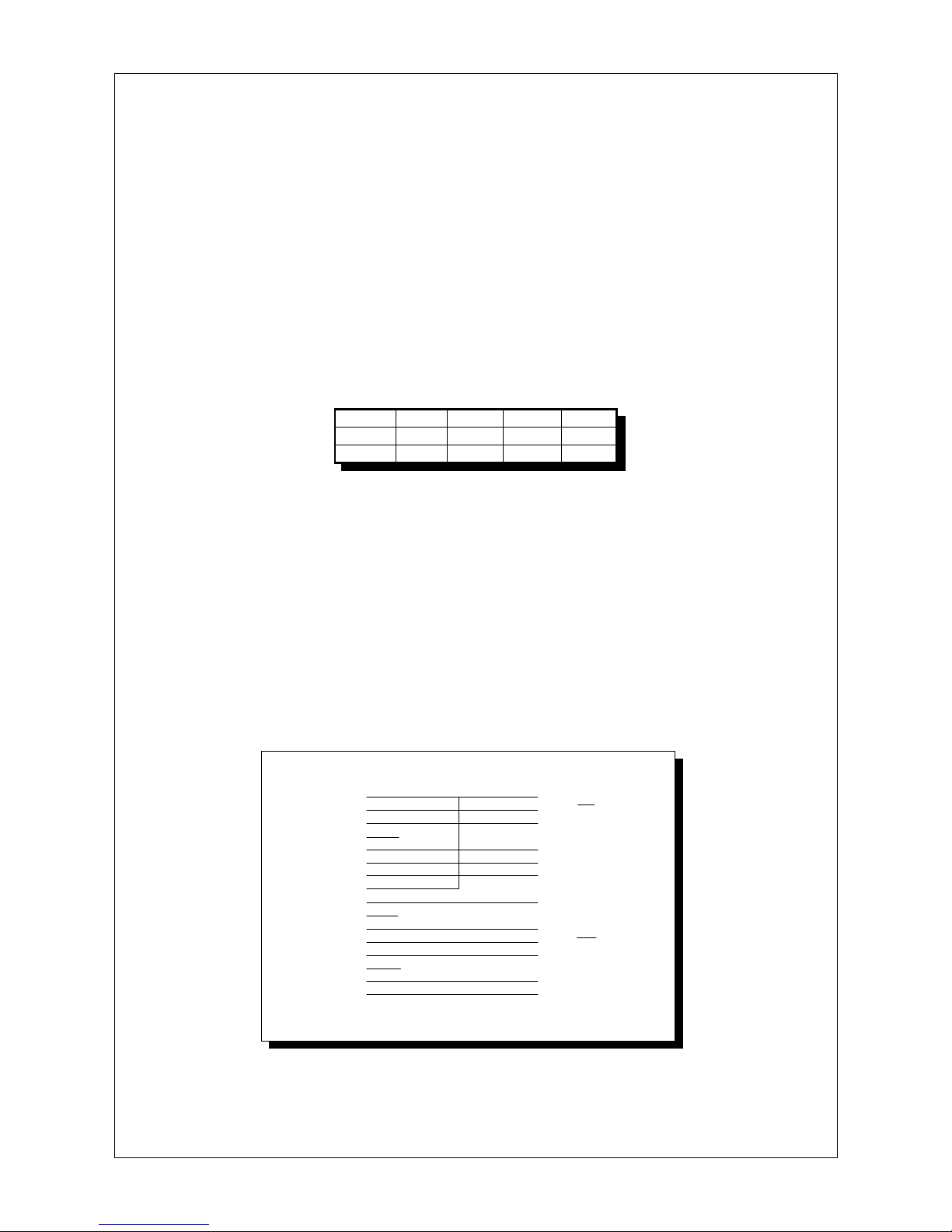

line for descenders and a dot line above and below each character line. The number of characters

required to fill a dot line varies according to the printer, as follows:

0.20mm0.33mm0.4 lines/second40 characters per lineAp25-40 0.25mm0.33mm0.5 lines/second32 characters per lineAp25-32 0.33mm0.33mm0.7 lines/second24 characters per lineAp25-24

Horizontal

dot pitch

Vertical dot

pitch

Lines per secondCharacters per linePrinter

The ASCII characters 32 to 255 (32 to 127 if using a backwards compatible 7 bit character set) are in

the printable range. Any character below character 32 is ignored unless it is one of the control codes

(section 5.7).

5.6 Graphics Printing

The product is programmed to take advantage of the graphics printing capability of the mechanisms.

Graphics are received as the least significant 6 bits of each byte. In this way the same number of

graphics bytes are required to terminate a line as the number of characters required to print a

complete line. The graphics mode is reset at the end of every dot line and hence the graphics

command, <ESC><02>, must be entered at the start of every dot line.Graphics patterns are built up

as a succession of dot lines across the paper. The number of bytes required to fill a dot line for each

mechanism are the same as the number of characters required to fill a dot line. Large areas of solid

dots are not recommended as they may cause over heating and shorten the ribbon life. Heavy

graphics printing may also require a higher current power supply.

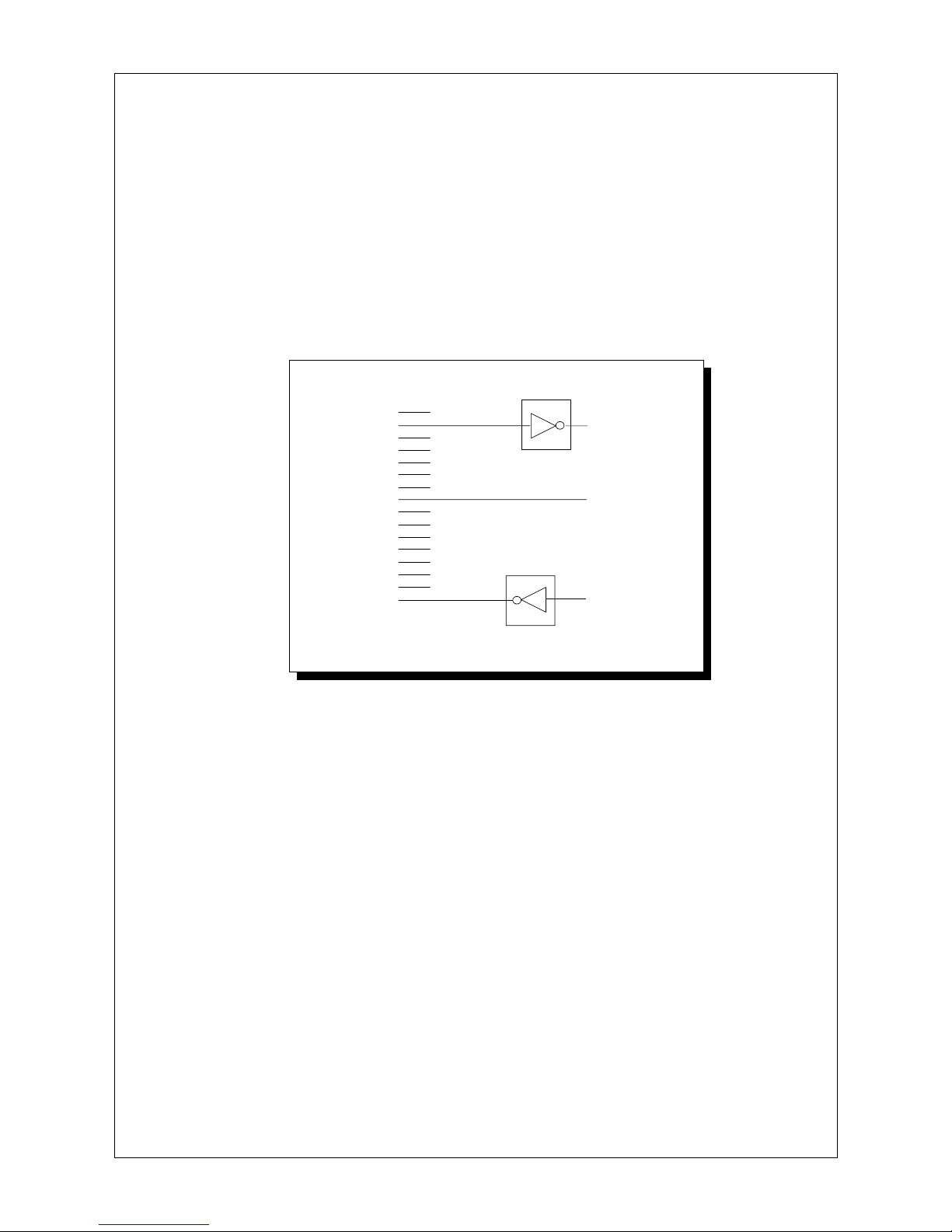

A typical graphics line for the Ap25 would be:

Control code Data (24 bytes for the Ap25-24)

<ESC><02> <00><00><01><02><03><04><05> etc.

5.7 Control Codes

9 character sets which may be selected for backwards compatibility. The default character set is the

8 bit IBM 224-character set.

Previous versions of the Ap24 family have been supplied programmed with 7 bit character sets, UK,

French, German, “Scandinavian”, Danish/Norwegian, Swedish, Japanese and Spanish character

variations (often to special order). The Ap25 contains all these variants, which are software selected

for backwards compatibility. 8 bit data is selected when using the 8 bit IBM character set, otherwise

the 8th data bit is ignored.

The structure of the command is as follows:

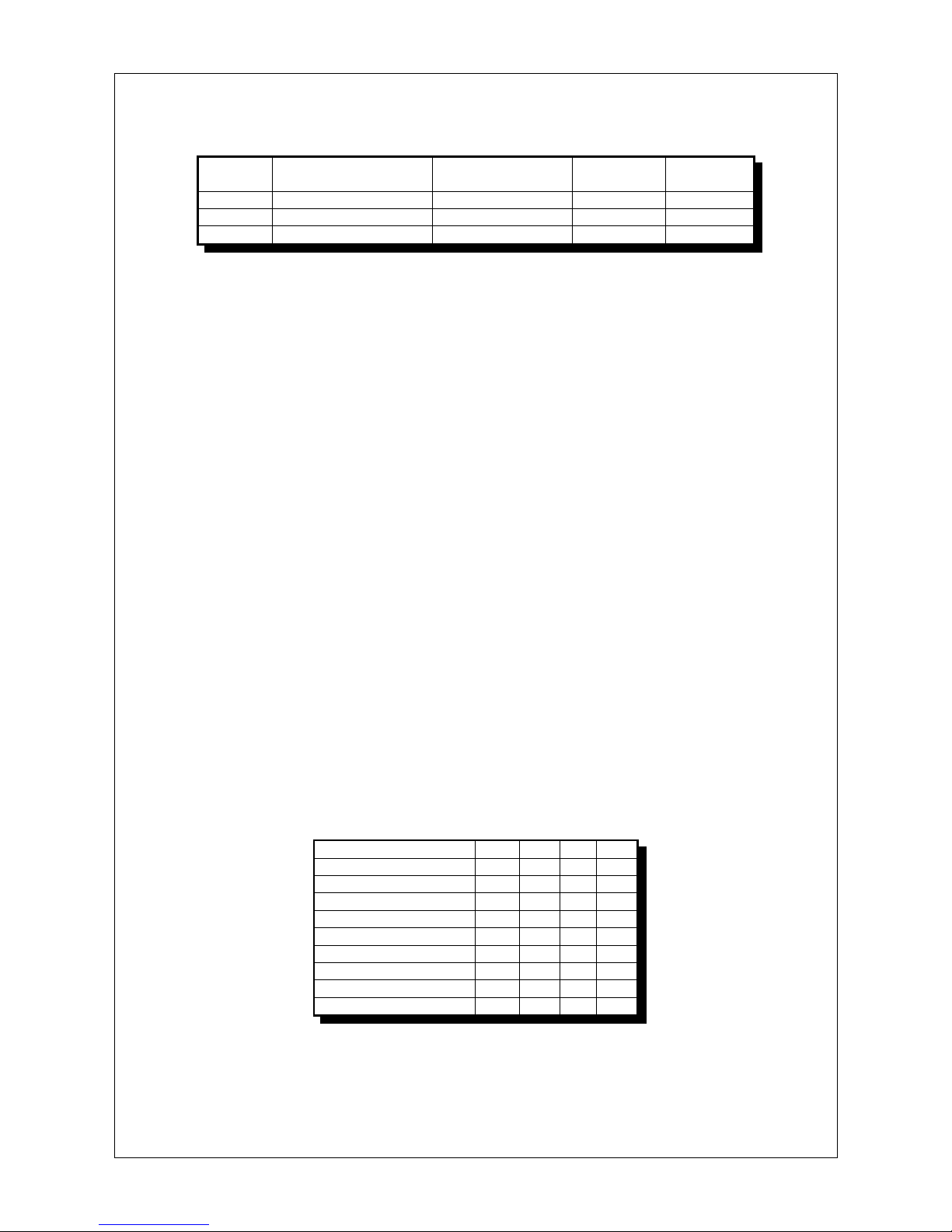

<ESC><127><n> where n is a byte of the form [X,X,X,X,B3,B2,B1,B0] (X = don’t care)

Country selection:

0001Spanish 1110Japanese 0110Swedish 1010Danish 0010Scandinavian 1100German 0100French 1000UK 0000Full 8 bit IBM (default) B0B1B2B3Character set

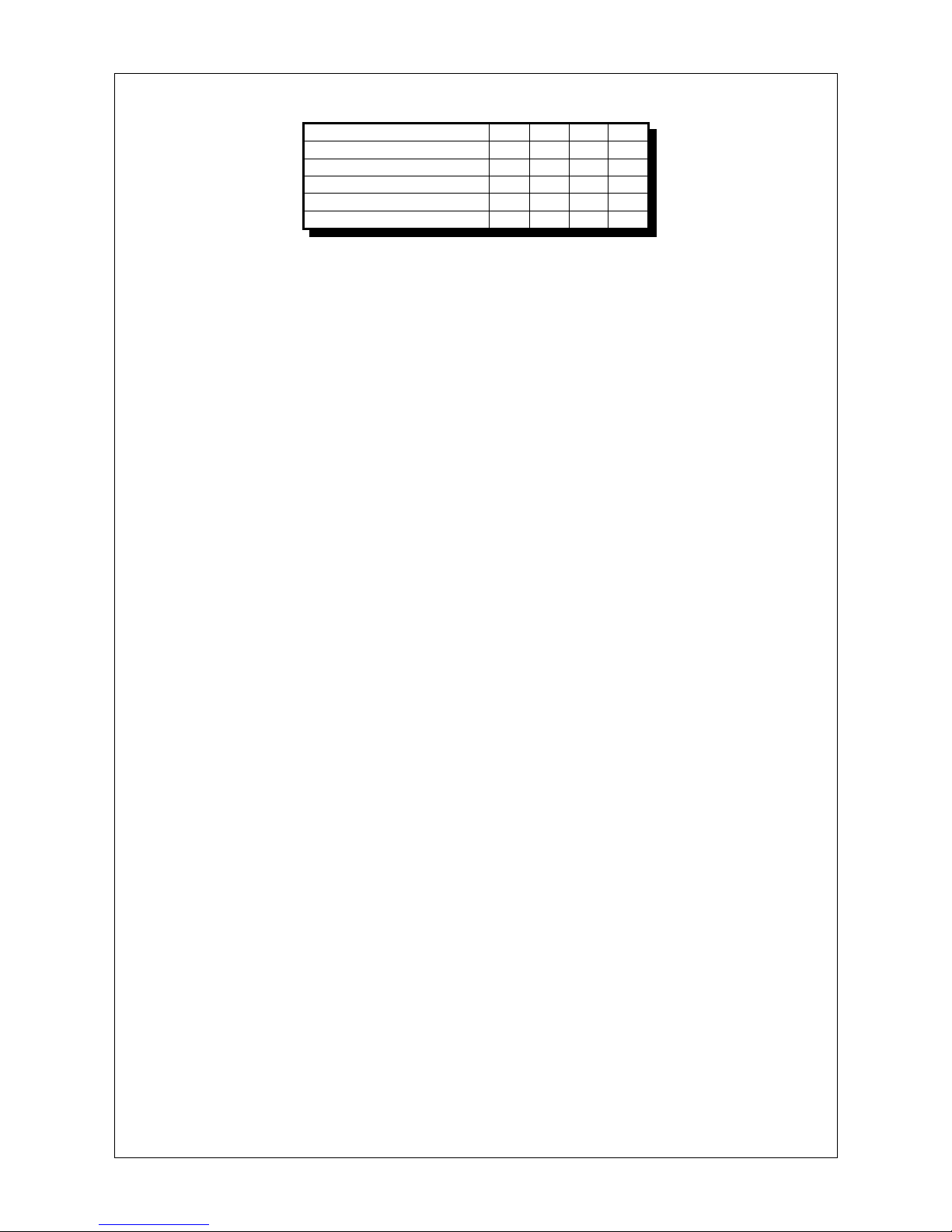

<ESC><n> (If buffer is not empty, print buffer contents and) Set print mode:.

Note: nis a byte of the form [ 0,0,0,0,B3,B2,B1,B0] (all except the lower 4 bits must be zero, to avoid

conflict with other ESCape codes).

Ap25 Users’ Guide Page 5 of 8