2 Installation and Operating InstructionsInstallation and Operating Instructions

ABS lifting station Sanimat

ABS reserves the right to alter specications due to technical developments

Contents

1 General................................................................................................................................................... 3

1.1 Application areas..................................................................................................................................... 3

1.2 Technical Data......................................................................................................................................... 3

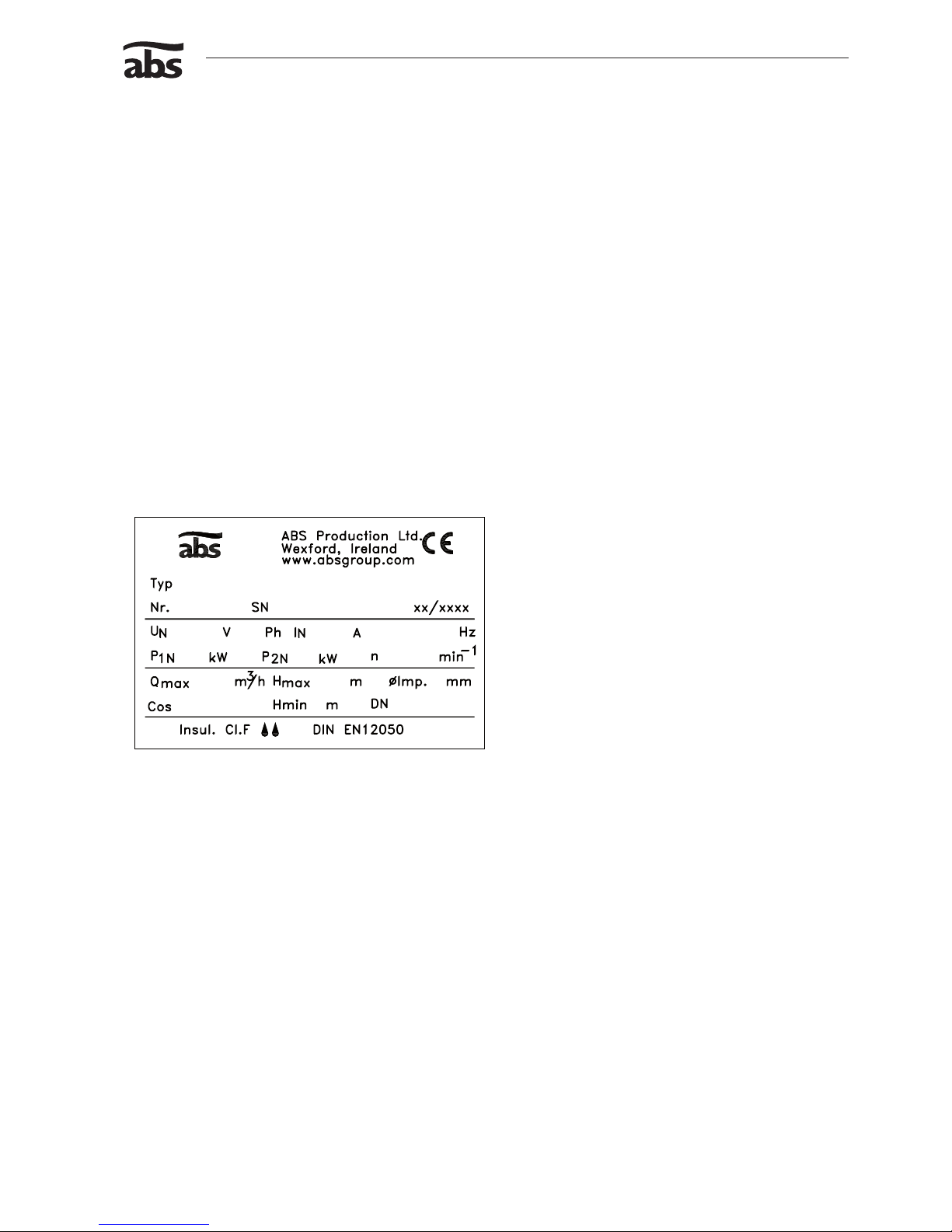

1.3 Nameplate............................................................................................................................................... 3

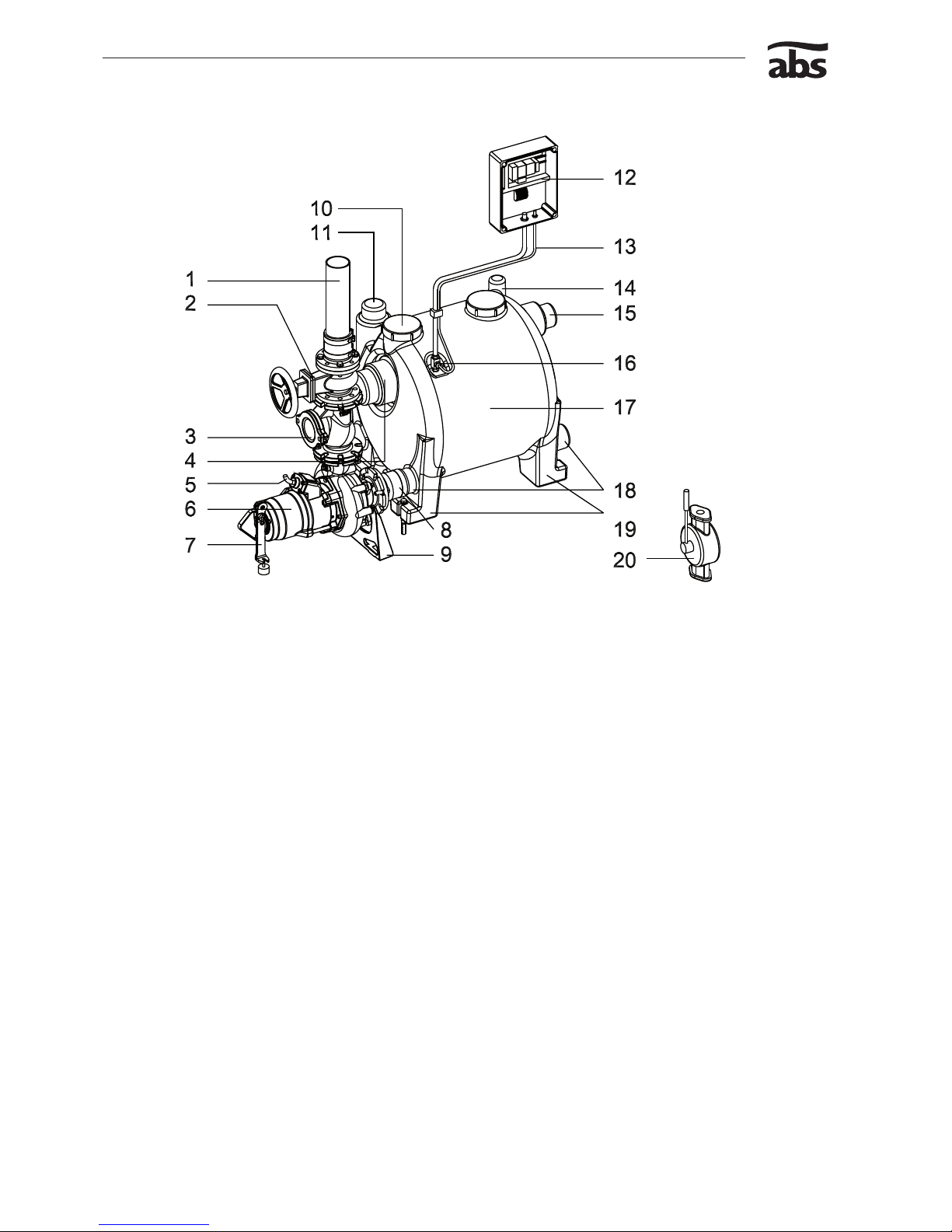

1.4 Design of the faecal lifting station ........................................................................................................... 4

1.5 Description .............................................................................................................................................. 5

2 Safety ..................................................................................................................................................... 5

3 Transport................................................................................................................................................ 5

4 Mounting and Installation.....................................................................................................................6

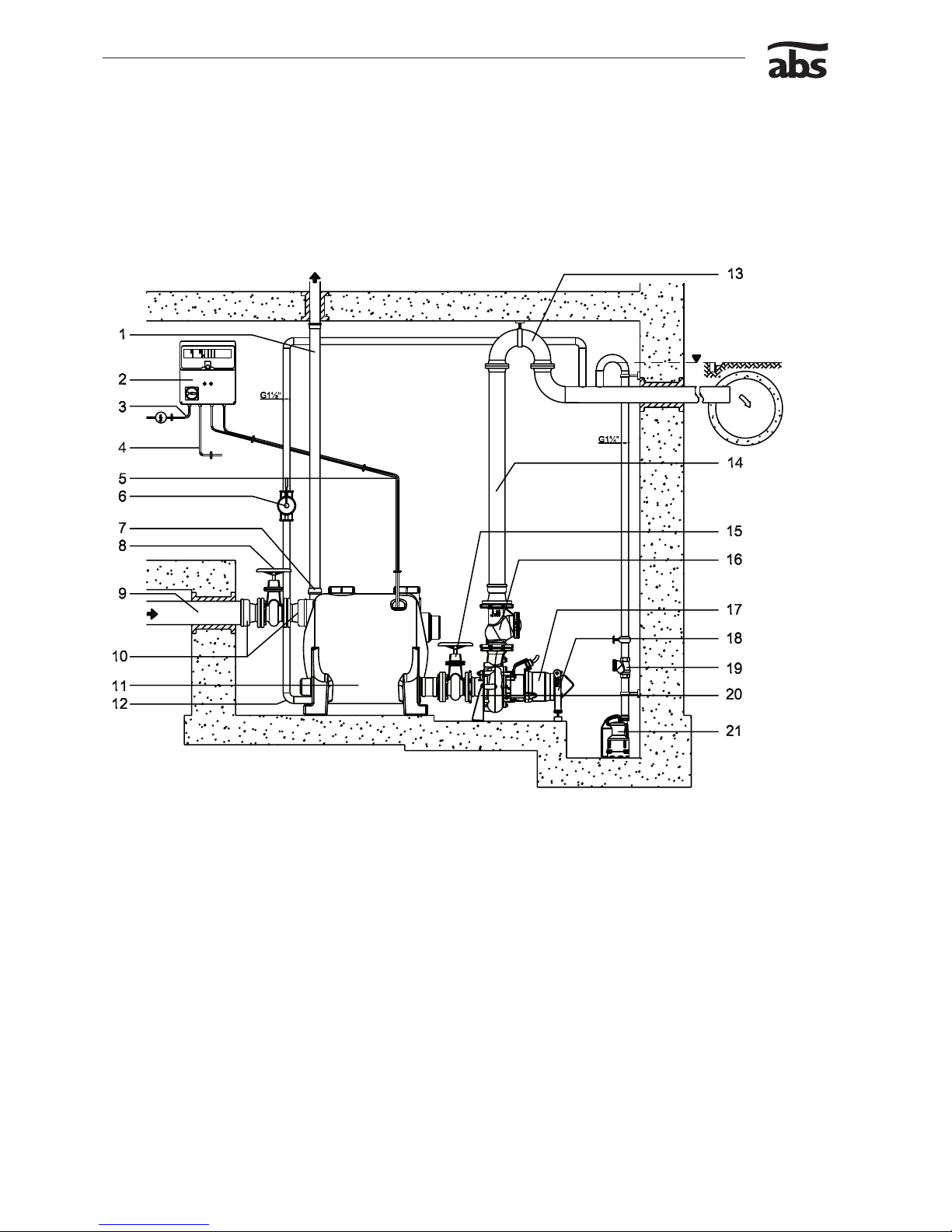

4.1 Site requirements .................................................................................................................................... 7

4.2 Installation of the collection tank ............................................................................................................. 7

4.3 Opening of the collection tank inlet ports ................................................................................................ 8

4.4 Discharge Line ........................................................................................................................................ 8

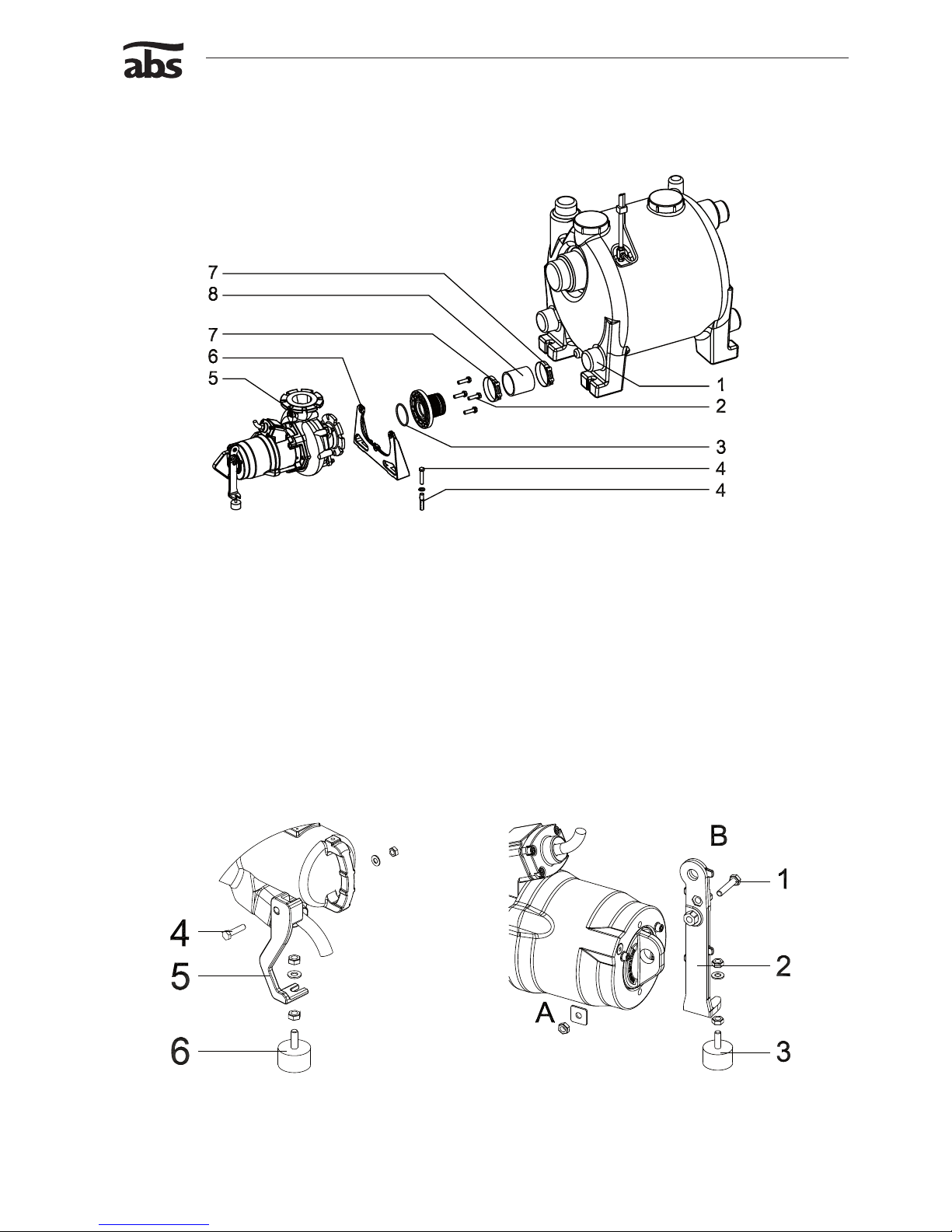

4.5 Installation of the submersible pump....................................................................................................... 9

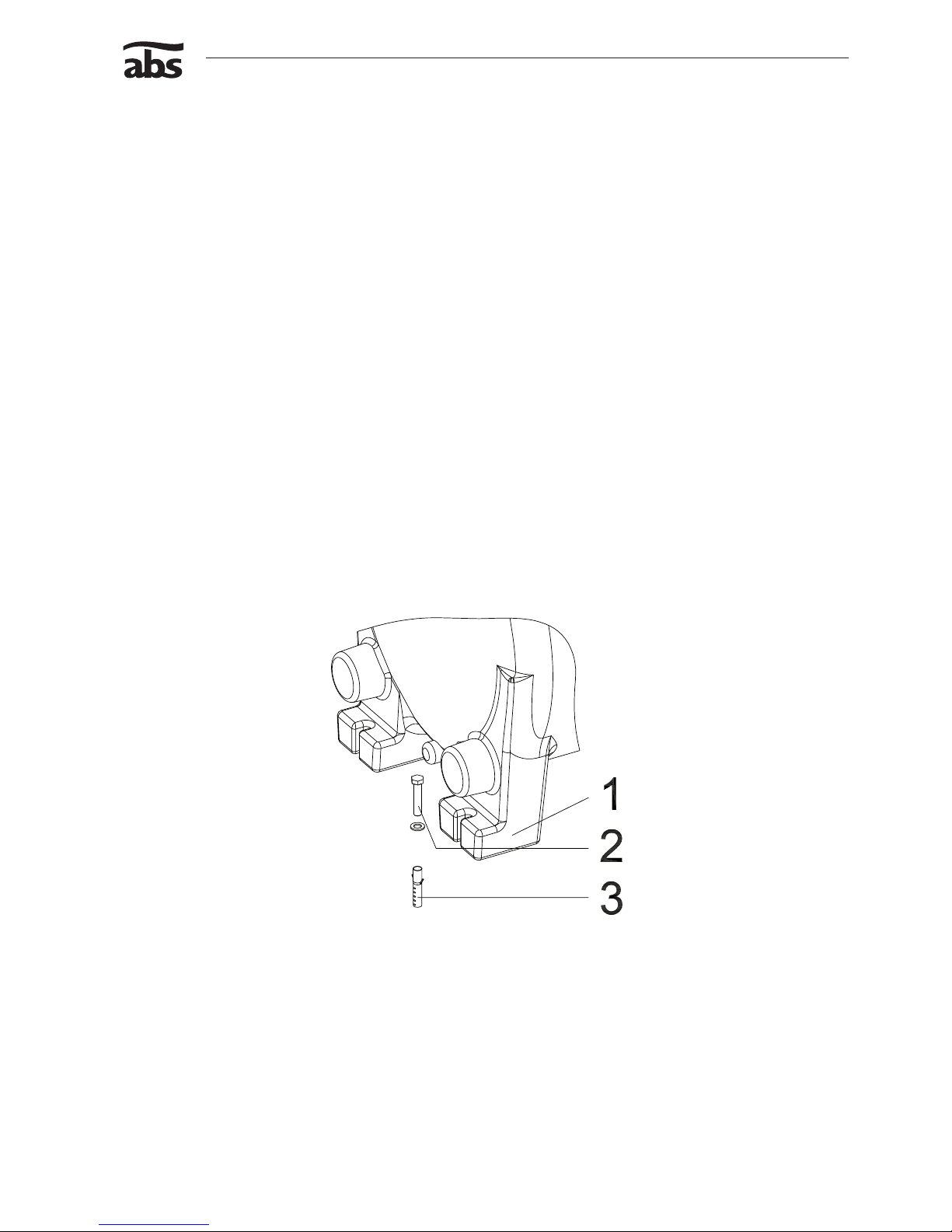

4.5.1 Mounting of the volute support................................................................................................................ 9

4.5.2 Installation of the pump head support ..................................................................................................... 9

4.6 Level Control ......................................................................................................................................... 10

4.7 Installation of the control unit ................................................................................................................ 11

4.8 Electrical Connection ............................................................................................................................ 11

4.9 Wiring Diagram ..................................................................................................................................... 12

4.10 Checking direction of rotation................................................................................................................ 13

4.11 Installation of the accessories ............................................................................................................... 13

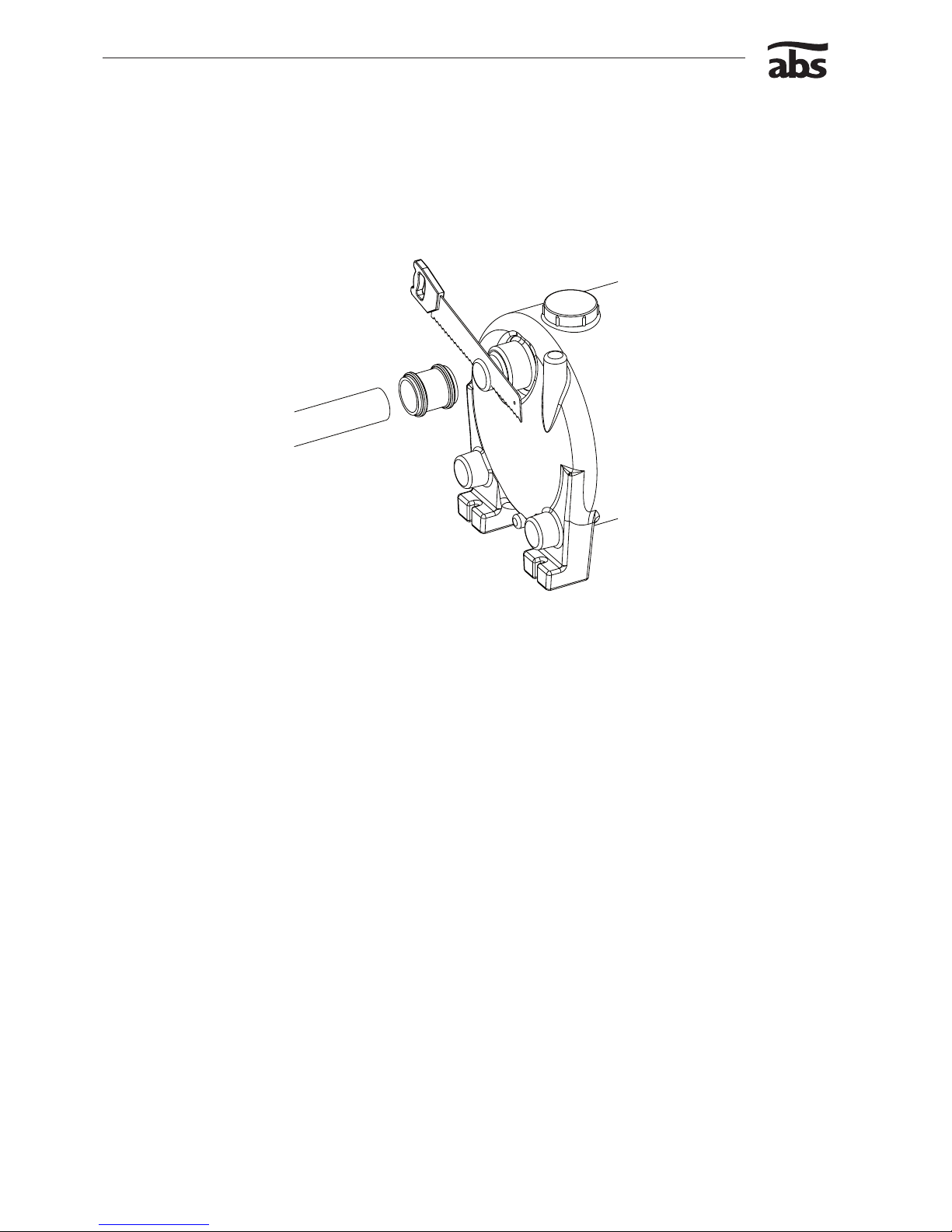

4.11.1 Installation of the Hand Membrane Pump (wall mounted) .................................................................... 13

5 Commissioning ................................................................................................................................... 14

6 Maintenance ........................................................................................................................................ 14

6.1 Commentary on maintenance of Lifting Stations in accordance with EN 12056................................... 14

6.2 General maintenance hints ................................................................................................................... 15

6.3 Oil lling and Oil changing..................................................................................................................... 15

6.4 Cleaning of level control pipe ................................................................................................................ 15

ABS Lifting station Sanimat

1501

3702