Abloy DA430 Guide

An ASSA ABLOY Group brand

ABLOY®DA430 SWING DOOR OPERATOR

– Installation and commissioning manual

2

APPROVALS / STANDARDS

Electrical safety tested and approved FI, S, N, D

Low Voltage directive 73/23/EEC as amended by the directive 93/68/EEC

EMC directive 89/336/EEC

----------------- THIS MANUAL CONTAINS IMPORTANT SAFETY INSTRUCTIONS -----------------

Warning - IT IS IMPORTANT FOR SAFETY OF PERSONS TO FOLLOW THESE INSTRUCTIONS.

------------------------------------ SAVE THESE INSTRUCTIONS --------------------------------------------

This appliance is not intended for use by persons (including children) with reduced physical,

sensory or mental capabilities, or lack of experience and knowledge, unless they have been

given supervision or instruction concerning use of the appliance by a person responsible for their

safety.

Do not allow children to play with fixed controls.

Frequently examine the installation for imbalance and sings of wear or damage to cables, springs

and mountings. Do not use if repair or adjustment is necessary.

Disconnect the supply when cleaning or other maintenance is being carried out.

Before installing the operator, check that the operator is in good mechanical condition and it

opens and closes properly.

Ensure that entrapment between door and the surroundings is avoided.

Ensure that the operator is suited for installation. Check temperature, humidity, door weights, etc.

restriction in line with specifications applicable in the manual or other Abloy® Oy material.

Note!

Instructions, design specifications and illustrations which are contained in this manual are not

binding. Abloy Oy reserves the right as part of ongoing product development to make changes

without previous notice.

Warning!

Warning!

3

CONTENTS

1 REVISION ................................................................................................. 4

2 CONTENT OF DELIVERY ........................................................................ 5

3 GENERAL INFORMATION ....................................................................... 6

4 OPERATION ............................................................................................. 7

5 MODE SWITCH......................................................................................... 7

6 INSTALLATION......................................................................................... 8

6.1 Installing the operator and the mounting plate DA105.............................................. 9

6.2 Assembly of the operator and standard arm DC190 to the closing side................. 10

6.3 Assembly of the operator and sliding arm DC194 to the closing side..................... 11

6.4 Assembly of the operator and sliding arm DC194 to the opening side ................... 12

7 INTERNAL CONNECTIONS ................................................................... 13

8 COMMISSIONING................................................................................... 14

9 A SAFE DOOR........................................................................................ 16

10 EXTERNAL CONNECTIONS.................................................................. 17

11 CONNECTION EXAMPLES.................................................................... 18

11.1 Safety sensors DA001 and DA002 ....................................................................... 18

11.2 DA061 and DA062 Microwave motion sensor ...................................................... 19

11.3 DA063 Microwave motion sensor ......................................................................... 19

11.4 DA033 Elbow switch ............................................................................................. 20

11.5 DA039 and DA049 rotary switch........................................................................... 20

11.6 Electric locks EL402, EL404, EL502..................................................................... 21

11.7 Motor locks EL490, EL590.................................................................................... 21

11.8 Motor locks EL420, EL520.................................................................................... 22

11.9 Electric lock EL410 ............................................................................................... 22

12 SELF DIAGNOSTICS.............................................................................. 23

13 MAINTENANCE ...................................................................................... 24

14 SPARE PARTS ....................................................................................... 25

4

1 REVISION

Following pages have been revised:

Page Revision

As at 21.09.2009.

5

2 CONTENT OF DELIVERY

DA430 Swing door operator

- screw M6x16, 1 pcs

- spring washer, 4 pcs

- washer 4 pcs

- hex-socket head screw M6x16, 4 pcs

- grooved spindle, 1 pcs

- tension sleeve, 1 pcs

DA105 Mounting plate

- screws 5,5x32, 6 pcs

- ordered separately

DC190 Standard arm

- screw M6x16, 1 pcs

- screws M5x12 Poz 2, 2 pcs

- screws 4,8x32 Poz 2, 2 pcs

- ordered separately

DC194 Sliding arm

- screw M6x16, 1 pcs

- screws M5x40 Poz 2, 2 pcs

- screws 4,8x60 Poz 2, 2 pcs

- ordered separately

6

Technical data

Measures

• (L) 523 x (H) 68 x (W) 80 mm

• weight 3,5 kg

Supply voltage

• 110 - 230 VAC (±15%) 50...60 Hz

• back-up inlet 24 VDC (±15%) 2A

Enclosure class

• IP20

Temperature range

• storage -20...70 °C

• operation 0...40 °C

Interfaces

• power output 24 VDC max 500 mA

• potential free relay output

0.8 A @ 30 VDC resistive load

0.3 A @ 30 VDC inductive load

Features

• Swing door operator for indoor use only.

• Door weight up to 80 kg (standard arm) and 60 kg (sliding arm).

• Low noise.

• Compact design - easy to install.

• Low resistance if manually used.

• Push&Go.

• Adjustable hold open time 0...60 s or sequential use.

• Built in 24 VDC/0.5 A power supply for external devices.

• Secondary DC inlet power back - up (24 VDC 2A).

• Maximum opening angles:

• With standard arm DC190

On the closing side, 100°

• With sliding arm DC194

On the closing side, 90°

On the opening side, 110°

3 GENERAL INFORMATION

7

AUTO

OPEN

MAN

Abloy®DA430 is an electromechanical swing door operator for moderate use.

It can be used on single, internal doors. The Abloy®DA430 has a ”Push&Go”

function. When Push&Go is in operation and door is pushed or pulled manually,

operator opens the door to adjusted opening angle and closes the door after a 5

second of hold open time.

Internal monitoring

Obstructed opening:

The door is set free for 5 seconds and the impulse is restrained during that time.

After that, the operator tries to open the door. If the door is still obstructed in the

same position after 4 trials, operator closes the door.

Obstructed closing:

The door is set free for. After that, new trial is done to close the door. Maximum

amount for trials is 4. If it is exeeded, the door is set free for 1 minute. Atfter this

new trial is done to close the door.

4 OPERATION

5 MODE SWITCH

Note! There is 3 seconds constant delay

when mode switch is changed position

OPEN to AUTO or MANUAL.

The door opens via an impulse and closes after

the adjusted hold open time.

Manual use.

The door opens and stays open.

8

6 INSTALLATION

Steps of installation

- Preparing installation

- Installing the mounting plate if needed

- Mounting the operator and the arm

- Connecting the operator to mains

- Commissioning

- Testing

- Connecting impulse devices

Preparing installation

- Check the correct function

of the door

- Hinges

- Door clearance

- Check the correct function

of the lock

- Lock case

- Striker plate

- Suitability of the

lock’s function

Removal of housing

Note! Remove the protective earth wire from cover and connect it back after

installation.

Ensure the mains disconnected when removing or re-fitting the cover.

9

6.1 Installing the operator and the mounting plate DA105

The operator is installed on the transom, with the mode switch located towards

the hinge side of the door. Securely fix the operator or the mounting plate to the

transom. Minimum requirement for wall profile is 5 mm (steel).

Installing the operator

Installing the mounting plate DA105

The mounting plate DA105 with the door operator ensures the installation base is

level. Use the mounting plate if needed.

0

261

86

15

0

66

55

33

11

522

436

Ø 22

44

210

261,5

399

479

0

44

Hinge line

10

9

10

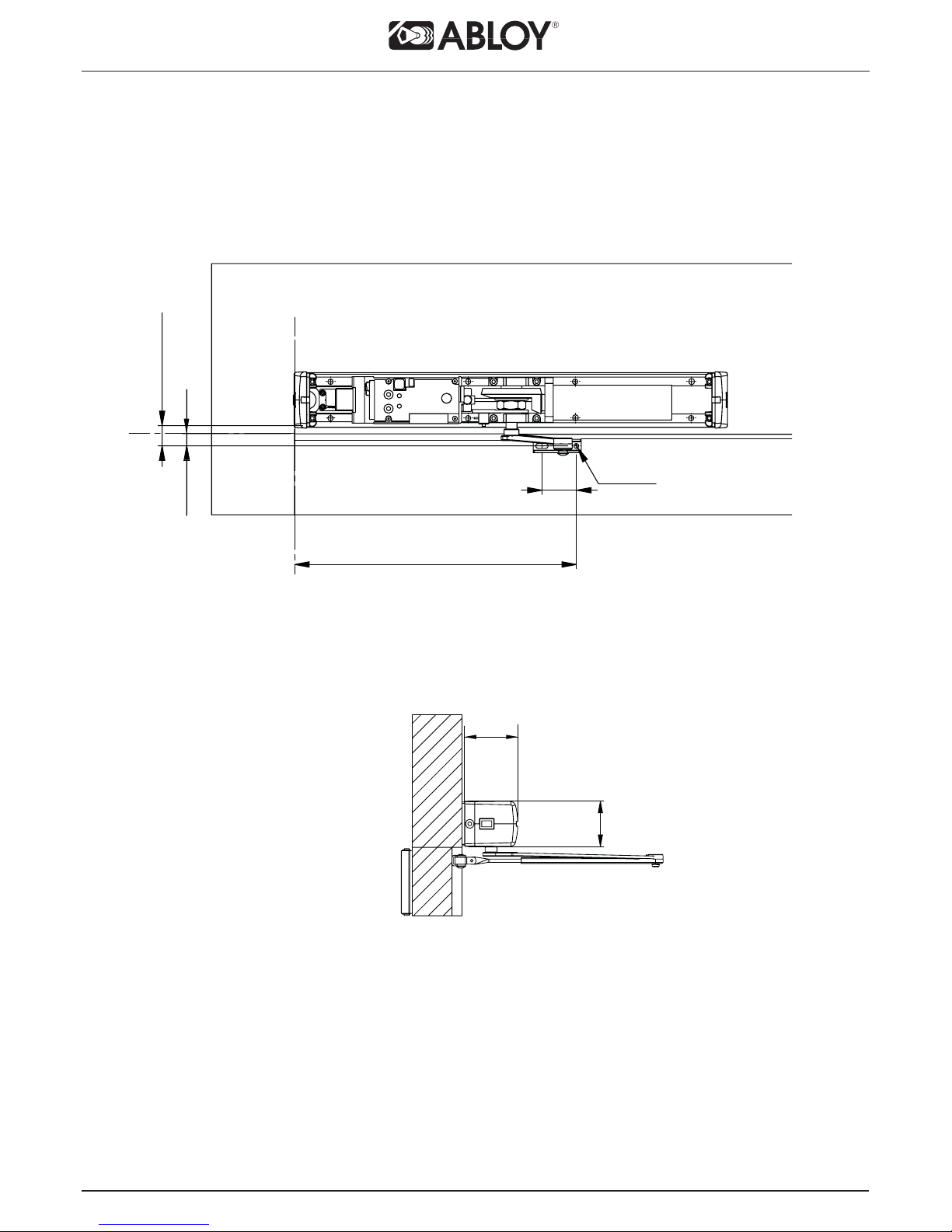

6.2 Assembly of the operator and standard arm DC190 to the

closing side

20**

42

Min. 21*

Max. 32*

340

Ø 6

Hinge line

*The measure from bottom of the operator

** The measure from bottom of the frame

80

68

Table of contents

Other Abloy Door Opening System manuals

Popular Door Opening System manuals by other brands

Besam

Besam Swingmaster MP Installation, adjustment and maintenance instructions

Assa Abloy

Assa Abloy SARGENT 1431 Series instructions

GAL

GAL MOVFR Quick setup

Häfele

Häfele Finetta T 70 VF manual

AGS

AGS D-PL Instructions for fitting, operating and maintenance

Stanley

Stanley MA900ñ Installation and owner's manual

WITTUR

WITTUR Hydra Plus UD300 Instruction handbook

Alutech

Alutech TR-3019-230E-ICU Assembly and operation manual

Pamex

Pamex KT-INP35 Installation instruction

MPC

MPC ATD ACTUATOR 50 ATD-313186 Operating and OPERATING AND INSTALLATION Manual

Chamberlain

Chamberlain T user guide

Dorma

Dorma MUTO COMFORT M DORMOTION 50 Mounting instruction