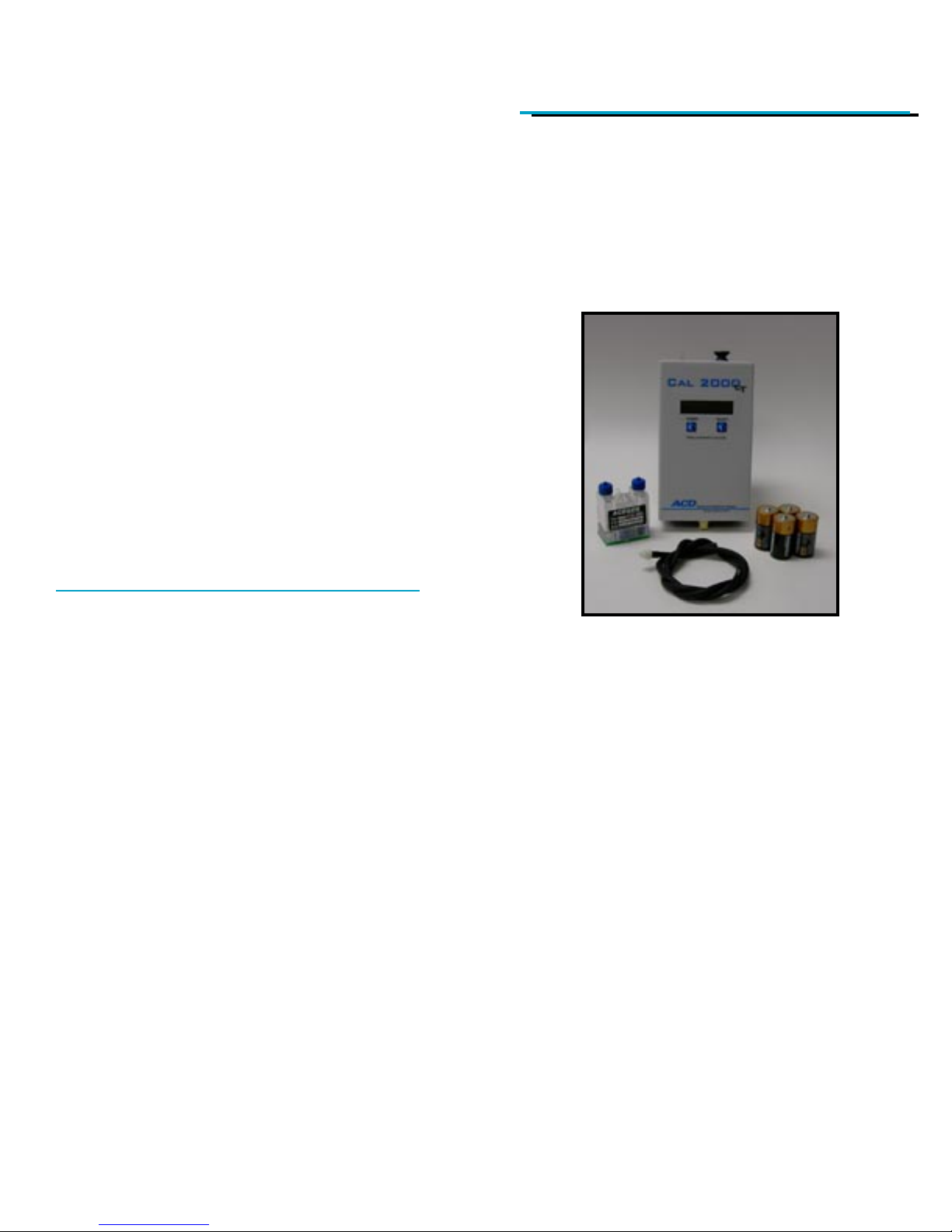

Alkaline "C" Batteries

A set of four fully charged, heavy duty alkaline "C" batteries

provides approximately 10 hours of operation. Note: Re-

chargeable or light duty batteries can be used, but they

give significantly less operating time. Using re-chargeable

batteries will also void the CSA safety certification during

the time of their use.

Microprocessor-Based Circuitry

The Cal 2000 LT has microproccessor based circuitry that

performsseveral different operations andoffers the usermany

different features. The microprocessor tracks cell and battery

usage,monitors theair flow rateand controlsthe cell andpump

to give the correct ppm and flow rate. In addition to English,

every Cal 2000 LT is capable of providing menu displays in

French, German and Spanish. See section III. Menu Options

for instructions on how to change the menu language.

Digital Display

The Cal 2000 LT has a liquid crystal display (LCD) located on

the front of the instrument. This display is protected by a thin,

clear plastic cover that is part of the front label and may be

replaced if it becomes scratched or unclear.

POWER and SELECT

The POWER and SELECT switches are momentary push but-

tontype switches activated throughthe front membranepanel.

They are physical switches mounted directly on the circuit

board.

Delivery Hose

The instrument comes standard with a three (3) foot long,

¼inch diameter norprene hose for delivering the gas to the

sensor or calibration adapter. The hose has a male quick

connect adapter for easy attachment to the instrument.

Page 4Page 15

VI. Standard Warranty

We warrant gas calibration equipment manufactured and

sold by us to be free from defects in materials, workmanship

and performance for a period of one year from date of

shipment. Any parts found defective within that period will

be repaired or replaced, at our option, free of charge, F.O.B.

factory. This warranty does not apply to those items which

by their nature are subject to deterioration or consumption in

normal service, and which must be cleaned, repaired, or

replaced on a routine basis.

Such items may include, but are not limited to:

a. Electrochemical type generating cells

b. Electrolyte

c. Batteries

Warranty is voided by abuse including rough handling,

mechanical damage, alteration, or repair procedures not in

accordance with the instruction manual. This warranty

indicates the full extent of our liability, and we are not

responsible for removal or replacement cost, local repair

costs, transportation costs or contingent expenses incurred

without our prior approval.

Advanced Calibration Designs, Inc.'s obligation under this

warranty shall be limited to repairing or replacing, and

returning any product which shall be returned to Advanced

Calibration Designs, Inc. at its manufacturing facilities, with

transportation charges prepaid, and which Advanced

Calibration Designs, Inc.'s Material Review Board examina-

tion shall disclose to its satisfaction to have been defective.

This warranty is expressed in lieu of any and all other

warranties and representations, expressed or implied, and

all other obligations or liabilities on the part of Advanced

Calibration Designs, Inc. including, but not limited to, the