- viii - INZ-TN2ZKMA-E

7. CALIBRATION......................................................................................................................................... 33

7.1 Preparation ............................................................................................................................................. 33

7.2 Manual calibration ................................................................................................................................. 34

7.3 Auto calibration (option)........................................................................................................................ 36

7.4 Remote calibration ................................................................................................................................. 38

7.5 All calibration (option)........................................................................................................................... 40

8. BLOWDOWN (OPTION)......................................................................................................................... 41

8.1 Preparation for blowdown...................................................................................................................... 41

8.2 Manual blowdown.................................................................................................................................. 41

8.3 Automatic blowdown ............................................................................................................................. 42

8.4 Remote blowdown ................................................................................................................................. 44

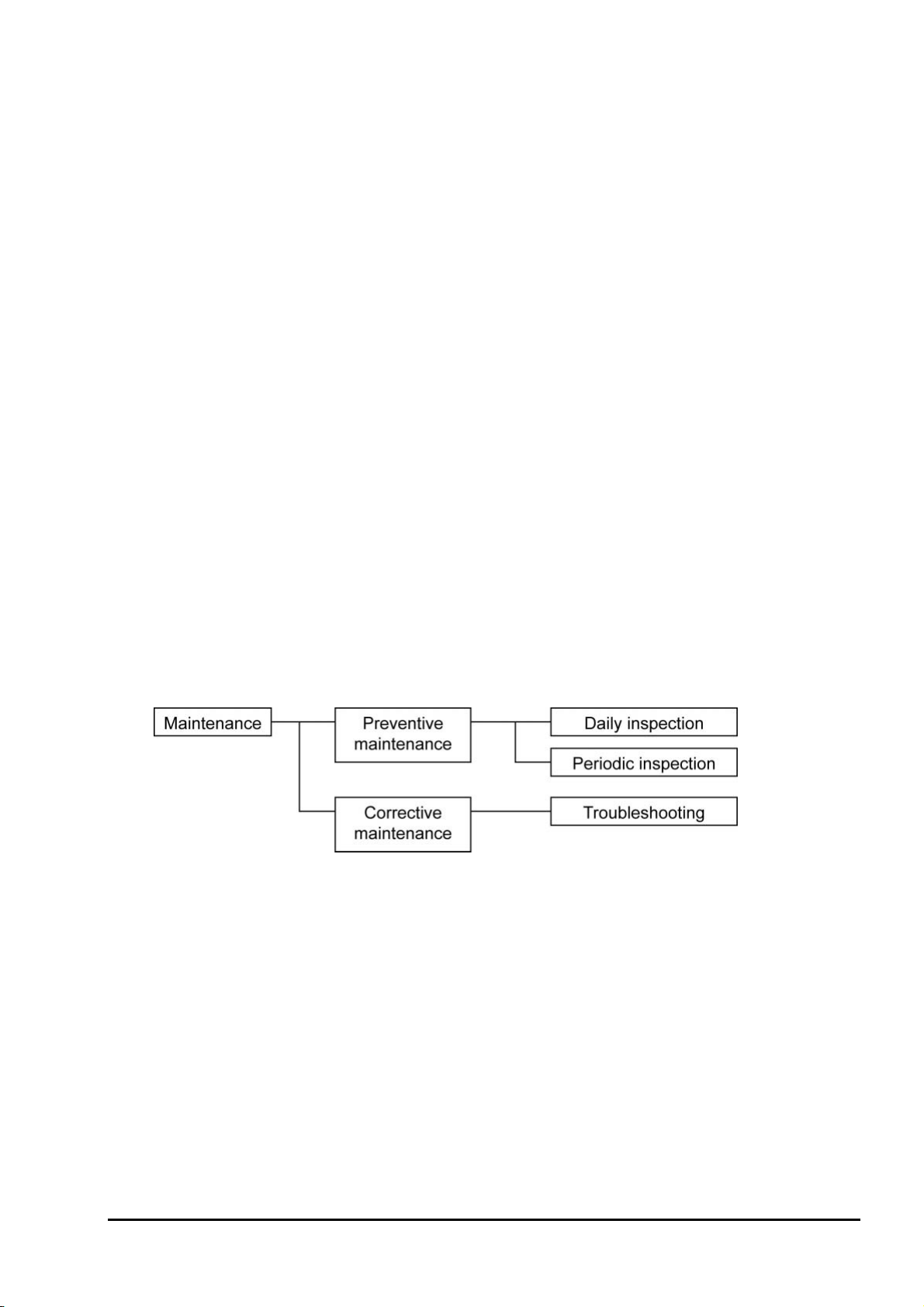

9. MAINTENANCE AND CHECK.............................................................................................................. 46

9.1 Checking ................................................................................................................................................ 46

9.2 Spare parts.............................................................................................................................................. 46

9.3 Replacement of fuse............................................................................................................................... 47

9.4 Adjustment of monitor contrast.............................................................................................................. 48

9.5 Troubleshooting ..................................................................................................................................... 49

10. SETTING AND OPERATING OF PARAMETER............................................................................... 51

10.1 Measured menu.................................................................................................................................... 51

10.1.1 Display range setting screen.......................................................................................................... 51

10.1.2 Decimal point position setting screen............................................................................................ 52

10.1.3 Full scale setting screen................................................................................................................. 53

10.1.4 Setting screen for calculation time of maximum and minimum values appears ........................... 54

10.2 Calibration menu.................................................................................................................................. 55

10.2.1 Automatic calibration setting (option)........................................................................................... 55

10.2.2 Date and time for starting automatic calibration (option) ............................................................. 56

10.2.3 Cycle time setting of automatic calibration (option)..................................................................... 57

10.2.4 Performing all calibration (option)................................................................................................ 58

10.2.5 Performing a manual span calibration........................................................................................... 59

10.2.6 Performing a manual zero calibration ........................................................................................... 60

10.2.7 Calibration gas setting ................................................................................................................... 61

10.2.8 Calibration waiting setting (option)............................................................................................... 62

10.2.9 Calibration error clear ................................................................................................................... 63

10.2.10 Operation setting screen of calibration range.............................................................................. 64

10.3 Blowdown menu (option) .................................................................................................................... 65

10.3.1 Automatic blowdown setting......................................................................................................... 65

10.3.2 Date and time setting of automatic blowdown .............................................................................. 66

10.3.3 Automatic blowdown cycle setting ............................................................................................... 67

10.3.4 Procedure for setting blowdown time............................................................................................ 68

10.3.5 Perfoming manual blowdown........................................................................................................ 69

10.4 Maintenance menu ............................................................................................................................... 70

10.4.1 Error log display............................................................................................................................ 70

10.4.2 Clearing error logs......................................................................................................................... 72

10.4.3 Alarm log display .......................................................................................................................... 73

10.4.4 Clearing alarm logs ....................................................................................................................... 74

10.4.5 Performing a manual sensor check................................................................................................ 75

10.4.6 Maintenance mode setting............................................................................................................ 76

10.4.7 Password setting ............................................................................................................................ 77

10.4.8 PID auto tuning ............................................................................................................................. 78

10.5 Parameter menu ................................................................................................................................... 79

10.5.1 Current date and time setting......................................................................................................... 79

10.5.2 Contact input setting...................................................................................................................... 80

10.5.3 Selection of alarm contact output.................................................................................................. 81

10.5.4 High limit setting of oxygen concentration ................................................................................... 82