TC 120 682.98767.00 • 10/04/2018 v

Pump Starter ......................................................................................................25

Transformer .......................................................................................................25

Heater Contactor................................................................................................25

Cooling ..............................................................................................................25

Electricals ..........................................................................................................26

Automatic Vent ..................................................................................................26

Pressure Switch .................................................................................................26

4-2 The Microprocessor Controller ................................................................................. 26

Controller Display ...............................................................................................27

Digital Flow Meter ..............................................................................................28

4-3 Identifying Graphic Panel Indicators (Eurotherm only) ............................................. 28

POWER ON Indicator ........................................................................................28

PUMP OVERLOAD Indicator .............................................................................28

HEATER ON Indicator .......................................................................................29

OVER TEMPERATURE Indicator ......................................................................29

COOLING VALVE ON Indicator .........................................................................29

LOW WATER PRESSURE Indicator ..................................................................29

VENT CYCLE Indicator ......................................................................................29

PURGE VALVE ON Indicator .............................................................................29

Units with Optional System Purge ......................................................................29

4-4 Using Graphic Panel Buttons ................................................................................... 30

START Button ....................................................................................................30

STOP Button ......................................................................................................30

VENT Button ......................................................................................................30

QUICK COOL Switch .........................................................................................30

ALARM SILENCE Button ...................................................................................30

AIR PURGE Switch ............................................................................................30

LOCAL/REMOTE Switch ...................................................................................30

4-5 Alarms ..................................................................................................................... 30

Audible/Visual General Fault Alarm ...................................................................30

4-6 Controller Internal Switches ..................................................................................... 31

CHAPTER 5: STARTUP AND OPERATION ............................ 32

5-1 Introduction .............................................................................................................. 32

5-2 Startup Checklist ..................................................................................................... 32

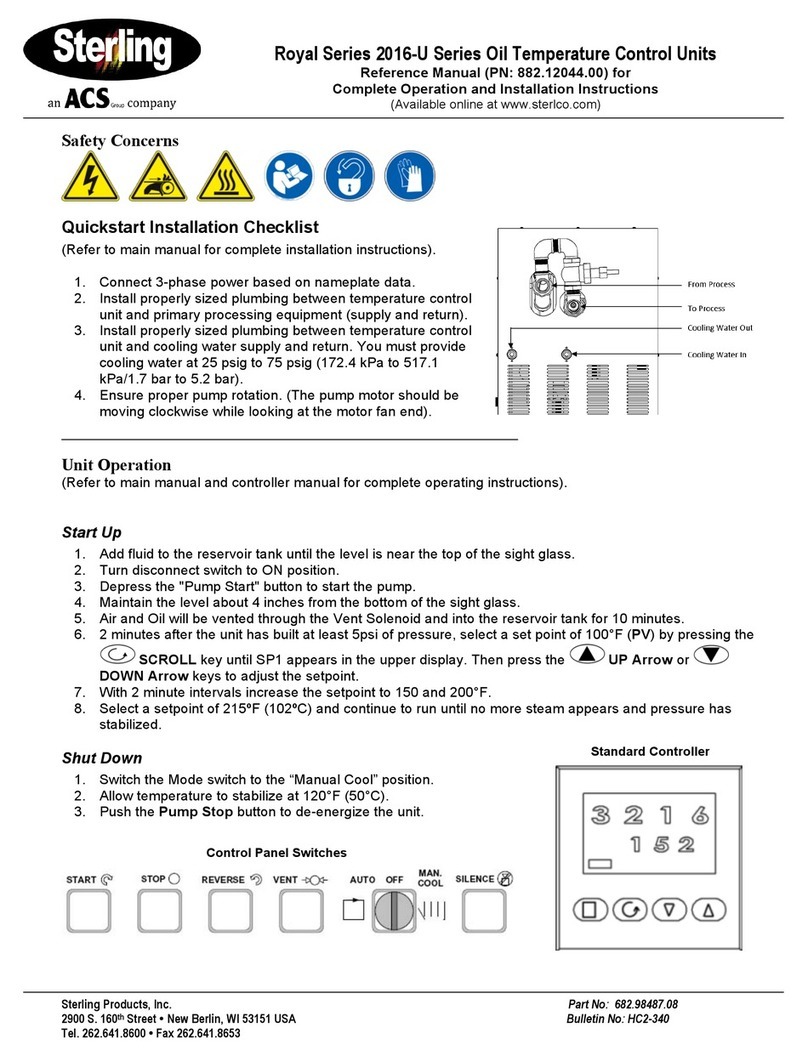

5-3 Starting the Temperature Control Unit ..................................................................... 33

5-4 Sequence of Operation ............................................................................................ 34

5-5 Checking Motor Rotation Direction .......................................................................... 34

5-6 Shutting Down the Temperature Control Unit ........................................................... 35

CHAPTER 6: UNIT MAINTENANCE ........................................ 36

6-1 Preventative Maintenance ....................................................................................... 36

Draining .............................................................................................................36

Every Six Months ...............................................................................................36

6-2 Corrective Maintenance ........................................................................................... 37

Pumps and Seals ...............................................................................................37

Heaters ..............................................................................................................38

Solenoid Valves .................................................................................................38

6-3 Electrical Connections ............................................................................................. 38

6-4 Safety Devices ......................................................................................................... 39