6

ADJUSTMENT METHOD

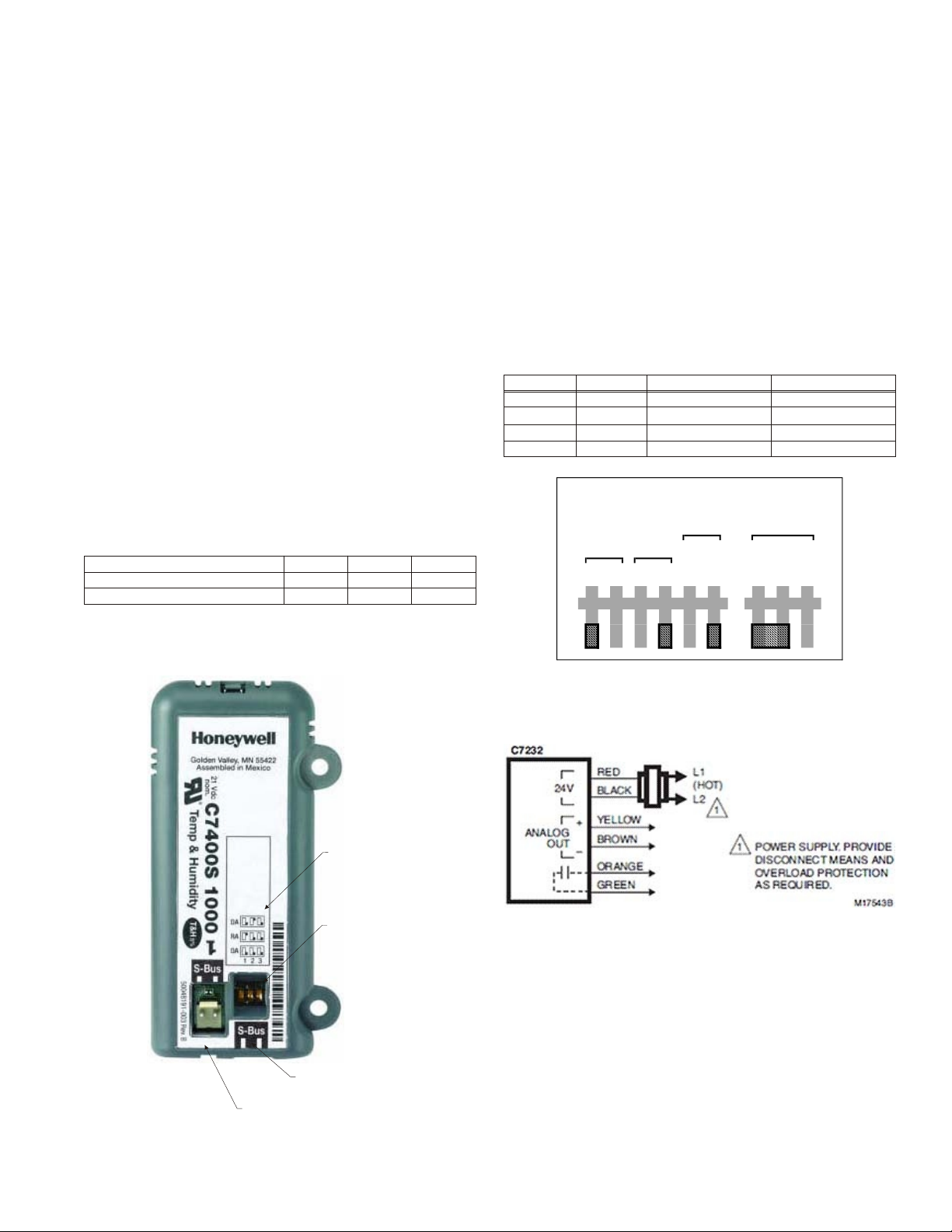

The user interface consists of an LCD display and a

4-button keypad on the front of the Economizer module.

The LCD is a 16 character by 2 line dot matrix display.

Power Up Cycle

All setpoints and advanced settings are restored after any

power loss (a power loss is assumed if voltage falls below

18 Vac). Normal operation is restored when power returns

above 18 Vac.

Initial Menu Display

On initial startup, Honeywell displays on the first line and

Economizer W7220 on the second line. After a brief

pause, the revision of the software appears on the first line

(second line is blank). It then displays W7220 on the first

line and STATUS on the second line.

Keypad

The four navigation buttons illustrated in Figure 9 are used

to scroll through the menus and menu items, select menu

items, and to change parameter and configuration

settings.

Using the Keypad with Menus

To use the keypad when working with menus:

lPress the pbutton to move to the previous menu.

lPress the qbutton to move to the next menu.

lPress the 8button (Enter) to display the first item in

the currently displayed menu.

lPress the Óbutton (Menu up) to exit a menu’s item

and return to the list of menus.

Using the Keypad with Settings and Parameters

To use the keypad when working with Setpoints, System

and Advanced Settings, Checkout tests, and Alarms:

lNavigate to the desired menu.

lPress the 8button (Enter) to display the first item in

the currently displayed menu.

lUse the pand qbuttons to scroll to the desired

parameter.

lPress the 8button (Enter) to display the value of the

currently displayed item.

lPress the pbutton to increase (change) the

displayed parameter value.a

lPress the qbutton to decrease (change) the

displayed parameter value.a

lPress the 8button to accept the displayed value and

store it in non-volatile RAM.

lWhen the value is accepted, CHANGE STORED is

displayed on the LCD.

lPress the 8button (Enter) to return to the current

menu parameter.

lPress the Óbutton (MenuUp/Exit) to return to the

previous menu.

Time-out and Screensaver

When no buttons have been pressed for 10 minutes, the

LCD displays a screen saver, which cycles through the

Status items. Each Status items displays in turn and cycles

to the next item after 5 seconds.

SETUP AND CONFIGURATION

Before being placed into service, the JADE™ Economizer

module must be setup and configured for the installed

system. Use the System Setup menu, the Advanced Setup

menu (if necessary), and the Setpoints menu to

accomplish this.

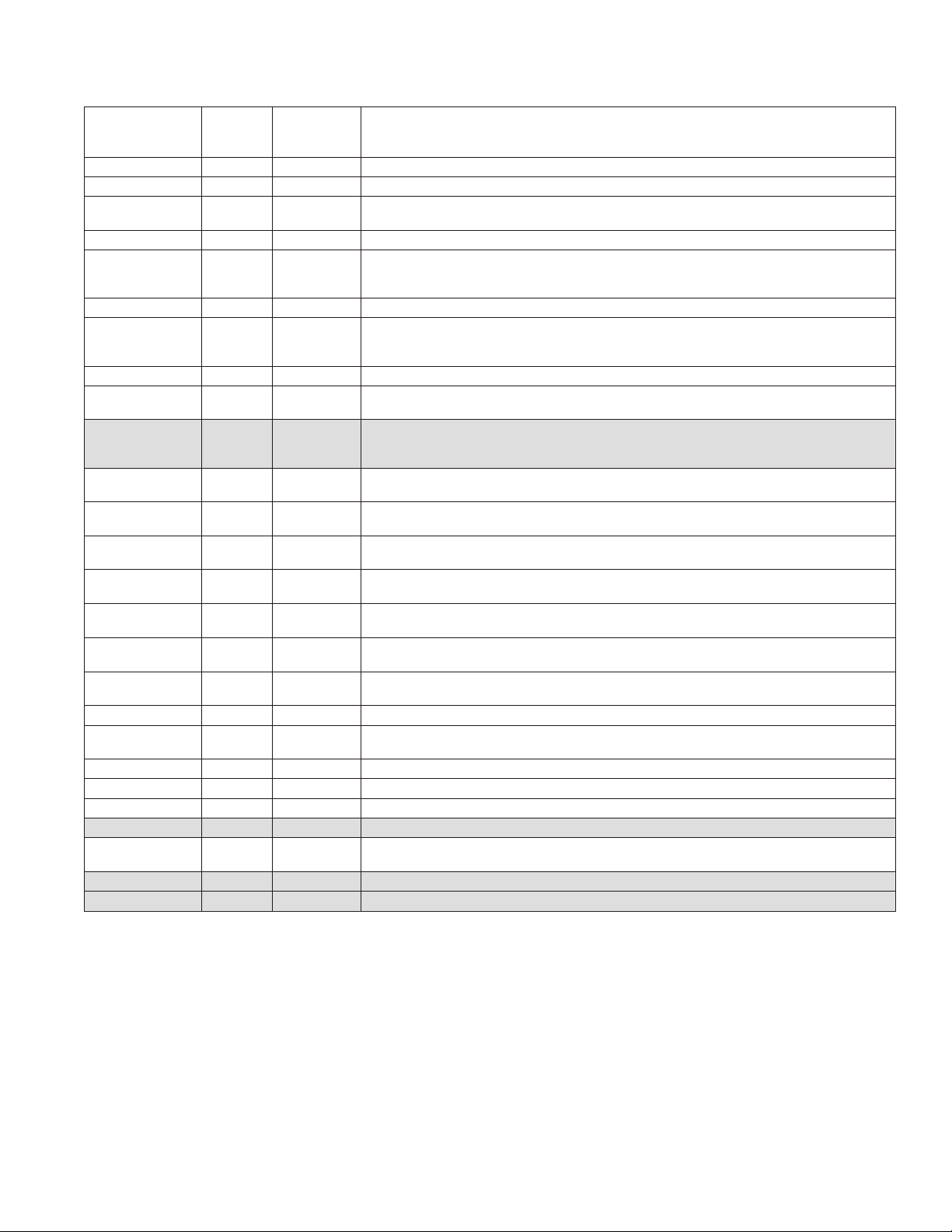

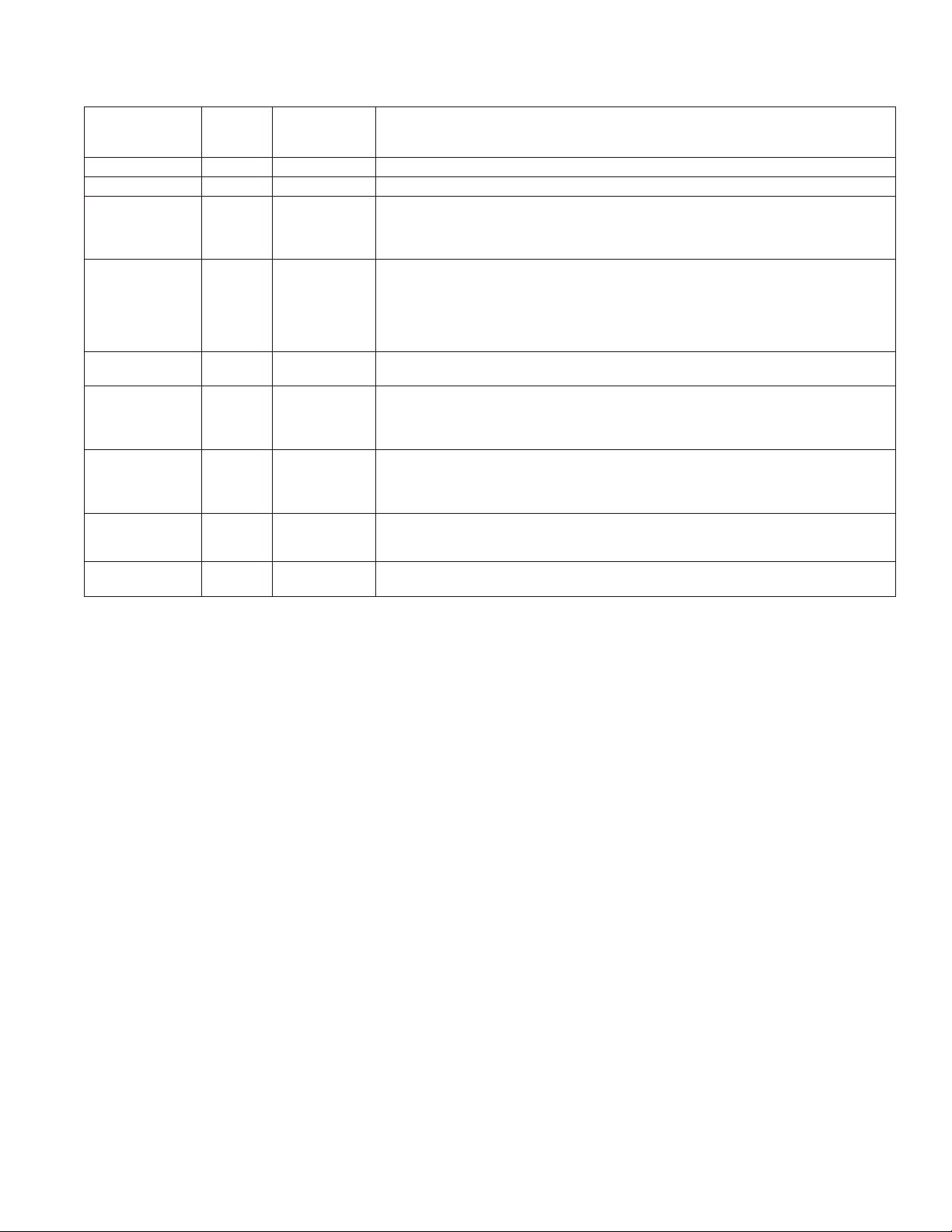

Menu Structure

The following tables illustrate the complete hierarchy of

menus and parameters for the JADE™ Economizer

system.

The Menus in display order are:

lSTATUS

lSETPOINTS

lSYSTEM SETUP

lADVANCED SETUP

lCHECKOUT

lALARMS

IMPORTANT

Your menu parameters may be different depending on

your configuration. For example if you do not have a DCV

(CO2) sensor, then none of the DCV parameters appear.

aWhen values are displayed, pressing and holding the por q button

causes the display to automatically increment.

FIGURE 9