Index

1Technical specifications.................................................................................... 2

2Safety instructions ............................................................................................. 3

3Constraints ......................................................................................................... 3

4Controls .............................................................................................................. 4

4.1 Ramp Control............................................................................................................................ 4

4.2 Signals ...................................................................................................................................... 4

4.3 Legal requirement according 2001-85 EC:............................................................................... 4

4.4 Electrical Components.............................................................................................................. 4

5Operation ............................................................................................................ 4

5.1 Deploy Operation procedure .................................................................................................... 4

5.2 Stow operation procedure ........................................................................................................ 4

6Mounting / Installation ....................................................................................... 5

7Repair .................................................................................................................. 5

7.1 Disassembly ............................................................................................................................. 5

7.2 Assembly .................................................................................................................................. 5

8Environment ....................................................................................................... 5

9Certification ........................................................................................................ 6

10 Spare parts....................................................................................................... 7

11 Appendix 1; Installation drawings: ............ Fout! Bladwijzer niet gedefinieerd.

1 Technical specifications

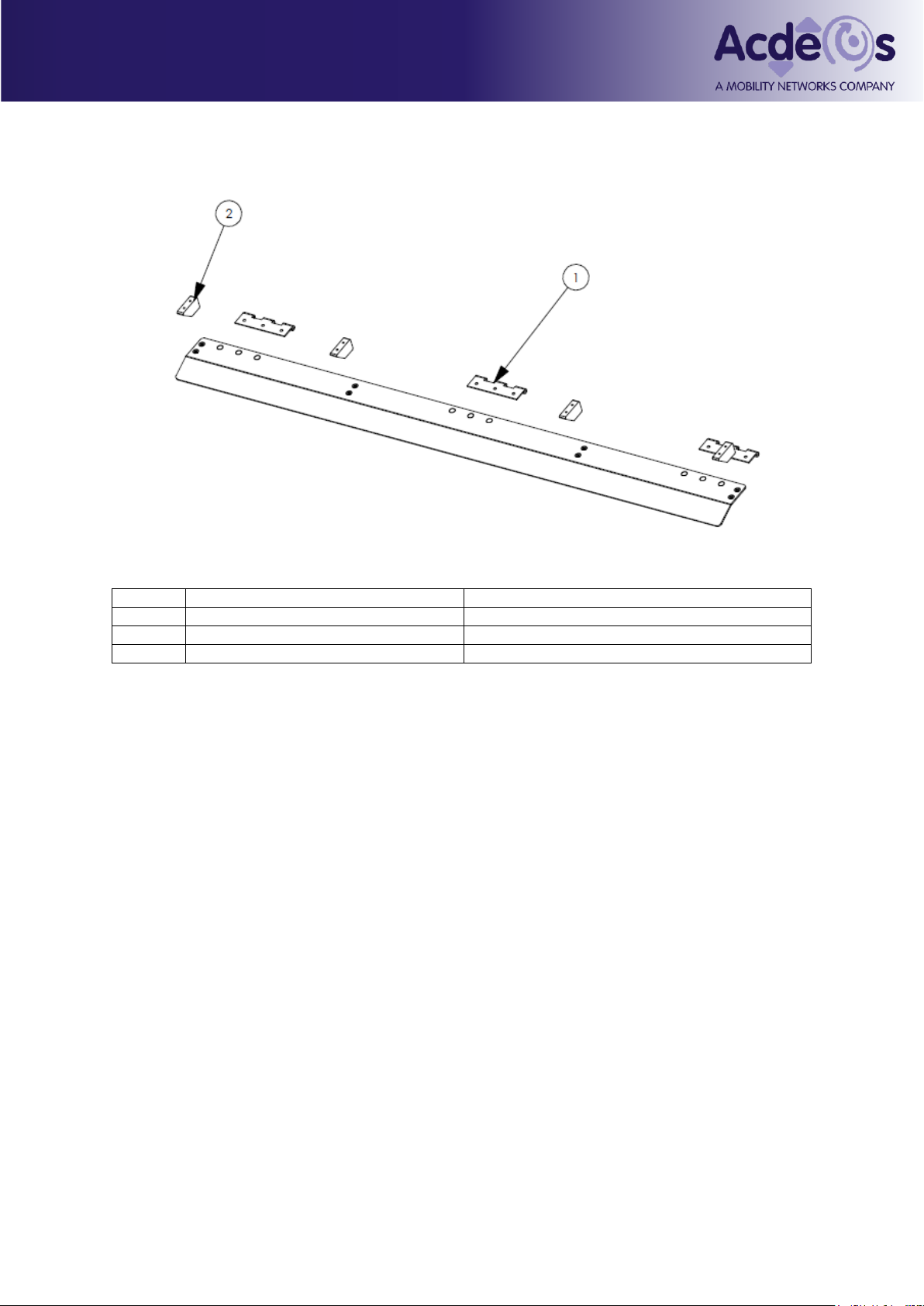

Product description Manual operated ramp for mounting outside under the floor of a vehicle.

Installation Under the vehicle Floor at the front- middle or rear door

Dimensions Ramp length 850 mm/1000mm - width 880 mm

For detailed dimensions please refer to the installation drawings

Weight total 27 Kg.

Load Maximum load 300 Kg (3000 N) this is always labeled on the ramp.

Materials Frame; steel plate work, powder coated.

Ramp: Polyester sandwich plate with Stainless steel edges.

Electric signals following electric signals are available: Ramp closed / stowed.

Legislation The product fulfils 2001/85 EC Bus directive and 98/37 EC Machine directive.