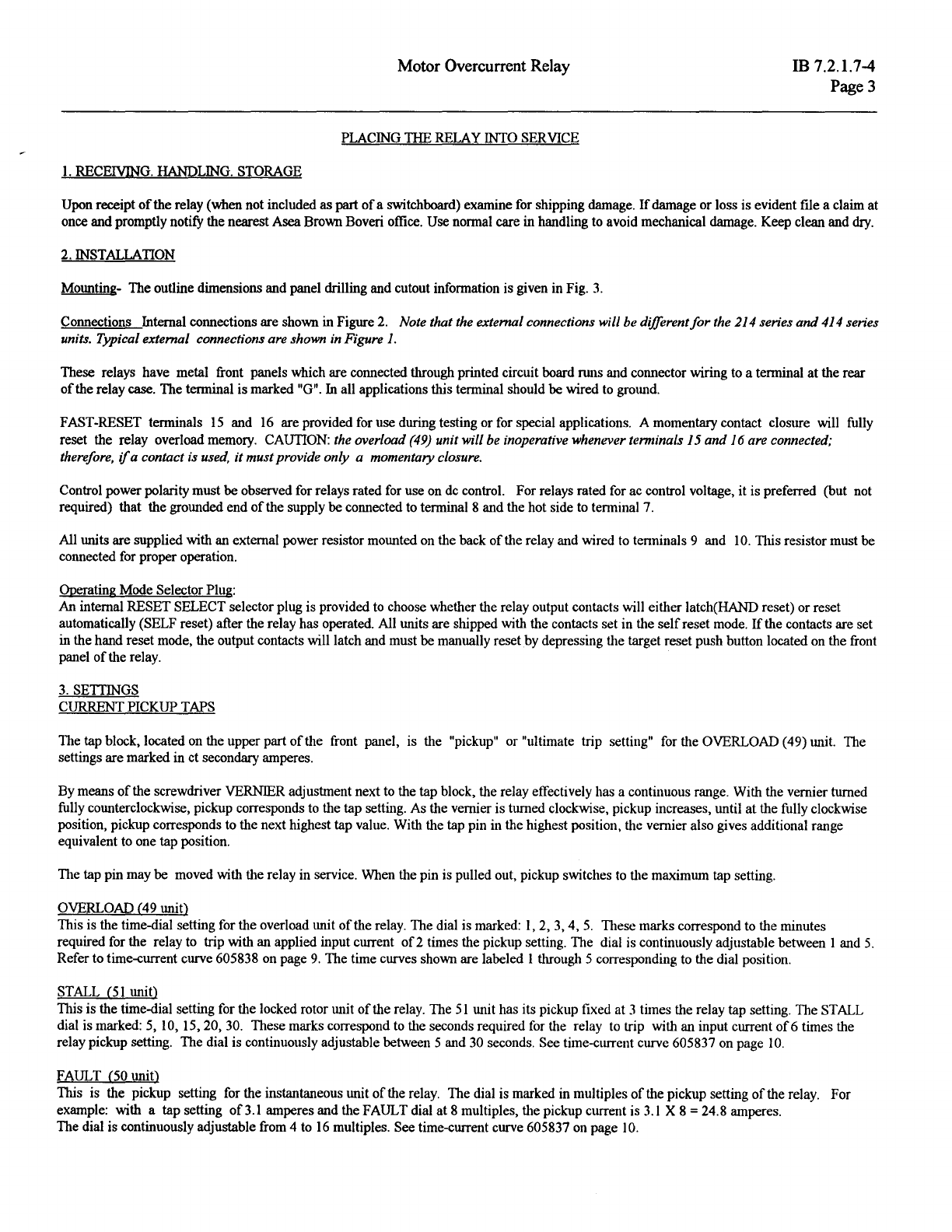

Connections Internal connections are shown in Figure 2. Note that the external connections will be different

for

the 214 series

and

414 series

units. Typical external connections are shown in Figure

1.

These relays have metal front panels which are connected through printed circuit board runs and connector wiring to a terminal

at

the rear

of

the relay case. The terminal is marked "G".

In

all applications this terminal should be wired

to

ground.

FAST-RESET terminals

15

and

16

are provided for use during testing or for special applications. A momentary contact closure will fully

reset the relay overload memory. CAUTION: the overload (49) unitwill be inoperative

when1..'Ver

terminals 15

and

16

are connected;

therefore,

if

a contact is used,

it

mustprovide only a momentary closure.

Control power polarity must be observed for relays rated for use on de control. For relays rated for ac control voltage,

it

is preferred (but not

required) that the grounded end

of

the supply be connected to terminal 8 and the hot side to tenninal 7.

All units are supplied with an external power resistor mounted on the back

of

the relay and wired to tenninals 9 and

10.

Tilis resistor must be

connected for proper operation.

Ooerating Mode Selector Plug:

An internal RESET SELECT selector plug is provided

to

choose whether the relay output contacts will either Iatch(HAND reset) or reset

automatically (SELF reset) after the relay has operated. All units are shipped with the contacts set in the

self

reset mode.

If

the contacts are set

in the hand reset mode, the output contacts will latch and must be manually reset by depressing the target reset push button located on the front

panel

of

the relay.

3.

SETTINGS

CURRENT PICKUP TAPS

The tap block, located on the upper part

of

the front panel, is the "pickup" or "ultimate trip setting" for the OVERLOAD (49) unit. The

settings are marked in ct secondary amperes.

By means

of

the screwdriver VERNIER adjustment next to the tap block, the relay effectively has a continuous range. With the vernier turned

fully counterclockwise, pickup corresponds to the tap setting. As the vernier is turned clockwise, pickup increases, until

at

the fully clockwise

position, pickup corresponds to the next highest tap value. With the tap pin in the highest position, the vernier also gives additional range

equivalent to one tap position.

The tap pin may be moved with the relay in service. When the pin is pulled out, pickup switches

to

the maximum tap setting.

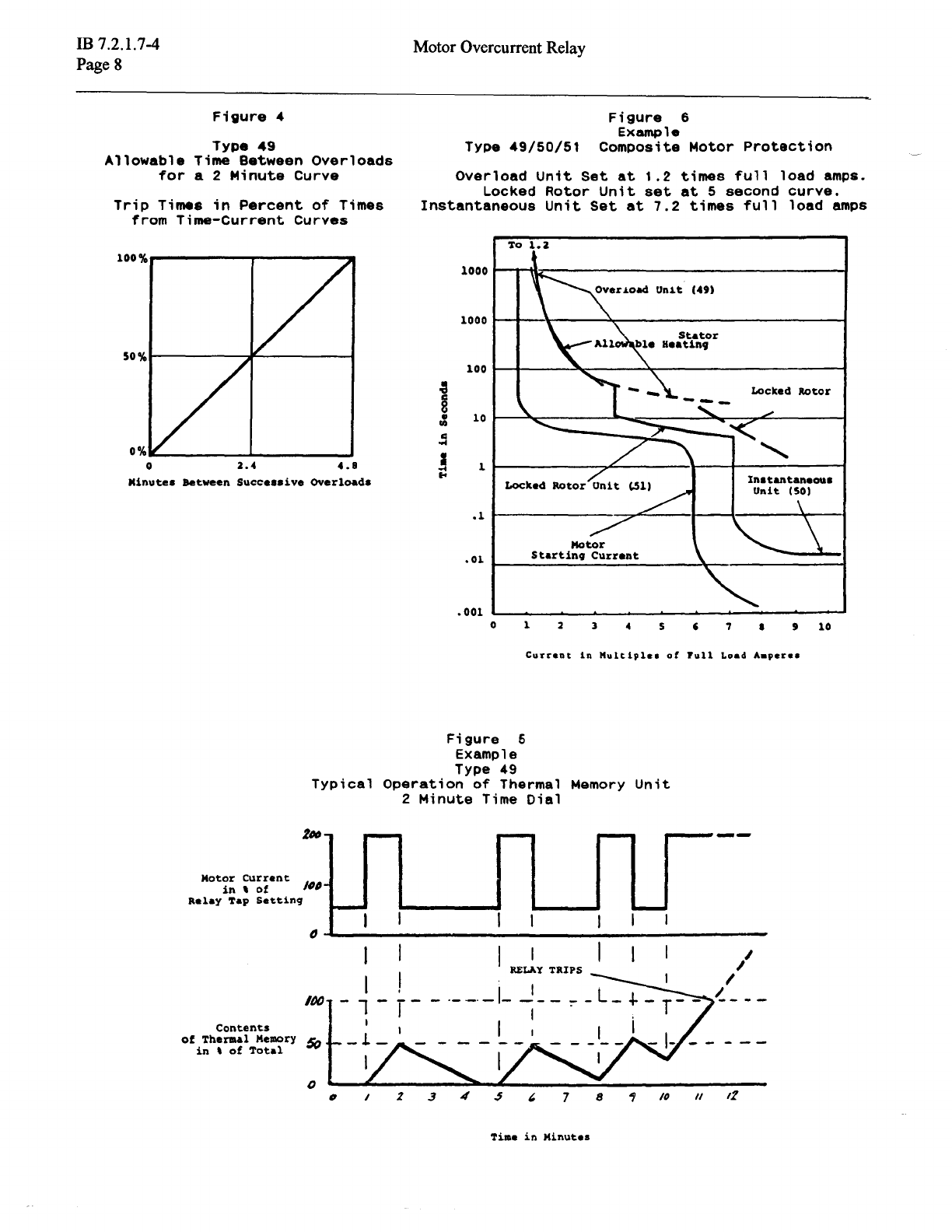

OVERLOAD (49 unit)

This is the time-dial setting for the overload unit

of

the relay. The dial is marked:

l,

2, 3, 4,

5.

TI1ese

marks correspond to the minutes

required for the relay to trip with an applied input current

of2

times the pickup setting. The dial is continuously adjustable between l and

5.

Refer to time-current curve 605838 on page

9.

The time curves shown are labeled I through 5 corresponding to the dial position.

STALL (51 unit)

This is the time-dial setting for the locked rotor unit

of

the relay. The

51

unit has its pickup fixed at 3 times the relay tap setting. The STALL

dial is marked: 5, 10, 15, 20, 30. These marks correspond to the seconds required for the relay

to

trip with an input current

of

6 times the

relay pickup setting. The dial is continuously adjustable between 5 and 30 seconds. See time-current curve 605837 on page

10.

FAULT (50 unit)

This is the pickup setting for the instantaneous unit

of

the relay. The dial is marked in multiples

of

the pickup setting

of

the relay. For

example: with a tap setting

of3.l

amperes and the FAULT dial

at

8 multiples, the pickup current is

3.1X8

= 24.8 amperes.

The dial is continuously adjustable from 4 to

16

multiples. See time-current curve 605837 on page I

0.