The Probe sensor may be mounted using a 1/4”

mounting clip (ACI Item #108169) on walls or with

cable ties along pipes.

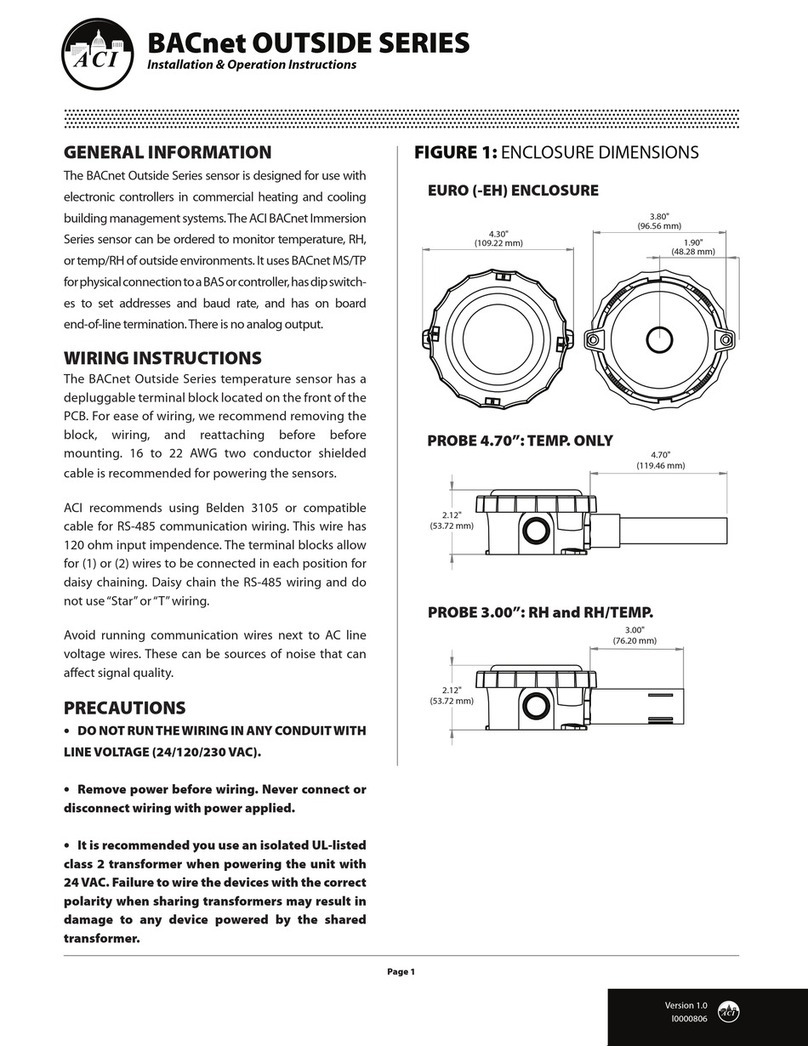

PIPE MOUNTING

For best accuracy and increased thermal conduction

between the pipe and the sensor, ACI recommends to

clean the pipe with an emery cloth or le, before

applying thermal grease. Be sure to insulate the probe

(from the eects of the ambient air) after tightly

fastening to the pipe.

PROBE ASSEMBLY ON PIPE

To x the sensor along a pipe, use cable ties to mount

the sensor probe and wires on the pipe - see Figure 1.

The sensor probe should be mounted under any insulation in direct contact with the pipe using metal pipe

straps. For proper measurement of temperature, thermal conductive compound should be used in

between the sensor probe and the pipe. The installation should be wrapped with insulation to reduce the

eect of ambient air. The plastic housing of the sensor can either be mounted on the pipe with metal pipe

strap or wall mounted.

Locate and record the sensor ID numbers located on a label inside the unit prior to mounting.

The sensor has a Low Battery LED that will start to blink continuously when the battery voltage is low. A low

battery signal is also sent to the receiver for remote indication that the battery should be replaced. If the

battery is not replaced in approximately 2 months, the battery voltage will become so low that the Low

Battery and Data-Link LEDs will not blink. Replace the battery and the Data-Link LED will start blinking

while the sensor is re-establishing communications with the receiver.

Then attach the cover of the sensor by installing the four screws.

Automation Components, Inc.

2305 Pleasant View Road | Middleton, WI 53562

Phone: 1-888-967-5224 | Website: workaci.com

Page 2

Version: 5.0

I0000684

GENERAL INFORMATION

The SST2630 is a battery operated wireless temperature sensor that can be used as a remote probe for monitoring

refrigeration or strap-on for pipes using the reliable 900MHz spread spectrum technology for communication. The

sensing element is in a 2”, 0.25” O.D. stainless steel probe with a 20’ cable length that will be able to cover most duct

applications. The SST2630 is available with a standard or NEMA 4X enclosure. The SST2630 will send the temperature

wirelessly to the RM2432D receiver, which converts the wireless signal to voltage for use with a DDC controller, or to

a transceiver that will send the data to a BAS using BACnet, Modbus, or Lonworks protocol. Transmission distance in

a typical building is 200-300 feet horizontal depending on the layout and construction of the building, and one oor

above and one oor below the transceiver. Sensor distance and reliability can be increased with the addition of a

RR2552B(s) repeater.

Wireless remote/strap-on sensors should be installed within 200 to 300 feet of the receiver. RR2552 signal

repeaters can be installed as needed to increase transmission distance between sensors and receivers.

For optimal temperature measurement, follow these tips:

•Do not install on external walls.

•Avoid air registers, diusers, vents, and windows.

•Eliminate and seal all wall and conduit penetrations. Air migration from wall cavities may alter temperature

readings.

•Do not install near heat sources. eg: lamps, radiators, direct sunlight, copiers, chimney walls, walls

concealing hot-water pipes.

MOUNTING INSTRUCTIONS

PRECAUTIONS

SENSORS, REPEATERS AND RECEIVERS SHOULD NOT BE INSTALLED IN THE FOLLOWING AREAS:

• INSIDE METAL ENCLOSURE / PANEL

• INSIDE OR IMMEDIATELY NEXT TO ELEVATOR SHAFT / ELEVATOR BANKS

• IN FRONT OF OR IMMEDIATELY NEXT TO LARGE TREES OR LARGE BODY OF WATER

TRANSMISSION DISTANCE AND PERFORMANCE WILL BE DRASTICALLY REDUCED.

To select the proper sensor location, rst install and power the receiver. To activate the sensor insert the

battery observing the polarity.

While the sensor is attempting to connect to the receiver the Data-Link LED will blink rapidly 8–10 times

every 10 seconds. Once a connection has been established, the Data-Link LED will blink once to indicate

the data transmission has been received successfully. The Data-Link LED will continue to blink once for

every data transmission. The data transmission rate is programmed into the sensor (normally 1 minute

intervals). To manually initiate a data transmission press the push button switch located by the negative

terminal of the battery.

FIGURE 1: BULLET PROBE (-BP)

ASSEMBLY

CABLE TIE CABLE TIE PIPE

PIPE

BULLET PROBE

BULLET PROBE

INSULATION ADDEDBARE ASSEMBLY

INSULATION ADDED

TO COVER BULLET PROBE