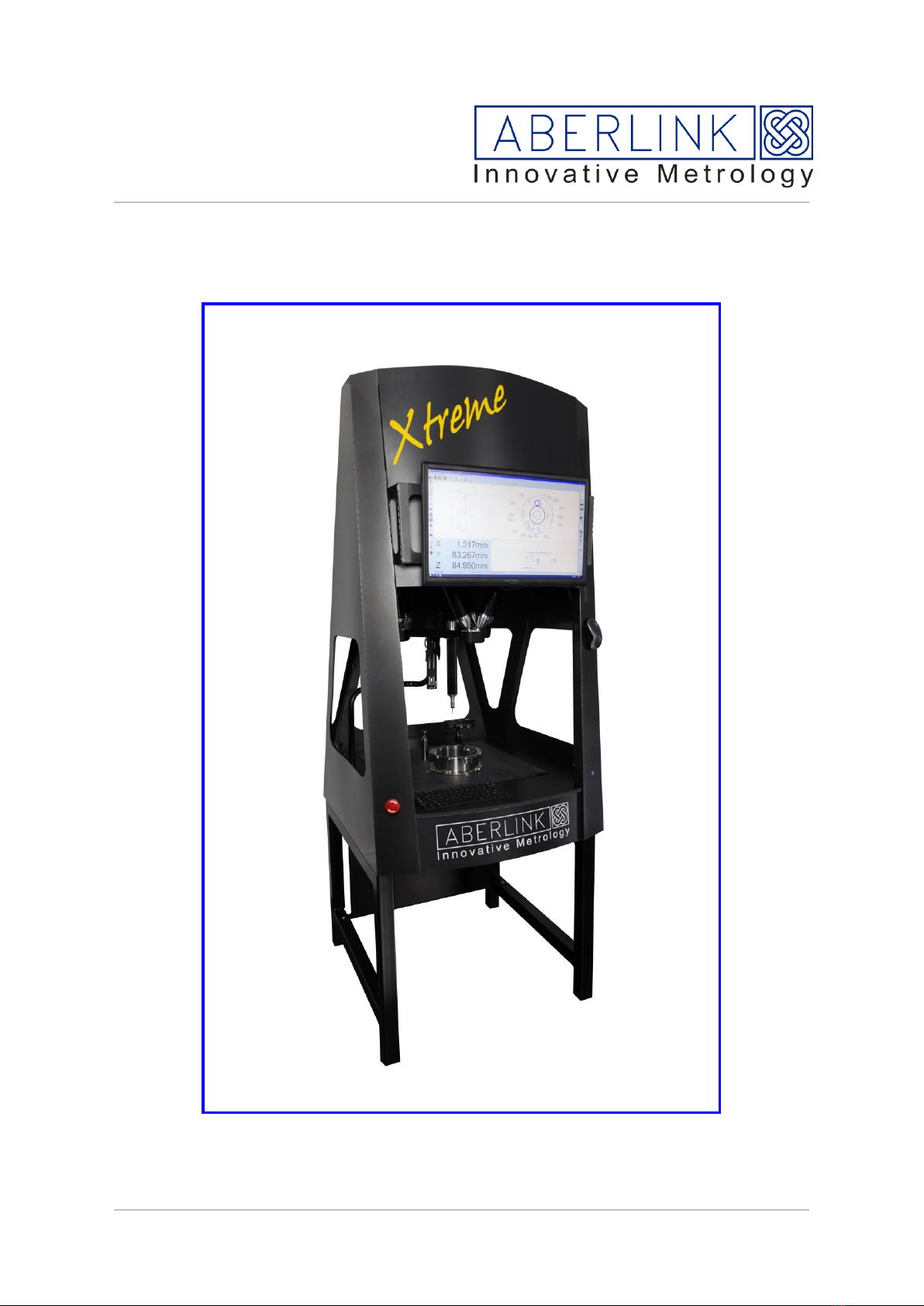

ABERLINK Xtreme User manual

Popular Analytical Instrument manuals by other brands

Fieldmann

Fieldmann FDLM 1050 user manual

Dewetron

Dewetron DEWE-30-16 Technical reference manual

Cocraft

Cocraft NLT04 Original instructions

EXTOL PREMIUM

EXTOL PREMIUM 8820043 Translation of the original user manual

M&C

M&C GENTWO PMA1000 instruction manual

MICRO-EPSILON

MICRO-EPSILON optoncdt 1700 instruction manual