MODELS VQL400 • VQL500 • VQL700

Page 4

ACME ENGINEERING & MANUFACTURING CORP.

P.O. Box 978

Muskogee, Oklahoma 74402

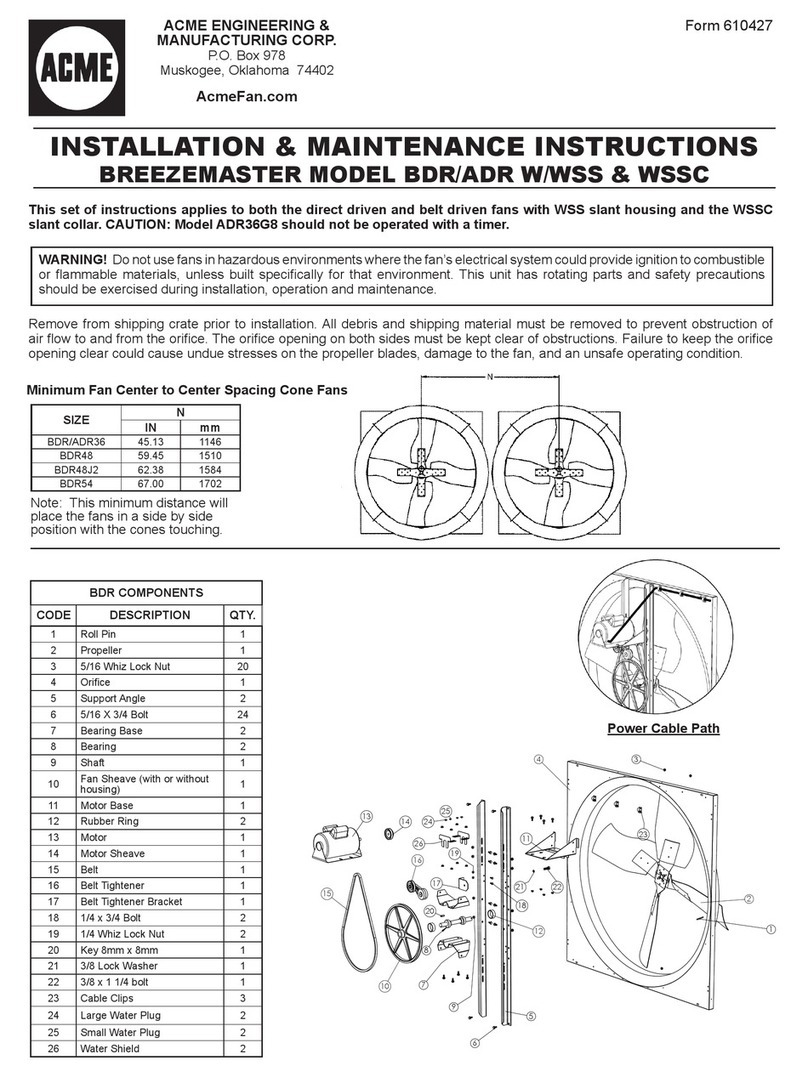

SERVICE PARTS SERVICE PARTS

KEY NO. PART NO. DESCRIPTION

1 97014744 Housing Assembly

2 97014728 Mounting Bracket (2 req.)

3 98009449 Duct Connector (2 req.)

4 97014822 Damper Flap Assembly (2 req.)

5 99150415 Screw, 8-18 x ¼ (18 req.)*

6 98005512 Wiring Plate

7 99150471 Ground Screw, 10-32 x ½ (2 req.)

8 98005513 Wire Box Cover

9 99400035 Strain Relief Bushing

10 97006039 Wire Harness

11 99260477 Nut, ¼-20 (12 req.)*

12 97014745 Scroll Assembly (2 req.)

13 99110805 Blower Wheel, (2 req.)

14 98009399 Inlet Ring (2 req.)

15 99080486 Motor (VQL400)

99080487 Motor (VQL500)

99080488 Motor (VQL700)

16 97014794 Motor Mounting Bracket

17 99100497 Rubber Isolator (4 req.)

18 99160380 Screw, 10-24 x 7/8 (4 req.)*

19 99250399 Washer (4 req.)*

20 99260306 Nut, Hex 10-24 (4 req.)*

21 99250254 Washer (4 req.)*

22 93260456 Nut, Hex Flange 3/8-16

23 98009461 Scroll Mounting Channel

--- ------------- Blower Assembly, Complete

(Includes Key Nos. 5 & 11-23)

97014817 (VQL400)

97014819 (VQL500)

97014821 (VQL700)

24 98009464 Access Panel

25 99420470 Access Panel Nut (4 req.)

26 99150472 Access Panel Mounting Screw (4 req.)

27 99150591 Screw, 10-16 x 7/8 (4 req.)

Order replacement parts by PART NO. - not by KEY NO.

* Standard hardware - may be purchased locally.

1

2

3

5

23

13

14

12 12

8

6

9

24

15

7

14

13

16

17

18

19

20

21

22

11

10

26

25

5

5

211

27

4

11

5

11

3

WARRANTY

5

BLOWER

ASSEMBLY

610603 March 2006 99042755F

LIMITED WARRANTY

WARRANTY AND DISCLAIMER: the Company extends this limited warranty to the original purchaser and warrants that products supplied by the Company, shall be free from original defects in workmanship and materials

for two years from date of shipment (except for the warranty periods noted for products listed below), provided same have been properly handled, stored, installed, serviced, maintained and operated. This warranty shall

not apply to products which have been altered or repaired without the Companys express authorization, or altered or repaired in any way so as, in the Companys judgment, to affect its performance or reliability, nor which

have been improperly installed or subjected to misuse, negligence, or accident, or incorrectly used in combination with other substances. The Purchaser assumes all risks and liability for results of use of all products.

LIMITATION OF REMEDY AND DAMAGES: All claims under this warranty must be made in writing and delivered to P. O. Box 978, Muskogee, Oklahoma, 74402, within 15 days after discovery of the defect and prior to the

expiration of two years from the date of shipment by the Company of the product claimed defective, and Purchaser shall be barred from any remedy if Purchaser fails to make such claim within such period.

Within 30 days after receipt of a timely claim, the Company shall have the option either to inspect the product while in Purchaser’s possession or to request Purchaser to return the product to the Company at Purchaser’s

expense for inspection by the Company. The Company shall replace, or at its option repair, free of charge, any product it determines to be defective, and it shall ship the repaired or replacement product to Purchaser F.O.B.

point of shipment; provided, however, if circumstances are such as in the Companys judgment to prohibit repair or replacement to remedy the warranted defects, the Purchaser’s sole and exclusive remedy shall be a refund

to the Purchaser of any part of the invoice price, paid to the Company, for the defective product or part.

The Company is not responsible for the cost of removal of the defective product or part, damages due to removal, or any expenses incurred in shipping the product or part to or from the Companys plant, or the installation

of the repaired or replaced product or part.

The warranties set forth above do not apply to any components, accessories, parts or attachments manufactured by other manufacturers; such being subject to the manufacturers warranty, if any. To the extent not prohibited

by the manufacturers warranty, the Company shall pass through to Purchaser such manufacturers warranty.

THE COMPANYS WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESS OR IMPLIED, ARISING BY LAW OR OTHERWISE, INCLUDING WITHOUT LIMITATION THE IMPLIEDWARRANTIES OF MERCHANT-

ABILITY AND FITNESS FOR A PARTICULAR PURPOSE, WHICH ARE HEREBY EXPRESSLY DISCLAIMED AND WAIVED. THIS WARRANTY CONSTITUTES THE COMPANYS SOLE AND EXCLUSIVE WARRANTY

FOR DEFECTIVE GOODS AND PURCHASERS SOLE AND EXCLUSIVE REMEDY FOR DEFECTIVE PRODUCTS.

No employee, agent, dealer, or other person is authorized to give any warranties on behalf of the Company or to assume for the Company any other liability in connection with any of its products except in writing and

signed by an officer of the Company.

REPLACEMENT PARTS If replacement parts are ordered, purchaser warrants that the original components in which these replacement parts will be placed are in satisfactory working condition, and when said replacement

parts are installed, the resultant installation will operate in a safe manner, at speeds and temperatures for which the original product was purchased.

TECHNICAL ADVICE AND RECOMMENDATIONS, DISCLAIMER: Notwithstanding any past practice or dealings or any custom of the trade, sales shall not include the furnishing of technical advice or assistance or system

design. Any such assistance shall be at the Companys sole option and may be subject to additional charge.

The Company assumes no obligation or liability on account of any recommendations, opinions or advice as to the choice, installation or use of products. Any such recommendations, opinions or advice are given and shall

be accepted at Purchaser’s and End User’s risk and shall not constitute any warranty or guarantee of such products or their performance.

LIMITATION OF LIABILITY The cumulative liability of the Company to the Purchaser and any other persons for all claims in any way relating to or arising out of the products, including, but not limited to, any cause of action

sounding in contract, tort, or strict liability, shall not exceed the total amount of the purchase price paid for those products which are the subject of any such claim. This limitation of liability is intended to apply without regard

to whether other provisions of this agreement have been breached or have proven ineffective even if the Company has been advised of the possibility of such claims or demands. In no event shall the Company be liable

to the Purchaser or any other person for any loss of profits or any incidental, special, exemplary, or consequential damages for any claims or demands brought by the Purchaser or such other persons.

INDEMNITY The Companys maximum liability to Purchaser and to any end user is as set forth above. The Company makes no warranty to anyone for any products not manufactured by the Company and shall have

no liability for any use or installation of any products (whether manufactured by the Company or other manufacturers) not specifically authorized by this sale. Purchaser acknowledges various warnings by the Company

regarding the products and its installation and use. If the Company incurs any claims, lawsuits, settlements, or expenses (including attorney fees) for any loss, injury, death or property damage including, but not limited to,

claims arising out of the Purchasers or any end users installation or use of the products, the Purchaser shall indemnify and hold the Company harmless.

Acme products are designed and manufactured to provide reliable performance but they are not guaranteed to be 100% free of defects. Even reliable products will experience occasional failures and this possibility should

be recognized by the Purchaser and all End Users. If these products are used in a life support ventilation system where failure could result in loss or injury, the Purchaser and all End Users should provide adequate back-up

ventilation, supplementary natural ventilation or failure alarm system, or acknowledge willingness to accept the risk of such loss or injury.

WARNING DO NOT use in HAZARDOUS ENVIRONMENTS where fans electrical system could provide ignition to combustible or flammable materials unless unit is specifically built for hazardous environments. Comply with

all local and national safety codes including the National Electrical Code (NEC) and National Fire Protection Act (NFPA).

CAUTION Guards must be installed when fan is within reach of personnel or within eight (8) feet (2.5 m) of working level or when deemed advisable for safety.

DISCLAIMER The Company has made a diligent effort to illustrate and describe the products accurately in all Company literature; however such illustrations and descriptions are for the sole purpose of identification and do

not express or imply any warranty.

WARNING