Dato LJS7035 User manual

USER’S MANUAL

1

Small scissor Lift

LJS7035

USER

USER’

’S

SMANUAL

MANUAL

Operation Manual & Instruction

USER’S MANUAL

3

Contents

Contents

Manufacture and service

Packing, transport and storage

Introduction

Description of the machine

Technical specifications

Safety

Installation

Adjustment

Operation

Maintenance and care

Troubleshooting

Accessory

USER’S MANUAL

4

PACKING, TRANSPORT AND STORAGE

ALL PACKING, LIFTING, HANDLING, TRANSPORT AND UNPACKING

OPERATIONS ARE TO BE PERFORMED EXCLUSIVELY BY EXPERT

PERSONNEL

Packing dimension picture

Transport

Packing can be lifted or moved by lift trucks, cranes or bridge cranes. In case

of slinging, a second person must always take care of the load, in order to

avoid dangerous oscillations

.During loading and unloading operation, goods must be handled by vehicles or ships.

At the arrival of the goods, verify that all items specified in the delivery notes are included. If

finding missing parts, possible defects or damage due to transport, one should examine

damaged cartons according to “Packing List” to verify the condition of damaged goods and

missing parts, also the person in charge or the carrier must be immediately informed.

The machine is heavy goods! Don’t take manpower load and unload and transporting way

into consideration, the safety of working is important.

Furthermore, during loading and unloading operation goods must be handled as shown in the

picture. (Picture 2)

Storage:

-The machine equipment should be stocked in the warehouse, if stocked outside should do the

disposal well of waterproof.

-Use box truck in the process of transport, use container storage when shipping.

-The control box should be placed perpendicularly during the transport; and prevent other

goods from extrusion.

-The temperature for machine storage: -25ºC-- 55ºC

Picture 1 (packing dimension)

Picture 2(Goods-lifted)

USER’S MANUAL

5

Manual Introduction

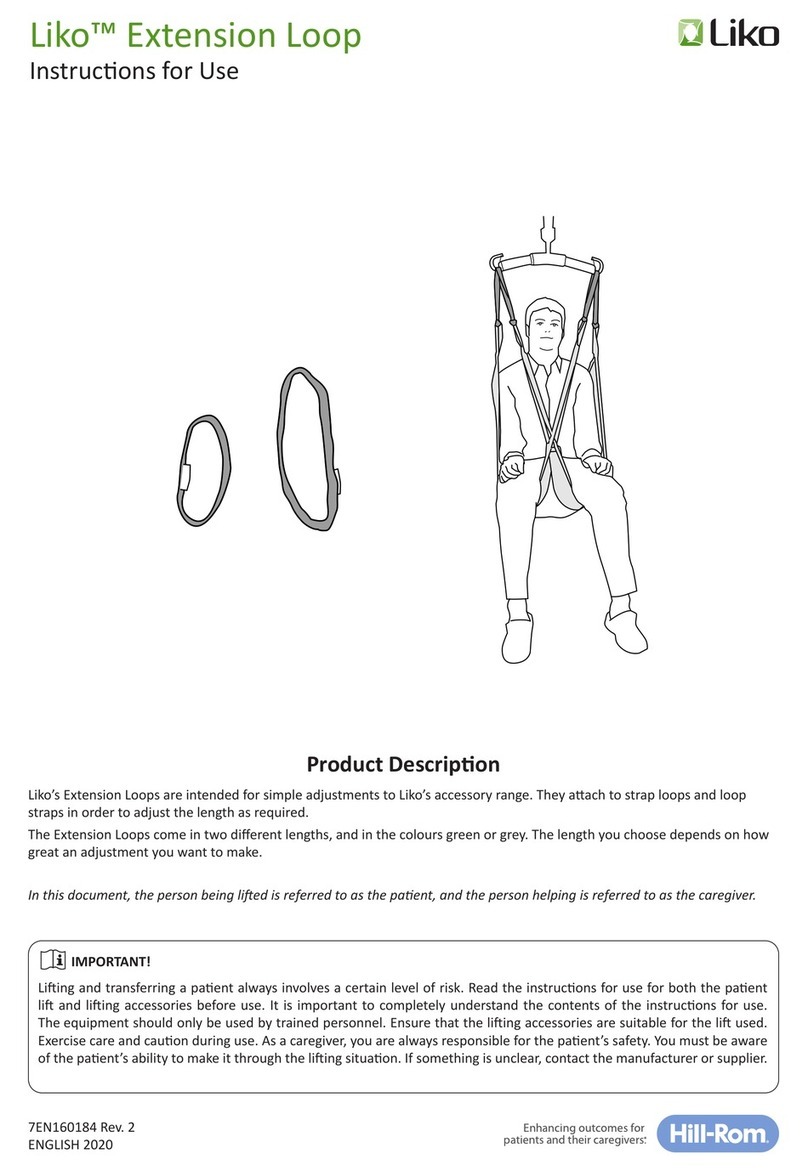

This manual has been prepared for workshop personnel expert in the use of the lift

operator and technicians responsible for routine maintenance fitter.

Workers should read the “User’s Manual” carefully before carrying out any operation

with the lift. This manual contains important information regarding:

- The personal safety of operators and maintenance workers;

- Lift safety;

- The safety of lifted vehicles;

CONSERVING THE MANUAL

This manual is an integral part of the lift.

The manual must be kept in the vicinity of the lift, so that the operator and

maintenance staff must be able to locate and consult the manual quickly and at any time.

Attentively reading Chapter 3, which contains important information and safety warning, is

particularly recommended.

The lift is designed and manufactured according to European Standard

The lifting, transport, unpacking, assembly, installation, starting up, initial adjustment

and testing, extraordinary maintenance, repair, overhauls, transport and dismantling

of the lift must be performed by specialized personnel from the licensed dealer

authorized by the manufacturer.

The manufacturer declines all responsibility for injury to persons or damage to vehicles or

objects when any of the above mentioned operations has been performed by unauthorized

personnel or when the rack has been subject to improper use.

This manual indicates: the operative and safety aspects that may prove useful to the

operator and maintenance worker. For better understanding the structure and

operation of the lift and for best use of the same, workers must read the “Maintenance

& Use Manual” carefully before carrying out it.

In order to understand the terminology used in this manual, the maintenance and repair

activities, the ability to interpret correctly the drawings and descriptions contained in the

manual and be the country in which the machine has been installed.

The same applies to the maintenance and the maintenance fitter must also possess specific and

specialized knowledge both in mechanical and engineering field.

OPERATOR: person authorized to use the lift

MAINTENANCE FITTER: person authorized for routine maintenance of the lift.

Manufacturer owns the right to make little change for the manual owing to the

improvement of technology.

USER’S MANUAL

6

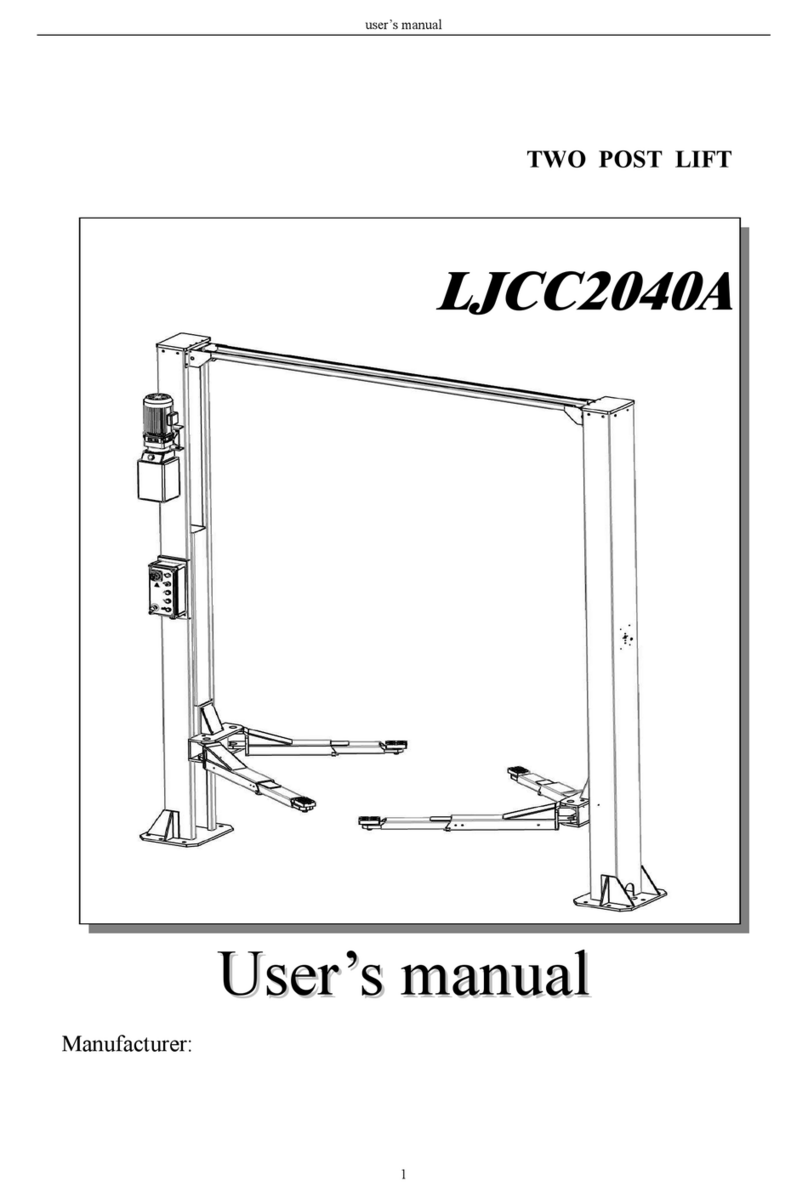

Chapter 1 DESCRIPTION OF THE MACHINE

Machine Application:

This lift can lift each kind of vehicle whose weight is less than 3500kg, and is suitable

for use in vehicle tests, maintenance, and caring for automobiles, which is particularly

suitable for use in the basement or on the floor, without construction and hole.

Structure Features:

-Use hidden and thin scissor structure, dispense with construction and ground hole, the

occupation is small;

-Independent control box, low-voltage controlling, good security;

-Hydraulic cubage and in-phase cylinder, the synchronization of platform;

-Own the double safety equipment of hydraulic lock and mechanical pawl on the safe

side;

-With photoelectric controlling the level of platforms and buzzer;

-Own protection of safety valve and burst-proof equipment for hydraulic failure and over

loading. So when the oil pipe bursts, the machine will not fall quickly.

-Use high quality hydraulic or electric element parts made in Italy, Germany, Japan and

so on.

-Own manual lowering operation when the power is cut.

Equipment:

-Machine basement (The position and space of equipment installation)

-Machine frame (The main structure of lift and insurance institution)

-Control box (Machine-controlled part)

Basic structure

The machine basement is made of cement and concrete.

Frame

Make of steel connecting rod, main lifting platform, sliding board, pneumatic double

tooth, Hydraulic oil tank.

Control box

Under the control box is hydraulic oil tank and hydraulic pump, valve and other control

system. On the control box is electrical system.

Scissor lift is designed and built to lift all kinds of vehicles, all other use are

unauthorized. In particular, the lift is not suitable for washing spray work. And not lift

the vehicle whose weight exceeds the maximum weight.

USER’S MANUAL

7

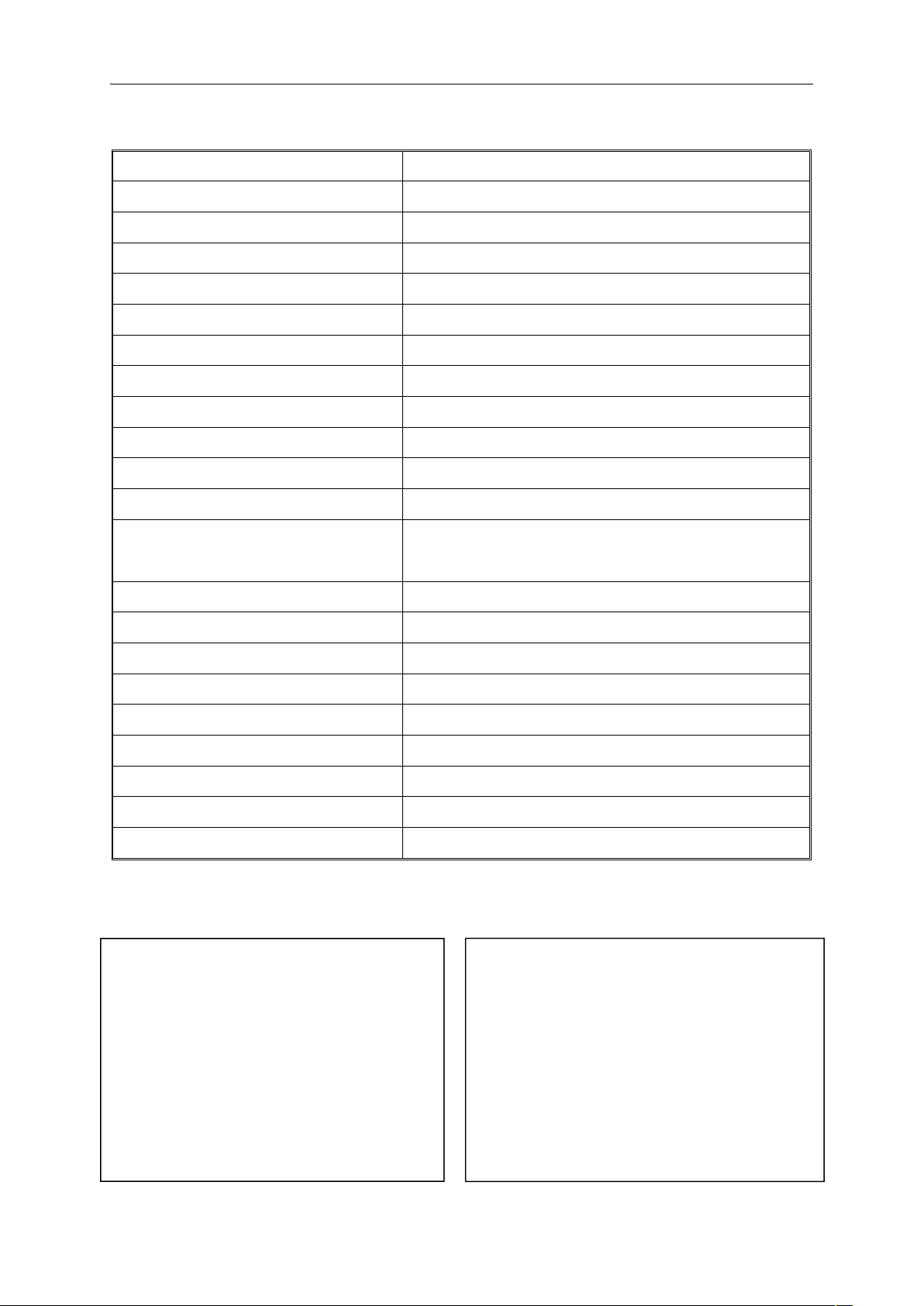

Chapter 2 SPECIFICATIONS

Main technical parameter

Item

Parameter

Drive

Electrical hydraulic

Max lift weight

3500 kg

Main machine lift height

Main machine Lift height

2160mm

Platform initial height

330mm

105mm

Platform length

1640-2040mm

1450mm

Platform width

548mm

Lifting time

≤50s

Descent time

≤60s

Whole machine length

1640mm

Whole machine width

2016mm

Whole machine weight

800kg

Voltage

AC 400V or 230V ± 5% 50/(or 60Hz (optional choose))

For detail please see the name plate on control box!

Whole machine power

2.2kw

2.2kw

Hydraulic oil

18L corresponds to wearable hydraulic oil (provide by user)

(provide for oneself)

Air pressure

6-8kg/cm2

6-8kg/cm2

Working temperature

5-40℃

5-40℃

Working humidity

30-95%

30-95%

Noisy level

< 76db

< 76db

Installation height

Height above sea level≤1000M

海拨≤1000M

Storage temperature

-25℃~55℃

-25℃~55℃

Installation

Indoor

Table 1

Motor Pump

Type……………………Y90L

Power…………… 2.2kw

Voltage………… AC 400 or 230V ±5%

Current……… 400V: 5A

…230V: 10A

Frequency…50Hz (or 60 HZ----special ordered)

Poles………………… 4

Speed……………… 1450 rpm/min

Building shape………… B14

Insulation class…………F

Type…………………………gear pump

Model…………………………P4.3

Flux……………4.3cc/r(50HZ)/3.2cc/r(60HZ)

Joint type………………………direct joint

Overflow valve

Setting pressure………………220 bar

Adjustable working pressure…………150~300 bar

USER’S MANUAL

8

Chapter 2 SPECIFICATIONS

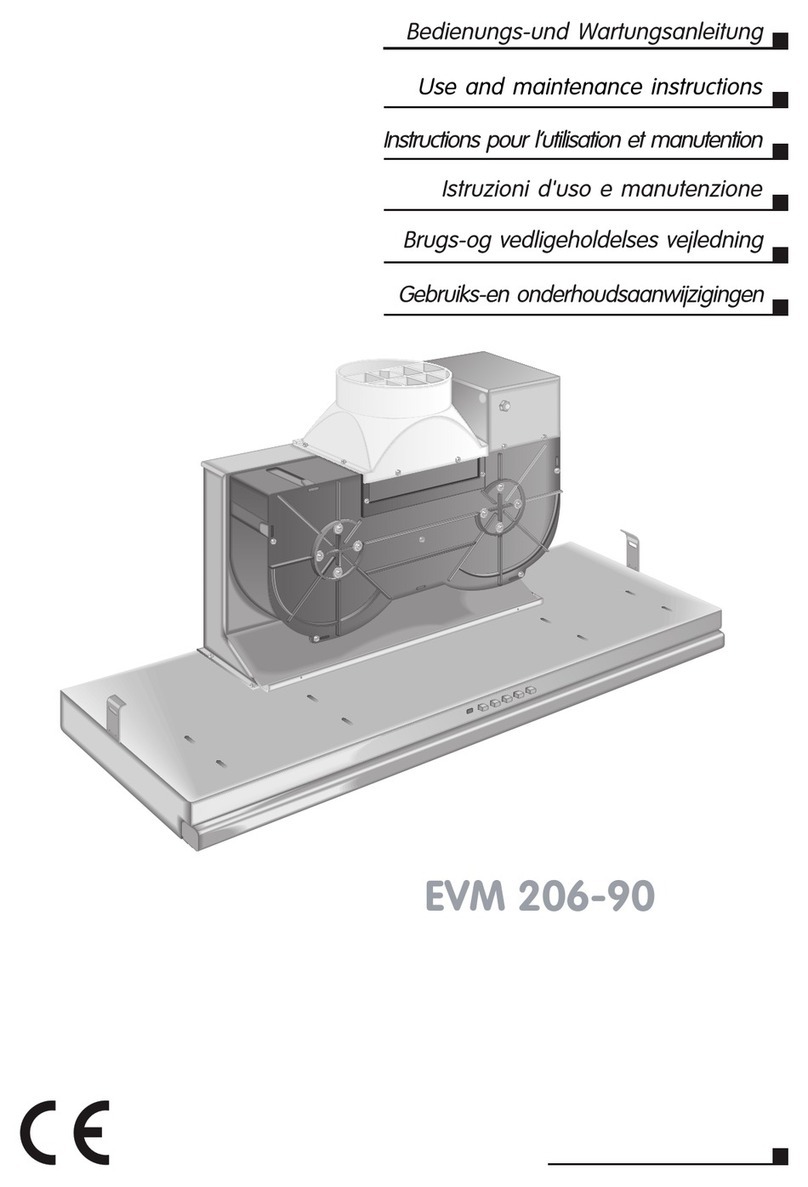

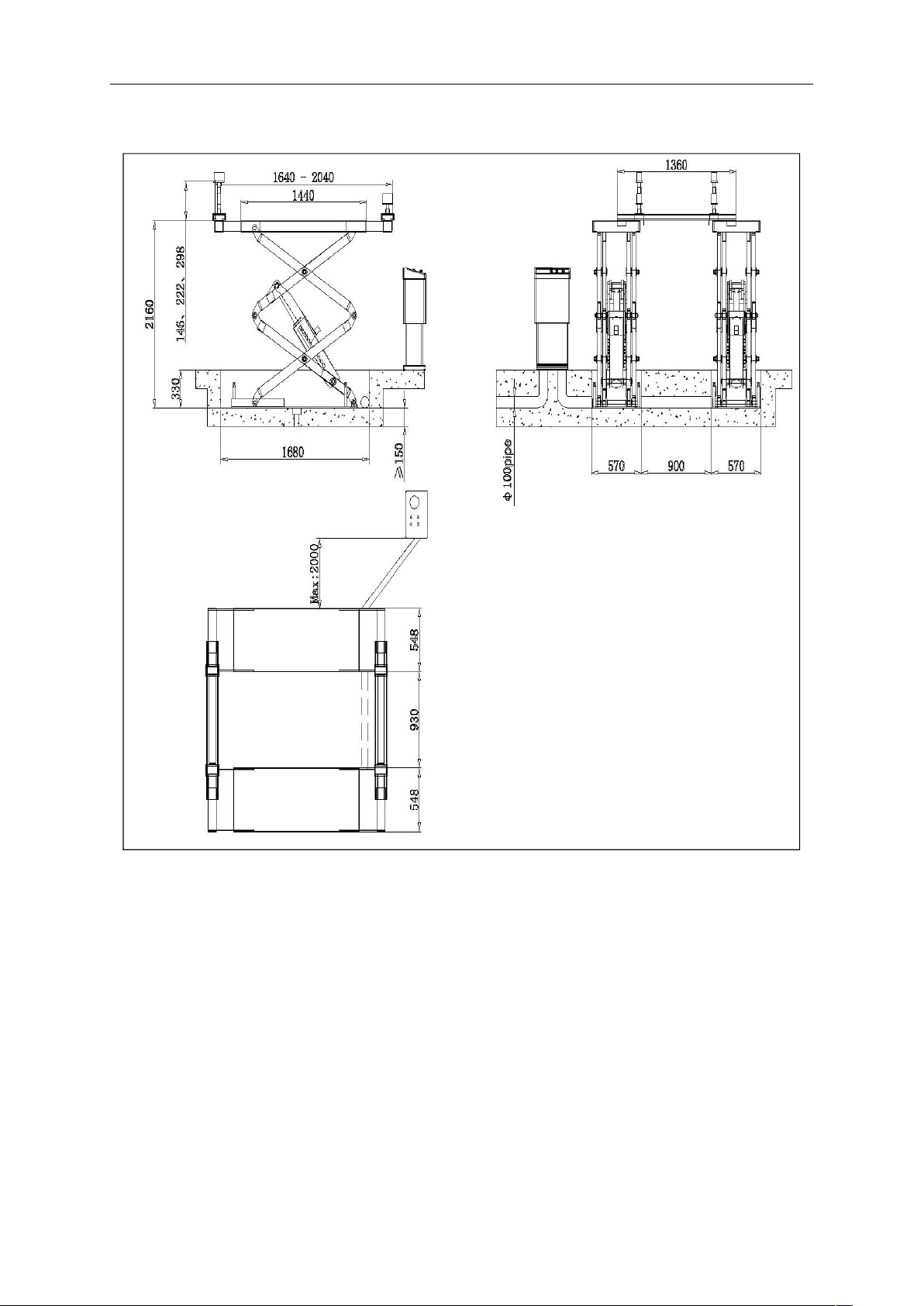

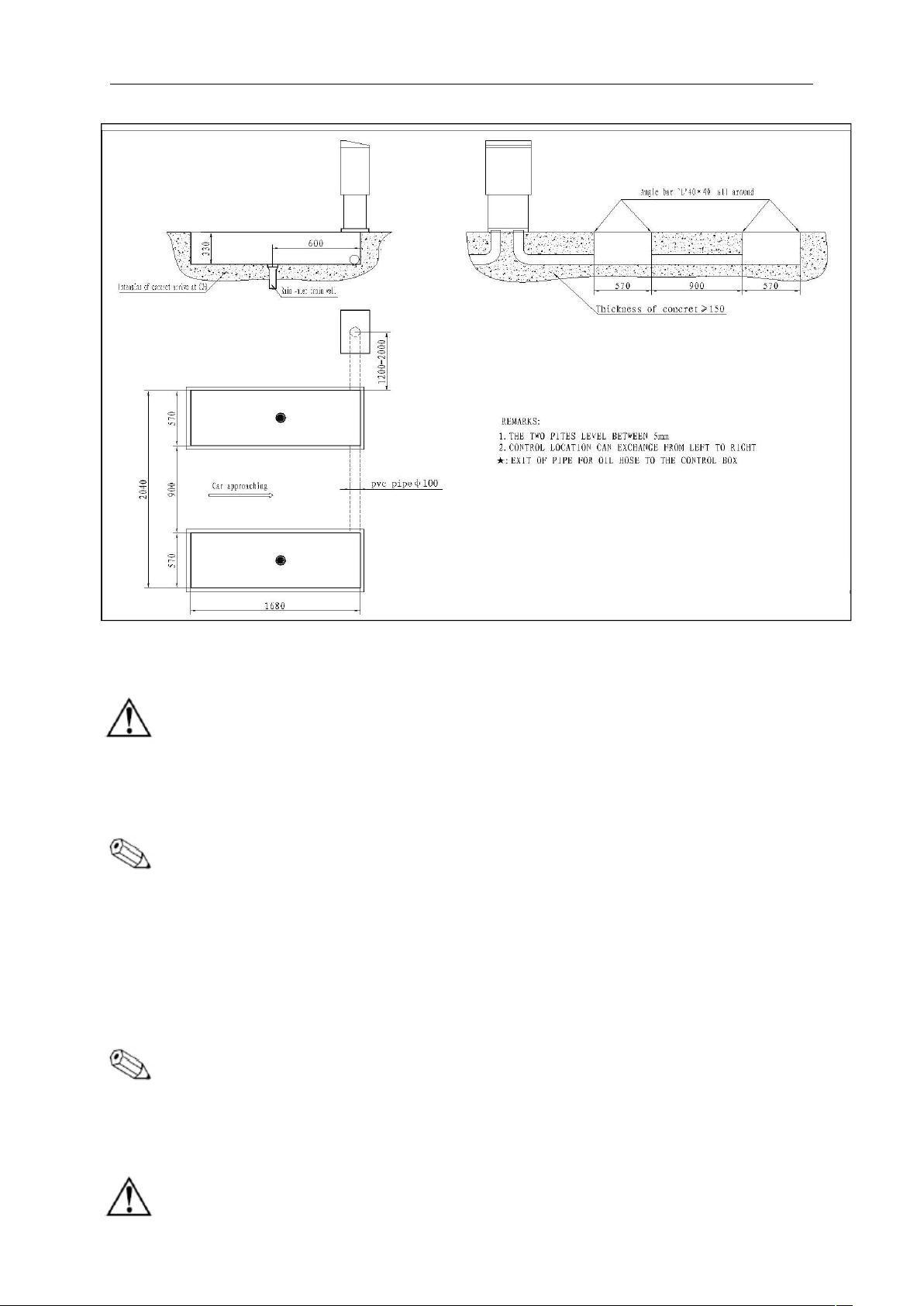

Lift dimension picture:

INSTALLATTON SCHEME FOR SMALL SCISSOR LIFT

Supply at the same time

-Connect to the power supply jack of control box (400V or 230V )

-Connect to the compressed air-entering pipe of control box (ф8×6mm)

Requirements:

-Concrete type 425#, the period of desiccation is 15 days

-Clean the basic layer, thickness of concrete ≥150mm, the leveling of whole

length≤5mm.

Picture 3

USER’S MANUAL

9

Chapter 2 SPECIFICATIONS

Note: The foundation of the end of the lift platformP1, P2 is the structure of concrete.

When the thickness of inside level ground is less than 150mm, the end of P1, P2

should be irrigated the acreage: 2500×2500mm and thickness of concrete≥150mm

The basic thickness of concrete and leveling are keys, shouldn’t egregiously expect

the ability of level adjustment of machine-self.

THE LOWER PARTS OF THE VECHILE UNDERBODY COULD INTERFERE

WITH STRUCTURAL PARTS OF THE LIFT, TAKE PARTICULAR PARTS OF

THE SPORTS-CAR.

The lift will also handle customized or non-standard vehicles provided they are within the

maximum specified carrying capacity.

Also the personnel safety zone must be defined in relation to vehicle with unusual

dimensions.

Chapter 3 SAFETY

Read this chapter carefully and completely since important information for the safety

of the operator or others in case of improper use of the lift is included.

In the following text there are clear explanations regarding certain situations of risk

or danger that may arise during the operation or maintenance of the lift, the safety device

installed and the correct use of such systems, residual risks and operative procedures to use

(general specific precautions to eliminate potential hazards).

Lifts are designed and built to lift vehicles and hold them in the elevated position in

an enclosed workshop. All other uses of the lifts are unauthorized. In particular, the

Picture 4 (ground drawing)

USER’S MANUAL

10

Chapter 3 SAFETY

lifts are not suitable for:

-Washing spray work;

-Creating raised platforms for personnel or lifting personnel;

-Use as a press for crushing purposes;

-Use as elevator;

-use as a lift jack for lifting vehicle bodies or changing wheels.

The manufacturer is not liable for any injury to persons or damage to vehicles and

other property caused by the incorrect and unauthorized use of the lifts.

During lifting and descent, the operator must remain in the control station as the

diagrams illustrated.

As the diagrams illustrated, the presence of persons inside the danger zone indicated is strictly

prohibited. During operations persons are admitted to the area beneath the vehicle only when

the vehicle is already in the elevated position, when the platforms are stationary, and when the

mechanical safety devices are firmly engaged (e.g.: the safety gear is completely locked).

DO NOT USE THE LIFT WITHOUT PROTECION DEVICES OR WITH THE

PROTECTION DEVICES INHIBITED.

FAILURE TO COMPLY WITH THIS REGULATION CAN CAUSE SERIOUS INJURY TO

PERSONS, AND IRREPEARABLE DAMAGE TO THE LIFT AND THE VEHICLE BEIN LIFED.

GENERAL PRECAUTIONS

The operator and the maintenance fitter are required to observe the prescriptions of

safety regulation in force in the country of installation of the lift.

Furthermore, the operator and maintenance fitter must:

-Always work in the stations specified and illustrated in this manual;

-Never remove or deactivate the guards and mechanical, electrical, or other types of safety

devices;

-Read the safety notices placed on the machine and the safety information in this manual.

In the manual all safety notices are shown as follows:

WARNING: indicates following operations that are unsafe and can cause minor

injury to persons and damage the lift, the vehicle or other property.

CAUTION: indicates possible danger that can result in serious injury to people and

damage property.

RISK OF ELECTRIC SHOCK: a specific safety notice placed on the lift in

areas where the risk of electric shock is particularly high.

RISK AND PROTECTION DEVICES

We shall now examine the risks that operators or maintenance fitters may be exposed to when

the vehicle is standing on the platforms in the raised position, together with the various safety

and protection devices adopted by the manufacturer to reduce all such hazards to the

minimum:

For optimal personal safety and safety of vehicles, observe the following regulations:

-Do not enter the danger zone when vehicles are being lifted. (Picture 6)

-Make sure the vehicle is positioned correctly. (Picture 7)

USER’S MANUAL

11

Chapter 3 SAFETY

-Be sure to lift only approved vehicles, never exceed the specified carrying capacity,

maximum height, and projection (vehicle length and width);

-Make sure that there is no person on the platforms during up and down movements and

during standing.

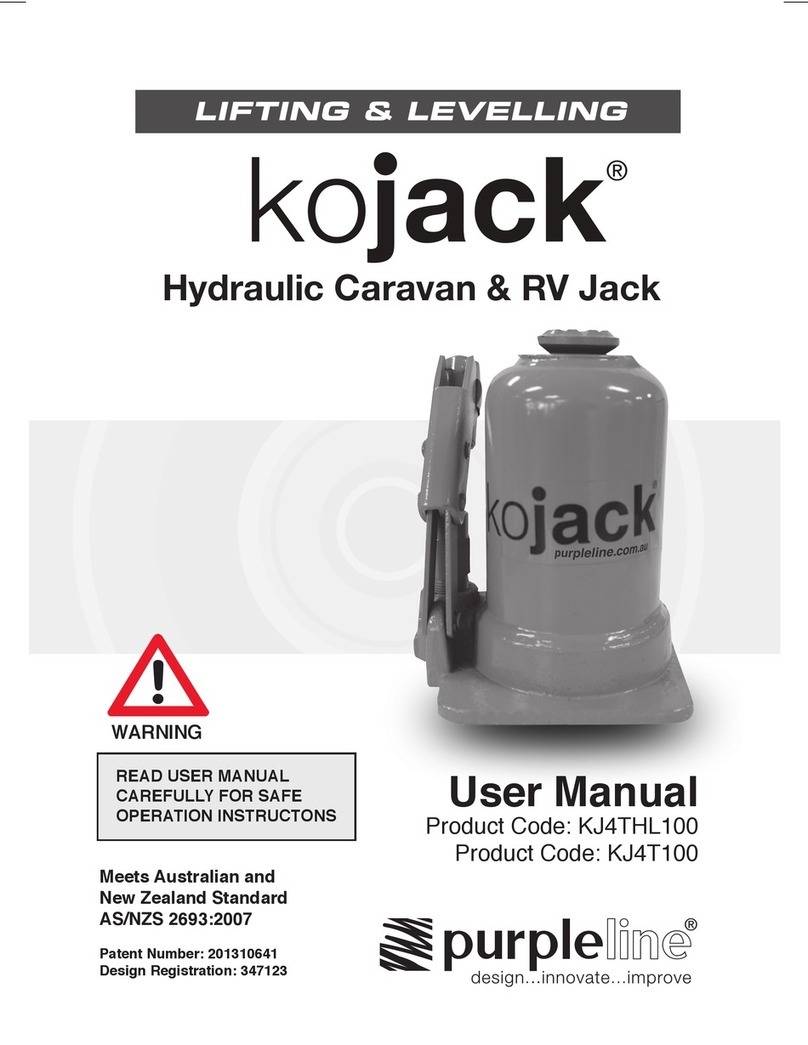

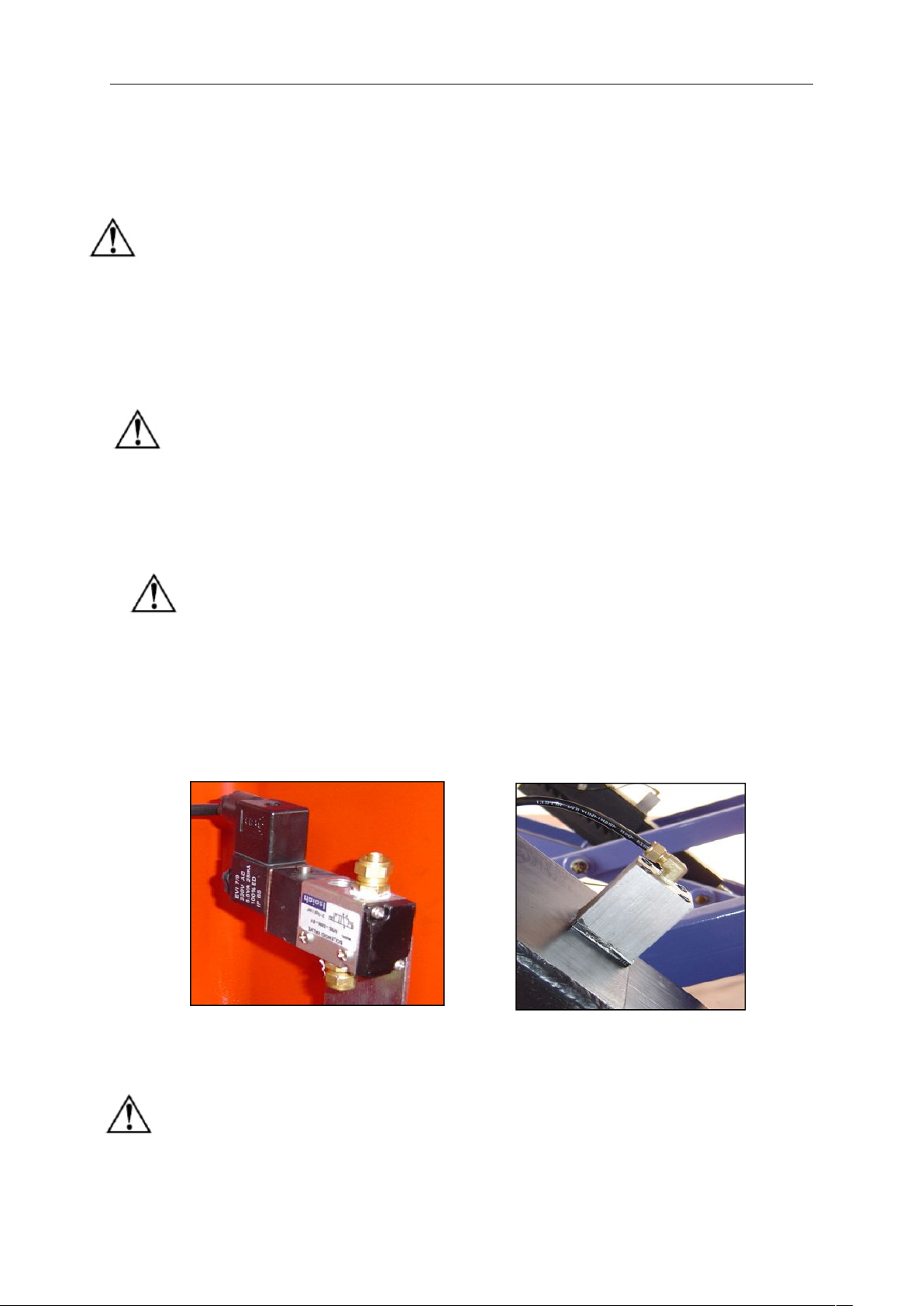

GENERAL RISKS FOR LIFTING OR DESCENT:

The following safety equipments are used to protect over

loading or the possibility of engine failure.

In the condition of over loading, the overflow valve will

open and directly return oil to the oil tank. (See Picture 8)

Each bottom of cylinder is equipped with antiknock valve.

When the oil pipe is burst in the circuit of hydraulic

pressure, the relevant antiknock valve will work and limit

the speediness of platform. (Picture 9)

Safety tooth and gear module are parts which guarantee the safety of personnel beneath

the machine in failure condition of other protections. So make sure the integrity of gear

module and that the safety tooth has occluded completely. (Picture 10)

There is nothing abnormal should be left on the safety modules to prevent safety

gear from occlude normally.

RISKS FOR PERSONNEL

Picture 8 (overflow valve)

Picture 9

Picture 10

Picture 7

Picture 6

USER’S MANUAL

12

Chapter 3 SAFETY

This heading illustrates potential risks for the operator, maintenance fitter, or any other person

present in the area around the lift, result from incorrect use of the lift.

RISKS FOR EXTRUSION

During up and down operations, personnel leave the said area without following the

rule and instruction.

During up and down operations, no person is admitted to work beneath the movable

parts of the lift, should work in the safe zone. (Picture 6)

RISK OF IMPACT

Before the operator begins up and down movements, make sure that there are no

personnel inside the danger zone. When, due to operational reasons, the lift is stopped

at relatively low elevations (lower than 1.75m above the ground) personnel must be

careful to avoid impact with parts of the machine not marked with special colors.

RISK OF FALLING OFF (PERSONNEL)

During up and down operations, personnel are prohibited from entering the platforms

and the vehicle to avoid falling off.

RISK OF FALLING (VEHICLE)

This hazard may arise in the case of incorrect positioning of the vehicle on the

platforms, overweight of the vehicle, or in the case of vehicles of dimensions that are

not compatible with the capacity of the lift.

When the platform is being tested, the vehicle engine can not be turned on.

There is nothing should be placed on the lift-lowering area and the movable parts of

the lift.

RISK OF SLIPPING (picture 12):

Caused by lubricant contamination that of the floor around the lift. The area beneath

and immediately surrounding the lift and also the platforms must be kept clean.

Remove any oil spills immediately.

RISK OF ELECTRIC SHOCK

Risk of electric shock that in area of insulated and shattered electric equipments.

Do not use jets of water, steam solvents or paint next to the lift, and take special care

to keep such substances clear of the electrical control panel.

Picture 11(risk of impact)

Picture 12(risk of slipping)

USER’S MANUAL

13

Chapter 3 SAFETY

RISKS RELATED TO IMAPPROPRIATE LIGHTING

The operator and the maintenance fitter must be able to assure that all the areas of the lift are

properly and uniformly illuminate compliance with the laws in force in the place of installation.

During up and down operations, the operator should continually observe the lift and

can operate it only in the position of operator. When lifting and lowering the vehicle,

the cushion needs being put in the bottom of chassis.

The handling of safety devices is strictly forbidden. Never exceed the maximum

carrying capacity of the lift, make sure the vehicles to be lifted have no load.

It is therefore essential to adhere scrupulously to all regulations regarding use,

maintenance and safety contained in this manual.

USER’S MANUAL

14

Picture 13

Chapter 4 INSTALLAION

SKILLED AND AUTHORIZED PERSONNEL ONLY SHOULD BE ALLOWED

TO PERFORM THESE OPERATIONS, FOLLOW ALL INSTRUCTIONS

SHOWN BELOW CAREFULLY, IN ORDER TO PREVENT POSSIBLE

DAMAGE TO THE CAR LIFT OR RISK OF INJURY TO PEOPLE.

Skilled technicians only appointed by the same manufacturer or by authorized dealers, are

allowed to install the car lift.

INSTALLATION REQUIREMENTS

The car lift must be installed according to the specified safety distances from walls, pole

and what other equipments stated.

The specified safety distances from walls must be

1000 mm at least, taking into consideration the

necessary space to work easily. Because space for

the control site and for possible runways in case of

emergency is also necessary.

The room must be previously arranged for the

power supply and pneumatic feed of the car lift.

The room must be 4000 mm in height, at least.

The car lift can be placed on any floor, as long as it

is perfectly level and sufficiently resistant. (≥250kg/cm²,the

thickness of concrete≥150mm)

All parts of the machine must be uniformly lit with sufficient light to make sure that the

adjustment and maintenance operations can be performed safely, and without reflected

light, glare that could give rise to eye fatigue.

The integrality of arrived goods should be checked before the lift is installed.

Moving and installing lift should follow the process as the picture instructs.

The transport and storage of machine refers to “TRANSPORT AND STORAGE” on

page 4.

Platform Installation:

-Place two platforms on the position of the location

-The bottom of cylinder is located in the frontage of

machine (the direction of getting on the vehicle)

-Use fork car or other lifting equipments to lift the

platform (Picture14) and make sure that the safety

equipment of machine is both turned on and locked.

Picture 14

USER’S MANUAL

15

Chapter 4 INSTALLAION

To avoid failure of machine safety equipment, can insert a wood in the middle part of

joint-pole.

Prohibit working beneath the lift when hydraulic system is not completely equipped

with hydraulic oil and take the action of up and down operations.

-When moving the lift platform, adjust the space between two platforms make sure that the

two platforms are parallel.

LINE CONNECTION

Connect the electrical and oil pipes according to “the electrical diagram” and “oil pipe

connection diagram”.

Only after connecting the hydraulic system can connect the air loop, can not damage

oil pipe, wires, and air pipe.

In the process of connecting oil pipe and air pipe, pay particularly attention to the

protection of pipe tie-in to prevent abnormal thing from entering oil loop and air loop,

then damaging hydraulic system.

ELECRICAL CIRCUIT CONNECTION:

Follow the stated line- pathway and line-number of “the electrical diagram” to connect

electrical circuit.

Only skilled person is allowed to perform the operations.

-Open the control box front cover

-Connection of power supply: the 400V three-phase and five-line connection wires

(3×2.5mm2+2×1.5 mm2cable wire) for power supply are connected to control box L1,L2,L3,N

and entering-wire terminal. The PE ground wire is connected under the bolt marked ground

firstly (Picture 15) and then connected under the bolt marked ground of two platforms.

-If the lift is operated at 230V three-phase, change the connection on the transformer and

motor. (Picture 1

-Connection of up limit switch (picture 17):

This For detail connection, please see electrical drawing.

Picture15

Picture 16

Picture 17 (up limit switch)

USER’S MANUAL

16

Chapter 4 INSTALLAION

OIL PIPE CONNECTION:

Follow “oil pip connection diagram “to connect the oil pipes.

Only skilled and authorized person is allowed to perform the operations. And pay

particularly attention to the protection of oil pipe head.

-Following oil pipe number to lead the oil pipe out from the oil make-up stop valve “H”

of control box and then connect it to the cylinder. (Refer to “oil pipe connection

diagram”)

-When connect oil pipe, pay attention to the protection of oil pipe tie-in to prevent

impurities from entering hydraulic circuit.

When connecting the oil pipe, take careful of the mistake of each oil pipe number.

During the standard installation, control box is in the nearside of vehicle-entering

direction. If placed on the right side should adjust relevant oil pipe.

COMPRESSED AIR PIPE CONNEVTION:

Follow “air pipe diagram “to connect air loop.

Only skilled and authorized person is allowed to perform the operations.

-Connect Φ8×6 compressed air supply pipe to the air supply jaws of solenoid air

valve inside the control box. (Picture18)

-Follow “air pipe diagram “to lead the compressed air pipe out from solenoid air valve

and then connect it to the uplifted-pawl air valve. (Picture 19)

-Pay attention to the protection of windpipe tie-in to prevent impurities from entering

compressed air circuit.

-Connect compressed air hose to the extra-installed grease separator which is in front of

control box to prolong the lift of pneumatic components and the reliability of action.

In the process of air hose installation, the air hose not be folded or tied to avoid that

the air loop is not smooth or it is jammed.

Before leading the compressed air supply pipe to the air supply jaws of pneumatic

electromagnetic valve inside the control box, should extra install grease separator to

separate compressed air, avoiding the failure of pneumatic cell action.

Picture 18

Picture 19

USER’S MANUAL

17

Chapter 5 ADJUSTMENT

Add oil and check the order of phase.

After installing lift as Picture 4 required and connecting hydraulic circuit, electric

circuit and air loop, operate it as following:

-Open the hydraulic oil tank; add 18L of hydraulic oil into the oil tank, the hydraulic oil is

prepared by the user.

Make sure the clean of hydraulic oil, prevent any impurity into the oil line, lead the

digest of the oil line and no working of the solenoid air valve.

-Turn the “MAIN SWITCH” on power, click the “UP” button, and check whether

the motor turns clockwise (looking downward); if not turn off the power, change

the phase of the motor.

-Turn on air power.

When turn on power, the high voltage will exist in the control box, only authorized person can

operate it.

Main machine oil make-up adjustment

1 -Close the oil make up stop valve “H”

2 -Press “UP” button, and thus the left platform (looking from machine head direction) is

lifted to about 1000mm.

3 -Press the “DOWN” button to lower the left platform to the lowest position.

4 -Then lift it up to approximately 1400mm.

5 -Open the oil make up stop valve “H”.

6 -Press “UP” button, and the right platform (looking from machine head direction) is lifted to

about 1000 mm.

7 -Press “DOWN” button to lower the platform to the lowest position.

8 -Repeat the lifting and lowering process for 6-7 times to vent air automatically.

9 -Then lift the right platform to 1400mm. (The two platforms are lifted to the same height).

10 -Finally close the oil make up stop valve “H”.

Check: oil leakage of the oil line and air tightness of the air loop.

Picture 20

Picture 21

USER’S MANUAL

18

Picture 22

Chapter 5 ADJUSTMENT

GROUND BOLTS INSTALLATION:

The ground bolts installation must start after the expiry date on the maintenance of

concert, otherwise, it will affect the quality of solidity.

-Adjust the parallel of the platform and the distance of two platforms as Picture 4

requires.

-Fix the anchor bolts with a percussion electric drill (percussion drill bit is of 16),

drill to 120mm hole and clean the hole.

-Use light hammer to install the ground bolts into the hole (do not need to install the

central expanded nail of ground bolts, and install it after level adjustment.)

Level adjustment:

-By using a level bar and the horizontal pipe and adjusting the adjustment screws at two sides

of the base plate.

-If platform unevenness is resulted from basic unevenness, use iron block to fill up the low

place.

-After level adjustment, insert the central expanded nail of ground bolts and use heavy

hammer to hammer it.

-Screw down the ground bolts cap.

When the expiry date on the maintenance of concrete hasn’t arrived, one can not

install the central expanded nail of ground bolts.

The gap between the base plate and ground after adjustment must be filled with iron

plate or concrete.

No load of main machine test:

-Turn on the power QS.

-Press “UP” button, pay attention to the synchronization and placidity of the lifting.

-Check whether safety pawl is correctly located.

-Check whether the oil line and the air line are leakage.

Picture 23(level adjustment)

USER’S MANUAL

19

Chapter 5 ADJUSTMENT

When testing the lift, no person or other things are allowed to stand or be put near

the two sides and beneath the machine. If any abnormal is found, press button

“emergency stop” to stop it timely. After clearing obstacles, do the test again.

Load of machine test:

-Drive the vehicle whose weight doesn’t exceed maximum lift weight to the platform, and

then the driver leave it.

-Put the lift rubber cushion on the nucha seat.

-Press “UP” button, lift the platforms and pay attention to the synchronization and placidity of

the lifting.

-Check whether safety pawl is correctly located.

-Check whether the oil line and the air line are leakage.

When begin load test, no person or other things are allowed to stand or be put near

the two sides and beneath the machine.

Test vehicle whose weight doesn’t exceed maximum lift weight.

Check whether the oil line and the air line are leakage. If any abnormal is found, press button

“emergency stop” to stop it timely. After clearing obstacles, do the test again.

USER’S MANUAL

20

Chapter 6 OPERATION

Only skilled and having been trained personnel is allowed to perform the

operations. Check proceedings as following.

Operation Notices:

-Clear obstacles around the lift before operation.

-During lifting or lowering, no person is allowed to stand neat the two sides and beneath the

machine, and no person is allowed on the two platform.

-Avoid lifting super heavy vehicles or other goods.

-When lifting vehicle, the chassis of the vehicle should be filled up with rubber cushion.

-Pay attention to the synchronization of the lifting and lowering. If any abnormal is found,

stop the machine timely, check and remove the trouble.

-When lowering vehicle, lift the platform a bit firstly, notice that whether two safety pawls

and safety teeth have been disengaged completely. If not, stop lowering.

-When the equipment is not used for a long time or over night, the machine should be lowered

to the lowest position on ground, and remove vehicle, and cut off power supply.

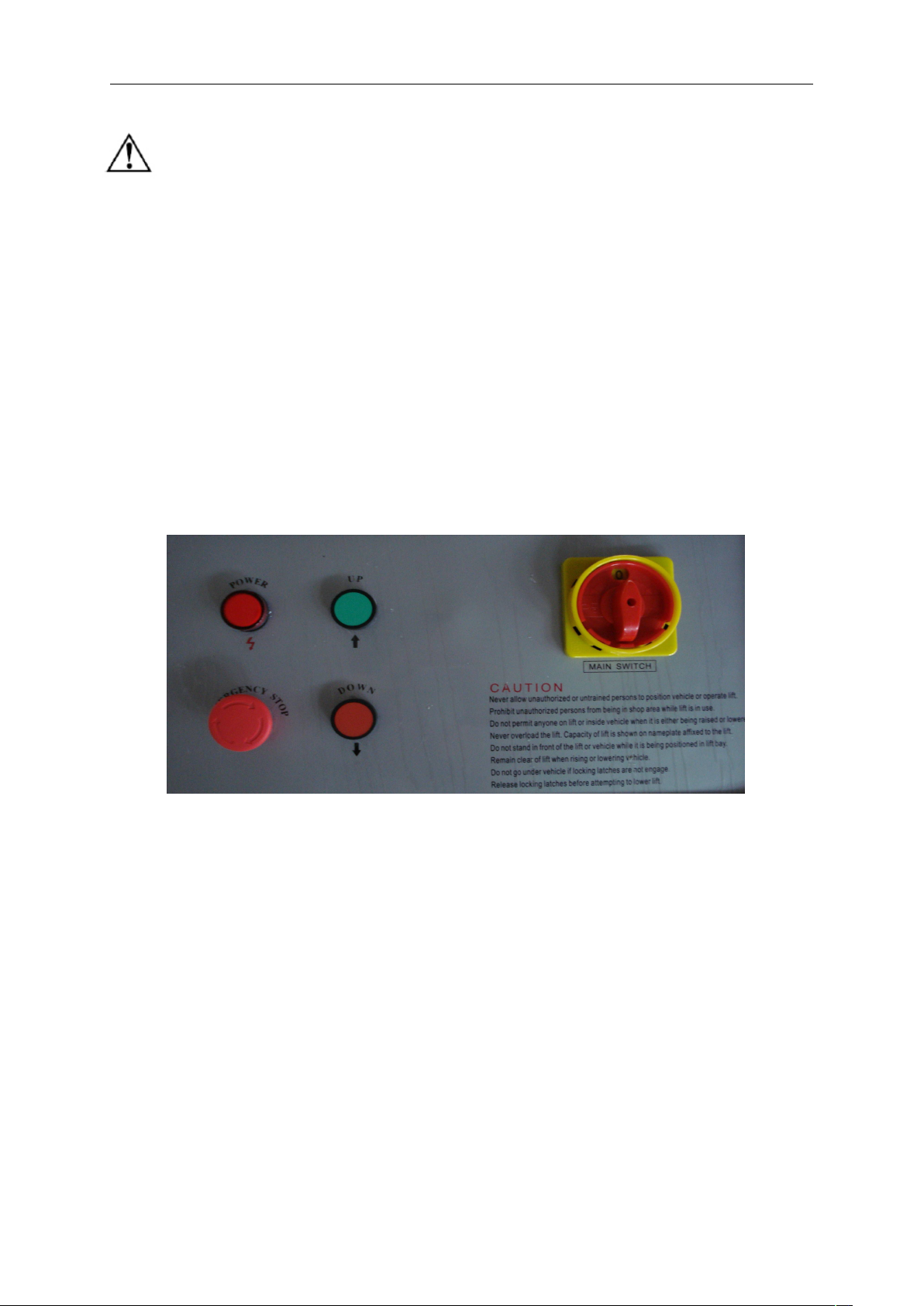

Instructions on electric operation: (see the operation panel)

LIFTING:

-Press “UP” button, the oil pump will work immediately and pump hydraulic oil to cylinder,

and the platform is being lifted and the safety pawl is also lifted because of the joint of air

loop.

-Release button, the oil pump will stop immediately, and the platforms stop lifting and the

safety pawl falls on the safety gear because solenoid air valve is out of electricity and then

close the air loop.

DESCENT:

-Press ‘DOWN’ button, the lock latch will be lifted because of joint air loop, since solenoid

air valve is connected for electricity, so the platforms descend.

-Release the button, platforms stop descending and the safety pawl falls on the safety gear.

EMERGENCY STOP:

When the machine has abnormal or car maintenance, push “emergency stop” button to lock,

Picture 24 (Operation panel)

Table of contents

Other Dato Lifting System manuals

Popular Lifting System manuals by other brands

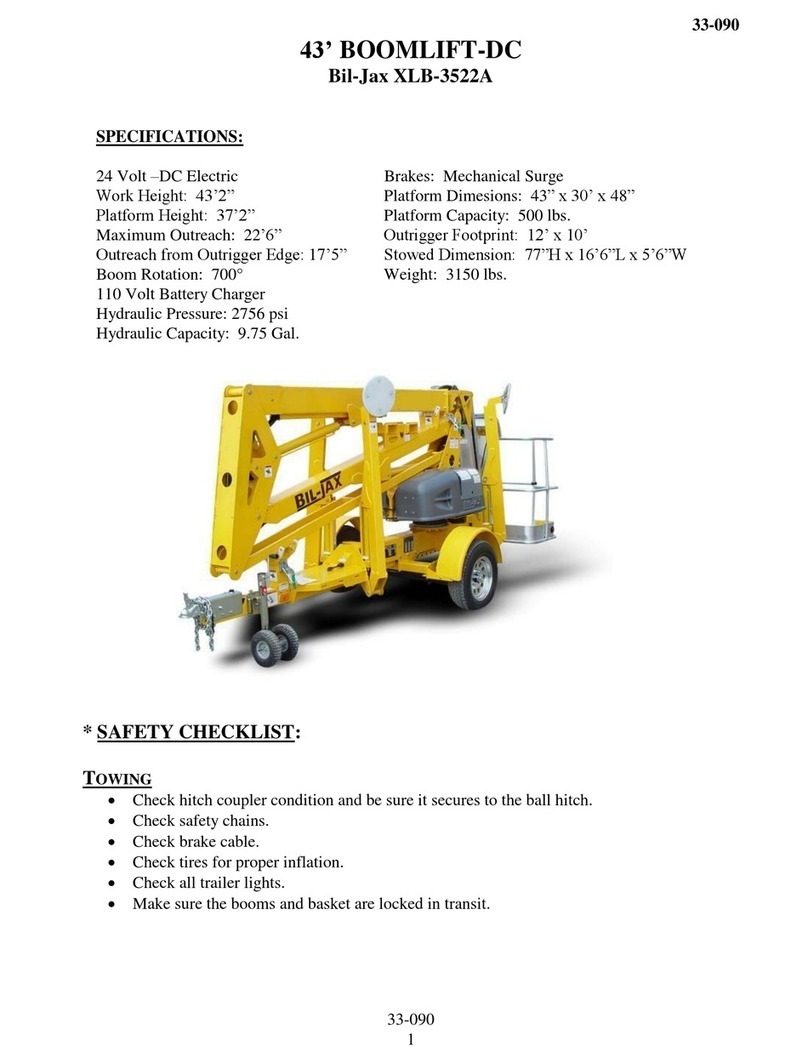

BilJax

BilJax XLB-3522A quick start guide

BLACKHAWK!

BLACKHAWK! STL27 instruction manual

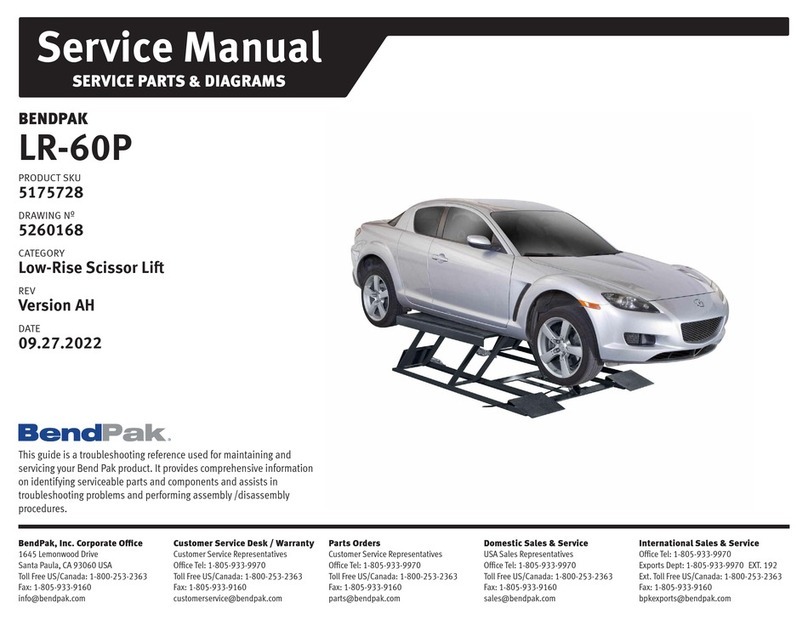

Bend-Pak

Bend-Pak LR-60P Service manual

Bend-Pak

Bend-Pak PL-6KDT Installation and operation manual

Big Joe

Big Joe PTE 30 Series Operation, maintenance, repair parts list

ARJO HUNTLEIGH

ARJO HUNTLEIGH Maxi Sky 1000 Instructions for use

Bend-Pak

Bend-Pak XPR-12CL Installation and operation manual

Hillrom

Hillrom Liko HygieneVest 50 Instruction guide

eZway

eZway EZ Light Lift Operator instructions

Equalizer

Equalizer VLW18TE Operator's instruction manual

Bend-Pak

Bend-Pak HD-7P Service manual

Dino lift

Dino lift DINO 135TB operating instructions