GENERAL SAFETY INFORMATION

WARNING: ROTATING PARTS & ELECTRICAL SHOCK HAZARD

Fans should be installed and serviced by qualied personnel only.

Improper installation can result in electric shock, possible injury due to

coming in contact with moving parts, as well as other potential hazards.

1. Follow all local electrical and safety codes, as well as National

Electrical Code (NEC) and the National Fire Protection Agency

(NFPA), were applicable.

2. Disconnect electric power before working on unit (prior to removal

of guards or entry into access doors).

3. Follow proper lockout/tag out procedures to ensure the unit

cannot be energized while being installed or serviced.

4. Ensure the power cable does not kink or come in contact with oil,

grease, hot surfaces or chemicals. Ensure the power source is

compatible with the equipment.

5. Air that is allowed to move through a non-powered fan will

allow the propeller to rotate, which is referred to as wind-milling.

Impellers should be blocked to prevent rotation when installing or

servicing the fan.

TRANSPORTING

If transporting fan in an open vehicle the propeller should be blocked

to prevent rotation. If not the speed of the air owing through the fan

may cause the propeller to go above its max safety speed limits which

can damage the fan.

RECEIVING AND INSPECTION

Immediately upon receipt of a shipment, carefully inspect for damage

and shortage. Turn the impeller by hand to see that it turns freely and

does not bind. If any damage and/or shortage is detected or suspected,

the carrier must be asked to conduct an inspection. The consignee’s

representative should not accept a shipment without a notation on the

delivery receipt indicating items not delivered or the apparent extent

of damage.

When a shipment is opened and damage is found which was not evi-

dent externally (concealed damage), it is mandatory that the consign-

ee request an immediate inspection by the carrier. Report any damage

to the carrier within 15 days. Failure to report damage within the above

time limit will result in rejection of a claim.

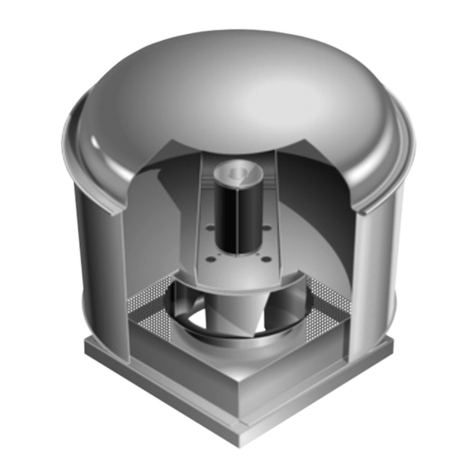

HANDLING

When handling fans and their accessories, always use equipment

and methods that will not cause damage. Fans should be lifted using

slings and padding or spreaders to avoid damage.

CAUTION! Always make sure that all lifting and handling equipment

and techniques conform to current safety standards.

Avoid lifting fans in a way that will bend or distort fan parts. Never pass

slings or timbers through the orices of fan.

CAUTION! Do not lift by the fan hood. Fans with special coatings or

paints must be protected in handling to prevent damage.

STORAGE

Fans are protected against damage during shipment. If they cannot

be installed and put into operation immediately upon receipt, certain

precautions are necessary to prevent deterioration during storage.

Responsibility for integrity of fans and accessories during storage must

be assumed by the user. The manufacturer will not be responsible

for damage during storage. These suggestions are provided solely

as a convenience to the user, who shall make his own decision as to

whether to use any or all of them.

INDOOR: The ideal storage environment for fans and accessories is

indoors, above grade, in a low humidity atmosphere which is sealed to

prevent the entry of blowing dust, rain, or snow. Temperatures should

be evenly maintained at between 70°F and 105°F (wide temperature

swings may cause condensation and “sweating” of metal parts). Win-

dows should be covered to prevent temperature variations caused by

sunlight. Provide thermometers and humidity indicators at several

points and maintain the atmosphere at 40% relative humidity, or lower.

It may be necessary to use trays of renewable desiccant or portable

dehumidier to remove moisture from the air in the storage enclosure.

Thermostatically controlled portable heaters (vented to outdoors) may

be required to maintain even temperatures inside the enclosure.

CAUTION! Provide re extinguishers, re alarms, or emergency re-

sponse communication to protect building and equipment against re

damage. Be sure that building and storage practices meet all local,

state and federal re and safety codes.

The following fans or accessories must be stored indoors, in a clean

dry atmosphere:

a. Propeller wall fans not in wall housings.

b. Any fan protected by a cardboard carton.

c. Motors dismounted from fans.

d. Spare wheels or propellers.

e. Belts, sheaves, bushings and other parts when not mounted

on fan.

f. Boxes, bags or cartons of hardware.

g. Curbs

h. Shutters

Remove any accumulations of dirt, water, ice or snow and wipe dry

before moving to indoor storage. Allow cold parts to reach room tem-

perature to avoid “sweating” of metal parts. Open boxes or cartons.

Remove any accumulated moisture; if necessary use portable electric

heaters to dry parts and packages. Leave coverings loose to permit

air circulation and to permit periodic inspection.

Rotate impeller by hand to distribute bearing grease over the entire

bearing surfaces.

Store at least 3 ½” o the oor on wooden blocks covered with moisture

proof paper or polyethylene sheathing. Provide aisles between parts

and along all walls, to permit air circulation and space for inspection.

OUTDOOR: Fans designed for outdoor use may be stored outdoors,

if absolutely necessary. The storage area should be reasonably level

and drained or ditched to prevent accumulation of water. Fencing and

lighting for security are desirable. Roads or aisles for portable cranes

and hauling equipment are needed. Consider the use of drift fencing

to minimize accumulation of blowing snow or dirt.

The following fans may be stored outdoors, if dry indoor storage space

is not available:

a. Fans intended for outdoor use that are crated in wood.

b. Wall fans installed in wall housings.

All fans must be supported on wooden blocks or timbers above water

or normal snow levels. Provide enough blocking to prevent settling

Read and Save These Instructions

Form 613163

INSTALLATION & MAINTENANCE INSTRUCTIONS

Models FQ, FQWBP, FQWCP, FQ-R, FQ-RWBP, FQ-RWCP,

FN, FNWBP, FNWCP, FN-R, FN-RWBP and FN-RWCP