SMART T EMP ER AT URE MO NITORING REL AYS

STATUS

Approved

SECURITY LEVEL

Public

DOCUMENT ID.

2CDC112285M0201

REV.

B

LANG.

en

PAGE

3/42

© Copyright 2020 ABB. All rights reserved.

Contents

1. Device overview .......................................................................................................................... 5

1.1. LCD display and symbol-based menu structure ...................................................................5

1.2. Near Field Communication (NFC) ........................................................................................... 6

1.3. Device description ....................................................................................................................... 7

2. Installation.................................................................................................................................. 8

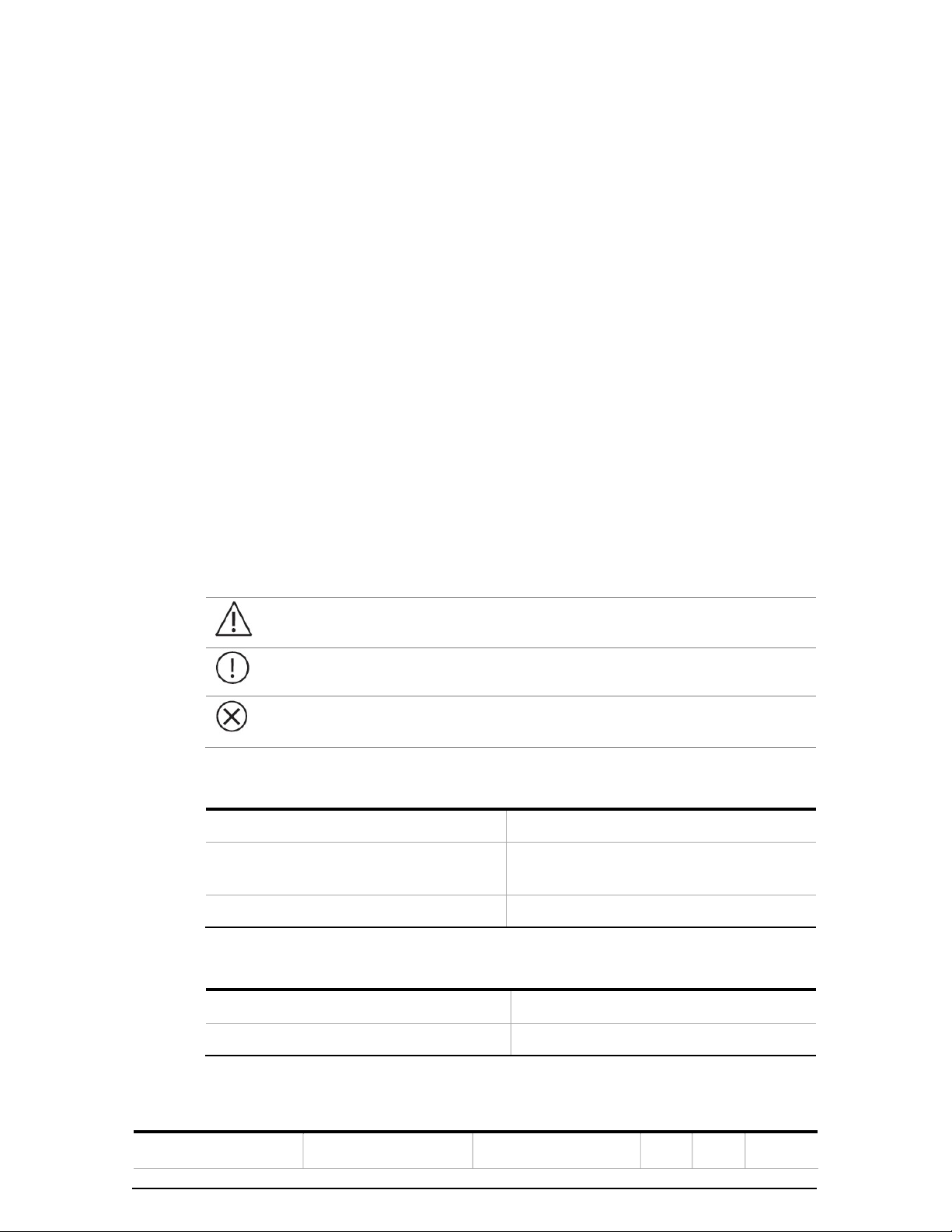

2.1. Mounting and de-mounting ..................................................................................................... 8

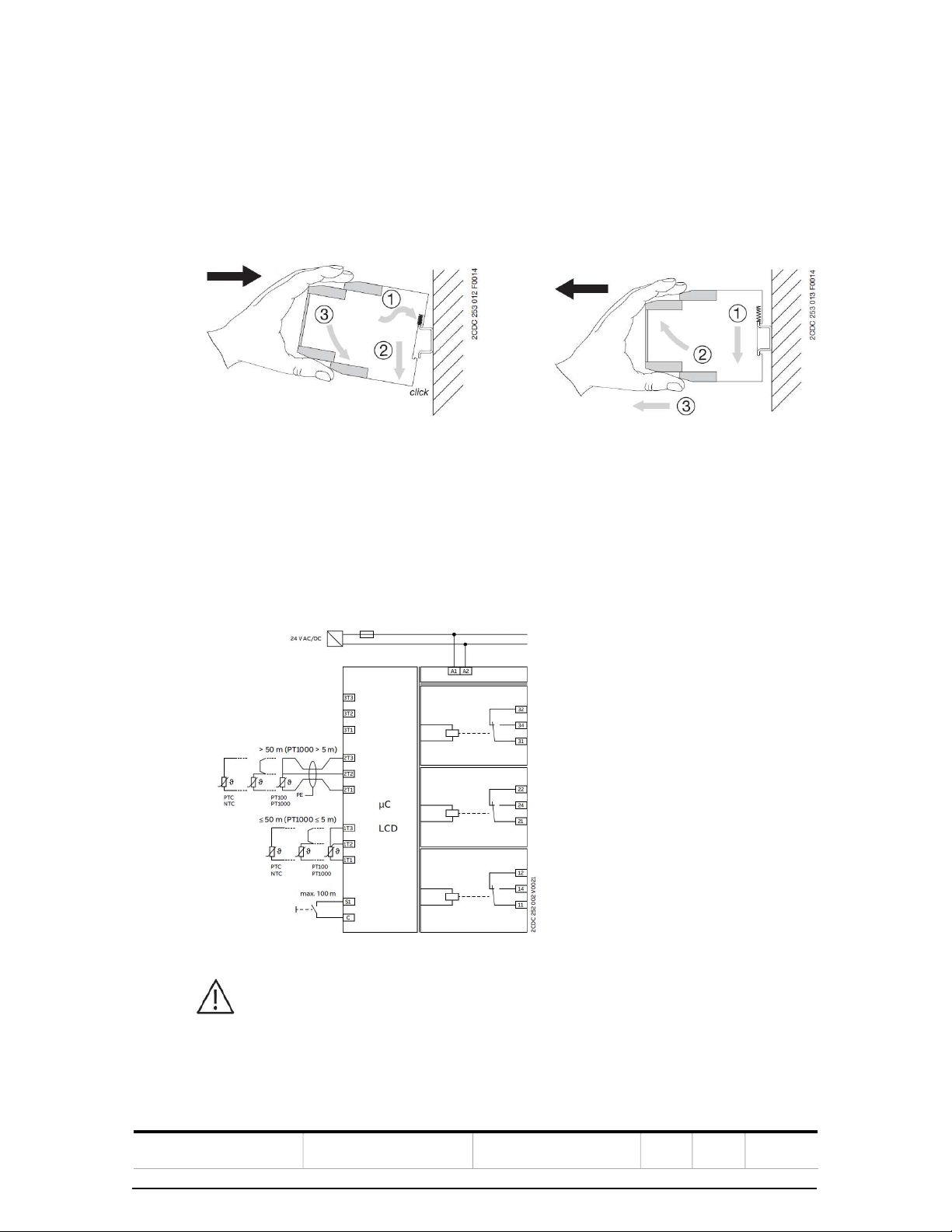

2.2. Block diagram .............................................................................................................................. 8

2.3. Sealable transparent cover ....................................................................................................... 9

3. Commissioning ......................................................................................................................... 10

The smart temperature relays are configurable in two ways: ..................................................... 10

- The first option is via the LCD and the push-rotate button on the front

of the device. .............................................................................................................................. 10

- The second option is to use the EPiC smartphone app.................................................... 10

In the next sections the configuration via LCD and push-rotate button is

explained. ..................................................................................................................................... 10

3.1. Main screen ................................................................................................................................. 10

3.2. Menu navigation......................................................................................................................... 11

4. Configuration and setup .......................................................................................................... 12

4.1. Factory profiles .......................................................................................................................... 12

4.1.1. Factory 1 - Motor protection with PT100 sensors ............................................ 14

4.1.2. Factory 2: Motor bearing supervision with PT100 ........................................... 15

4.1.3. Factory 3: Motor supervision with PT100 – 2 ..................................................... 16

4.1.4. Factory 4: Motor winding supervision with PTC ............................................... 17

4.1.5. Factory 5: Transformer supervision with PT100 ............................................... 18

4.1.6. Factory 6: Transformer supervision with PTC ................................................... 19

4.1.7. Factory 7: Individual temperature supervision with PT100 ........................... 20

4.2. User profiles and individual parameterization ................................................................... 21

4.2.1. Step 1: Sensor configuration ................................................................................. 21

4.2.2. Step 2: Signal definition .........................................................................................22

4.2.3. Step 3: Relay assignment and configuration .................................................... 26

4.2.4. Save configuration into user profiles ................................................................. 29

5. Security ..................................................................................................................................... 30

5.1. Parameter lock........................................................................................................................... 30

5.2. Password protection ................................................................................................................. 31

5.3. Near Field Communication ..................................................................................................... 32

6. Error handling, maintenance and service ............................................................................... 33

6.1. Additional functions ................................................................................................................ 33

6.1.1. Display ON-time ...................................................................................................... 33

6.1.2. Temperature unit .................................................................................................... 34

6.1.3. Power-on delay ........................................................................................................ 34

6.1.4. User-defined text .................................................................................................... 35

7. Condition monitoring ...............................................................................................................36

7.1.1. Event history ............................................................................................................. 37

7.1.2. Operating hour counter ......................................................................................... 38

7.1.3. Maintenance counter .............................................................................................. 38

7.1.4. Statistics ................................................................................................................... 39

7.1.5. Password reset counter ......................................................................................... 39