PCM600 and relay connectivity package version..............................39

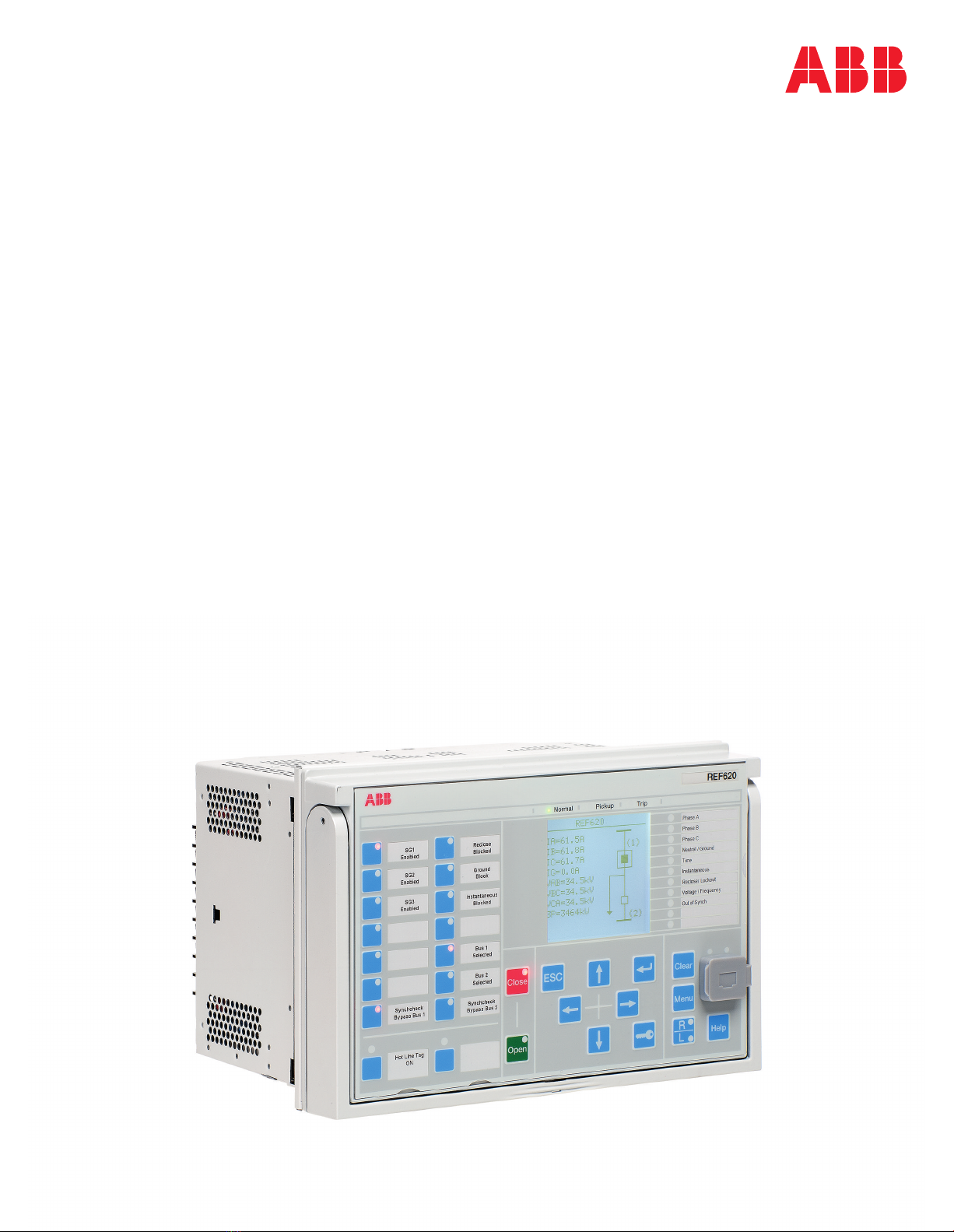

Section 4 Using the HMI......................................................................41

Using the local HMI.................................................................................41

Logging in.......................................................................................... 41

Logging out........................................................................................42

Turning the display backlight on........................................................ 43

Selecting local or remote use............................................................ 43

Identifying the device.........................................................................44

Adjusting the display contrast............................................................45

Changing the local HMI language..................................................... 46

Changing display symbols.................................................................46

Navigating in the menu......................................................................47

Menu structure..............................................................................47

Scrolling the display......................................................................47

Changing the default view............................................................ 48

Viewing single-line diagram...............................................................48

Changing single-line diagram symbol formats..............................49

Browsing setting values.....................................................................50

Editing values.................................................................................... 51

Editing numerical values...............................................................51

Editing string values..................................................................... 53

Editing enumerated values........................................................... 53

Committing settings........................................................................... 53

Clearing and acknowledging............................................................. 54

Using the local HMI help....................................................................55

Using the Web HMI.................................................................................55

Logging in.......................................................................................... 56

Logging out........................................................................................56

Identifying device...............................................................................57

Navigating in menus.......................................................................... 58

Menu structure..............................................................................59

Selecting single-line diagram.............................................................59

Showing parameters..........................................................................60

Editing values.................................................................................... 61

Committing settings........................................................................... 63

Clearing and acknowledging............................................................. 65

Selecting programmable LEDs view..................................................66

Selecting event view..........................................................................66

Selecting DFR records view.............................................................. 67

Table of contents

2620 series ANSI

Operation Manual