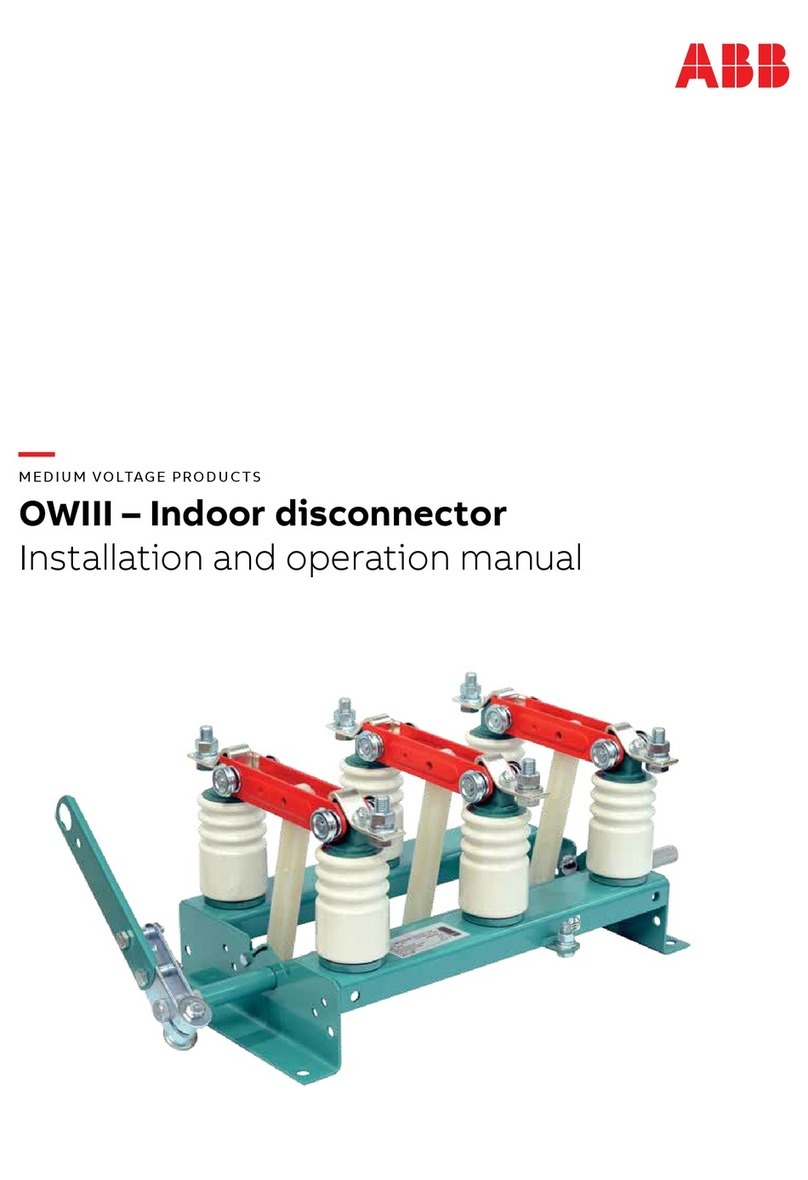

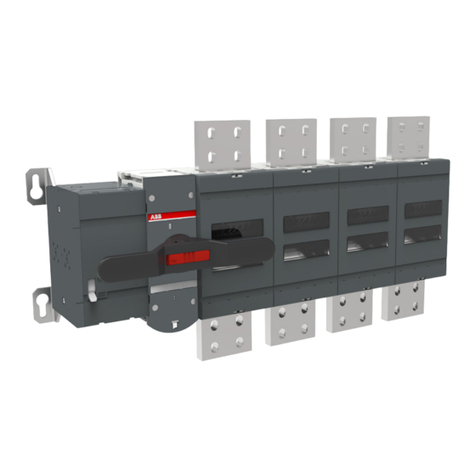

6MOUNTING AND OPERATION MANUAL INDOOR AIR SWITCH-DISCONNECTOR, NAL/NALF/VR

—

1.0 Your safety first – always!

That’s why our manual begins with these recommendations:

comply in full with the legally recognized standards (ANSI / IEC)

and the applicable safety regulations at work.

WARNING!

• Pay special attention to the hazard notes in the

manual marked with this warning symbol.

• Make sure that under operation condition of the

switchgear or switchboard the specified data is

not exceeded.

• Keep the manual accessible to all persons

concerned with installation, operation and

maintenance.

• The user’s personnel are to act responsibly in all

matters affecting safety at work and the correct

handling of the switchgear.

• There are hazards of electrical shock and burns

whenever working in or around electrical

equipment. Turn off power before performing

any inspection or maintenance operations.

Check line terminals to verify that the

equipment is de-energized and earthed.

• Check terminals to ensure that no back-feed

condition exists.

If you have any further questions on this manual,

the members of our field organization will be

pleased to provide the required information.

In case of any uncertainty or questions related to

mounting and/or operation which are not

described in the manual please contact ABB.

1.1 General notes:

1. Regular equipment designed for normal

indoor service condition (Class 0 acc. to IEC

62271-304) to be used in locations with

humidity/temperature control (i.e. sufficient

heating source, humidity absorbers, etc.)

and/or buildings with special thermal design

to prevent negative influence of rapid

outside temperature change to avoid

condensation.

2. For the normal indoor service condition

(water condensation max 2 times a year and

low pollution level) there is no need to do any

special test of indoor switch-disconnectors.

For more severe conditions, the substation

with applicable components, needs to be

classified and tested according to IEC 62271-

304.

3. The regular NAL/F and VR with BMC (Bulk

(Dough) Moulding Compounds) insulators is

designed to class 0 (C0PL) that corresponds

to normal indoor service conditions. The

standard NAL/VR works fine everywhere

these operating conditions are provided.

4. Wherever we observe harsh operating

conditions, special type of the switch-

disconnector NAL/F-H is recommended that

has been type tested according to IEC 62271-

304 design class 2 for severe operating

conditions.

5. Regardless of the type of switch-

disconnector in use, all installation work,

station design, location selection, ground

preparation, and maintenance must be done

in a professional way to keep the installation

in good condition throughout it's assumed

lifetime.

6. Correct installation is of primary importance.

The manufacturer’s instructions must be

carefully studied and followed. It is good

practice to use gloves for handling the pieces

during installation.

7. Operations describe in this manual shall be

carried out by specialists only.

8. According to IEC 62271-1 p. 5.12 and IEC

62271-102 p. 5.104.3.1 position of switch-

disconnector has to be clearly indicated.

NAL/NALF/VR air insulated switch-

disconnector allows 100% certainty to

_

WARNING

Always observe the manual and follow the

rules of good engineering practice!

Hazardous voltage can cause electrical

shock and burns. Disconnect power, then

earth and short-circuit before proceeding

with any work on this equipment.