Content

1 Typographical conventions ...................................................... 6

1.1 Warning signs ..............................................................................................6

1.2 Reference signs ...........................................................................................6

2 Description ................................................................................ 7

3 Identifying the device version .................................................. 9

3.1 Nameplate ....................................................................................................9

3.2 Order details .................................................................................................9

3.3 Accessories (included in delivery) ..............................................................11

3.4 Accessories (optional) ................................................................................11

4 Assembly ................................................................................. 12

4.1 General .......................................................................................................12

4.2 Dimensions ................................................................................................12

5 Installation ............................................................................... 13

5.1 Installation instructions ..............................................................................13

5.2 Electrical isolation ......................................................................................14

5.3 Connection .................................................................................................15

5.4 Connecting a pH combination electrode ...................................................20

6 Operation ................................................................................. 23

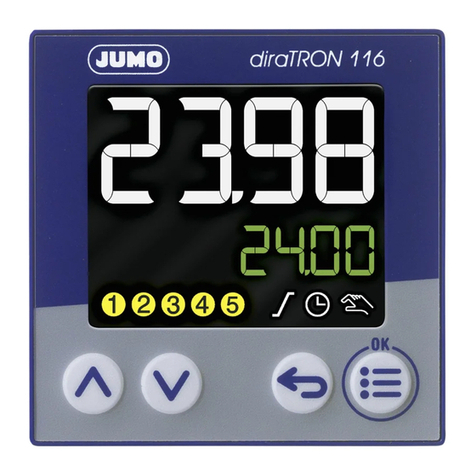

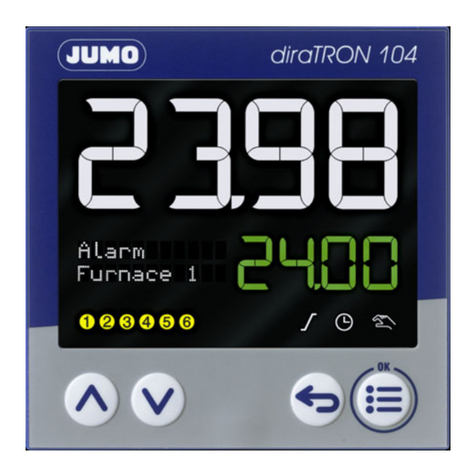

6.1 Controls ......................................................................................................23

6.2 Display .......................................................................................................24

6.3 Principle of operation .................................................................................25

6.4 Measuring mode ........................................................................................28

6.5 Input/output information ............................................................................29

6.6 User level ...................................................................................................34

6.7 Administrator level .....................................................................................35

6.8 MANUAL mode/Simulation mode ..............................................................37

6.9 HOLD mode ...............................................................................................40

7 Commissioning ....................................................................... 42

7.1 Getting started ...........................................................................................42

7.2 Setting examples .......................................................................................43

8 Calibrating a pH measurement chain ................................... 51

8.1 Notes ..........................................................................................................51

8.2 General information ....................................................................................51

8.3 Zero point (1-point) calibration ...................................................................53