Ap1400 Installers’ Guide Page 2 of 16

1 TABLE OF CONTENTS

1TABLE OF CONTENTS............................................................................................................. 2

2REVISION HISTORY.................................................................................................................. 3

3INTRODUCTION........................................................................................................................ 3

3.1 NOTES ON PRINTER FIRMWARE REVISIONS (INCLUDING FLASH)..................................................3

3.2 COPYRIGHT NOTICE AND DISCLAIMER ..................................................................................... 3

3.3 IMPORTANT INFORMATION....................................................................................................... 3

4EMC STATEMENT AND CAUTION ........................................................................................... 4

5ORDERING PART CODES, OPTIONS AND ACCESSORIES.................................................... 4

6INTERFACE DETAILS............................................................................................................... 5

6.1 RS-232SERIAL INTERFACE ....................................................................................................5

6.2 USB INTERFACE....................................................................................................................5

7POWER SUPPLY DETAILS....................................................................................................... 6

7.1 ALTERNATIVE POWER SUPPLY ARRANGEMENTS........................................................................6

8CONNECTION GUIDE ............................................................................................................... 7

8.1 J4–RS232DATA .................................................................................................................7

8.2 J3–POWER.......................................................................................................................... 8

8.3 J2–USB DATA.....................................................................................................................8

8.4 CHASSIS EARTH STRAP.......................................................................................................... 8

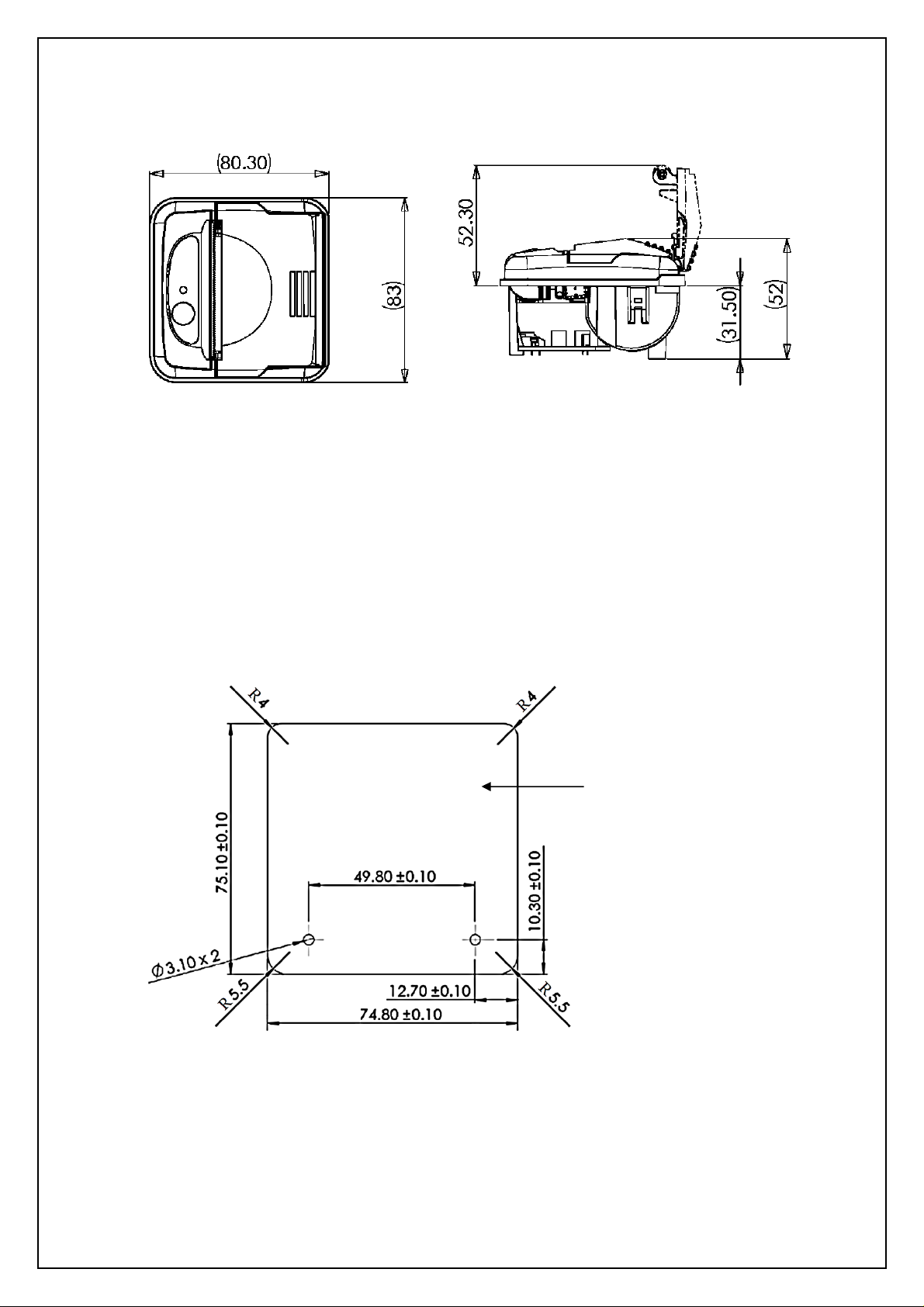

9UNIT DIMENSIONS.................................................................................................................... 9

10 MECHANICAL FIXINGS......................................................................................................... 9

10.1 BACK FIXING ......................................................................................................................... 9

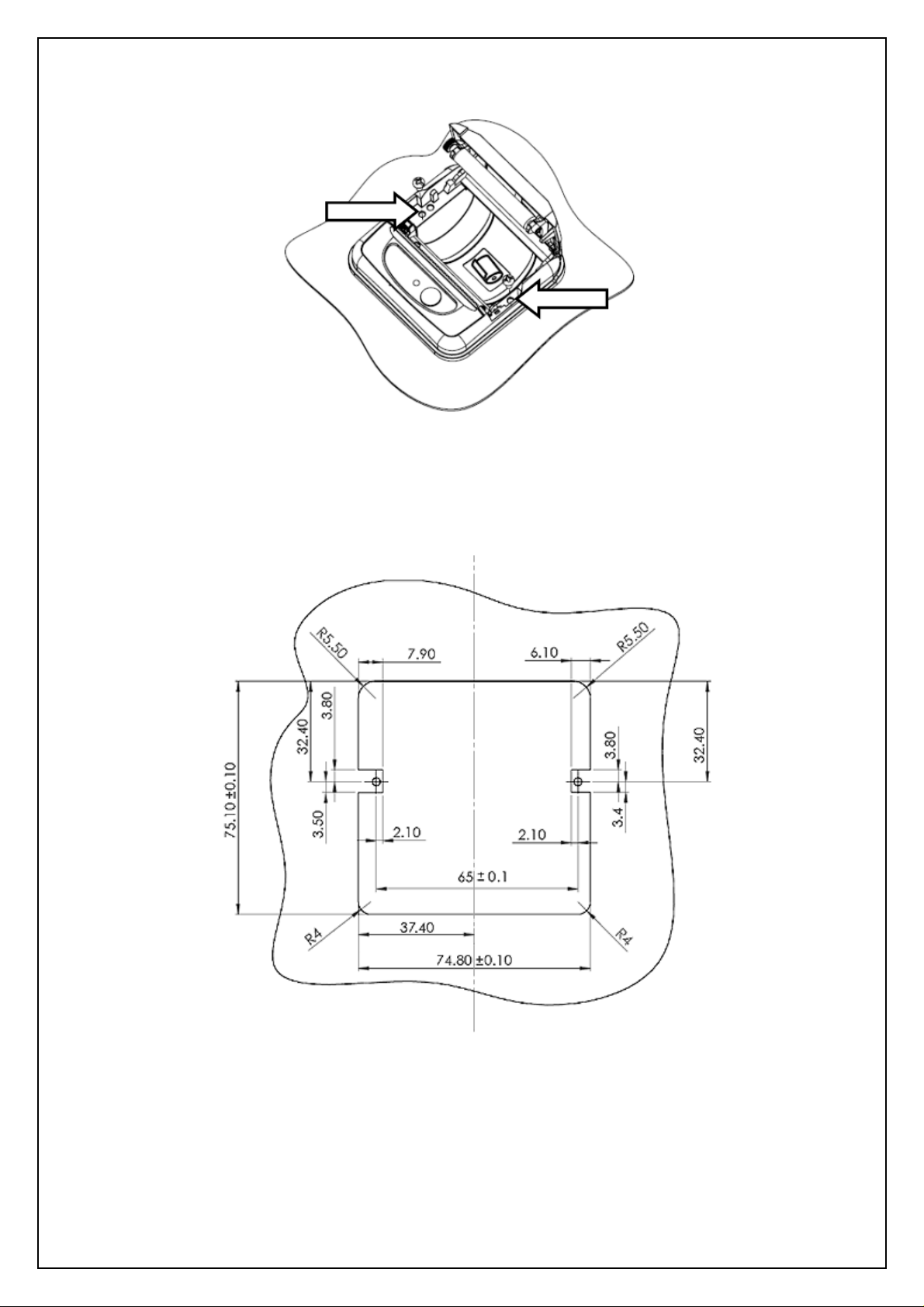

10.2 FRONT FIXING ..................................................................................................................... 10

10.3 MOUNTING BRACKET............................................................................................................ 11

10.4 FIXING ORIENTATIONS .......................................................................................................... 11

10.5 LOCATING THE PRINTER ....................................................................................................... 11

11 MODES OF OPERATION..................................................................................................... 12

11.1 IDLE MODE.......................................................................................................................... 12

11.2 SPOOL MODE...................................................................................................................... 12

12 PAPER................................................................................................................................. 13

12.1 LOADING PAPER .................................................................................................................. 13

12.2 PAPER OUT AND HEAD UP SENSORS..................................................................................... 13

13 LED INDICATIONS............................................................................................................... 14

14 PRINTER OPERATION AND PROGRAMMING.................................................................... 15

14.1 DATA BUFFER ..................................................................................................................... 15

14.2 SPOOL MODE...................................................................................................................... 15

14.3 CHARACTER PRINTING AND FONTS ........................................................................................ 15

14.4 GRAPHICS PRINTING AND OTHER PROGRAMMING MODES ........................................................ 15

15 TECHNICAL SUPPORT ....................................................................................................... 16