AXS –Ramp Manual

AXS FL RAMP Manual rev 1 1

Index

1Technical specifications.................................................................................................1

2Nomenclature ....................................................................................................................2

3Safety instructions...........................................................................................................3

4Constraints.........................................................................................................................4

4.1 Legal requirements: ............................................................................................................................... 4

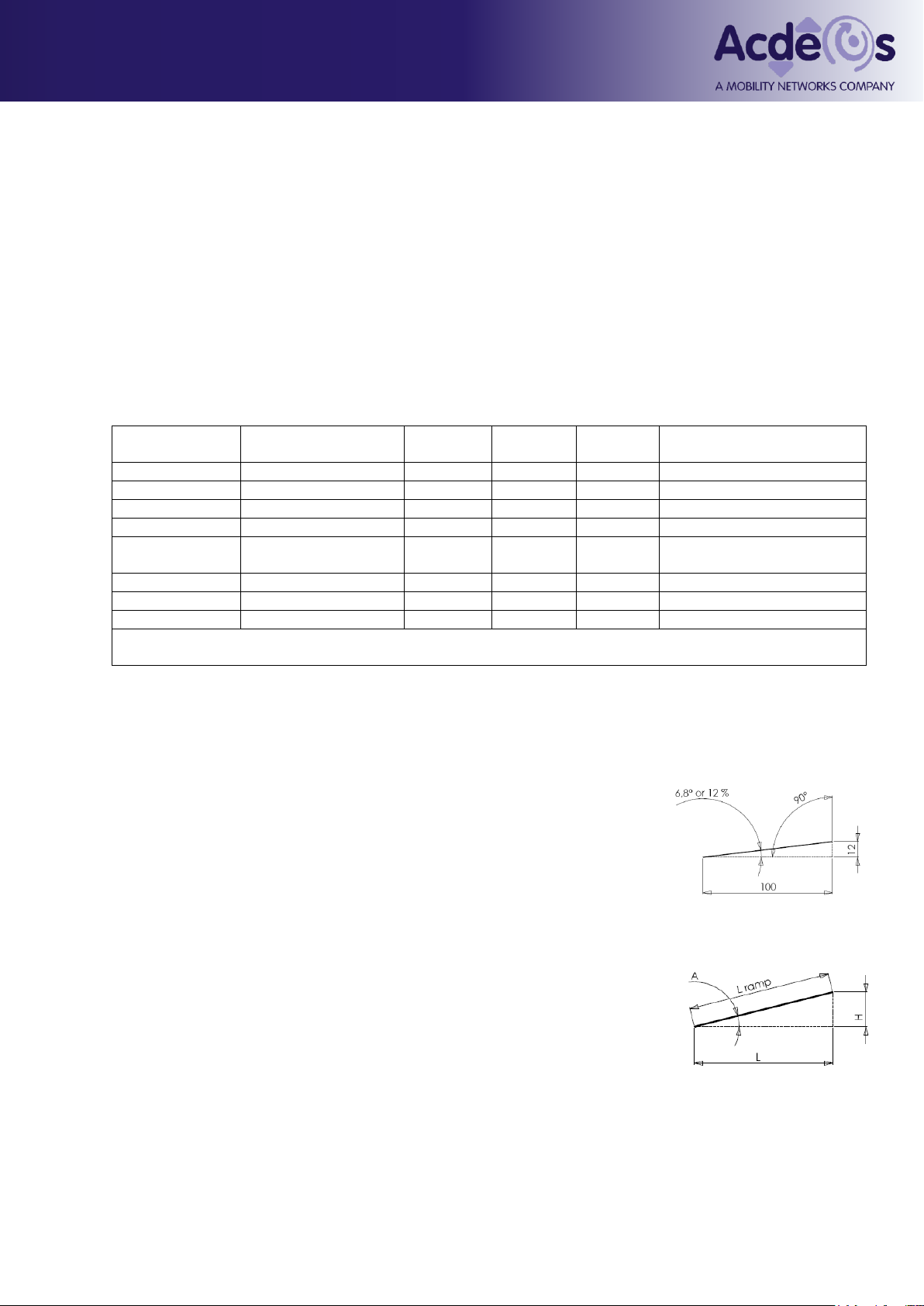

4.2 Slope in % and Deg. .............................................................................................................................. 4

5Operation............................................................................................................................5

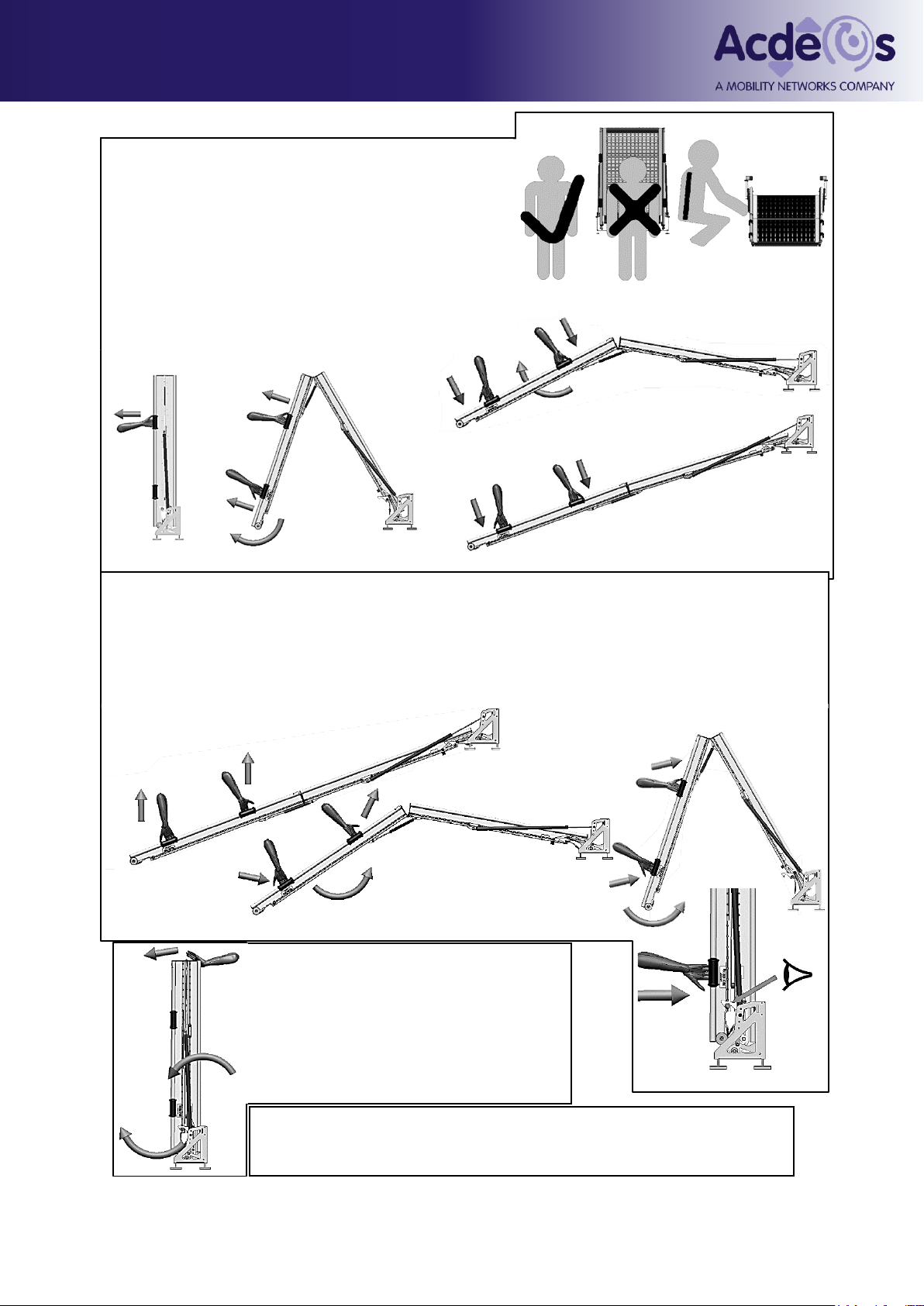

5.1 Deploy Operation procedure ramps with auto lock ................................................................................ 5

5.2 Close operation procedure ramps with auto lock .............................................................................. 5

5.3 Emergency operation procedure ramps with auto lock .................................................................... 5

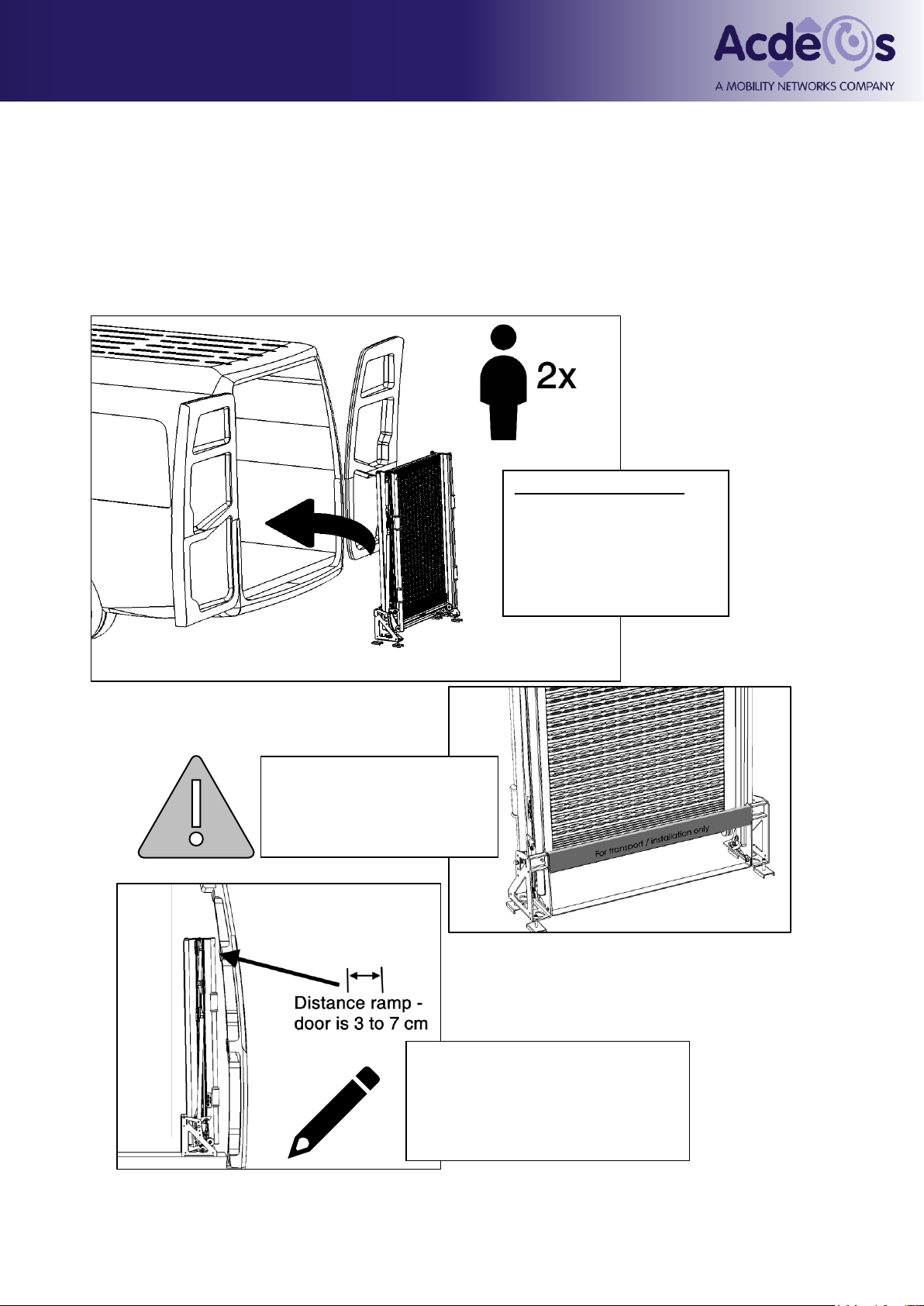

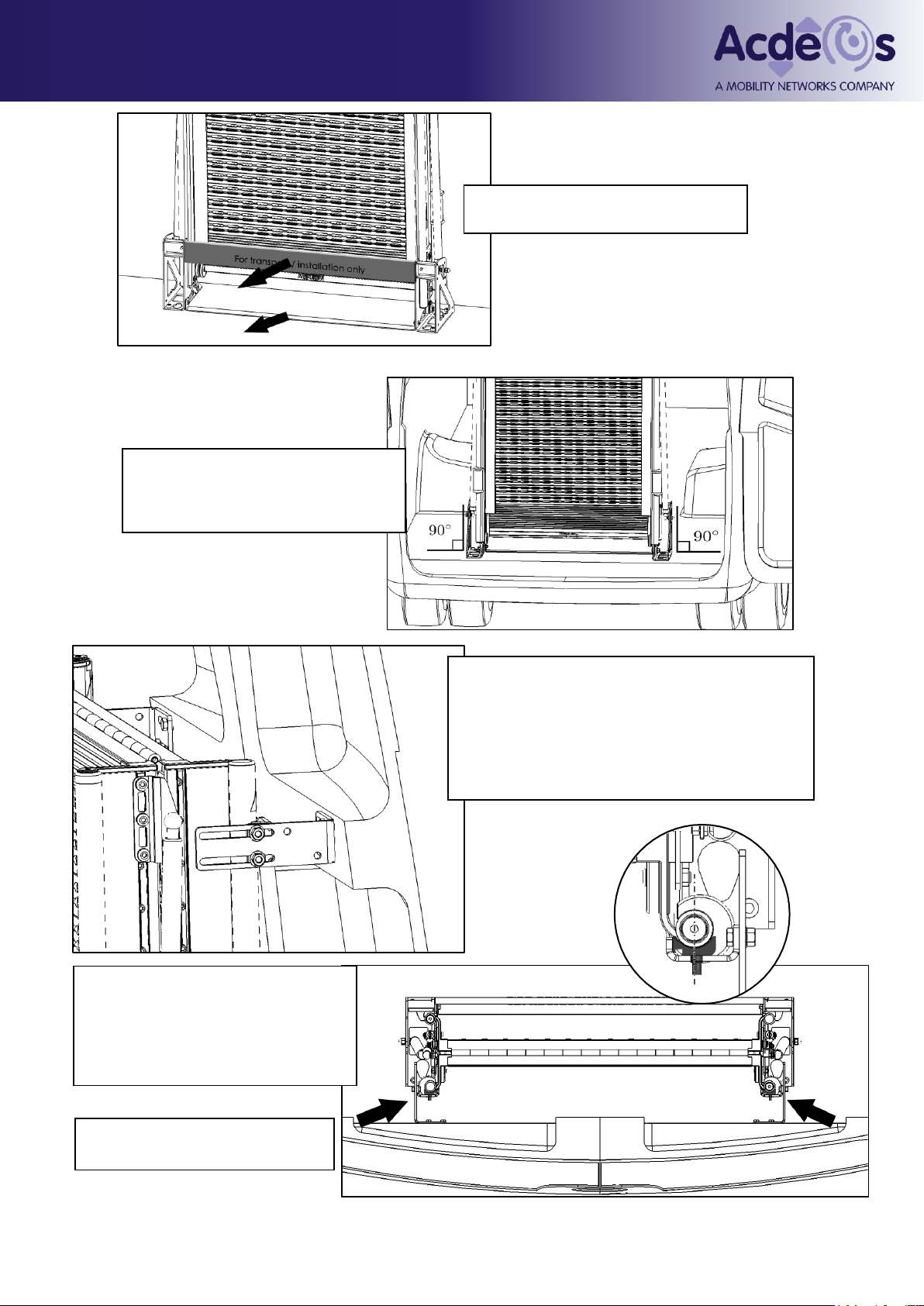

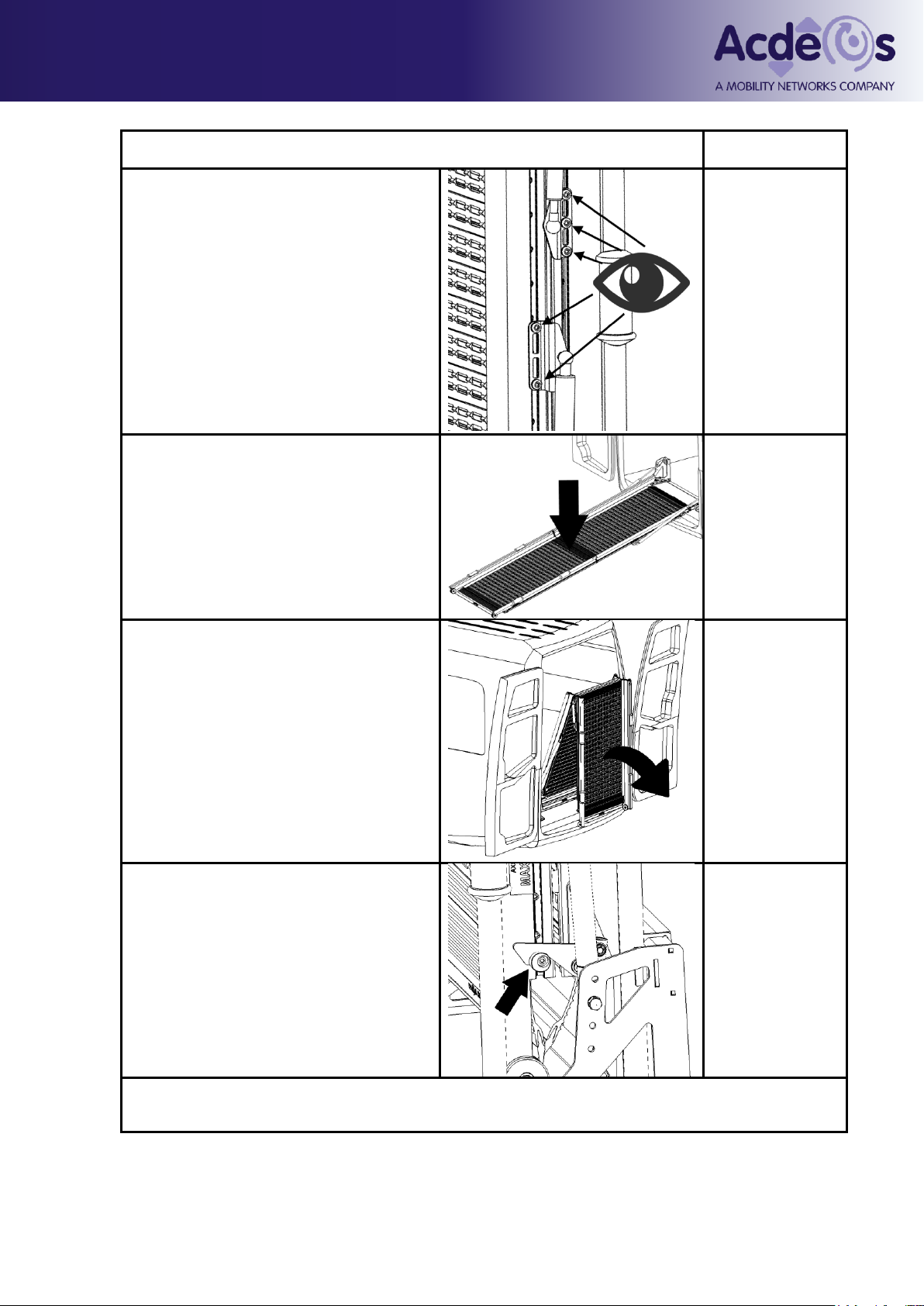

6Mounting / Installation ....................................................................................................6

6.1 Mechanical Installation .......................................................................................................................... 6

Place brackets left and right ............................................................................................................................. 8

The black nylon roll is eccentrically and can be adjusted if the ramp lock is to loose. ............................ 9

7Maintenance.....................................................................................................................24

7.1 Cleaning ................................................................................................................................................ 24

7.2 Periodical maintenance....................................................................................................................... 24

7.3 Yearly inspection .................................................................................................................................. 24

8Repair ................................................................................................................................25

8.1 Replacement of Gas springs .............................................................................................................. 25

8.2Adjustment of the auto lock ................................................................................................................ 27

8.3 Adjustment of the platform.................................................................................................................. 29

9Spare parts.......................................................................................................................30

10 Additional kits..............................................................................................................32

11 Environment .................................................................................................................32

12 CE Certification............................................................................................................33

13 M1 Certification............................................................................................................34

Appendix I; Installation drawing Double ramps:..........................................................36

Appendix II: Drill tool ...........................................................................................................37

1Technical specifications

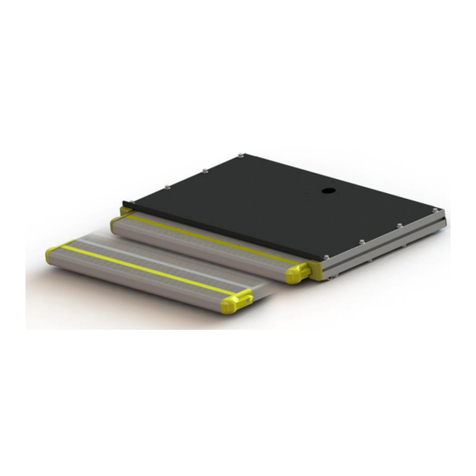

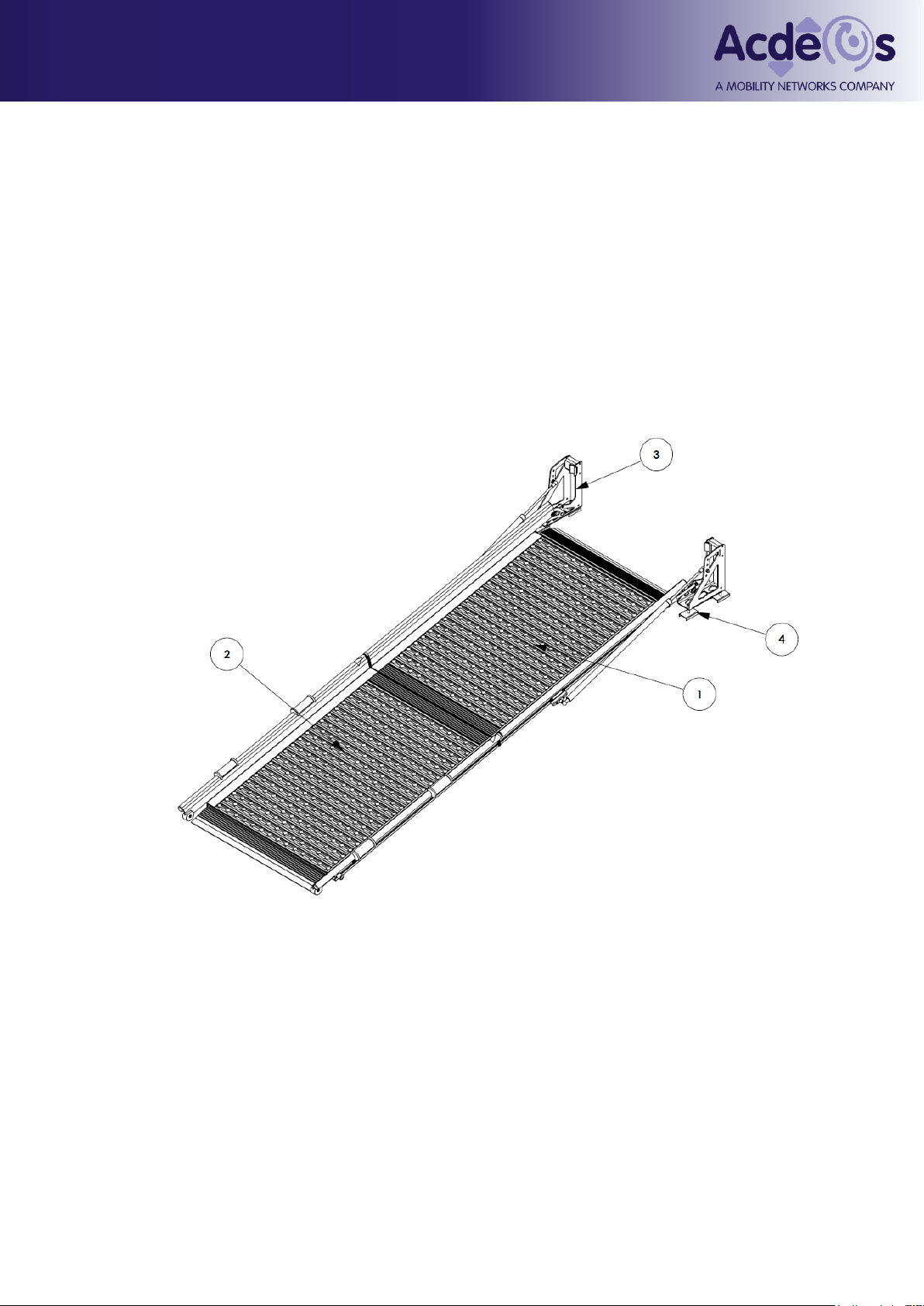

Product description Manual operated wheelchair ramp for vans and mini buses.

Installation On the vehicle Floor at the middle or rear door

Dimensions Ramp length 2100, 2500, 2800 mm

For detailed dimensions please refer to the installation drawings

Weight AXS AR FL 210-8/2 39 Kg

AXS AR FL 250-8/2 45 Kg

AXS AR FL 280-8/2 48 Kg

AXS AR FL 280-10/2 52 Kg

Load Maximum load 400 Kg (4000 N) This is always labeled on the Ramp.

Materials Ramp; Anodized Aluminium structure with Aluminium profile anti-slip platform.

Integrated Aluminium hinge. Mounting points: steel.

Legislation The product complies with the 2006/42/EC and NEN-EN 1756-1