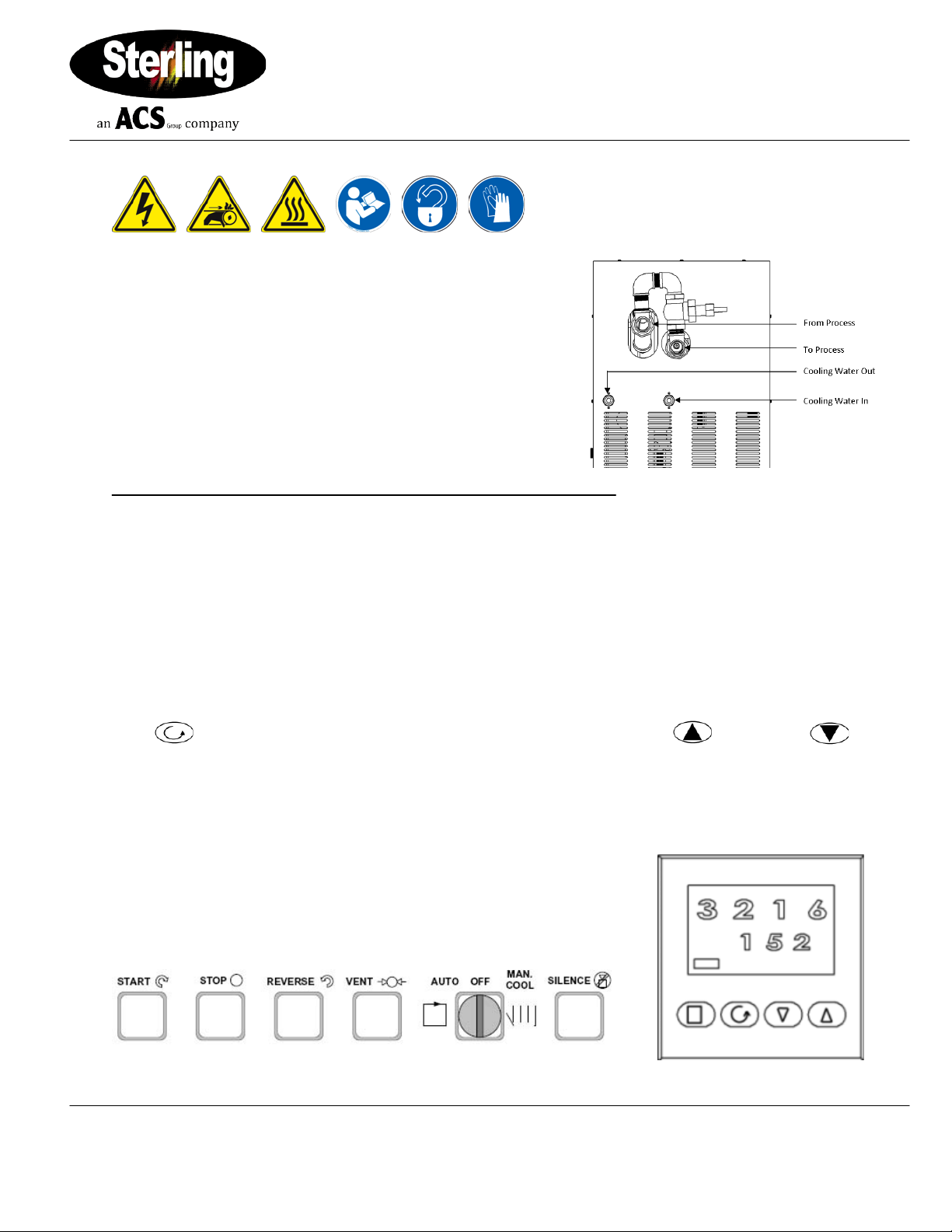

Royal Series 2016-U Series Oil Temperature Control Units

Reference Manual (PN: 882.12044.00) for

Complete Operation and Installation Instructions

(Available online at www.sterlco.com)

Sterling Products, Inc. Part No: 682.98487.08

2900 S. 160th Street • New Berlin, WI 53151 USA Bulletin No: HC2-340

Tel. 262.641.8600 •Fax 262.641.8653

Troubleshooting - Quick Guide

Check main disconnect, fuses, wiring, and power lead to unit.

Wrong voltage supplied to unit

Voltage must be within plus or minus 10% of nameplate rating

Defective START push button

Control circuit fuse blown

Defective control transformer

Check transformer. Replace if necessary.

Broken or loose wire in pump motor control

circuit

Pump motor contactor holding coil is open

Reset and test each leg for balanced amp draws

Temperature

fluctuations/rapid cycling

from hot to cold.

Undersized connectors/lines.

Increase size of connectors/fluid lines.

Long connecting lines between unit and mold.

Move the unit closer to the process and shorten connecting

lines.

Check process for debris or deposits. Clean mold.

Carbon build-up in unit piping or fittings.

Clean or replace affected piping. Replace fluid.

Unit overheats or does not

cool.

Water supply to unit is turned OFF.

Water drain is plugged or excessive back

pressure in drain line.

Clear drain line or eliminate back pressure condition.

Heat exchanger tubes plugged by lime

deposits.

Remove tube bundles; clean/replace as required.

Test solenoid valve by switching to Manual Cool mode and

listen for valve operation. Replace if faulty.

Unit does not heat

properly/cannot achieve

set point.

Loss of fluid in process.

Check all lines/connections/fittings.

Allow vent timer to run out; or, check valve operation when unit

is cold by opening the fill port.

Faulty/dirty solenoid valve; usually detected

when there is a steady stream or trickle of

water out of the drain line.

Switch to Manual Cool mode several times to flush valve. If the

leak continues, disconnect the power to the unit, turn off the

water supply, and clean or replace the solenoid.

Defective heater contactor.

Visual inspection of coil and contacts. Repair/replace defective

contactors.

Defective immersion heater.

Check resistance on all three (3) legs of heater with an

ohmmeter. If not all equal, contact factory for replacement

heater.

Check heater tank for scorched/discolored paint. Check

resistance on all three (3) legs of heater with an ohmmeter.

Replace heater as needed.

Controller heater output open.

Check the heater output with an ohmmeter to ground. It should

read in the mega-ohm range. Infinite or zero readings indicate a

defective output.

Rapid drop in pressure/no

pressure.

Leaks in connecting lines.

Inspect/replace faulty line or connection.

Air in circulating lines.

Preform venting sequence in Chapter 3.

Check fluid level in sight glass. Add fluid if required.

Drain water from low point in piping (see Chapter 3), or boil

water off.

Allow vent timer to run out; or, check valve operation when unit

is cold by opening the fill port.

Check motor; rewire if necessary. (See electrical diagrams)

Pump repair/adjustment needed.

Adjust head spacing or replace warn pump components.

Drain water from low point in piping ( see Chapter 3), or boil

water off.

Drain and flush system. Replace fluid.