ABB HU Manual

Other ABB Relay manuals

ABB

ABB SPAJ 142 C Parts list manual

ABB

ABB REM 610 User manual

ABB

ABB Relion 615 series User manual

ABB

ABB CIRCUIT SHIELD 437W Series User manual

ABB

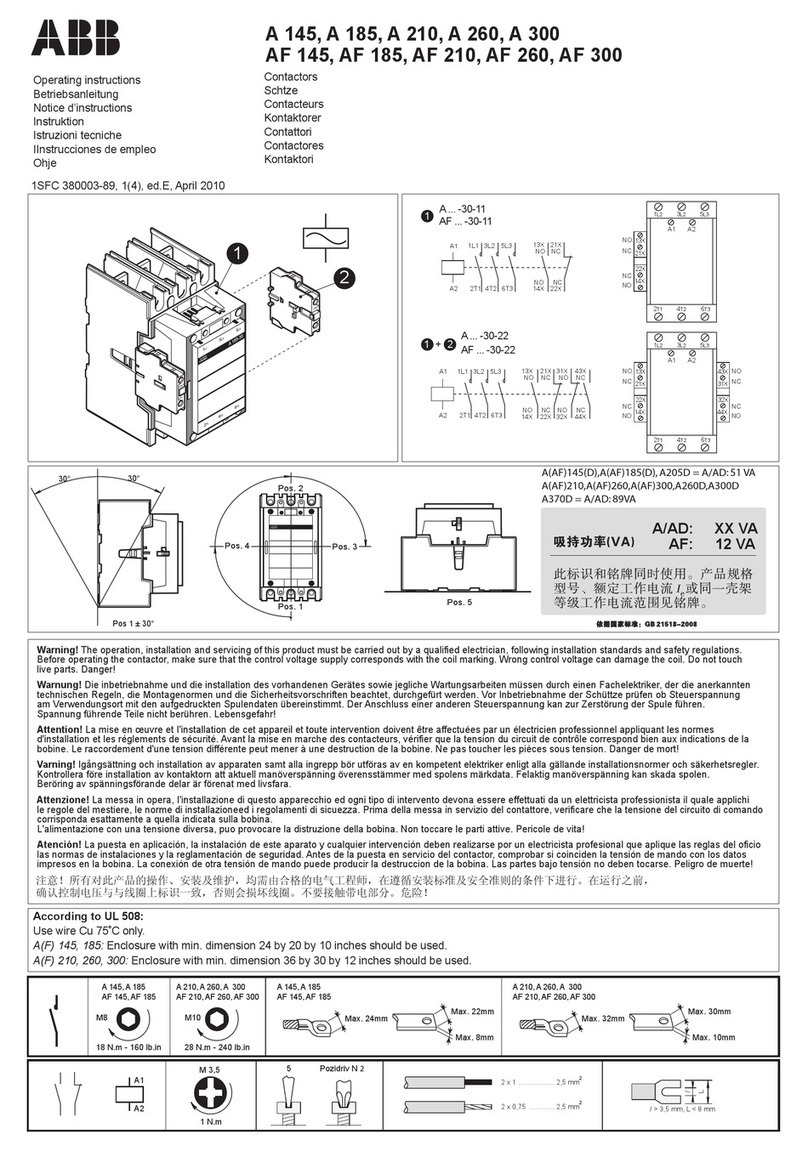

ABB A 145 User manual

ABB

ABB REU 523 Product manual

ABB

ABB C6701 User manual

ABB

ABB IRP Manual

ABB

ABB Relion REC670 Quick start guide

ABB

ABB REL 301 User manual