Sesamo PROSWING R Simple manual

P R O S W I N G

R

ENGLISH

OPERATOR FOR SWINGING DOORS

MANUAL INSTRUCTIONS

3

SESAMO PROSWING

Thank you for choosing this product. For best automatism performance, Sesamo recommends

you carefully read and follow the installation and use instructions found in this manual.

Installation of this automatism must only be performed by the professionally qualified

personnel for whom this manual is addressed. Any errors during installation may be harmful

to people or things. Packaging material (wood, plastic, cardboard, etc.) should not be

scattered in the environment or left within the reach of children as potential sources of

danger. Every installation phase must be performed in accordance with the regulations in

force and following Good Technique standards. Before beginning installation make sure that

the product is integral and has not been damaged during transportation or by poor storage

conditions. Before installing the product make sure that each architectural and structural

element of the entrance (girder fastening surfaces, casings, guide, etc.) is appropriate and

sufficiently robust to be automated. Conduct a careful risk analysis and make suitable

modifications to eliminate conveyance, crushing, cutting and hazardous areas in general. Do

not install the product in environments where gas, steam or inflammable fumes are present.

The manufacturer is not liable for any neglect of “good technique” or specific regulations in

the construction of the casing to be motorized and any collapse of the same. All automatic

entrance safety and protection devices (photocells, active sensors, etc.) must be installed in

accordance with the regulations and directives in force, with the completed risk analysis,

system type, use, traffic, forces and inertia in play. Pay careful attention to area where the

following may occur: crushing, cutting, conveyance and any other type of hazard in general

applying, if necessary suitable indications. Indicate the motorized door identification

information on every installation. Make sure that the upstream electrical system is correctly

dimensioned and has all the opportune protections (circuit breakers and fuses). Only use

original spare parts in maintenance and repairs. Do not tamper or alter devices in the

automatism and all the safety devices in the control panel for any reason. The manufacturer

is not liable if parts within the automatism are altered or tampered with or if safety devices

other than those indicated by the manufacturer are used in the system. The automatism

installer must provide the automatic entrance manager with the use manual and all the

information required for correct use in automatic and manual modes (even for electronic

locking) and in the event of emergency. Pay careful attention to the messages in this manual

that are marked with the hazard symbol. They can either be warnings aimed at avoided

potential equipment damage or specific signals of potential hazard to the installer and others.

This device was designed to automate pedestrian swinging doors. Any other use is considered

contrary to the use foreseen by the manufacturer who therefore shall not be held liable.

4

SESAMO PROSWING

DIRETTIVA MACCHINE

The installer who motorised a door becomes the automatic door machine manufacturer according

to directive 2006/42/CE and must:

–Arrange the Technical Booklet with the documents indicated in attachment VII of the

Machine Directive and keep them for at least 10 years.

–Draft the CE declaration of conformity according to attachment II-A of the machine

directive and provide the use with a copy.

–Apply the CE markings on the motorized door according to point 1.7.3 of attachment I

of the machine directive.

–In particular, but not exclusively, if for the purpose of the standard EN 16005 it is

necessary to install monitored sensors, the wiring has to carry out as described in

this manual (see pages 13/14/15/19) and the correct sensors operation has to be

checked following instruction manual of the sensors themselves.

For more information and for assist installers in applying the specifications of the directives and of

European standards concerning the safe use of motorized gates/doors consult the guidelines

available on internet at the address www.sesamo.eu

DECLARATION OF INCORPORATION

(Directive 2006/42/CE, Annex II, part B)

Manufacturer: SESAMO S.R.L.

Address: Str. Gabannone 8/10 - 15030 Terruggia –AL -ITALY

Declares that the product: PROSWING R

- is made to be incorporated in a machine to construct a machine considered by Directive 2006/42/CE

- conforms with the essential safety requirements indicated in appendix I of the directive with the

exception of the following points: 1.2.4.3, 1.2.4.4, 1.3.4, 1.3.5, 1.3.7, 1.3.8.2, 1.4, 1.5.3, 1.5.7, 1.5.14,

1.5.15, 1.5.16

- complies with the conditions of the following other CE Directives: 2014/30/UE Electromagnetic

Compatibility, 2014/35/UE Low Voltage

and that

- the following (parts/clauses of) agreed regulations have been applied:

EN 60335-1 EN 61000-6-2 EN 50366 EN 61000 -6–3EN16005

and also declares that:

- the relevant technical documentation has been completed in accordance with part B of appendix VII;

this documentation, or parts of it, will be delivered electronically or by traditional post upon justified

request from the competent national authorities

- the relative technical documentation will be compiled by: SESAMO SRL, Strada Gabannone, 8/10 - 15030

Terruggia (AL) - Italy

- it is not permitted to use the product until the machine in which it will be incorporated or will become a

component of has been identified and has received the declaration of conformity with the conditions of

Directive 2006/42/CE and the national legislation that transposes it, in other words, until the machinery

referred to in this declaration forms a single unit with the machine.

SESAMO S.R.L. Aldo Amerio

Maggio 2016 (Amministratore)

5

SESAMO PROSWING

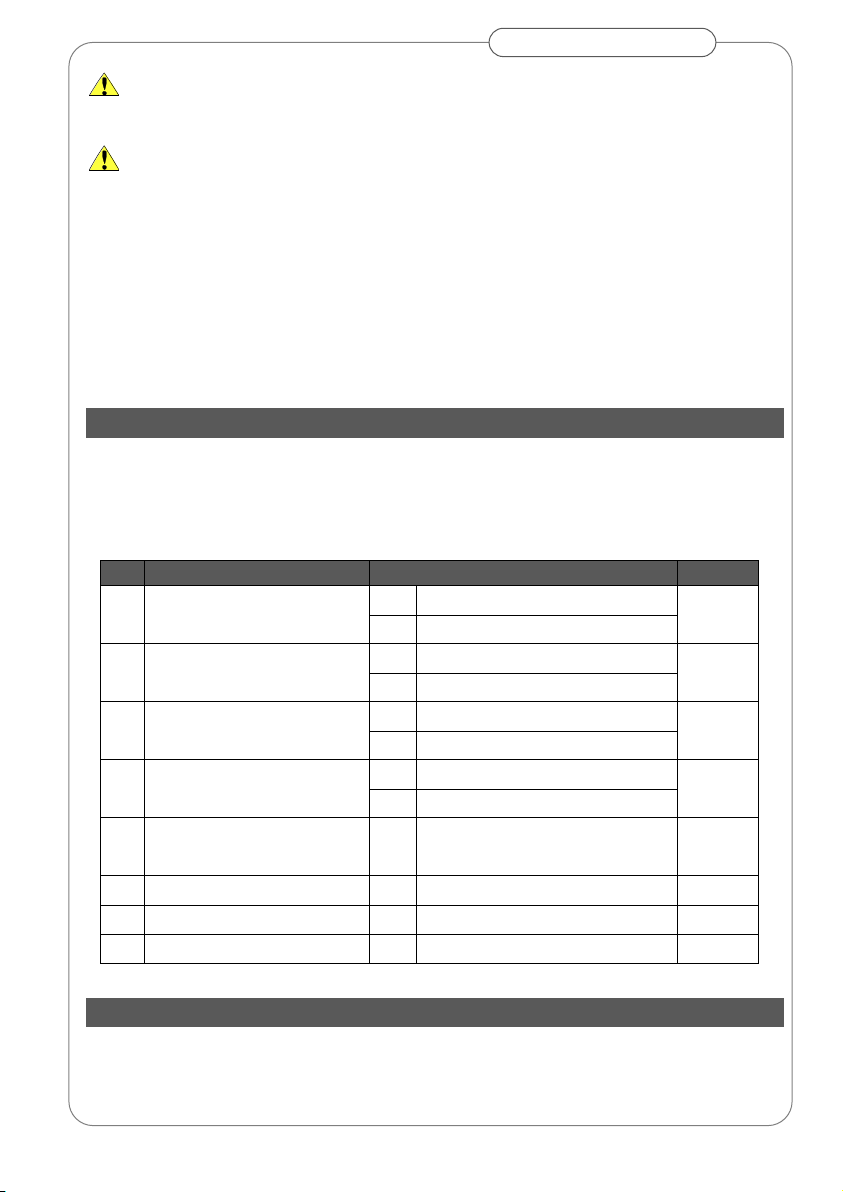

CARATTERISTICHE TECNICHE

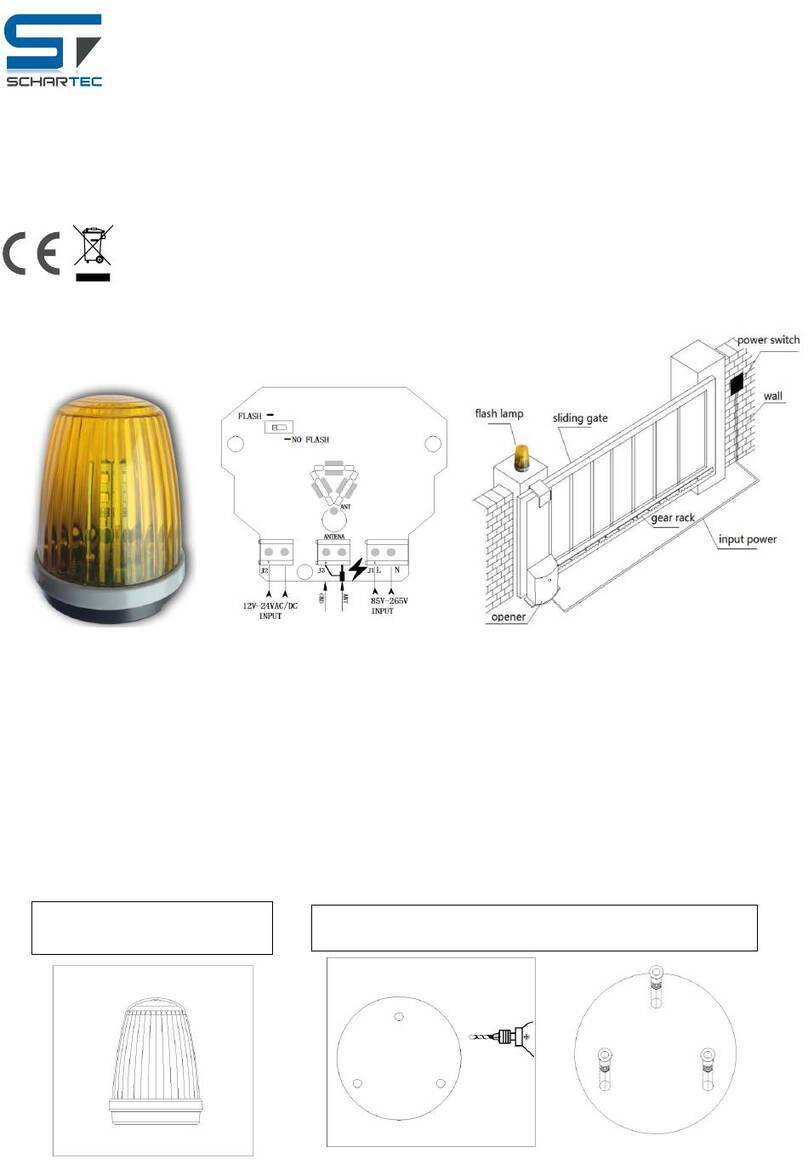

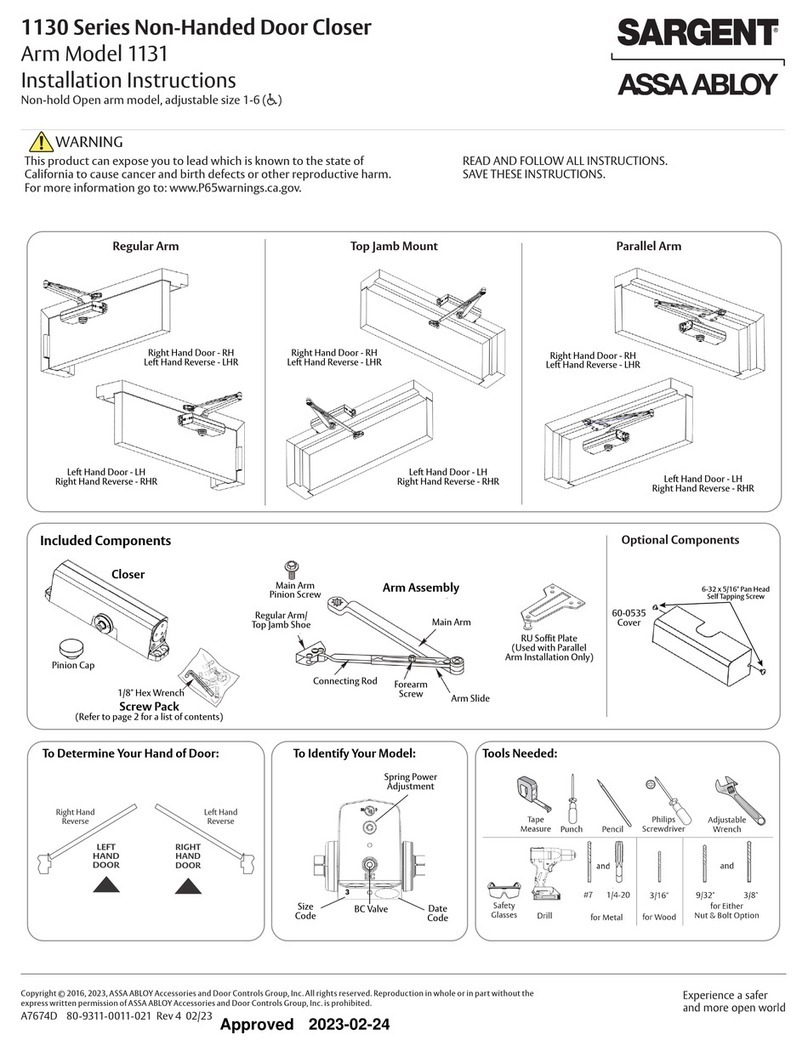

DIMENSIONS

see Fig.1

POWER SUPPLY

230V ±10% AC 50/60Hz

NOMINAL POWER

85W

NOMINAL MOTOR TORQUE

45Nm

EXTERNAL DEVICE POWER

15VDC - 12W MAX

POWER BATTERY KIT (1)

24V -1,3Ah

OPENING TIME

3s ÷ 6s (70°/s ÷ 20°/s)

CLOSING TIME

4s ÷ 15s (40°/s ÷ 10°/s)

CLOSING FORCE (ACCORDING EN 1154) (2)

EN4 ÷ EN6

MAX OPENING ANGLE

110°

WING DIMENSION

700 ÷ 1400 mm

MAX.WING PAYLOAD

see Fig.2

WORKING TEMPERATURE

from -10°C to +50°C

ANTI-CRUSHING

Automatic traction restriction in presence of

obstacles

WEIGHT

11 kg approx

SERVICE

Intensive

OPERATOR WITH SPRING OPENING, IN CASE OF POWER FAILURE OR SIGNAL

–PLEASE CHECK INSTRUCTIONS

LOW ENERGY

PROSWING can be set in the order to meet requirements of Low-Energy application according

EN16005.

- reduced dynamic force;

- low speed;

- reduced dynamic/static force.

It is installer's responsibility to verify the compliance of the installation Low-Energy compared

with current standards. The protection of the closing edge must be assessed individually.

WARNINGS FOR THE INSTALLER (AND GENERAL SAFETY)

1) It is important for the safety of the people installing the automatism according to the

regulations. A wrong installation or use of the product might lead to serious damages to

people.

2)Read carefully the operating instructions before installing the product.

3)Store the operating instructions for future reference.

4)This automatism has been designed and built exclusively for the use specified in this

documentation. Any different use not stated herein could affect the integrity of the product

and/or represent danger situation.

5)SESAMO declines any responsibility from misuse or different use from which it was

intended.

6

SESAMO PROSWING

6)Do not install the product in explosive environment: the presence of flammable gases or

fumes is a serious safety hazard.

7)SESAMO is not responsible for the failure to comply with the Good Technical construction

procedure of the door to be automated, as well as deformations that may occur to the door

when using the same.

8)Before making any service to the product, switch off power supply.

9)Install a bi-polar switch to cut off power supply.

10)Verify functionality of ground wiring.

11)Safety devices (norm EN 12978) protect possible dangerous areas from mechanical risks

during movement, as. anti-crashing, conveying, shearing.

12)For maintenance use only genuine SESAMO spare parts.

13)Do not modify components that belongs to the whole automatism.

14)The installer must supply end user all the information in case of manual operating in

emergency.

15)End user shall refrain from any attempt to repair or direct intervention and ask only to

qualified personnel.

16) Installation must be done only from a qualified personnel and in full compliance with

regulations.

17) Everything not including in this operating instruction manual is not allowed.

18) This operating instructions manual is only intended for qualified personnel.

19) It is mandatory to use a MAG-LOCK to keep the door in closed position.

RECYCLING AND DISPOSAL

This product is built with different materials. The major parts (aluminum, plastic, iron, wires)

are solid urban waste. They can be recycled through collection and disposal in authorized

centers. Other components (control boards, etc.) may contain pollutants. They need to be

removed and hand over to companies authorized to recover and dispose them. The packaging

(paperboard, plastics etc.) are solid urban waste and they can be disposed of without any

problem, simply performing waste collection for recycling. Before proceeding it is always

recommended to verify local specific norm for disposal.

PLEASE RECYCLE!

INTENDED USE

IMPORTANT: PROSWING R must be used to automate pedestrian swinging door only.

This device is an electro mechanical system that allows to open and close a swinging door

using a transmission arm.

The door is moved by a movement open/close thanks to a spring/motor system or in opening

only with spring in case of NO power supply.

Programmable electronic control board allows correct functioning depending on the type of

installation.

It is alwasy necessary to combine a MAG-LOCK in order to keep the door in closed position.

7

SESAMO PROSWING

LIMIT OF USE

ATTENTION: Do not exceed door weight and width as shown in the diagram in “technical

specification” paragraph. Fig.2. At each transmission arm also corresponds a different value

of the maximum depth of the jamb that must not be over taken in order to perform a proper

installation of the system. This device is intended only for swinging pedestrian door, dry and

inside use. SESAMO shall not be held liable for any other use contrary to the use foreseen.

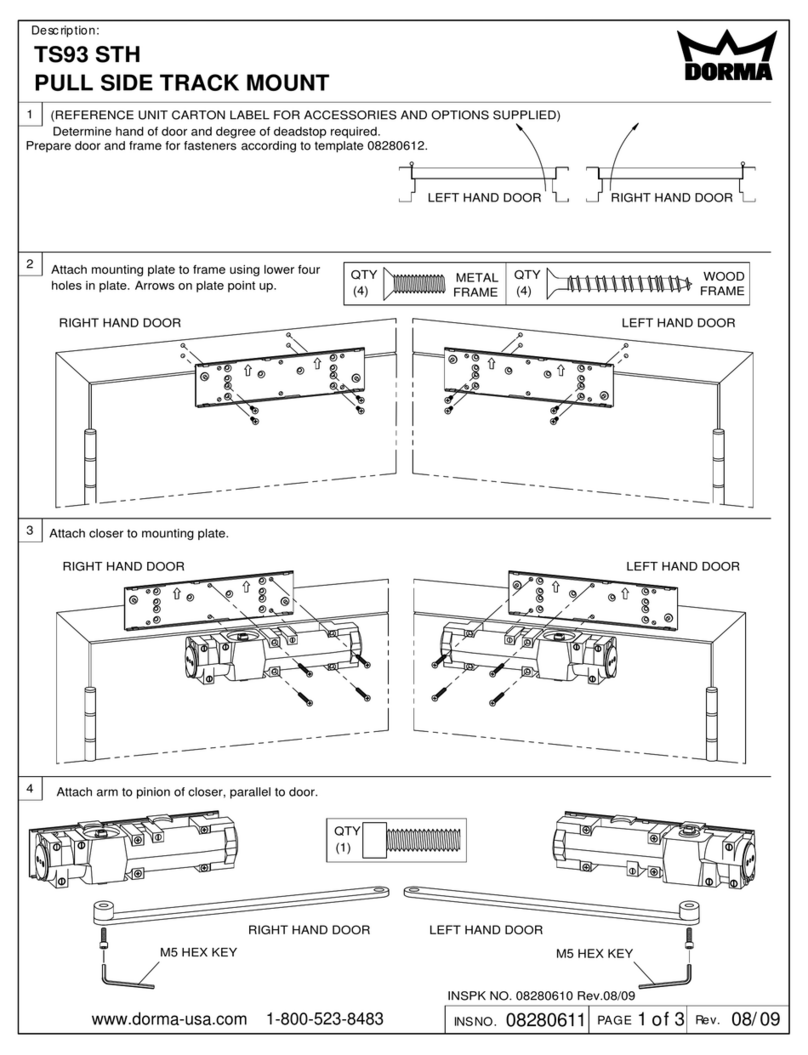

TYPES OF ARMS

-RIGID ARM: the rigid arm can be used as PULLING arm (when the operator is

installed on the same side of the opening of the door).

-STANDARD PUSH ARM: the pushing arm can be fitted : PUSH (it is used when the

automatism is installed on the opposite side of the door opening).

-LONG PUSH ARM: the long push arm can be fitted: PUSH (it is used when the

automatism is installed in the opposite side of the door opening with extra

150mm depth of the jamb).

ATTENTION: For a proper positioning refers to paragraphs “Arms Installation”.

PRELIMINARY CHECKS

Before installing the automatism please check:

–verify the installation does not create dangerous situations;

–prearrange proper pipes and conduits for the wires, granting the protection of the

same against mechanical damages;

–the surface where fixing the automatism has to be resistant. Use screws, bolts, etc.

adequate to the type of surface;

–the structure of the door has to be strong to hold the weight of the automatism as

well the hinges, also check to not have friction between fixed and mobile parts;

–use proper equipment and tools to install in security and in accordance with the

regulations.

OPERATOT FIXING

Refer to Fig.4, to fix automatism proceed as follows:

-remove cover (B);

-disconnect all wiring (encoder, switches, transformer, motor) on control board (C);

-unscrew the 2 screws and remove control board with its support (C) (screws

remain between control board and support);

-unscrew the 2 screws (G) and remove transform;

-unscrew the 4 screws (D) and remove gear motor;

-unscrew the screws and remove end caps (E) and (F);

-fix aluminum base (A) to the structure following instructions of the following

paragraphs, depending on arm type;

-reassemble all components except end caps and aluminum cover.

8

SESAMO PROSWING

To make easier reassembling gear motor, partially screw the screws, then lean gear motor on

to them. Insert screws. Tight all screws paying attention that gear motor axis is perpendicular

to the door top edge.

ALUMINIUM BASE HOLES POSITIONING

Drill holes according to the type of screws chosen and fix the base only after verifying the

“Positioning dimensions” listed in the paragraph concerning the type of arm selected.

With double automatism prearrange the connection (wiring) between the two single

automatisms.

INSTALLAZIONE BRACCIO RIGIDO A TIRARE

Pull arm has to be used when automatism is installed on the same side of door opening.

ATTENTION: For a correct positioning always refer to the hinge axis and gear motor axis,,

as indicated in Fig.5 (Door opening LEFT) e Fig.6 (Door opening RIGHT).

ATTENTION: final tightening of the screws must be performed only after checking that

vertical positioning of the automatism allow a good parallelism between hinge axis and gear

motor axis. Therefore, after fixing the pulling arm and its guide, the coupling bolt of the arm

with the cylindrical skid have not to create force in opening/closing cycle. A positioning error

of the automatism might create bending between the bolt of the pulling arm and the

cylindrical skid more than the allowed tolerance, damaging parts of the automatism.

INSTALLATION PULL SLIDE ARM (PROSWING R)

-Remove the cover (Fig.9 Part.A) from the guide (Fig.9 part.B) to allocate the fixing

points.

-Fix the guide profile horizontally (Fig.9 part.B) following dimensions shown in Fig.5

e Fig.6.

-Unthread profile and drill 4 holes on the “V” mark on guide profile and fixed the

guide to the wing through adequate screws (Fig.9 part.B)

-Insert skid (Fig.9 part.C) into the guide rail (Fig.9 part.B)

-Tighten screw (Fig.12 part. A) to PRE-CHARGE the sping unitll the extremity of the

circle plate (Fig.12 part. B) will match with the line indicating the beginning of the

line EN4 (quote L=0).

-Position the door at desired point of opening as indicated in Fig.14.

-Find the correct position to insert the arm (Fig.11 part. A so that the extremity of

the arm (Fig.9 part.F) will be onlthe same line of the axis of the guide skid (Fig.9

part.C)

-Insert the washer (Fig.11 part.B) and tight the screw (Fig.11 part.C).

-Insert the arm (Fig.11part.D) in the arm extension slot, and tight two screws

(Fig.11 part.E).

ATTENTION THE MAX. TORQUE TO BE USED TO TIGHTEN SCREW “E” FIG.12 IS 10.5 N/m

-Screw the self-threated part (Fig.9 part.C) to pull arm (Fig.9 part.F).

9

SESAMO PROSWING

-Close the cover (Fig.9 Part.A) of the guide.

-Closed the right cap (Fig.9 part.E) and left cap (Fig.9 part.D) with the supplied

screws.

-Proceed with the adjustment of the spring [vedi paragrafo “[see paragraph “Spring

adjustment”].

Before tighten the arm extension, please check the distance between the guide and the upper

part of the arm, it should be around 17 mm

ATTENTION: After installing guide and slide arm, ALWAYS check the Switch on left

position in Fig.16 .

PUSH ARM INSTALLATION

Push arm is used when automatism is installed on the opposite side of door opening.

ATTENTION: For a correct positioning always refer to the hinge axis and gear motor axis,

as shown in Fig.7 (door opening LEFT) ed 8 (door opening RIGHT).

ATTENTION: final tightening of the screws must be performed only after checking arm

can easily rotate under door jamb.

FIX PUSH ARM TO THE DOOR

-Insert washer (Fig.11 part.B) and screw (Fig. 11part.C) on the arm extension (Fig.

11 part.A).

-Fix the first part of the articulated push arm (Fig. 11 part.D) in the slot of the arm

extension, as indicated in Fig. 11 and tight screws (Fig. 11 part.E).

ATTENTION THE MAX. TORQUE TO BE USED TO TIGHTEN SCREW “E” FIG.12 IS 10.5 N/m

-Unscrew 3 scews M8 x 16 (Fig.10 part.B) to leave independent the part of the arm

you will fix to the door leaf.

-Adjust the lenght of the arm following the calculation in Fig.13

-Screw, without tighten, 3 screws M8 x 16 (Fig. 10 part.B) to joint the two part of

the articulated arm.

-Drill the door leaf as indicated on Fig. 7 e 8.

-Position the door leaf on the desired opening point

-Fix the arm extension (Fig.10 part.A) of the pushing arm onto the above profile of

the wing through adequate screws.

ATTENTION: fix door bracket considering door material in case using a

reinforcement.

-Tighten screw (Fig. 12) to tension the spring up to the end of the plate (Fig.12 part.

B) matches the line indicating field EN4 (quote L=0).

-Fix the arm extension (Fig.11 part.A) into gear motor shaftto the door axis.

-Tight screw (Fig.11 part.C) until arm extension is well fixed to gear motor shaft

-Continue with spring adjustment (see paragraph “Spring adjustment”).

10

SESAMO PROSWING

ATTENTION: For articulated push arm, both right/left opening, set switch as shown

in Fig. 16.

SPRING ADJUSTMENT

The spring has to be charged according to the width of the door keeping in consideration the

norm EN 1154 in the range from EN 4 to EN 6.

Range of adjustment can be obtained from diagram in Fig.17 according to the width and

weight of the door, both for pull or push arm. During spring adjustment, wind force, over-

pressure and other environmental condition that might open the door, must be considered.

Adjust force of the spring tightening the screw (Fig. 12, Part.A) in order to tension the spring

up to the end of the plate (Fig. 12 part. B) on the range requested for the type of installation

(class EN identified).

ATTENTION: Keep in consideration the spring is a component that, when at maximum

compression, accumulates very high energy, it is necessary that both the spring both the

related components would be only replaced by using ORIGINAL parts. It is also recommended

to program service using qualified technicians. For maintenance please have a look on the

manual.

BREAKE ADJUSTEMENT WITHOUT POWER

Set breaking level on terminal board (Fig. 30) to suit closing speed without power supply to

door width/weight, ref. to Fig.16. Verify functionality opening door by hand and checking

closing cycle with spring, without power.

PRELIMINARY CHECKING

Before electrical wiring, check as follows:

-Remove carefully dust or any other residual of the installation

-Verify automatism being well fixed

-Verify all screws well tighten

-Verify all wiring well fixed and not near moving parts

-Verify arm well fixed to door.

-Verify arm well fixation of the plastic end side caps to the aluminium base

ATTE ATTENTION: ensure that the spring protection bracket is fixed (Fig.12, part. C) and

that the label with the seal hasn’t been removed (Fig.12, part. D).

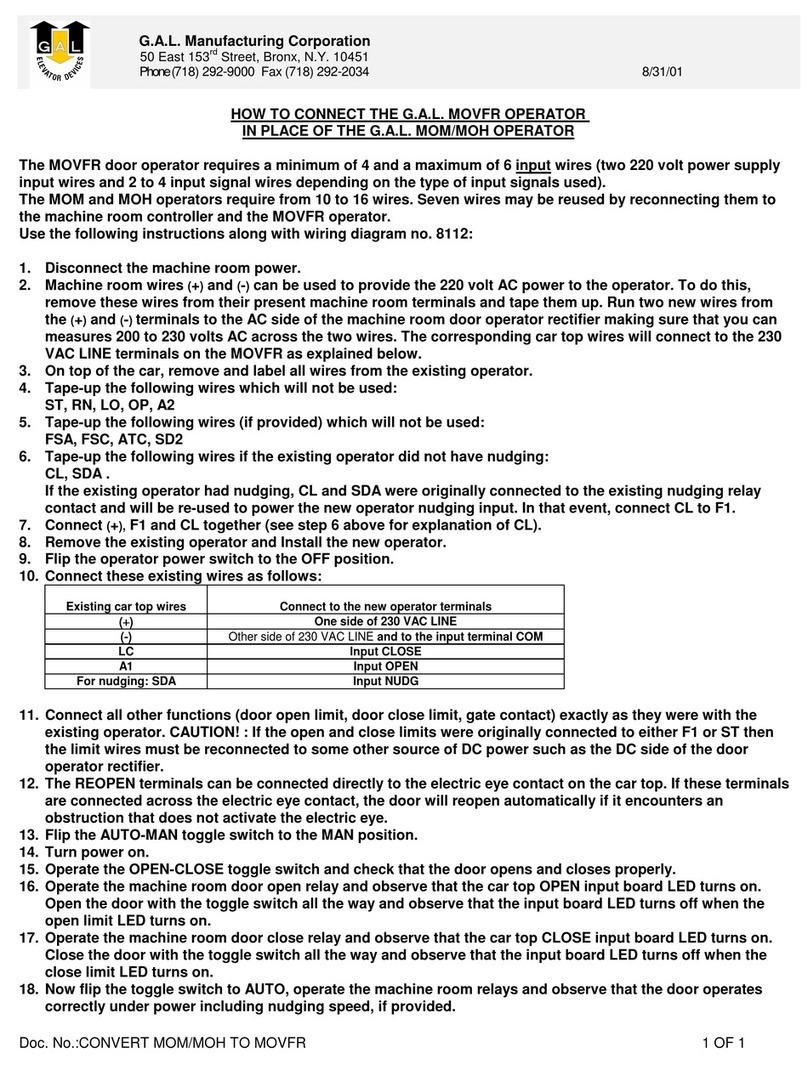

WIRING POWER SUPPLY

ATTENTION: Wiring the connectors of the control panel or external peripheral

connections must be in absence of power supply in order to avoid irreversible damages of the

electronic device.

ATTENTION: before performing the following operation make sure the power supply is

OFF. Before starting the automatism, check and perform as paragraph “Start up”.

11

SESAMO PROSWING

-Bring the cable inside the automatism paying attention not to damage it against

metallic edges.

-Open the cover (Fig.18 Part.A)

-Connect the power supply and the ground cable on the terminal (Fig.18 Part.B)

-Close the cover (Fig.18 Part.A)

ATTENTION: Never invert power supply cable and ground cable. Power supply must be

isolatable from the general panel with a bi-polar switch with minimum contact opening equal

to 3 mm (not supplied) (Fig.32 E)

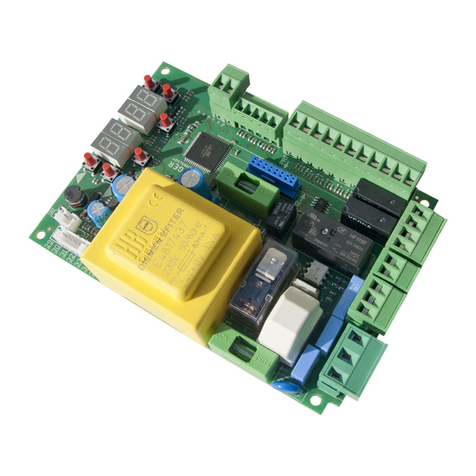

CONTROL BOARD PROSWING

In Fig.19 show the important components of electronic control board:

A. Expansion connector for additional board (Optional)

B. Display and buttons

C. Dip switches

D. PC connector

E. Transformer connector

F. Batteries connector

G. Switch ON-OFF connector

H. Logics switch connector

I. Auxiliary exit connexion

J. Logics connectors

K. Sensors / accssories power supply

L. Selector connector

M. Electronic lock connector

N. Encoder connector

O. Gear motor connector

P. Brake level selection connector

Q. Arm type selection

WIRING

Connect the following terminal boards (Rif.Fig.19):

- logic switch [H];

- ON-OFF switch [G];

- transformer [E];

- motor [O];

- encoder [N

ARM TYPE SELECTION

Rigid pull arm (both right/left opening) → Set switch on LEFT as shown in Fig.16.

Articulated push arm (both right/left opening) → Set switch to RIGHT as shown in Fig.16.

12

SESAMO PROSWING

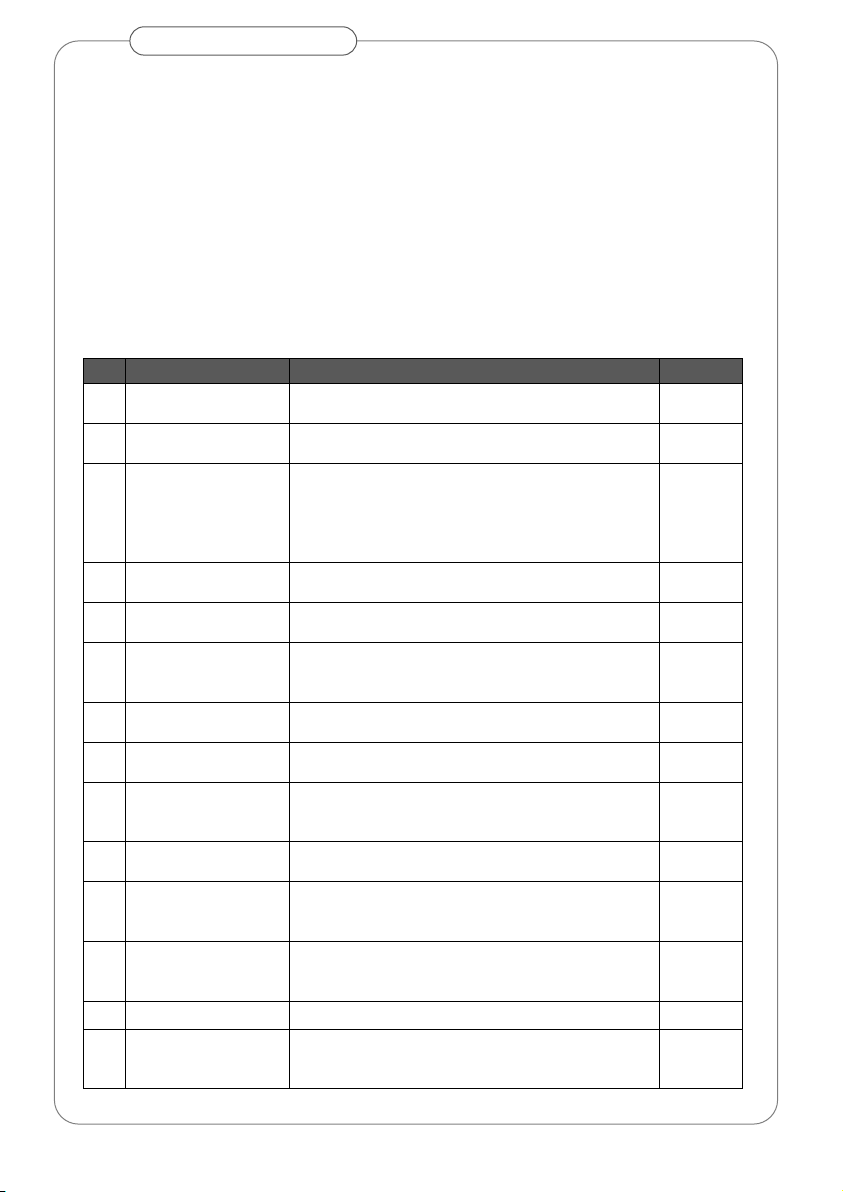

EXTERNAL PERIPHERALS CONNECTORS/INPUT

SEGNALE

DEFAULT*

DESCRIZIONE

FUNZIONAMENTO

KEY

NC

Lock contact. Lock devices

can be connected such as

electronic key, key

selector, proximity reader,

etc.

If the contact opens the unit sends a

complete closing cycle command (from

any position) From this moment until the

signal is closed the door stays closed and

no external peripheral is detected

(including the multi-logics selector). As

soon the signal closes the door opens and

allows again the standard operating.

The signal must be short circuited with

COM if no device is connected

START 1

NO

Opening contact door

opening devices can be

connected.

Closing this signal gives the command to

open the door. This signal is only

monitored in 2 Radars logic, selectable

through base or advanced selectors

(optionals).

START 2

NO

Opening contact door

opening devices can be

connected.

Closing this signal gives the command to

open the door. This signal is monitored

both in 2 Radars logic both in 1 Radar logic

selectable through base or advanced

selectors (optionals).

SAFE

OPEN

NC

Opening safety contact for

safety sensors monitoring

opening cycle.

If the door is opening and the contact

opens, the control board gives a stop

command immediately. Opening will only

continue after this signal is deactivated.

The signal must be connected with COM if

no device is connected.

SAFE

CLOSE

NC

Closing safety contact for

safety sensors monitoring

closing cycle

If the door is closing and the contact

opens, the control board commands the

door to reverse immediately. Closing will

continue only after the contact returns

closed again. The signal must be connected

with COM if no device is connected.

COM

Common electrical contacts.

AUX IN 1

AUX IN 2

NO

Auxiliary input signal that can be set as follows:

0 - DDA opening

Command DDA opening (disabled people).

Opens with motor and closes with spring

(LOW ENERGY mode) with minimal idle

time of 5 seconds

1 - Emergency open

It opens not depending on the existing

logic, over taking as priority also input KEY.

It opens door with priority on all other

contacts.

2 - Inter lock with priority

Opens with priority in case of simultaneous

command

3- Inter lock without

priority

It doesn’t open in case of simultaneous

command

4- Feedback Lock released

Micro switch or contact detecting the

status of lock released

13

SESAMO PROSWING

5- Command lock release

This contact allows to unlock manually the

lock without opening door through motor.

6- Single command in

double system

In case of Double system, opens only

MASTER door.

7- Stand-by

When the contact is closed the door goes

in stand by status (unlocked and

deactivated) - this logics works with door

in closing.

8-Reactivation after stand-

by

When the contact is closed the door start

working again after a stand by status.

9-Step/step function

An opening impulse will open the door.

Subsequent closing is possible with

another impulse.

* NO =Normaly open NC =normaly close

All INPUT mist refer to (COM)

Deafault setting. Can me modified (see par.”Setting parameters-display”)

EXTERNAL PERIPHERICALS CONNECTORS/OUTPUT

SEGNALE

DEFAULT*

DESCRIZIONE

AUX OUT 1

AUX OUT 2

NO

Auxiliary output contact that can be set as follows:

0 - Monitoring sensors

It monitors safety sensors.

1 - Inter lock

To be connected to the input interlock of

the other automatism, to obtain interlock

logic.

2 - Door opened

It signals door in opened position.

3 - Door closed

It signals door in closed position.

4 - Fault

It signals door in fault.

5- Repeat lock command

it repeats the command of the electric

lock.

* NO =Normaly open NC =normaly close

All INPUT mist refer to (COM)

Deafault setting. Can me modified (see par.”Setting parameters-display”)

ATTENTION: to connect aux out contacts see electrical wiring as shown in Fig.22, Fig.23

e Fig. 26. Carico di max contact rating: 24V - 100mA

ATTENTION: Absorbing more than the max rating can damage control board.

INSTALLATION OF THE SENSORS

The automatism can work with:

-Safety sensors (vedi Fig.32 A e B): they are fixed on the door and detect the area in

front of them in order to avoid contact with persons/obstacles;

-Detection sensors (vedi Fig.32 C e D): generally fixed on the wall or wall frame,

detect the approach of peoples and give the input to open the door.

14

SESAMO PROSWING

Sensors wiring and control board setting:

ID

SENSORE

SCHEMA

17=0

30=1

Safety monitoring sensor in closing (ref. Fig.39 A)

ref. Fig.22

17=0

30=1

Safety monitoring sensor in opening (ref. 39 B)

ref. Fig.23

Detection sensor (radar) entry (ref. Fig.39 D)

ref. Fig.24

Detection sensor (radar) exit (ref. Fig.39 C)

ref. Fig.25

If monitored sensors configuration has not been memorized, on display appears E6 error. Exit

from this status through procedure LS, see paragraph “parameters adjustment – display”.

During this procedure control board checks which sensors are connected and checks if they

are correctly working.

ATTENTION during LS procedure stay away from sensors and be sure they are not

detecting obstacles. In case they are not correctly wired or working, LS blinks. Abort procedure

pushing ESC. Checks sensors and launch LS again.

At the end of LS procedure display shows one of the following configurations:

ID

CONFIGURATION

DESCRIPTION

S0

No monitored sensor

detected

There are no monitored sensors wired or the sensors

connected will be managed as a normal sensors without

monitoring.

S1

monitored sensor only in

opening.

There is only monitored sensor in opening. In closing there

is no sensor connected or the sensor connected will be

managed as a normal sensor without monitoring.

S2

monitored sensor only in

closing.

There is only monitored sensor in closing. In opening , there

is no sensor connected or the sensor connected will be

managed as a normal sensors without monitoring.

S3

monitored sensor in

opening and closing.

There are monitored sensors wired both in closing and

opening.

The indication remains on the display until it is pressed one of the following push buttons:

-ENT: to confirm the configuration indicated, making sure that it correspond to the

real configuration of the connected sensors;

-ESC: to abort the detected configuration and go back to the error status E6.

ATTENTION: never confirm the detected configuration if does not correspond to the

real configuration of the connected sensors. This might create danger situations or

malfunction of the automatism.

LS procedure can be repeated in any occasion through the parameter LS (look at

paragraph “parameters adjustment – display”).

15

SESAMO PROSWING

ATTENTION: LS must be repeated whenever the configurations of the sensors

connected or the automatism are modified.

ATTENTION: in case of double Proswing (2 wings) it is necessary to carry out LS

procedure on both control boards (master and slave).

Every time after power ON: initially is showed control board firmware version and later, for

two seconds, sensors configuration: S0 or S1 or S2 or S3.

In case sensor monitoring fails, the value of the relevant sensor blinks on the display (S1: safety

in opening; S2: safety in closing; S3: both). Blinking ends when monitoring is working again.

.

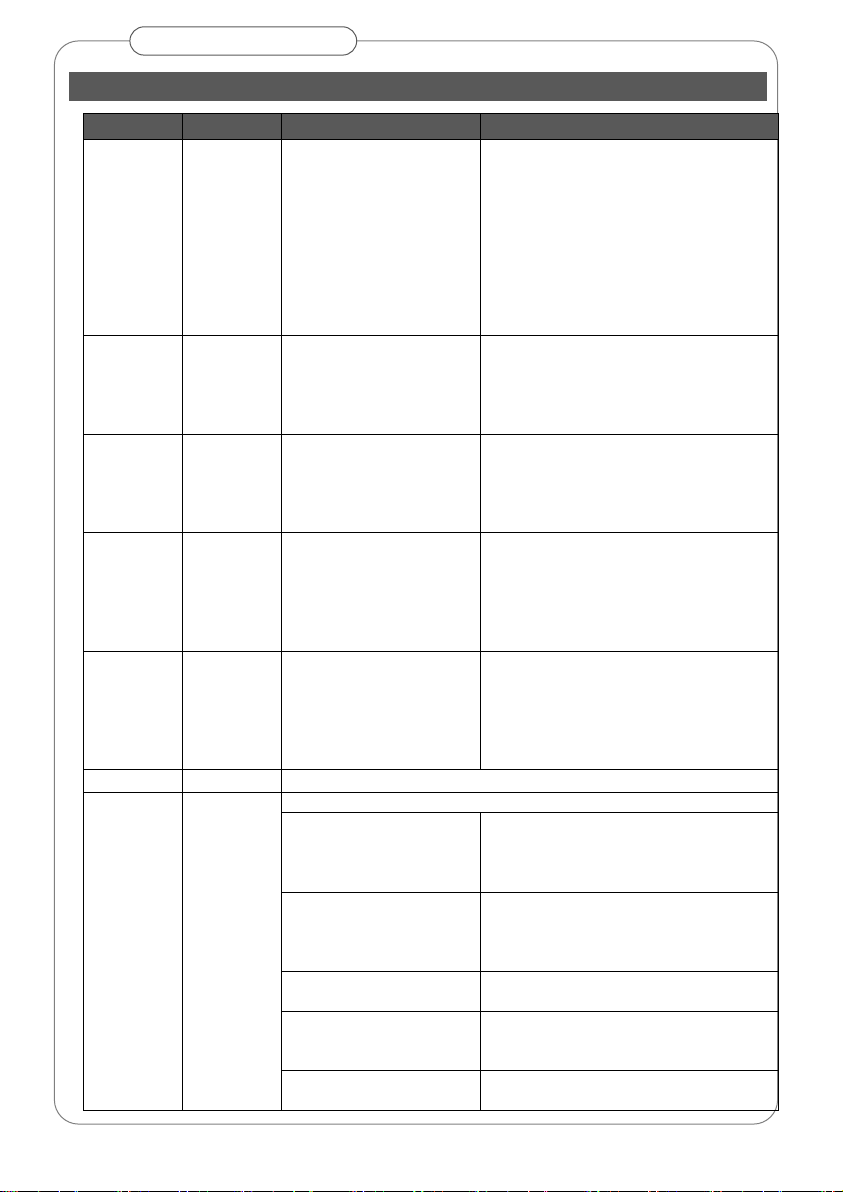

DIP –SWITCHES SETTING

On the control board there is a dip-switch 8 positions to adjust functionality and basic options

ON-OFF. These settings are set and memorized, duringt reset of the dip-switch during

operation they cannot be considered:

Changing of setting is considered only after automatism RESET

DIP

PARAMETER

OPTION

DEFAULT

1

Arm selection

OFF

Push arm

OFF

ON

Pull arm

2

Mode

LOW ENERGY

OFF

Normal

OFF

ON

Low Energy

3

PUSH & GO

OFF

Disabled

OFF

ON

Enable

4

Key mode

OFF

Bistable

OFF

ON

Monostable

5

Tipologia Attuatore

ON

Proswing S ed R (Molla)

ON

6

Inutilizzato

OFF

7

Inutilizzato

OFF

8

Inutilizzato

OFF

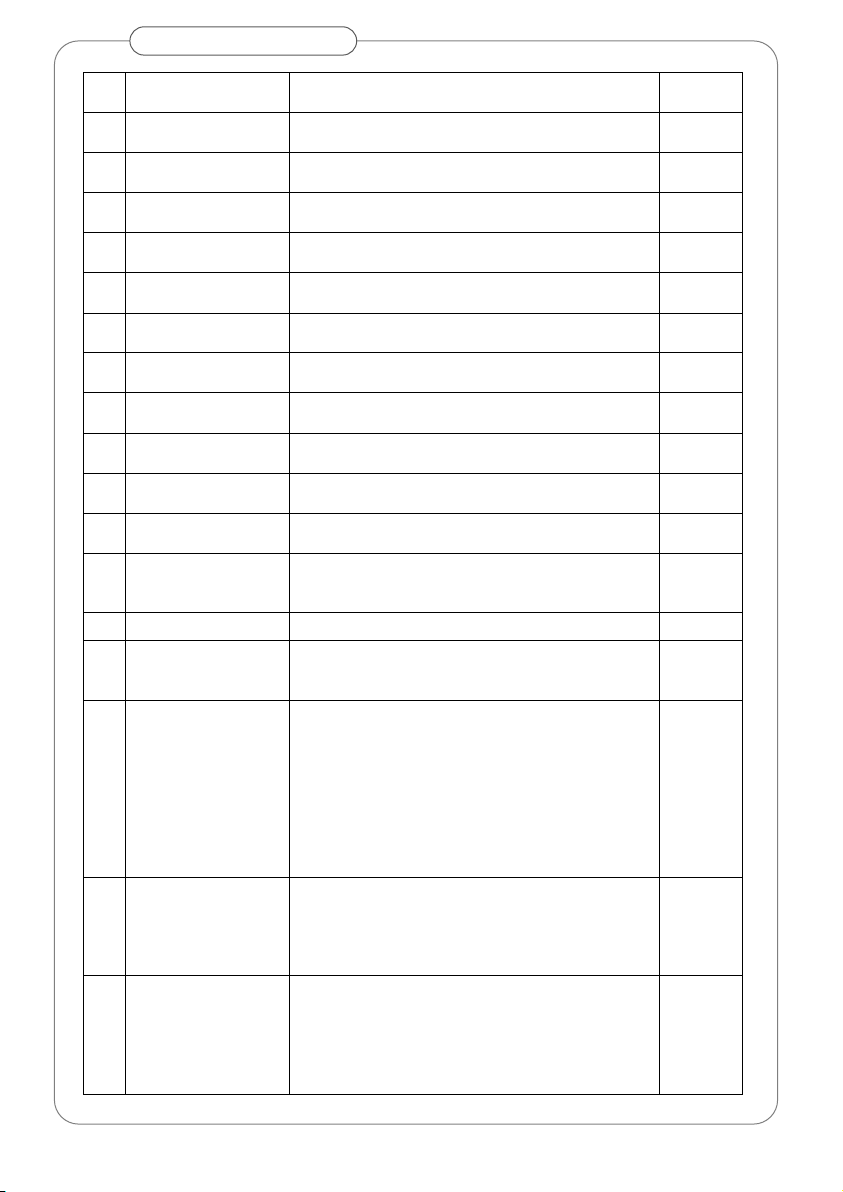

PARAMETERS ADJUSTMENT-DISPLAY

It is possible to adjust several function parameters through two displays and relevant four

push buttons (Fig. 27).

16

SESAMO PROSWING

To properly see the display set the jumper according the opening direction of the wing as

shown in Fig.27.

La modalità di programmazione è la seguente:

1. Select parameter thorough push button [+] and [-]; press [ENT] to enter in the

adjustment procedure.

2. In adjustment procedure, parameter value is indicated in flashing mode. Press [+]

and [-] to change value, press [ENT] to memorize value and press [ESC] to come back to

parameter selection.

3. During procedure is active a timeout; if no push buttons are pressed for 10 seconds,

system exit from adjustment mode.

4. To validate teh commandit is necessary to press continuosly [ENT] for 5 seconds,

after validation the display will return to previous position.

ID

DESCRIPTION

SETTING

DEFAULT

01

Opening speed

RANGE: 20°/s ÷ 70°/s

(step of 5°/s)

60

02

Closing speed

RANGE: 10°/s ÷ 40°/s

(step of 5°/s)

20

03

Idle time

RANGE:

0 ÷ 60 seconds

62 = 2 min

63 = 3 min

64 = 4 min

0

04

Idle time in Low

Energy

RANGE: 5 ÷ 60 seconds (adjustment step of 1 second)

5

05

Closing speed with

spring (PROSWING S)

RANGE: 1 ÷ 9

(1 minimum speed, 9 maximum speed)

5

Force in closing

position

(PROSWING M)

RANGE: 0 –9

(0=no force, 9= max force)

0

06

Anti-crushing

RANGE: 1 ÷ 9 It is applied both for opening and

closing (1=more sensitive; 9=less sensitive)

5

07

Acceleration and

deceleration

RANGE: 5 ÷ 30

It is applied both for opening and closing

30

08

Approaching angle

RANGE: 10 ÷ 40

[it modifies both parameters (closing 1/2 of the

opening)]

20

09

Electric lock power

0=12 VDC

1=24 VDC

0

10

Lock type

0 = Lock not installed

For different type of electric locks please refer to

paragraph “electric locks setting”

0

11

Opening delay

RANGE: 0 ÷ 9

Timing depends on the type of electric lock:

please refer to paragraph “electric locks setting”

2

12

Lock closing force

RANGE: 0(min) ÷ 9(max)

5

13

Single/Master/Slave

0 = Single

1 = Double Master

2 = Double Slave

0

17

SESAMO PROSWING

14

Activation of the

electric lock or motor

closing according to

the logic selected

3 = Proswing R mag lock always active on logic ONE

radar and TWO radards (automatic)

3

15

Auxiliary input

configuration 1

0 = DDA opening

1 = Emergency opening

2 = Interlock door with priority

3 = Interlock door without priority

4 = Feedback lock release

5 = Command lock release

6 = Command Single on Double door

7 = Stand-by

8 = Reactivate the door after stand-by

9 = step/step function (1 impulse open, 1 impulse

close)

0

16

Auxiliary input

configuration 2

0 = DDA opening

1 = Emergency opening

2 = Interlock door with priority

3 = Interlock door without priority

4 = Feedback lock release

5 = Command lock release

6 = Command Single on Double door

7 = Stand-by

8 = Reactivate the door after stand-by

9 = step/step function (1 impulse open, 1 impulse

close)

1

17

Auxiliary output

configuration 1

0 = Sensors monitoring

1 = Interlock

2 = Stop open condition

3 = Stop closed condition

4 = Failure

5 = Repetition of lock command

0

18

Auxiliary output

configuration 2

0 = Sensors monitoring

1 = Interlock

2 = Stop open condition

3 = Stop closed condition

4 = Failure

5 = Repetition of lock command

1

19

MultiMaster

0 = No managing Multimaster,

1 ÷ 15 Keynote for MultiMaster connections

0

20

Opening safety

sensor exclusion

Opening safety sensor angle exclusion.

RANGE: 0 ÷ 40% of total angle opening

0

21

Phase displacement

in opening for double

door

RANGE: 0 –100

displacement in opening unit of 100 ms

(0=syncronized)

0

22

Phase displacement

in closing for double

door

RANGE: 0 - 100 displacement in closing unit of 100

ms (0=syncronized)

0

23

Polarity safe open

input

0 = NA (Normally Open)

1 = NC (Normaly Close)

1

18

SESAMO PROSWING

24

Polarity safe close

input

0 = NA (Normally Open)

1 = NC (Normaly Close)

1

25

Polarity key input

0 = NA (Normally Open)

1 = NC (Normaly Close)

1

26

Polarity Start1 input

0 = NA (Normally Open)

1 = NC (Normaly Close)

0

27

Polarity Start2 input

0 = NA (Normally Open)

1 = NC (Normaly Close)

0

28

Polarity Aux In 1

input

0 = NA (Normally Open)

1 = NC (Normaly Close)

0

29

Polarity Aux In 2

input

0 = NA (Normally Open)

1 = NC (Normaly Close)

0

30

Polarity Aux Out 1

input

0 = NA (Normally Open)

1 = NC (Normaly Close)

0

31

Polarity Aux Out 2

input

0 = NA (Normally Open)

1 = NC (Normaly Close)

0

32

Force level during LP

procedure

RANGE: 5 ÷ 60 (0 = force min 9= force max)

5

33

Opening angle

reduction

RANGE: 0÷50%

0

34

Installation on lintel

or door

2=Proswing R only lintel

2

35

DDA speed

0=Low Energy

1= speed according to parameters 1 e 2

0

36

Batteries mode

0=std (only spring)

1=continuos operation

2=antipanic

0

ST

Stop movement

TS

Test

0= no cyclical

1= cyclical

2= intensive cyclical

0

LS

Learning Sensor

(procedure for

monitored sensors

1-Select LS with push button [+] e [-]

2-Press [ENT] to start procedure

3-Display show value (SO; S1; S2; S3) correspondant

to detected situation (look at paragraph

“INSTALLATION OD SENSORS).

4- push ENT to confirm the detected configuration,

making sure that it correspond to the real

configuration of the connected sensors, or ESC to

reject the detected configuration.

Sd

Set to default

1-Select Sd pushing buttons [+] e [-]

2-Push [ENT]

3-when displays [--] push again[ENT] for 5 seconds to

confirm

4-when disappears [--] leave the push button [ENT].

Lp

Learning cycle

1- Select Lp pushing buttons [+] e [-]

2-Push [ENT]

3- when displays [--] push again[ENT] for 5 seconds to

confirm

4- when disappears [--] leave the push button [ENT].

Lp starts , see Start Up.

19

SESAMO PROSWING

During parameters setting any movement of motor is allowed.

When parameters setting it is not used, push button [ENT] is an opening command (only with

One Radar or Two Radars logics).

START UP

1. Set main power switch (Fig.1 A) on OFF.

Make sure to have properly adjusted DIP-Switches, in particular 1 and 5. Make sure

contacts KEY, SAFE CLOSE e SAFE OPEN are properly connected or, if not used, connected

to COM.

2. Give power supply to the automatism switching on 230 V the general switchboard.

3. Set the switch (Fig.1 A) in ON.

4. Verify lighting of the display and if it shows E6 (if necessary set the jumper to light

properly the display (look at Fig.27);

5. Select LS with push buttons [+] e [-], push [ENT] when it shows [--] push again

[ENT] for 5 seconds to confirm, when disappears [--] release push button [ENT], the

procedure of the acquisition of the monitoring sensors will start (refers to

paragraph “sensors installation” page 13/14 to finalize the procedure)

6. If present an electric lock, set parameters 10/11/12/14 (look paragraphs

“parameters adjustment-display” and/or “electric locks setting”).

7. Pushing buttons [+] e [-], select LP and push [ENT], when it shows [--] push again

[ENT] for 5 seconds to confirm the commend; when disappears [--] release push

button [ENT]. Door opens and it will start a cycle of parameters acquisition.

ATTENTION: While opening of the door, stop the wing in the position fixed as limit

in opening, to get the maximum opening angle. Immediately after this operation, the

door will close fully and on display CL blinks. When the door reaches the completely

closed position, and CL do not blink any more, it will be possible to test the operation of

the automatism pushing the button [ENT]: the door opens and closes normally. The

opening angle, during normal operation, will be reduced compared to the limit detected

during the acquisition of the limits so to allow the operation even if the mechanic door

limit is missing. The percentage of reduction is defined by parameter n.33. At each start

(or RESET operation), automatism must reach the position of door fully closed. Later the

first cycle will be at reduced speed.

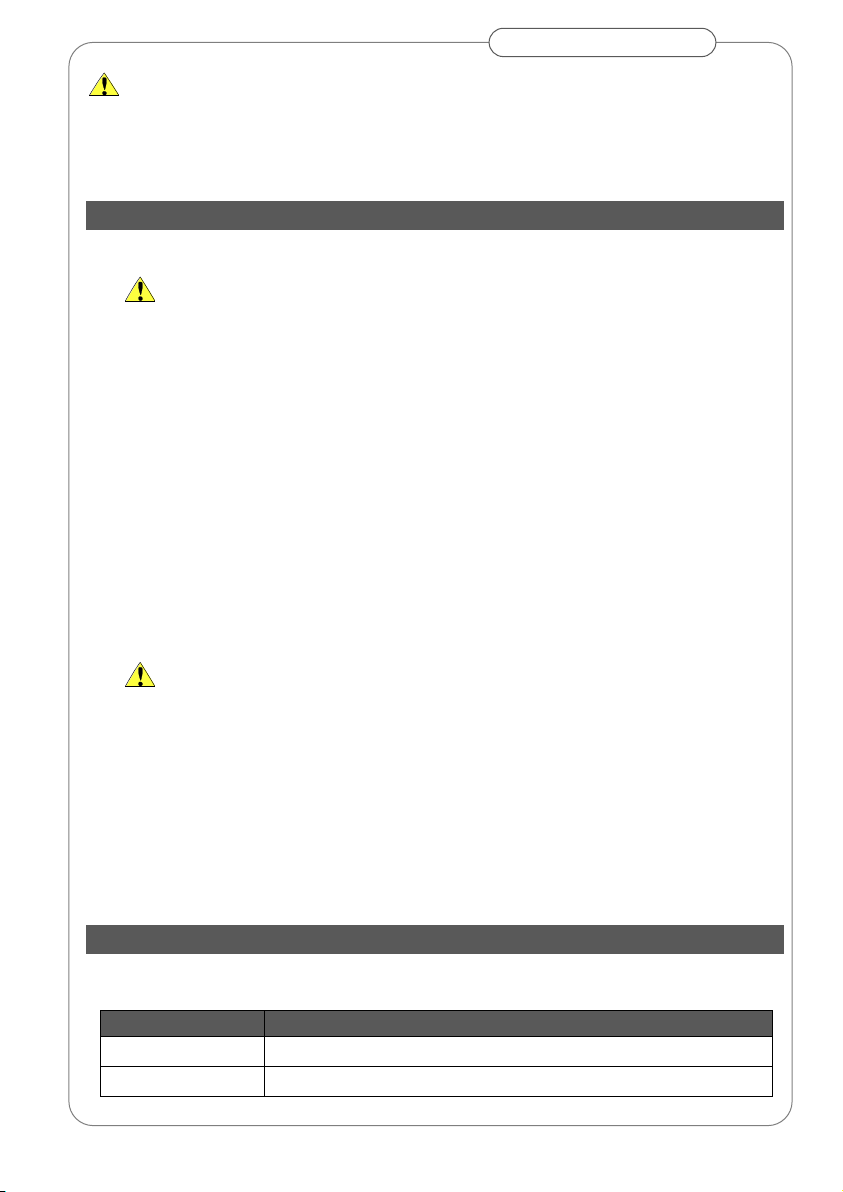

MESSAGE OR ERRORS CODE

Display are also used to show message or error code:

SEGNALAZIONE

DESCRIZIONE

OP Fixed

Door opened

OP Blinking

Door opening

20

SESAMO PROSWING

CL Fixed

Door closed

CL Blinking

Door closing

E1

Door needs self learning procedure (see Paragraph “Start up”)

E2

Wrong arm selection [DIP 1 or switch on break board - see Paragraph

“type arm selection”), or wrong selection automatism- DIP 5.

E3/E4

Over Current

E6

Error monitored sensors

E8

NO encoder

OPERATING LOGICS

LOGICA

DESCRIZIONE

LOW-ENERGY

In all operative procedures (except Stop Close) it is possible a motor

opening with a reduced speed (Low Energy speed) and higher idle

time (idle time for disabled people) using the opening command for

disabled [AUX IN 1set through parameters 15=0 paragraph

“Parameter adjustment display”. The following closing is by spring.

PUSH & GO

An opening/closing automatic movement is possible slightly pushing

door in opening by hand while it is in a closed position. Set DIP 3 =

ON.

SAFE CLOSE

If closing safety sensor detects an obstacle whilst the door is closing,

it immediately stops and opens door completely .

If sensor detects while door is opening door continues opening.

SAFE OPEN

If opening safety sensor detects an obstacle whilst door is opening, it

immediately stops door movement. When detection stops, door

continues to open and then close.

If sensor detects while door is closing door continues closing.

If door opens toward a wall (in a corridor, for example) it is possible

to cancel the final part sensor detection to avoid wall detection. This

parameter is modifiable through parameter 20 (see paragraph

“Parameter adjustment display”).

Logic switch,

basic selector,

advanced

selector

operating logic

Manual

START 1 and START 2 are not working. Open and close only through

push button on selector or low energy or manually pushing the door.

1 radar

RADAR ONLY EXIT: Only START 2 input is working. A signal coming

from a sensor connected to START2 makes opening and closing of

the door. If the door is blocked by a lock or by motor (when no lock is

selected), the closing position depends on the type of lock or the

setting of parameter 14.

2 radar

RADAR ENTRY AND EXIT (Automatic): Both input START1 e START2

are working. A signal coming from a sensor connected to one of

these two inputs makes the opening and closing of the door. The

door blocked by lock or motor (when no lock is selected), the closing

position depends on the type of lock or the setting of parameter 14.

Stop

close

Automatism sends door in fully closed position. In this logic the

inputs START1 and START2 of the electronic control card are not

working; if installed, electric locking system locks door. When there

Table of contents

Other Sesamo Door Opening System manuals

Sesamo

Sesamo LIGHT MILLENIUM User manual

Sesamo

Sesamo Puma Millenium User manual

Sesamo

Sesamo SwinGo User manual

Sesamo

Sesamo MILLENNIUM SERIES Operating instructions

Sesamo

Sesamo Digidor User manual

Sesamo

Sesamo PROSWING User manual

Sesamo

Sesamo smart PRO User manual

Sesamo

Sesamo Digidor User manual

Sesamo

Sesamo PROSWING User manual

Sesamo

Sesamo PIUMA User manual

Popular Door Opening System manuals by other brands

Dormakaba

Dormakaba 8900 FT installation instructions

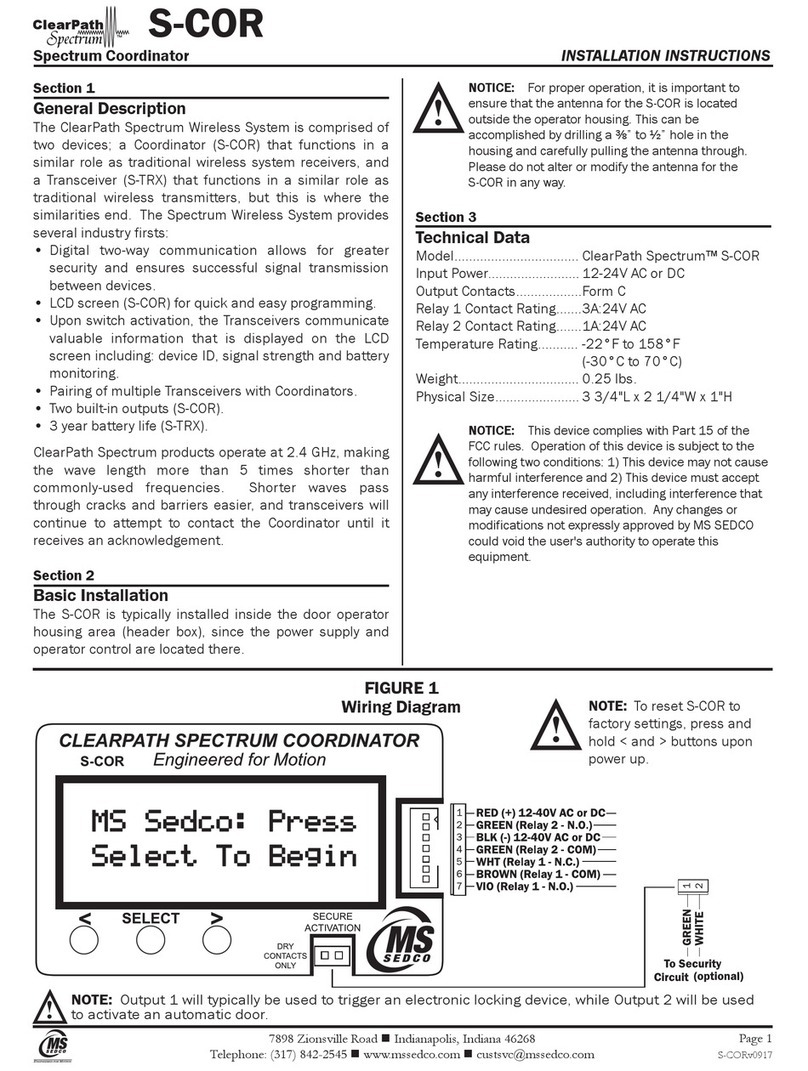

MS Sedco

MS Sedco CleraPath Spectrum S-COR installation instructions

Remote Solutions

Remote Solutions SAFE-T-RACK SR-U Operation manual

SECO-LARM

SECO-LARM ENFORCER SD-962AR-36G manual

Ellard

Ellard PROMAX 3 Product Instruction

Aprimatic

Aprimatic RAIDER installation instructions