Index

1Environment .................................................................................................................... 2

2Technical specifications............................................................................................... 3

3Safety instructions......................................................................................................... 3

4Constraints....................................................................................................................... 4

5Controls ............................................................................................................................ 4

5.1 Step Control .......................................................................................................................................... 4

5.2 Signals ................................................................................................................................................... 4

5.3 Legal requirement according R 107 UN Bus directive: .................................................................. 4

5.4 Electrical Components ........................................................................................................................ 4

5.5 Power..................................................................................................................................................... 4

5.6 Current control...................................................................................................................................... 4

5.7 Motor ...................................................................................................................................................... 4

6Operation.......................................................................................................................... 5

6.1 Deploy Operation procedure .............................................................................................................. 5

6.2 Stow operation procedure................................................................................................................... 5

7Manual Operation ........................................................................................................... 6

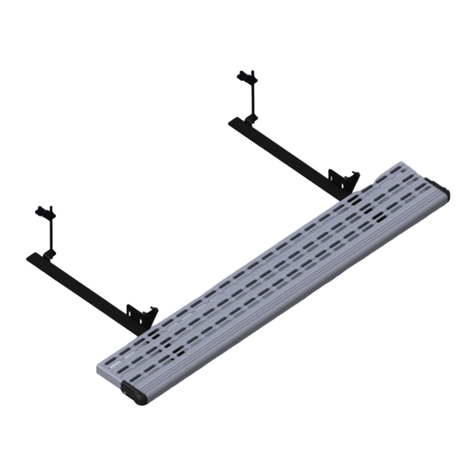

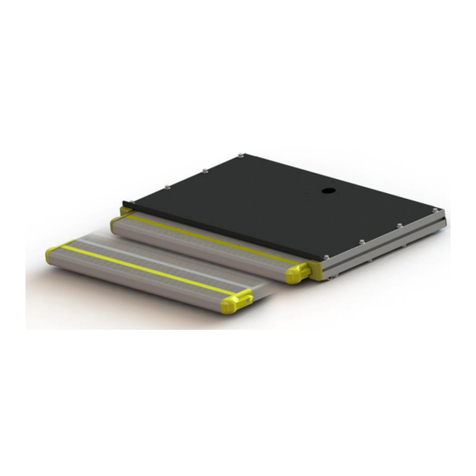

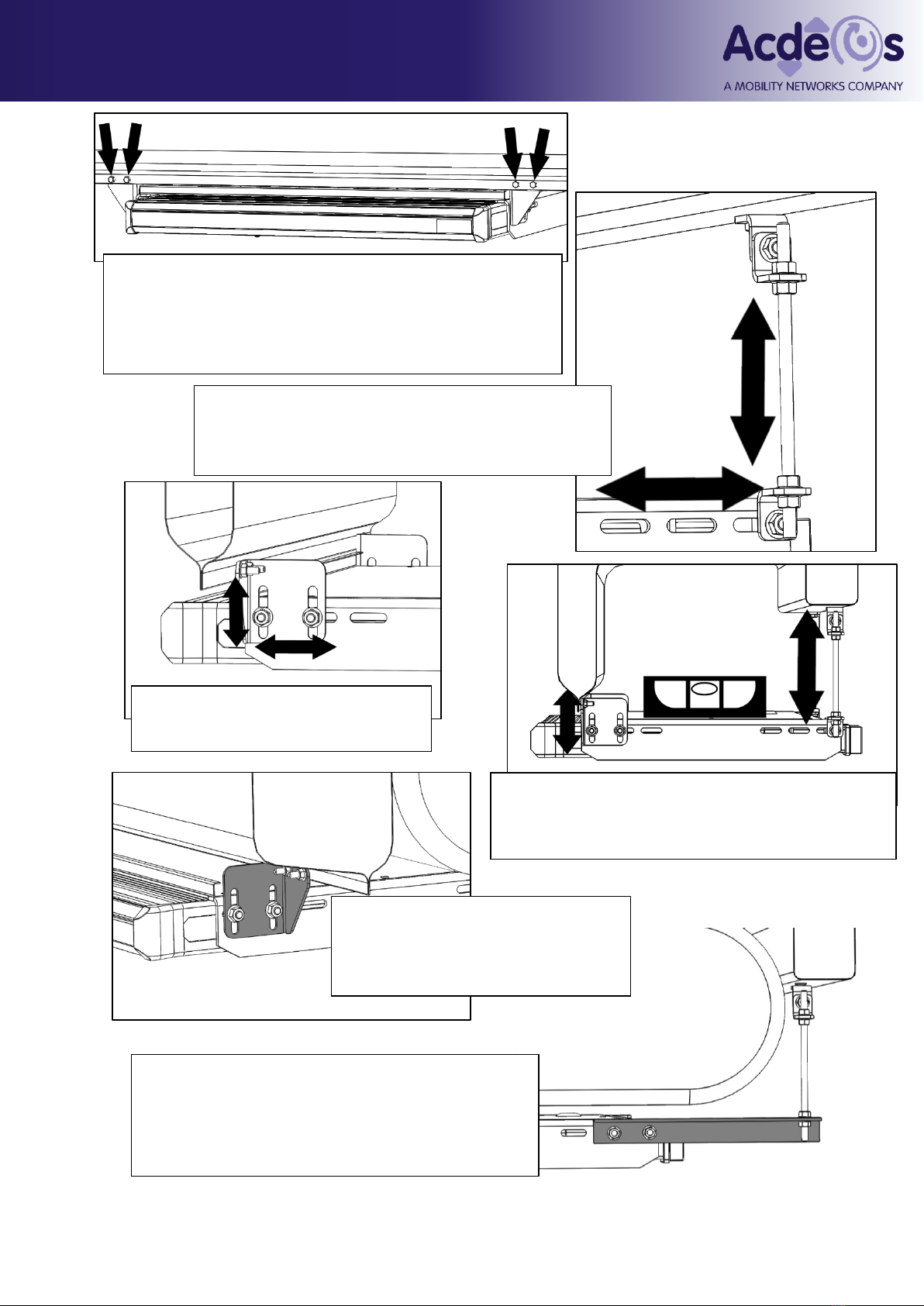

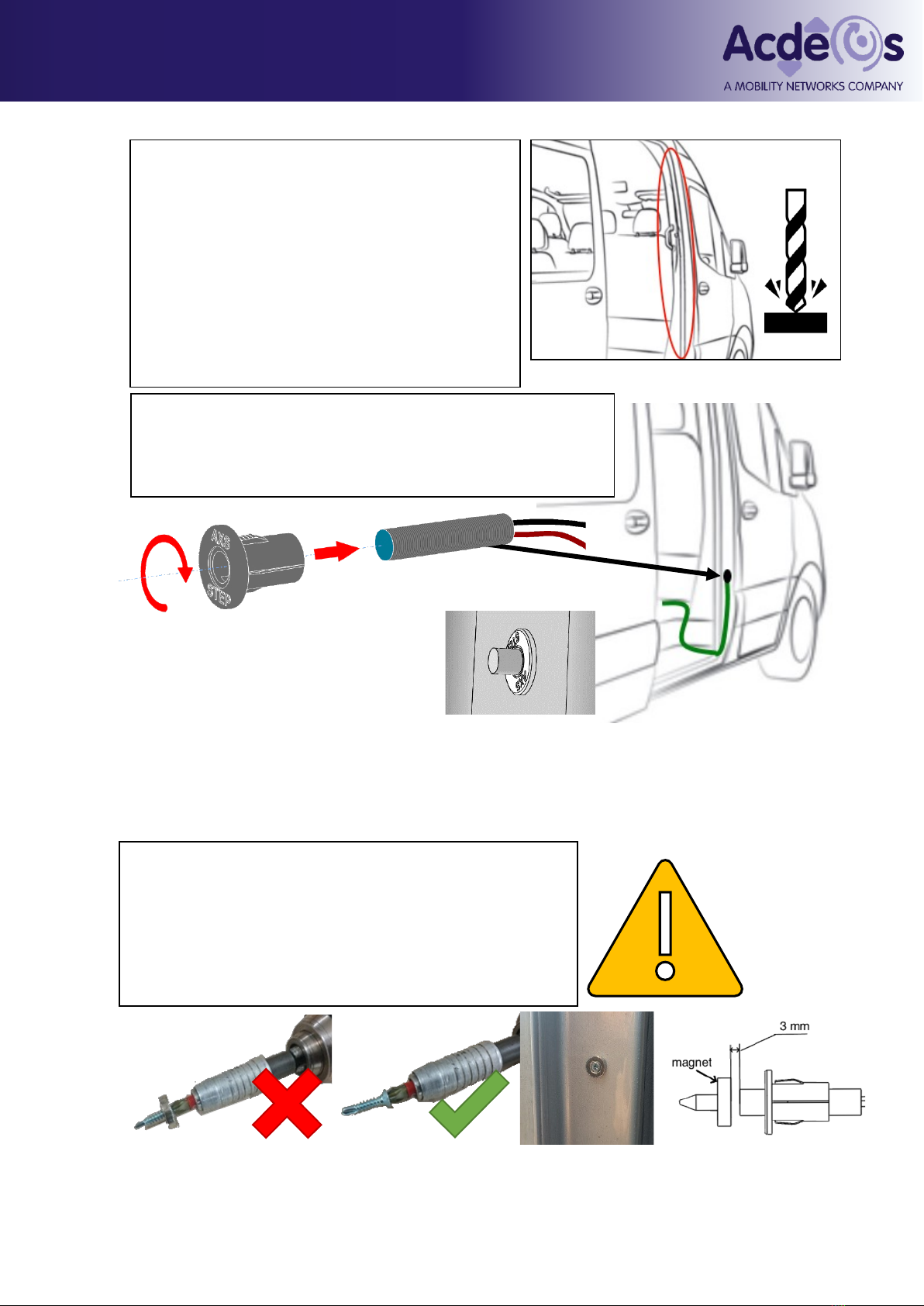

8Mounting / Installation ..................................................................................................6

8.1 Mechanical Installation ........................................................................................................................ 6

8.2 Electrical Installation ............................................................................................................................ 8

8.3 Installation of the LED (optional):..................................................................................................... 11

8.4 Testing the Step: ................................................................................................................................ 13

9Periodic maintenance / Inspection .......................................................................... 13

9.1 Cleaning .............................................................................................................................................. 13

9.2 Periodic maintenance / Inspection................................................................................................... 13

9.2.1 Small maintenance .................................................................................................................... 13

9.2.2 Regular inspection ..................................................................................................................... 13

9.2.3 Yearly maintenance / normal maintenance............................................................................ 13

10 Repair ........................................................................................................................... 14

10.1 Disassembly.................................................................................................................................... 14

10.2 Assembly......................................................................................................................................... 16

11 Failure search ............................................................................................................ 20

12 Certification ................................................................................................................ 21

13 Spare parts..................................................................................................................22

Appendix 1;........................................................................................................................... 26

Appendix 1 a; ....................................................................................................................... 27

Appendix 2;........................................................................................................................... 28

Installation drawings: ........................................................................................................ 28

1Environment

The use of energy from the step is reduced to an absolute minimum.

The AXS - Step is made of durable materials which all can be recycled. All different materials can easily

be separated from each other for separate recycling.