3

CONTENTS

Approvals............................................................................................................

Revision.................................................................................................................

Content of delivery......................................................................................................4

Technical specifications....................................................................................................5

Operation.............................................................................................................6

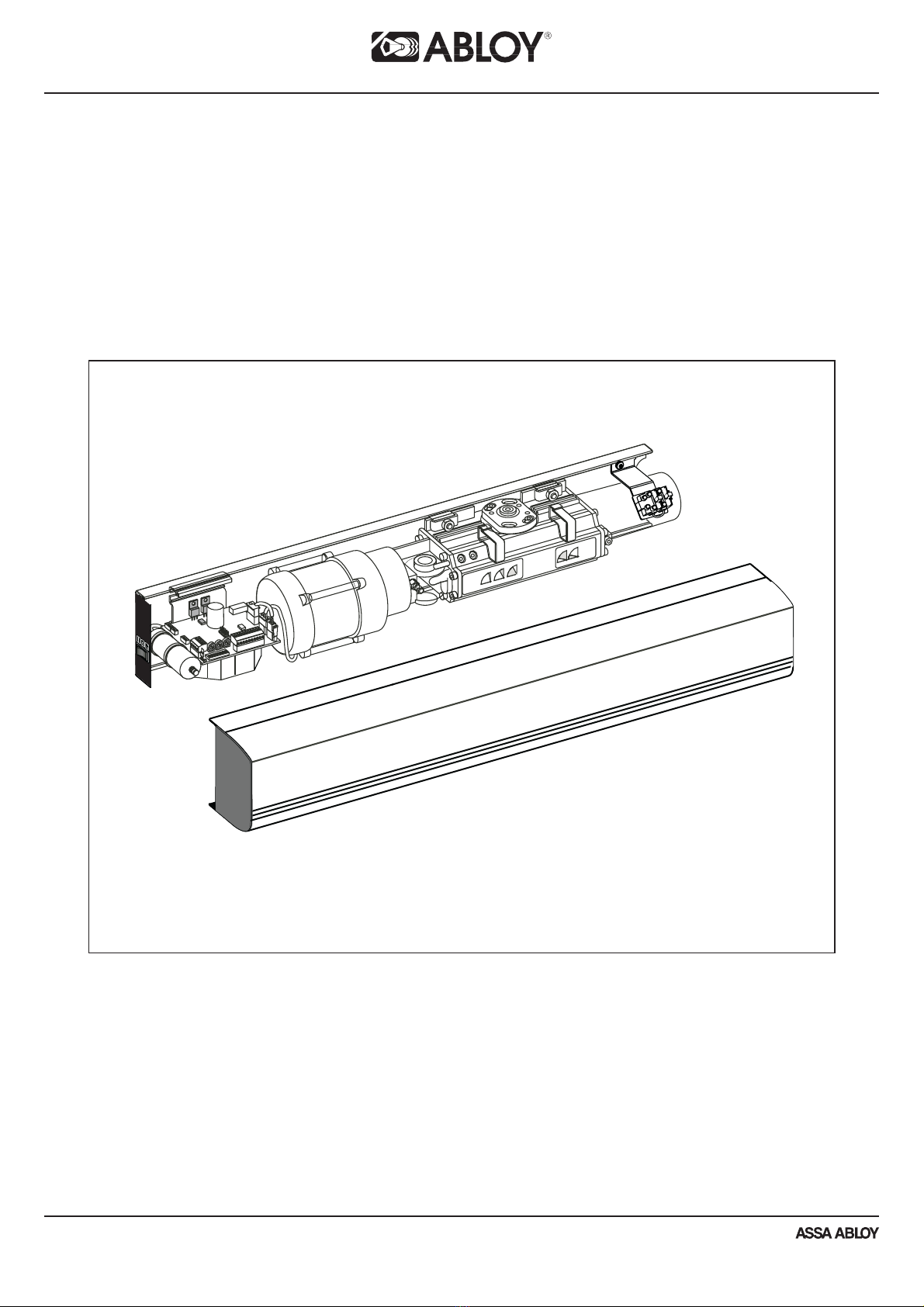

Part idendification...........................................................................................7

Installation..........................................................................................................8

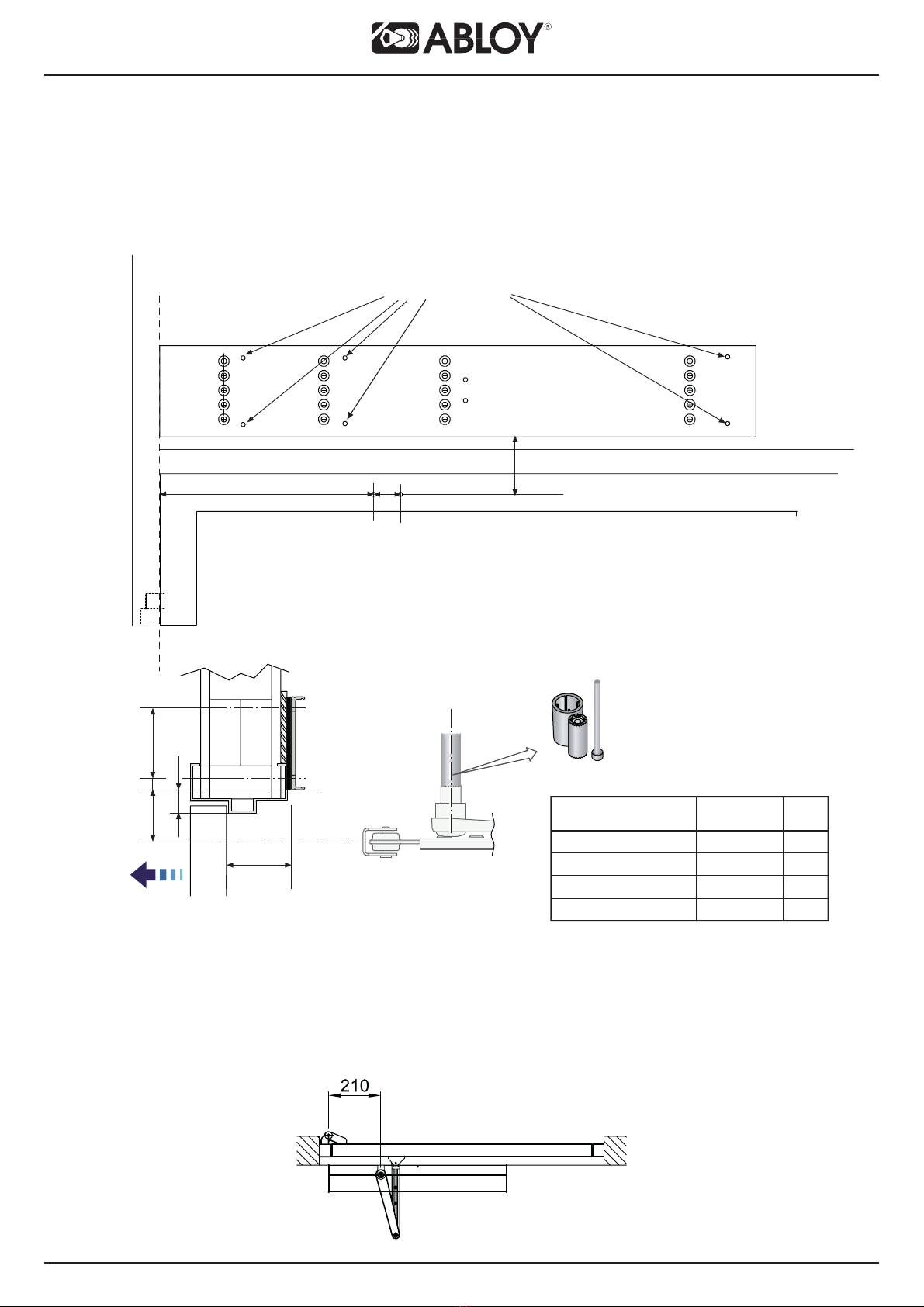

Installing the mounting plate DB103.........................................................................9

Assembly of the operator and the standard arm DB104 to the closing side...............10

Assembly of the operator and the sliding arm DB105 to the opening side...............1

Assembly of the operator and the sliding arm DB105 to the closing side.....................14

Electrical connections.......................................................................................15

Adjustments.........................................................................................................16

A safe door..................................................................................................................18

Changing the direction of rotation ..................................................................................19

Control unit........................................................................................................................... 0

Dip -switches FS.................................................................................................

TB and TB1................................................................................................................. 4

Connection examples

Program selector PS-3A....................................................................................... 5

Kill input.................................................................................................................... 7

DA061, DA06 and DA063 microwave motion sensor..................................................... 8

DA033 elbow switch and DA039 and DA049 rotary switch................................... 9

Extension unit EXB-FI.........................................................................................................30

Connection examples extension unit EXB-FI

DA001 / DA00 safety sensor in the opening side of the door........................................31

DA001 / DA00 safety sensor in the closing side of the door.......................................3

Connection examples control unit and extension unit EXB-FI

Electric locks EL40 , EL404, EL50 ................................................................33

Program switch, motor lock and safety sensor in the opening side of the door.................34

Fire door use........................................................................................................35

Connection of double doors...........................................................................................36

Coordinator DB109...........................................................................................38

Closing side.......................................................................................39

Opening side..................................................................................................40

Push&Go DB116.....................................................................................................41

Troubleshooting...........................................................................................................................4

Accessories and spare parts...............................................................................................43