2Safety instructions

These Safety instructions should always be kept with the step. The

operator must be made aware of these instructions before operating

the Step. Read and follow these safety instructions carefully.

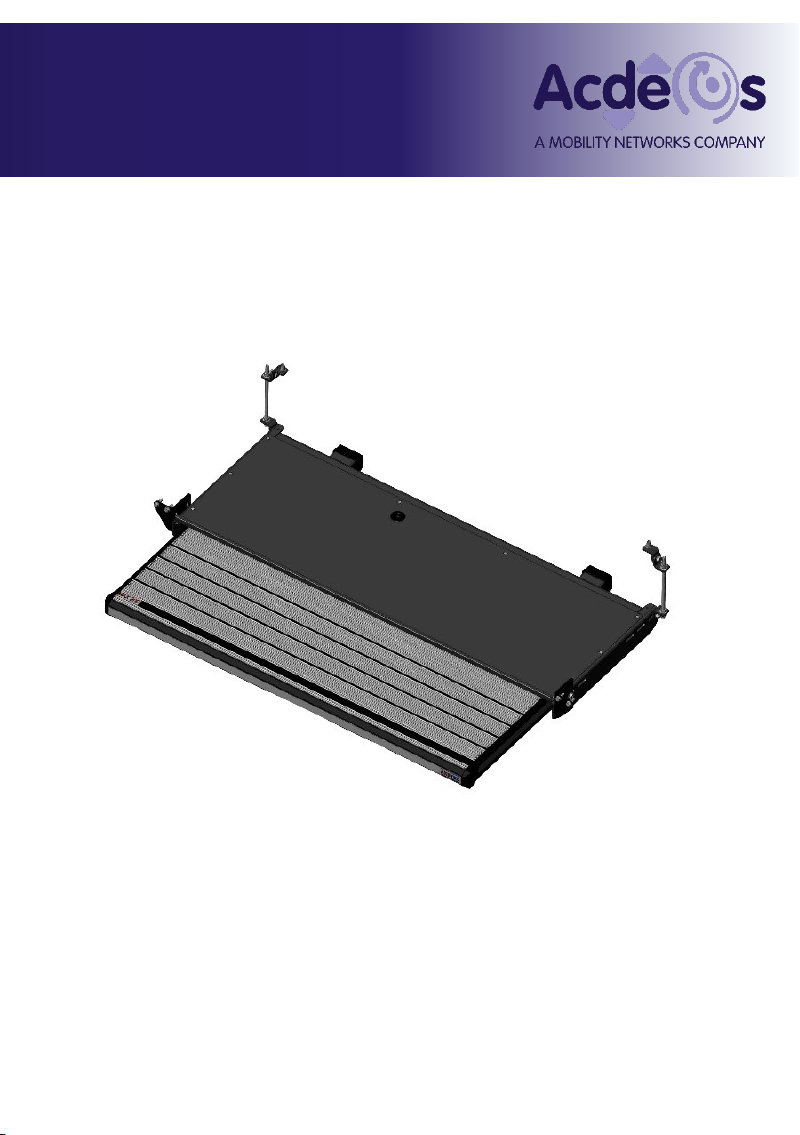

The step is intended to be an extra step to enter a vehicle. It should be used appropriately by

passengers to enter or exit a minibus, taxi camper or other vehicle, and the maximum load

should not be exceeded.

1. Before operating the step the vehicle must be stationary and the hand brake

or parking brake must be applied.

2. Before operating the step, ensure that there is nothing obstructing it. Look out

for people moving outside the vehicle near the step.

3. It is recommended that the step is only operated by the driver or other

qualified operators.

4. The driver or operator must have a clear view of the step when they are

operating it.

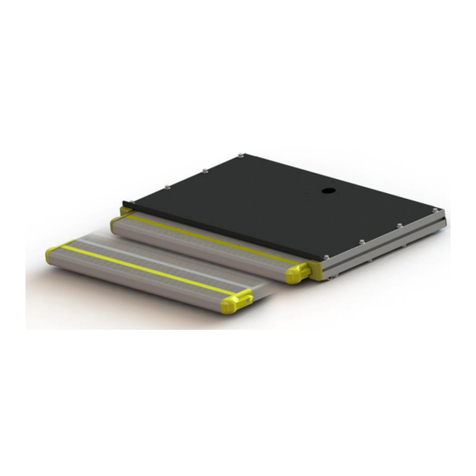

5. It is recommended that the middle of the platform is used when stepping onto

the step.

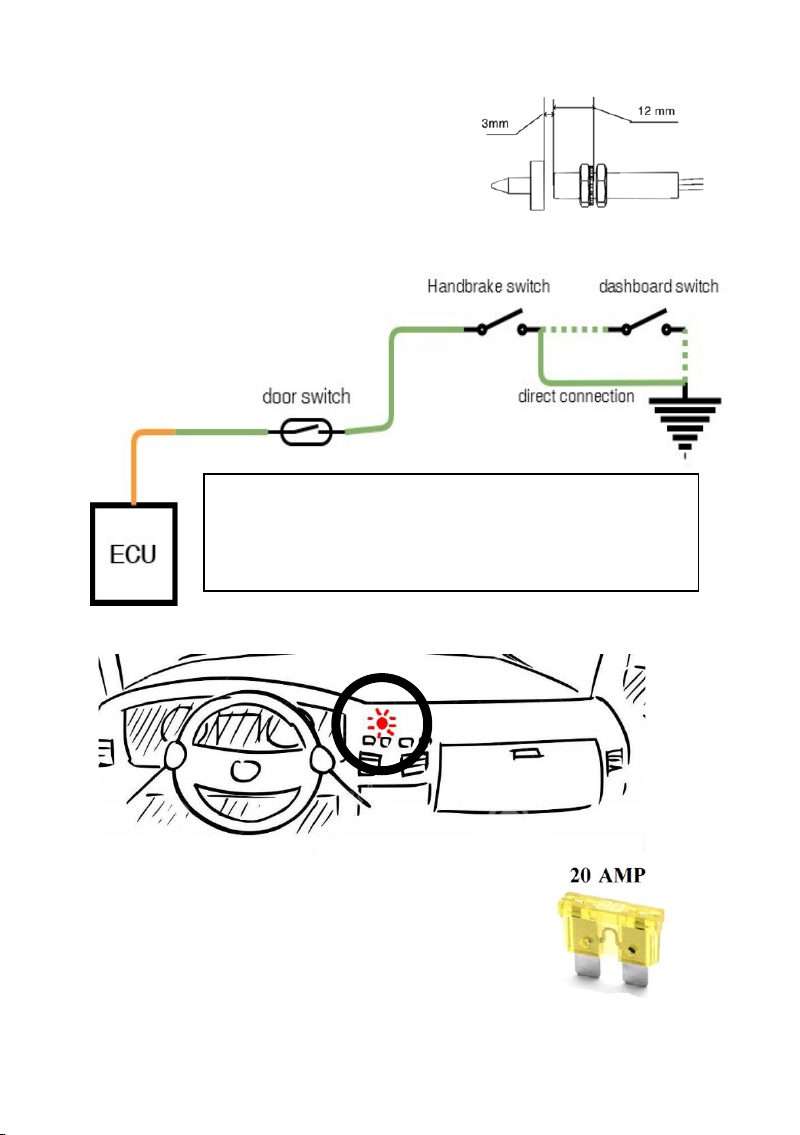

6. NEVER drive away when the RED dashboard LED light is still on, this means

that the step is not properly stowed.

7. The step platform must be kept clean and free of oil and other greasy

materials.

8. If there is any doubt about the safety of a passenger when using the step,

ensure they are assisted.

9. If you have any questions about the safe operation of the step, contact the

person responsible directly.

10. Never use the step for any other use than described here.

11. Never overload the step.

12. The step should always be operated until it is fully in or out.

13. Repair and maintenance must be done by qualified and trained staff only.

14. If any parts need replacing, ensure only original Acdeos Parts are used.

15. If the anti slip profile on the step becomes worn, the step platform must be

replaced.

16. Always use the recommended cleaning materials.

17. Report any unsafe aspects of the step to the step supplier.