4Installation

The installation must only be done by a company that is familiar with bodybuilding or modifying

vehicles, and that have the trained technical staff.

4.1 Mechanical Installation

Below instruction is based at mounting the step with the optional flexi fit mounting kit which is

available under number S130 01 024. Ask your dealer for availability

In order to mount the step you do not need to make any major vehicle adaptations. The step

is placed under the floor in the middle of the front, middle or rear door. Chassis modifications

are not needed, but you may need to remove some plastic underbody parts.

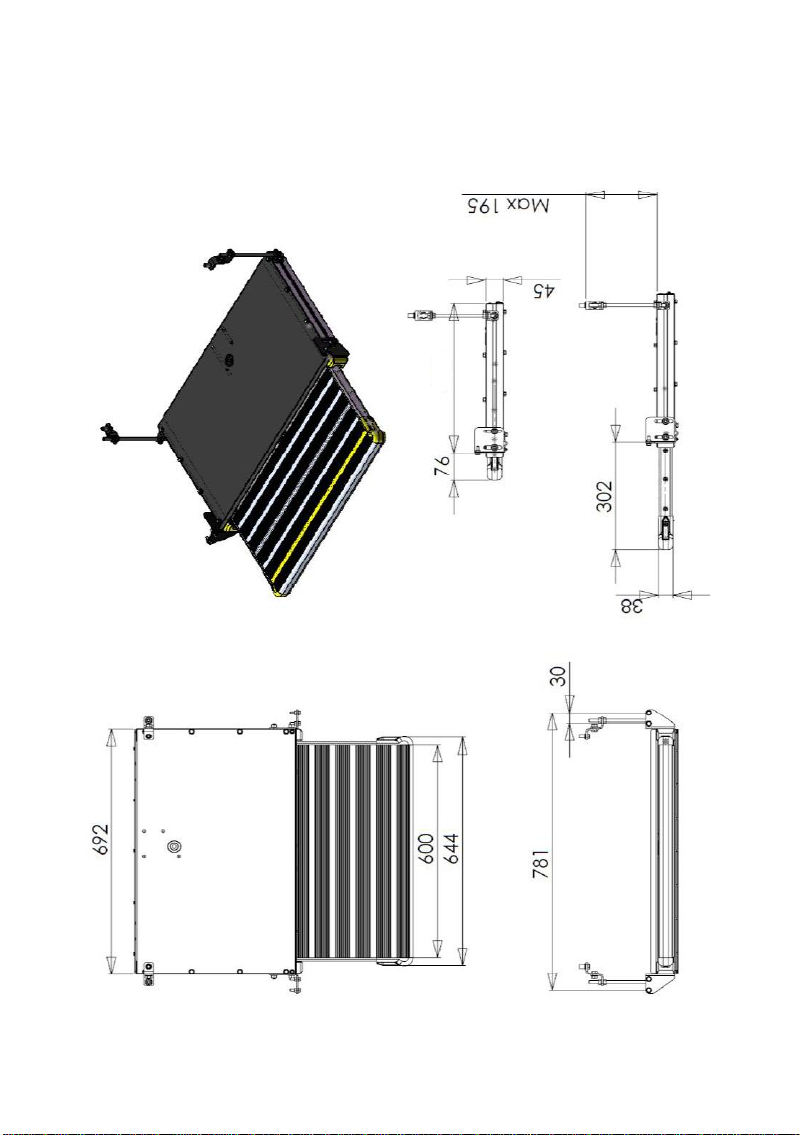

Exact measurements of the product should be taken from the official installation drawings. Ask

Acdeos for the last revision and official installation drawing. Figures and drawings in this

manual are only indicative.

Installation:

Create a safe working environment. Raise the vehicle to the appropriate working height.

Identify the location underneath the

vehicle where the step will be mounted.

Ensure the cassette can be mounted in

the required position without being

obstructed by the chassis or other

vehicle parts.

Make sure that the step is not too

close to hot parts such as the

exhaust system. This can damage the

step.

The picture shows the basic principles

for mounting the step.

Identify where the 4 front mounting bolts will go. The holes for this

fixation should be drilled in the lower flange of the outer chassis bar of

the vehicle. Drill the holes ø6.5

mm. Always protect all drilled

holes with zinc spray. Make

sure there is enough material in

the flange underthe hole. Place

the step with two bolts at the

flange and support it at the rear.

Take the flexible mounting

brackets supplied with the step.

These brackets can be

mounted in several ways. The

brackets should be used to fix

the rear side of the step to the bottom of the vehicle. It is recommended

that a sturdy section of the vehicle floor us used. Mount the brackets so

that they bridge the gap between step and vehicle floor / chassis. The

M8 studs should be placed as vertical as possible. This fixing requires

some technical knowledge and own interpretation.