Automation Components, Inc.

2305 Pleasant View Road | Middleton, WI 53562

Phone: 1-888-967-5224 | Website: workaci.com

Page 3

OPERATION

Keypad

The keypad comes in a 2 button, 3 button, 4 button, 5 button,

or 6 button version. A 6 button keypad is needed for fan or

system mode. A 3 button or 5 button keypad is needed for

override mode.

Normal Mode

The LCD can display temperature, RH, occupied status, system

mode, and fan mode. The display conguration can be setup

when ordered or changed through the setup menu. The

backlight will turn on when the any key is pressed and will

turn o 10 seconds after the last key press.

Setpoint Mode

Press or to get into setpoint mode and

change the setpoint. If a temperature and RH setpoint are

used, pressing or and will switch

the large numbers between temperature and RH. If

temperature is displayed in the large numbers, the

temperature setpoint will adjust when or

is pressed. If RH is displayed in the large numbers, the RH

setpoint will adjust when or is pressed. If no

keys are pressed for 10 seconds the unit will automatically

return to normal operation.

Fan/System Mode

Press WWWW to change the fan or system setting. The fan or

system setting will start blinking after WWWW is pressed.

Press WWWW or WWWW and WWWW to switch between the

fan and system modes. The mode that is blinking will change

when WWWW or WWWW is pressed. Press WWWW to return

to normal operation. If no keys are pressed for 10 seconds the

unit will automatically return to normal operation.

Setup Mode

Press and hold WWWW for 5 seconds or press and hold WWW

and WWW for 10 seconds to enter setup mode. Once in the

setup menu, WWWW or WWWW will scroll through the setup

menu. Press WWWW or WWWW and WWW to enter menus.

Press WWW or WWW and WWWW to save menu selections.

GENERAL INFORMATION

The TUC2 provides temperature space monitoring with a

backlit LCD. The TUCH2 provides temperature and relative

humidity monitoring with a backlit LCD. Depending on the

conguration, the units can display and output Temperature,

Relative Humidity, Setpoint, Fan Speed, System Status, and

Occupied/Unoccupied Status.

The TUC2 and TUCH2 supports single temperature sensor

operation for several common sensor types and it provides the

exibility to choose from numerous setpoint output options.

The TUCH2 supports relative humidity output in all standard

analog signals at 2%, 3%, or 5% accuracy. A setup menu

provides easy output and display conguration changes.

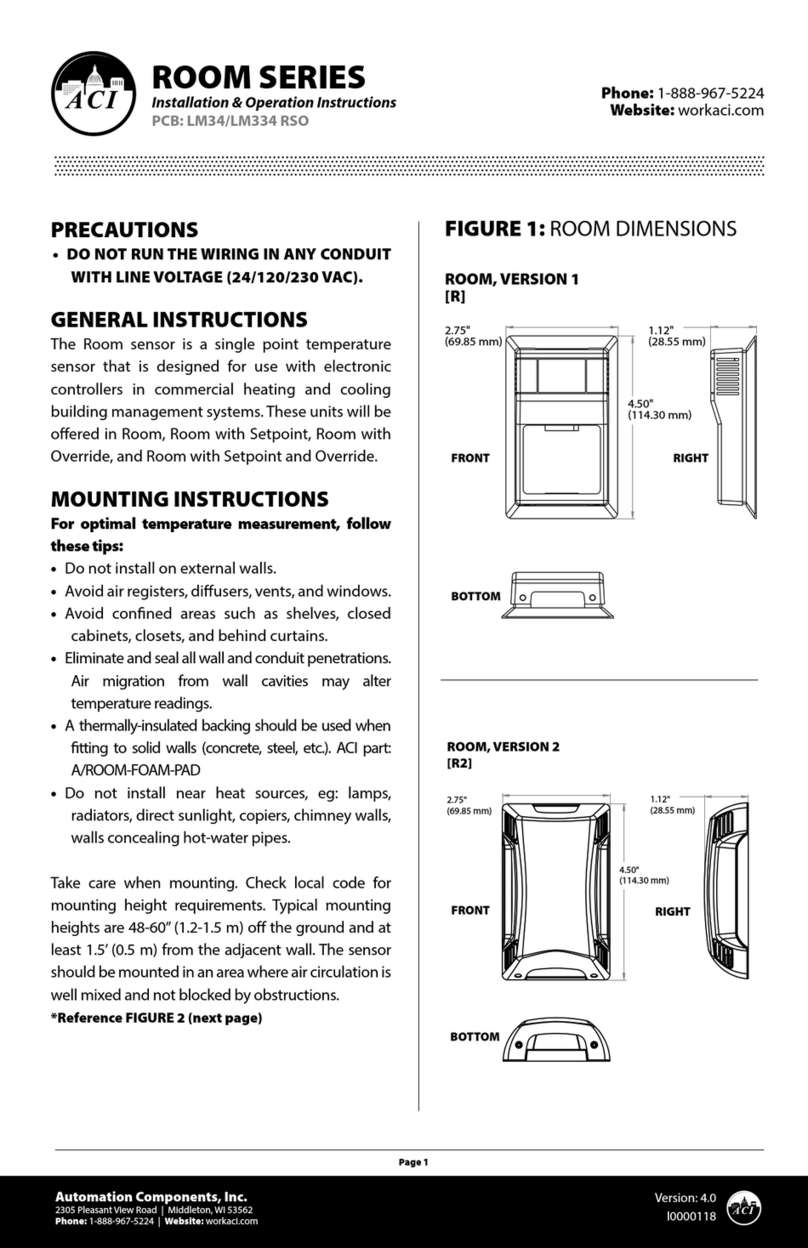

MOUNTING INSTRUCTIONS

Carefully separate the cover from the base by pulling the

cover and base apart towards the bottom of the device. The

hex screws(1/16” Allen) may need to be turned in to release

the cover. Route the wires through the access hole in the

center of the base and screw them into the terminal blocks.

Refer to the wiring instructions to make the necessary

connections. Attach the base directly to drywall, or to a

standard 2”x 4” junction box using the hardware provided.

*Reference FIGURE 2 (p. 2)

WIRING INSTRUCTIONS

PRECAUTIONS

• Do not run the temperature sensor wiring in any

conduit with line voltage (24/120/230 VAC) if utilizing

resistance temperature signal.

• Remove power before wiring. Never connect or

disconnect wiring with power applied.

• When using a shielded cable, ground the shield only at

the controller end. Grounding both ends can cause a

ground loop.

• It is recommended you use an isolated UL-listed class 2

transformer when powering the unit with 24 VAC.

Version: 6.0

I0000621

WIRING INSTRUCTIONS (Continued)

Failure to wire the devices with the correct polarity when sharing transformers may result in damage to any

device powered by the shared transformer.

• If the 24 VDC or 24VAC power is shared with devices that have coils such as relays, solenoids, or other inductors,

each coil must have an MOV, DC/AC Transorb, Transient Voltage Suppressor (ACI Part: 142583), or diode placed

across the coil or inductor. The cathode, or banded side of the DC Transorb or diode, connects to the positive side

of the power supply.Without these snubbers, coils produce very large voltage spikes when de-energizing that can

cause malfunction or destruction of electronic circuits.

Carefully separate the cover from the base by pulling the cover and base apart towards the bottom of the device. ACI recommends

16 to 26 AWG twisted pair wires or shielded cable for all sensors. Be sure to connect the cable shield to the ground at the controller

only. The number of wires needed depends on the application, with 3 wires minimum required to support the outputs of theTUC2

unit. Generally, one wire is required for each output, one wire for power, and one wire for ground. All outputs are common ground

referenced. All wiring must comply with all local and National Electric Codes. After wiring, attach the cover to the base and turn

out the hex screw(1/16”Allen) until the cover cannot be removed. A 1/16”Hex driver is needed to secure the cover to the base.

Note: TUC2 units do not have RH or RHS terminal locations loaded.

Attach the required wires to the proper terminal locations. The TUC2 or TUCH2 supports three signal wires, ring, tip, and

shield. The number of wires needed depends on the application.

Note: ACI’s stats are not two-way communicating. Communication jacks allow the user to query and modify operating

parameters of the local room terminal unit from the portable operator’s terminal (laptop). This feature allows a technician to

commission or service the controller via the sensor.

Temperature Wiring Instructions

Signal wiring must be run separate from low and high voltage wires (24/120/230 VAC). All ACI thermistors and RTD

temperature sensors are non-position sensitive.

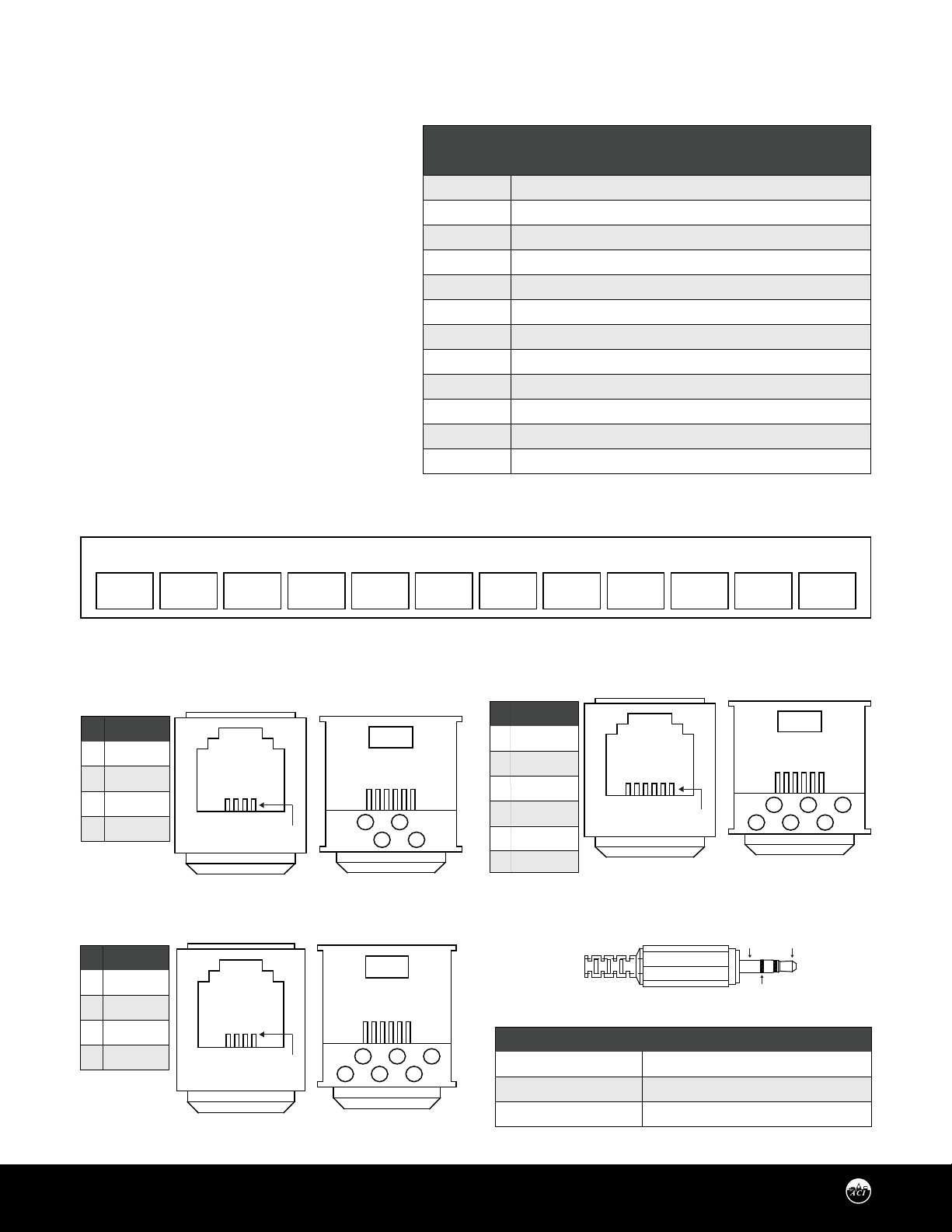

TABLE 1: TERMINAL BLOCK CONNECTIONS

FIGURE 5: 3.5 mm STEREO JACK

TABLE 2: STEREO JACK CONNECTIONS

FIGURE 4: COMMUNICATION JACK

FIGURE 3: TERMINAL BLOCK

WIRING INSTRUCTIONS

(Continued)

Note: If your TUC2 or TUCH2 has any output

congured with a 10V or Current output, the

voltage at the +V terminal must be at least +18

VDC.

Communication Jack Wiring

Before mounting the base to the wall, make the

appropriate connections to the communication

jack as described below. The number of wires

needed depends on the application. Using the

provided wire nuts, attach the required wires to the

proper connector pins used by your application.

*Reference FIGURE 4 (right, below)

+V T TS O/R F/A OFB S1 S2 S3 RH RHSCOM

TERMINAL

BLOCKS

+V

COM

T

TS

O/R

F/A

OFB

S1

S2

S3

RH

RHS

CONNECTIONS

+12 to +40 VDC or 20 to 28 VAC

Ground or signal common, 20 to 28 VAC

Temperature sensor signal to controller analog input

Temperature set point signal to controller analog input

Override signal to controller analog input

Fan signal to controller analog input

Occupied feedback signal from controller analog input

3.5 mm phone jack ring / Digital input or output

3.5 mm phone jack tip / Digital input or output

3.5 mm phone jack shield

RH signal to controller analog input

RH set point or system signal to controller analog input

# COLOR

1 BLACK

2 RED

3 GREEN

4 YELLOW

# COLOR

1 BLUE

2 BLACK

3 RED

4 GREEN

5 YELLOW

6 WHITE

*Reference FIGURE 3 (below)

2

1

4

3

6

5

1 3

2 4

1 3

2 4

FRONT VIEW REAR VIEWWIRING

# COLOR

1 BLACK

2 RED

3 GREEN

4 YELLOW

(4.1): 4 PIN, 4 CONNECTOR FRONT VIEW REAR VIEWWIRING

(4.2): 6 PIN, 6 CONNECTOR

FRONT VIEW REAR VIEWWIRING

(4.3): 6 PIN, 4 CONNECTOR

PIN 1

PIN 1

PIN 1

SHIELD TIP

RING

TERMINAL BLOCKS

S1 Terminal

S2 Terminal

S3 Terminal

JACK CONNECTIONS

Ring

Tip

Shield

OPERATION (Continued)

Setup Mode (Continued)

Press WWW to return to the previous menu. If no keys are pressed for 15 seconds the unit will automatically return to normal

operation.

Setup Menu

The full setup menu with descriptions of all the options is shown on page 6. The setup menu will change depending on the

conguration ordered. Only the menu options that apply to the conguration ordered will be shown. For instance, if no Fan

or System were ordered then those menu options would not appear.

Setup Lockout

In the setup menu there is an option to lockout setup mode. This can be used if you do not want users to change the setup.

Once the setup menu is locked, press WWW and WWW for 10 seconds to get into setup mode.

FULL SETUP MENU

The full setup menu with descriptions of all the options are shown on page 5. The setup menu will change depending on the

conguration ordered. Only the menu options that apply to the conguration ordered will be shown on the unit.

Press and hold SETUP for 5 seconds or press the UP arrow and DOWN arrow for 10 seconds to enter the Setup mode.

Press UP/DOWN arrows to scroll through top level menus.

Press SELECT to enter into Options Menus

Press UP/DOWN to scroll through Options Menu

Press SELECT to chose and save option in Options Menu

A full size version of this diagram can be found at:

www.workaci.com