963.3 Inspection activities ...........................................................................................

963.3.1 Inspecting the oil level in axis-1 gearbox .....................................................

983.3.2 Inspecting, oil level gearbox axes 2 - 3 .......................................................

1013.3.3 Inspecting, oil level gearbox axis 6 ............................................................

1033.3.4 Inspecting, balancing device bearings and piston rod guide ring ......................

1073.3.5 Inspecting, cable harness ........................................................................

1103.3.6 Inspecting the information labels ................................................................

1123.3.7 Inspecting the axis-1 mechanical stop pin ...................................................

1143.3.8 Inspecting the additional mechanical stops .................................................

1163.3.9 Inspection, dampers ................................................................................

1183.3.10 Inspection, position switch axis 1 ...............................................................

1203.3.11 Inspecting the signal lamp (option) .............................................................

1223.4 Replacement/changing activities ..........................................................................

1223.4.1 Type of lubrication in gearboxes ................................................................

1233.4.2 Changing oil, axis-1 gearbox .....................................................................

1263.4.3 Changing oil, gearbox axes 2 and 3 ...........................................................

1303.4.4 Changing oil, gearbox axis 6 .....................................................................

1323.4.5 Replacing the SMB battery ........................................................................

1363.5 Lubrication activities ..........................................................................................

1363.5.1 Lubricating balancing device bearings and piston rod ....................................

1393.6 Cleaning activities .............................................................................................

1393.6.1 Cleaning the IRB 660 ...............................................................................

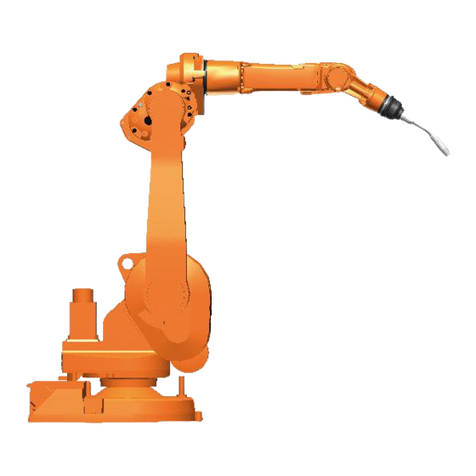

1414 Repair

1414.1 Introduction ......................................................................................................

1424.2 General procedures ...........................................................................................

1424.2.1 Performing a leak-down test ......................................................................

1434.2.2 Mounting instructions for bearings .............................................................

1454.2.3 Mounting instructions for sealings ..............................................................

1484.2.4 Cut the paint or surface on the robot before replacing parts ............................

1494.2.5 The brake release buttons may be jammed after service work .........................

1504.3 Complete robot .................................................................................................

1504.3.1 Replacing cable harness, lower end (axes 1-3) .............................................

1584.3.2 Replacing the cable harness, upper end (incl. axis 6) .....................................

1644.3.3 Replacing the base, including axis 1 gearbox ...............................................

1724.4 Upper and lower arm .........................................................................................

1724.4.1 Replacing the turning disk ........................................................................

1764.4.2 Replacement of tilthouse unit ....................................................................

1914.4.3 Replacement of upper arm ........................................................................

2014.4.4 Replacement of linkage - upper rod ............................................................

2054.4.5 Replacing the linkage - lower rod ...............................................................

2094.4.6 Replacement of linkage - link .....................................................................

2164.4.7 Replacing the parallel rod .........................................................................

2214.4.8 Replacing the complete lower arm ..............................................................

2294.4.9 Replacement of parallel arm ......................................................................

2364.5 Frame and base ................................................................................................

2364.5.1 Replacing the balancing device ..................................................................

2444.5.2 Replacing the SMB unit ............................................................................

2474.5.3 Replacing the brake release board .............................................................

2514.6 Motors ............................................................................................................

2514.6.1 Replacing motor, axis 1 ............................................................................

2584.6.2 Replacing motors, axes 2 and 3 .................................................................

2694.6.3 Replacing motor, axis 6 ............................................................................

2764.7 Gearboxes .......................................................................................................

2764.7.1 Replacing the axis 1 gearbox .....................................................................

2874.7.2 Replacing the gearbox, axes 2- 3 ...............................................................

2994.7.3 Replacing gearbox axis 6 ..........................................................................

6 Product manual - IRB 660

3HAC025755-001 Revision: W

© Copyright 2006-2020 ABB. All rights reserved.

Table of contents