Adaltis NEXgen User manual

Read this operator’s manual carefully before using NEXgen

U

SER

'

S

M

ANUAL

NEXgen User’s Manual

2

T

ABLE OF CONTENTS

1.

Introduction ................................................................................................................................................................ 5

1.1

Identification data ............................................................................................................................................. 5

1.2

Copyright ........................................................................................................................................................... 6

1.3

Conformity to International and European regulations .................................................................................... 6

1.4

Using the manual .............................................................................................................................................. 6

1.5

Symbols ............................................................................................................................................................. 6

1.6

Intended use and general description .............................................................................................................. 7

1.6.1

Intended use ................................................................................................................................................. 7

1.6.2

General description....................................................................................................................................... 7

1.7

Environmental protection instructions ........................................................................................................... 10

1.7.1

Disposal precautions ................................................................................................................................... 10

1.7.2

Decontamination ........................................................................................................................................ 11

1.8

Package contents ............................................................................................................................................ 12

2.

General information ................................................................................................................................................. 14

2.1

Technical specifications ................................................................................................................................... 14

2.1.1

Samples rack ............................................................................................................................................... 14

2.1.2

Disposables rack.......................................................................................................................................... 15

2.1.3

Used tips case ............................................................................................................................................. 16

2.1.4

Reagents rack .............................................................................................................................................. 17

2.1.5

Microplates holder ...................................................................................................................................... 18

2.1.6

IFA slides rack .............................................................................................................................................. 18

2.1.7

Reading system ........................................................................................................................................... 19

2.1.8

Barcode reader ........................................................................................................................................... 20

2.1.9

Barrier sensors ............................................................................................................................................ 21

2.1.10

Microplate robotic arm .......................................................................................................................... 22

2.1.11

Incubators ............................................................................................................................................... 22

2.1.12

Shaker-incubator group optional......................................................................................................... 23

2.1.13

Pipetting system ..................................................................................................................................... 24

2.1.14

Washing system ...................................................................................................................................... 25

2.1.15

Workstation minimum requirements ..................................................................................................... 28

2.1.16

Operating System specifications ............................................................................................................ 28

2.1.17

Application software specifications ........................................................................................................ 28

2.1.18

Sizes ........................................................................................................................................................ 28

2.1.19

Environmental requirements for operation ........................................................................................... 28

2.1.20

Power requirements ............................................................................................................................... 29

2.1.21

Consumption .......................................................................................................................................... 29

NEXgen User’s Manual

3

2.1.22

Connections ............................................................................................................................................ 29

2.2

Precautions and operating limitations ............................................................................................................ 29

2.2.1

General precautions.................................................................................................................................... 29

2.2.2

Health precautions ...................................................................................................................................... 29

2.2.3

Electric safety .............................................................................................................................................. 30

2.2.4

Environmental requirements ...................................................................................................................... 31

2.2.5

Waste disposal ............................................................................................................................................ 31

2.3

Main information for installation by the operator .......................................................................................... 31

3.

Operating procedure ................................................................................................................................................ 34

3.1

Before using the instrument ........................................................................................................................... 34

3.1.1

Safety recommendations ............................................................................................................................ 34

3.1.2

Treatment of samples ................................................................................................................................. 34

3.1.3

Reagents and consumables ........................................................................................................................ 35

3.2

Before programming an assay ........................................................................................................................ 36

3.3

Session programming, running and results ..................................................................................................... 36

3.3.1

Startup screen ............................................................................................................................................. 37

3.3.2

Self-test report ............................................................................................................................................ 38

3.3.3

Main Menu.................................................................................................................................................. 40

3.3.4

Load Session ................................................................................................................................................ 40

3.3.5

Select Tests ................................................................................................................................................. 42

3.3.6

Load samples .............................................................................................................................................. 43

3.3.7

Load reagents.............................................................................................................................................. 66

3.3.8

Load disposables ......................................................................................................................................... 73

3.3.9

Load plates .................................................................................................................................................. 77

3.3.10

Load tanks............................................................................................................................................... 83

3.3.11

Run session ............................................................................................................................................. 86

3.4

End of work ..................................................................................................................................................... 96

3.4.1

Clean the washing system ........................................................................................................................... 97

3.4.2

Empty the waste liquids tank ...................................................................................................................... 97

3.5

Archive .......................................................................................................................................................... 100

3.5.1

Results to be printed ................................................................................................................................. 101

3.5.2

Archived results ........................................................................................................................................ 102

3.6

Self-test report .............................................................................................................................................. 102

3.7

Maintenance ................................................................................................................................................. 103

3.8

System setup ................................................................................................................................................. 105

3.8.1

Resource page ........................................................................................................................................... 105

3.8.2

Operation page ......................................................................................................................................... 106

NEXgen User’s Manual

4

3.8.3

Report layout page ................................................................................................................................... 108

3.8.4

Run page ................................................................................................................................................... 109

3.8.5

Service page .............................................................................................................................................. 111

4.

Maintenance ........................................................................................................................................................... 112

4.1

General rules ................................................................................................................................................. 112

4.2

Responsibilities .............................................................................................................................................. 113

4.3

Daily maintenance procedure ....................................................................................................................... 113

4.4

Weekly maintenance procedure ................................................................................................................... 113

4.4.1

Washer check ............................................................................................................................................ 113

4.5

Monthly maintenance procedure ................................................................................................................. 114

5.

Troubleshooting guide ............................................................................................................................................ 116

5.1

General criteria ............................................................................................................................................. 116

5.2

Self-test system ............................................................................................................................................. 116

5.3

Classification of causes of main malfunctions ............................................................................................... 116

5.3.1

Malfunction caused by a fault in the power supply .................................................................................. 116

5.3.2

Error messages and anomalies about software that can occur during Computer startup and OpenLAB

program run ............................................................................................................................................................ 117

5.3.3

Error messages that can occur during instrument self-test ...................................................................... 117

5.3.4

Error messages due to pipetting system .................................................................................................. 118

5.3.5

Incubators malfunctions ........................................................................................................................... 118

5.3.6

Moving parts malfunctions ....................................................................................................................... 119

5.3.7

Reading system malfunctions ................................................................................................................... 119

5.3.8

Washing system malfunctions .................................................................................................................. 119

5.4

Error messages due to an incorrect session loading ..................................................................................... 119

5.5

Error messages and actions to be taken by the operator ............................................................................. 120

5.6

Responsibilities .............................................................................................................................................. 120

NEXgen User’s Manual

Introduction

5

1. I

NTRODUCTION

1.1 I

DENTIFICATION DATA

This is the Operator’s Manual for the NEXgen instrument, an automatic analyzer for enzyme immunoassay

kits on microplates and IFA kits on slides.

This document must be considered as an integral part of the NEXgen instrument and the information

herein must carefully be read by the operator before using the instrument.

It is strongly recommended to carefully read the content of this Manual before working on the instrument.

the operator must pay particular attention to the Intended use and general description and Precautions

and operating limitations (page 29) paragraphs content and follow the directions included in the present

Manual. In case any possible damages or problems occur, please contact the proper Technical Assistance.

The Manufacturer disclaims any responsibility for partial or unauthorized copies of the present Manual.

Manual

Manual part number

NEX2337V4

.

2

Revision

Rev.

A

Software version

4.2

Date of issue

13/10/2015

Instrument

Instrument

code

NXG

Manufacturer

Adaltis Srl

Via Durini, 27

20122 Milano (Italy)

Tel. +39-0774-5791 - Fax +39-0774-353085

www.adaltis.net

NEXgen User’s Manual

Introduction

6

1.2 C

OPYRIGHT

The Operator’s Manual is an integral part of the NEXgen instrument, its content is the exclusive property of

Adaltis Srl, all rights reserved. Any disclosure, unauthorized copy of its contents or transfer to third-party is

forbidden without having a previous license by Adaltis Srl.

1.3 C

ONFORMITY TO

I

NTERNATIONAL AND

E

UROPEAN REGULATIONS

This document is written in accordance to the UNI EN ISO 18113-3:2012 regulation.

The NEXgen instrument conforms to the 98/79 European Community Directive and subsequent

modifications.

The NEXgen instrument has also been designed in accordance to the following regulations:

Safety

CEI EN 61010

-

1 (E

D

. 20

13

-

1

0)

Electromagnetic compatibility

CEI EN 61326

-

1 (E

D

. 20

13

-

0

7

)

CEI EN 61326-2-6 (E

D

. 2014-06)

1.4 U

SING THE MANUAL

The Manufacturer recommends the operator to read every section of the present Operator’s Manual.

Particular attention must be paid to the NOTES, providing important information for a proper use of the

NEXgen instrument and to the WARNINGS, emphasizing potential risks or dangers deriving from the

instrument use.

In this present manual, the accent color term will be used to identify the blue color that is used by the

software to underline any specific element that has a particular meaning in the current context.

1.5 S

YMBOLS

The following symbols are present on the NEXgen instrument. It is important that the operator knows their

meaning in order to make a proper and safe use of the instrument.

Key to symbols on the external label on the right side of NEXgen

Instrument th

at conforms to the requirements of European Directive for in vitro

diagnostic device (98/79/CE).

In vitro diagnostic device.

Instrument that conforms to the CSA standards for Canadian and American market.

Instrument manufacture

r

date.

NEXgen User’s Manual

Introduction

7

Instrumen

t serial number.

Manufacturer data.

Key to electric and safety symbols on the different parts of NEXgen

Grounding terminal.

RAEE: Electric

-

Electronics Instrument

Separate compulsory collection of waste under

D.L. 25/07/2005 n° 151 (Italy), implementation of 2002/96/EC and 2003/108/EC

Directives.

Warning, read the Manual and pay attention to the safety symbols.

Warning, risk of electric shock.

Warning, hot surface.

Warning, biohazard.

Warning, hands prick/cut danger.

Warning, cru

sh danger.

Warning, laser beam.

1.6 I

NTENDED USE AND GENERAL DESCRIPTION

1.6.1 I

NTENDED USE

The NEXgen is an automated analyzer which comes with the integrated OpenLAB software and it is

designed to simultaneously perform, even on the same samples, ELISA tests on microplates and IFA tests on

slides.

The NEXgen automates every step of the diagnostic tests processes for which it is enabled (dilution and

dispensing of both samples and controls, reagents dispensing, incubation, shaking, washing, reading, results

processing, interpretation and archiving) to be performed quickly, accurately and precisely.

1.6.2 G

ENERAL DESCRIPTION

The NEXgen is an open system able to process both ELISA microplate and IFA slide tests designed for high

volume throughput and multiple assay applications.

NEXgen User’s Manual

Introduction

8

Image 1- NEXgen

The NEXgen is equipped with 3 robotic arms. Two of them are located in the working area, one is used for

pipetting and liquid management, and the other for the wash manifold. The third robotic arm is located

under the working area and devoted to moving the microplates holder and the IFA slides racks both in the

working area and in the reading area.

Each robotic arm has independent movements that do not interfere with the movements of the others.

This gives the NEXgen an extreme advantage for flexibility and independence of the single operations to the

benefit of the execution time of the single sessions.

The NEXgen w rking area is designed to be extremely flexible. Numerous resources configurations can be

loaded on the slots so that, as needed, many samples can be processed against one or more tests or less

samples against many tests. Up to 5 microplates can be loaded on incubators on the working area and 2

additional microplates can be loaded in a compartment equipped with incubator located under the working

area.

NEXgen User’s Manual

Introduction

9

Image 2 - W rking area

The NEXgen is able to process samples both in batch mode and in continuous loading. NEXgen’s batch

mode is able to manage up to 600 samples against one test and 192 samples against multiple tests.

Intermediate configurations depend on the number of samples and tests. By decreasing the number of

tests, the number of samples increases.

The NEXgen is also able to process up to 20 IFA slides per run. In this case, the maximum number of

samples is related to the IFA slides configuration in terms of number of wells, considering the capacity of 5

racks, each can hold 4 IFA slides. The NEXgen can also run both ELISA and IFA tests in the same session.

Image 3 - ELISA and IFA c nfigurati n

NEXgen carries out the diluti n and dispensing procedures by using a double channel pipetting system that

allows the system to dispense the liquids in an extremely short time. The advantage is to minimize the

NEXgen User’s Manual

Introduction

10

“drift” effect across the plate in addition to a reduction of the execution times of each single session. The

use of the 1000 µL and 200 µL standard disposable tips eliminates carryover. The flow sensor, together with

a modern electronics, enables the 2 pipettors to precisely and unequivocally control both the quantity of

aspirated/dispensed liquids and the detection of possible clots in the sera.

The NEXgen wash stati n, on the working area, and the incubators positioned under the 5 microplates

enable it to follow the incubation times of the single strips for each microplate as stated in the Instruction

for use. While a strip is being washed, the others are incubated until the end. This unique feature of the

NEXgen instrument, together with the high speed liquids dispensing, minimizes the “drift” effect.

NEXgen is equipped with a 8-channel manif ld that uses short dispensing needles and long aspirating

needles. Washing cycles, volume and soak time are programmable. In the case of IFA slides, the 1000 µL tip

carries out the wash buffer dispensing into each single well while the manifold carries out the aspiration.

NEXgen is equipped with 5 incubat rs located in the working area under the microplates and 2 incubat rs

located under the working area. The incubators work in a temperature range from room temperature to 42

°C. The 5 incubators located under the microplates enable all test steps to be performed without moving

the microplate into specific areas.

Under the working area, NEXgen can be equipped with a relevant compartment - optional - that can

contain from 1 to up 4 positions with shakers and incubators. The shaking ranges from 200 to 1000 rpm.

NEXgen handles 5 different wash buffers plus 1 of distilled water.

The internal waste tank capacity is 8 liters of waste liquids.

The microplate is read by means of a state of the art LED reading system that is designed to guarantee high

performances, low maintenance, large measurement range and excellent reproducibility. The optics gives a

high resolution scan, 29 readings per each well and a fast reading, 8 seconds to read the whole microplate

at double wavelength.

A barc de reader identifies all resources loaded on the working area. The barcode reader is able to detect:

•The presence of vials, test-tubes, etc… in the positions requested by the software

•The barcode printed on the vials, test-tubes, etc…labels if it is present

The sensors on the working area guarantee the correct positioning of all racks and holders loaded on board.

OpenLAB is the NEXgen system software. It is based on essential graphics and all necessary information for

the operator to rapidly perform the loading, assay runs and results management procedures make the

NEXgen instrument an easy to use instrument.

1.7 E

NVIRONMENTAL PROTECTION INSTRUCTIONS

1.7.1 D

ISPOSAL PRECAUTIONS

NEXgen must be considered as a non household waste and its waste must be disposed of in conformity to

the end-user’s national laws on electric and electronics waste.

NEXgen User’s Manual

Introduction

11

NEXgen is built with materials that do not harm the environment; during its usage it can be contaminated

by infectious substances. It is recommended to decontaminate the NEXgen instrument before disposal

(refer to Waste disposal on page 31)

Make sure that NEXgen is disposed of in a proper way in order to avoid:

•potential environmental damages resulting from an improper disposal of the instrument

•administrative penalties resulting from an illegal waste disposal.

1.7.2 D

ECONTAMINATION

Decontamination of NEXgen must be carried out by wearing a lab coat in order to shelter your clothes from

contaminating agents and protect the skin from the contaminating agents exposure, disposable latex or

vinyl gloves, to prevent the direct contact with the potentially contaminated NEXgen parts and a facial

mask, to protect the mucosae, eyes, nose and mouth from any potential contaminating agents.

Prepare two solutions of sodium hypochlorite (commercial hypochlorite): one at 1% and the other at 0.5%.

The commercial sodium hypochlorite concentration is generally 5.25%; such solutions must be prepared as

follows:

Solution A (1%): 200 mL of sodium hypochlorite and 800 mL of deionized water;

Solution B (0.5%): 100 mL of sodium hypochlorite and 900 mL of deionized water.

WARNING

:

Plea

se contact the Manufacturer before decontaminating

NEXgen

through different

methods than the ones recommended in this chapter.

WARNING

:

The decontamination procedure proposed in this section does not guarantee the complete

sterilization of NEXgen or that all viruses and microorganisms are completely inactivated. In

spite of this, this procedure allows minimizing the contamination hazard.

W

ORKING AREA DECONTAMINATION

Remove all the resources from the working area (racks, holders, etc..).

Soak an absorbent non-fibrous towel in A Solution to clean the surfaces of the instrument. In order to get

an acceptable decontamination level, leave A Solution for 15 minutes at least, then remove the sodium

hypochlorite by using an absorbent cotton swab soaked in the deionized water.

R

ACK DECONTAMINATION

Remove the racks from their positions and remove the possible resources that must be disposed of in the

specially provided containers.

Soak an absorbent non fibrous towel with A Solution to clean the rack surfaces and holes. Leave A Solution

for 10 minutes at least, then remove the sodium hypochlorite by using an absorbent cotton wad soaked in

the deionized water.

NEXgen User’s Manual

Introduction

12

U

SED TIPS CASE DECONTAMINATION

Remove the used tips case from its position and make sure any left tips are removed from the inside;

dispose of the tips in the supplied special containers. Clean the case by using an absorbent towel soaked in

B solution. Leave the solution on for 10 minutes at least, then remove the solution by using an absorbent

towel soaked in the deionized water.

Place the used tips case back to its position.

M

ANIFOLD AND WASTE LIQUIDS TANK DECONTAMINATION

From the position number 6 of the tank drawer, remove the tank number 6 with red label and empty the

distilled water usually contained in it. Fill the same tank with 2 L of B Solution.

Empty the waste liquids tank as follows: from the main menu screen, click on end of work then click on start

empty waste. Wait for the tank to be completely emptied, then click on end empty waste.

To decontaminate the manifold and the waste liquids tank, click on end of work from the main menu

screen, then click on clean wash system and wait for the cycle to be completed. Repeat the procedure until

the emptying of tank number 6 is completed. At the end, clean tank number 6 with distilled water and fill it

with 2 L of distilled water and reposition it in the tanks drawer in number 6 position.

Empty the waste liquids tank containing B Solution by following the procedure described above.

1.8 P

ACKAGE CONTENTS

NEXgen basic accessories list

Code

Description

Quantity

30004372

NEXgen

v.2

1

30600980

Operator's Manual in English

1

30600990

Service Manual in English (for distributors)

1

30650090

Multilingual Operator's Manual CD

1

30213711

Samples rack

6

30213721

Reagents an

d controls rack

6

30213741

Disposable tips rack

1

30213750

Microplate holder

6

30213961

IFA slides rack

2

30214270

Dilution plates rack (5)

1

26603

200 µL Disposable tips

960/1

26606

1000 µL Disposable tips

960/1

62910

Dilution plates

1

10163341

Us

ed tips case

1

13000300

2L Wash buffers tank

6

20400500

10A Time

-

lag fuse 5x20mm UL

2

21890570

FTP CAT.5 RJ45 3mt Shielded cord

1

NEXgen User’s Manual

Introduction

13

Code

Description

Quantity

21890040

EU Power cord

1

21890370

USA Power cord

1

30214380

Valve drain pipe

1

30214390

External waste tank

1

30502560

NEXgen

transportation handles kit

1

19901070

Pipettors calibration tool

1

19901080

Manifold calibration tool

1

19901090

Aspiration needle cleaning tool

1

19901100

Dispensing needle cleaning tool

1

NEXgen optionals list

Code

Description

Quantity

302

14101

Shaker

-

incubator unit

4 max

30214150

Shakers/Heaters frame ass Y

Frame

30214160

Bottom heater unit

30214400

Bottom exchange unit

30213750

Microplate holder

NEXgen User’s Manual

General information

14

2. G

ENERAL INFORMATION

2.1 T

ECHNICAL SPECIFICATIONS

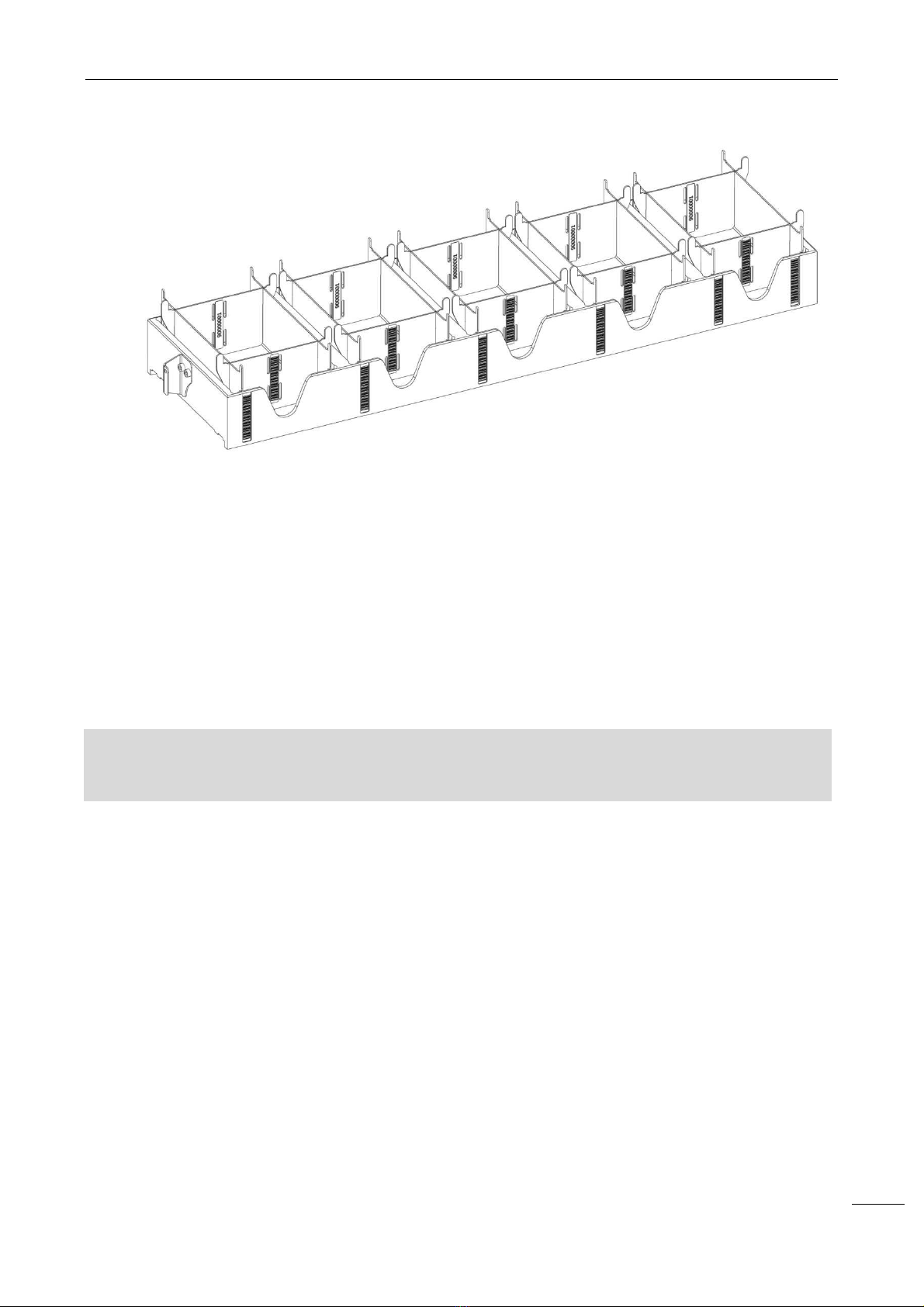

2.1.1 S

AMPLES RACK

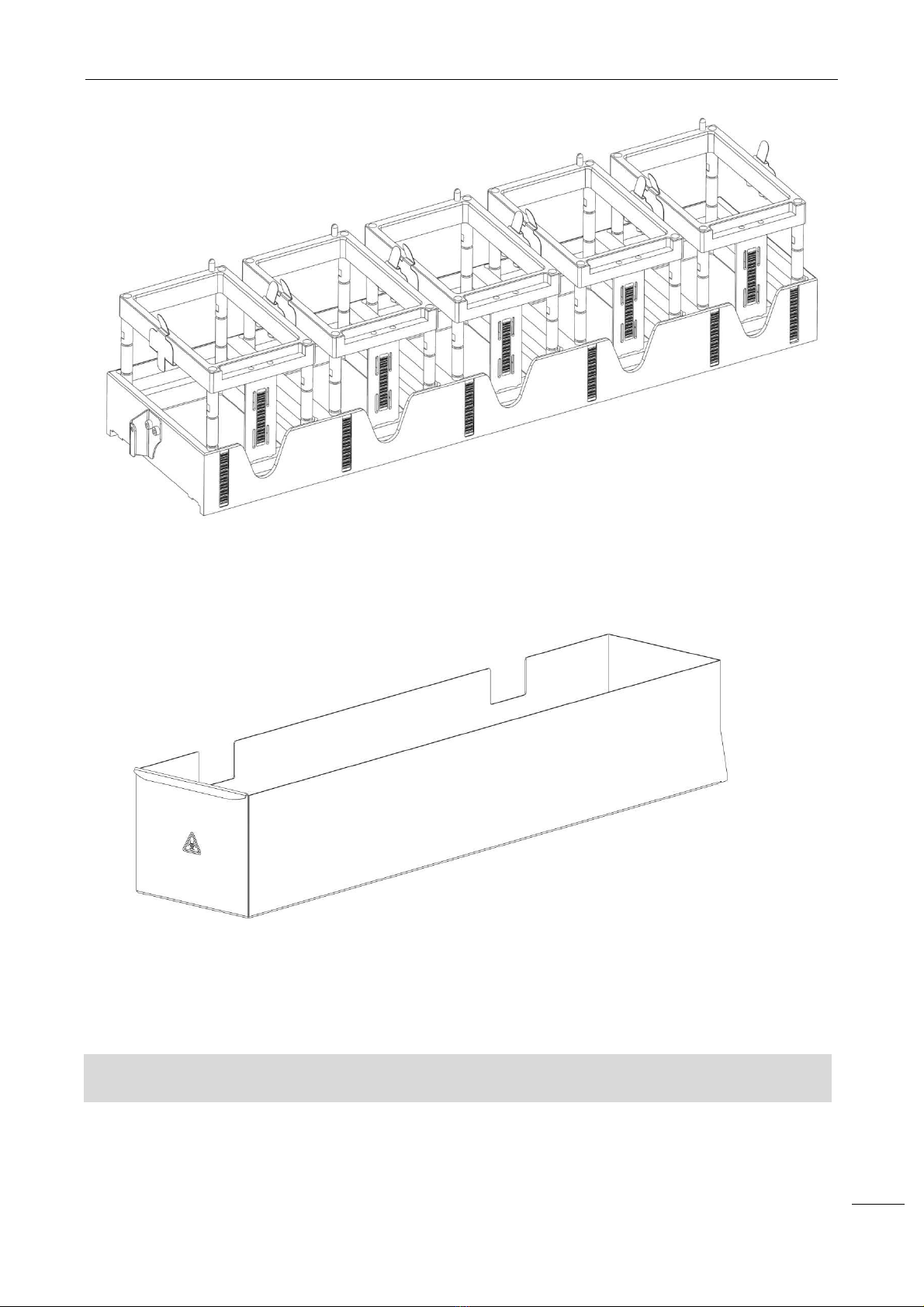

Image 4 - Samples rack

NEXgen is supplied with 6 sample racks that can be removed and loaded on the instrument allowing them

to slide on the working area slots. The insertion of test-tubes with different diameters into the rack and

their support are facilitated by springs that ensure the stability. Each single rack is identified by a unique

barcode. Inside the rack, each position has a barcode providing the following information.

a) Test-tube absence - the barcode reader reads the position back barcode;

b) Test-tube presence - the barcode reader reads the barcode in the label on the test-tube;

c) Test-tube wr ng p siti ning - the barcode reader gives no reading.

Samples rack specifications

Capacity

24

/28

samples

Test

-

tubes sizes

75 to 85 mm height

12 to 16 mm diameter

Minimum sample volume

100 µL

Sample positive identification

Yes

NEXgen User’s Manual

General information

15

2.1.2 D

ISPOSABLES RACK

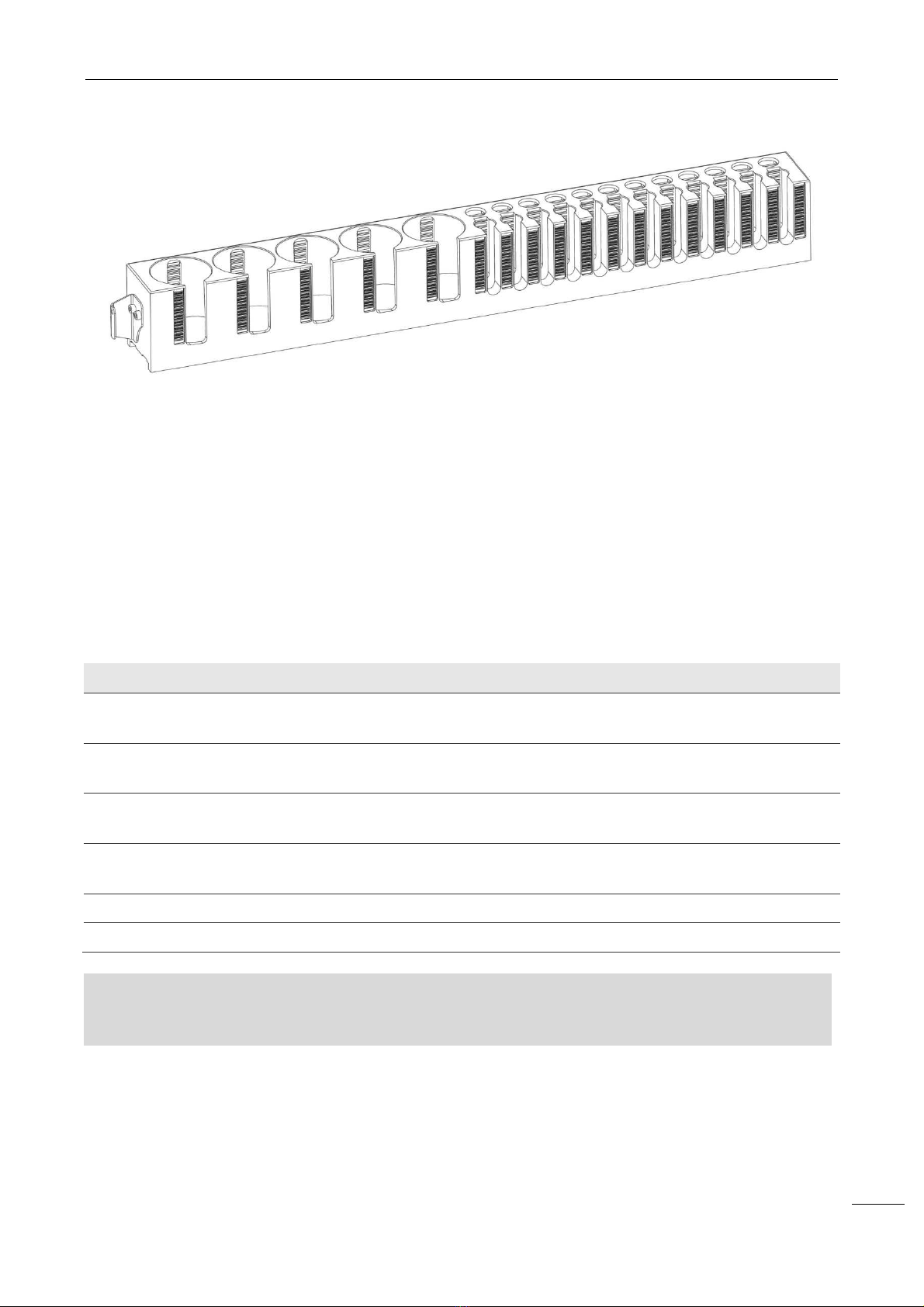

Image 5 - Diluti n plate rack

NEXgen is supplied with 2 rem vable racks where both dilution strips and disposable tips can be loaded.

Each rack consists of 5 positions; it can be loaded on the instrument by sliding it on the working area slots.

The racks are identified by a unique barcode. The standard instrument configuration comes with 3 holders

for the dilution strips and 8 for the disposable tips.

Each dilution strip consists of 8 wells, 2 mL each. Each support for the disposable tips contains 96 tips

(200µL or 1000µL).

Dilution strips and disposable tips must be purchased separately, please refer to NEXgen’ Sales

Department.

WARNING

:

After usa

ge, dilution

strips and disposable tips

have to be removed from the

holder

and

disposed of as contaminated biological material.

NEXgen User’s Manual

General information

16

Image 6 - Tips rack

2.1.3 U

SED TIPS CASE

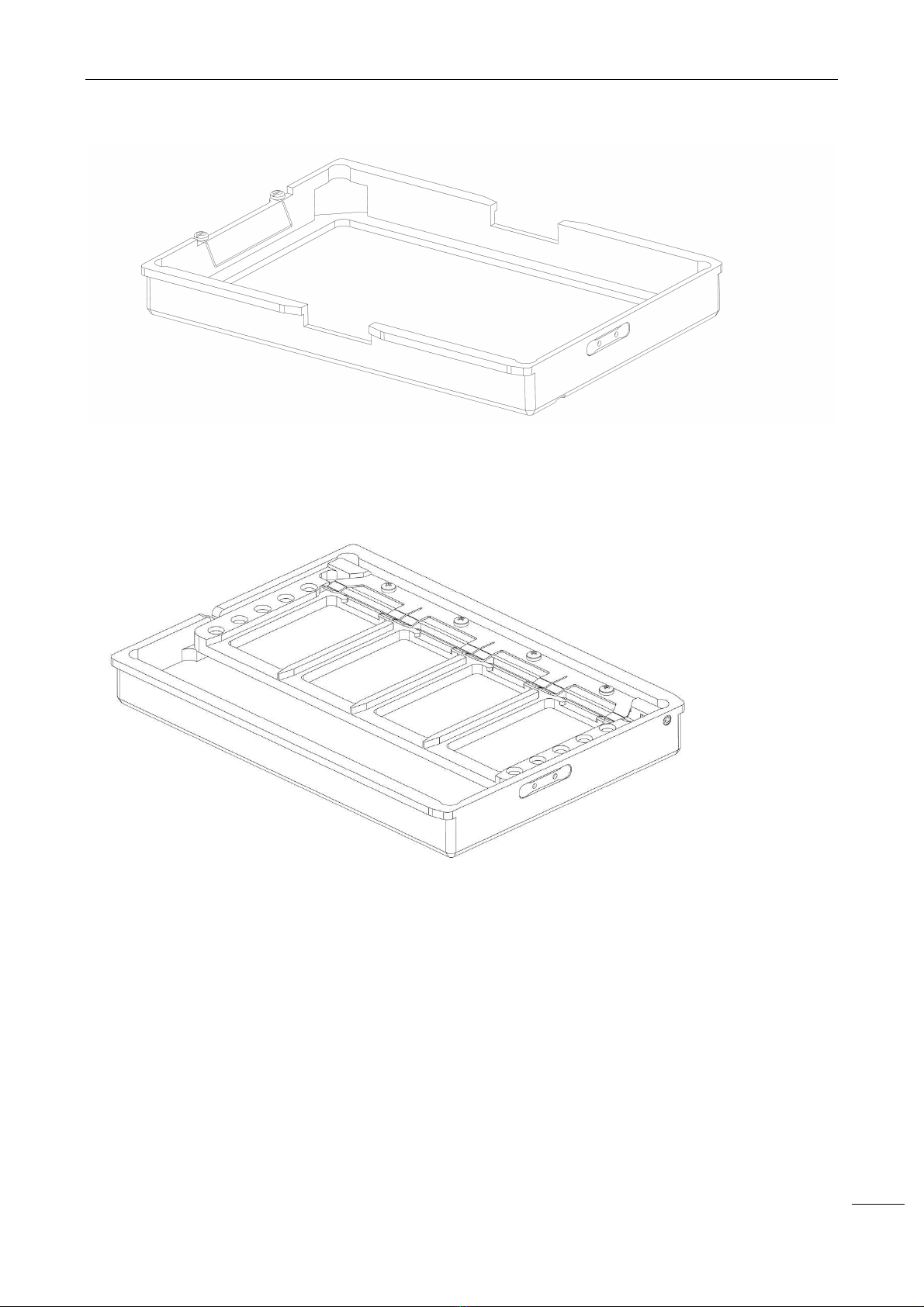

Image 7 - Used tips case

The used tips case is in a raised position on the working area, on the right side of NEXgen.

The software manages the release of the tips to happen randomly throughout the case length, avoiding the

tips to accumulate in a single area of the case.

WARNING

:

Used tips have t

o be handled and disposed of as contaminated biological material.

NEXgen User’s Manual

General information

17

2.1.4 R

EAGENTS RACK

Image 8 - Reagents rack

NEXgen is supplied with 6 reagents racks that can be removed and loaded on the instrument allowing them

to slide on the working area slots. Each single rack is identified by a unique barcode. Inside the rack, each

position has a barcode that provides the following information:

a) reagent r c ntr l/calibrat r/standard vial absence - the barcode reader reads the position back

barcode;

b) reagent r c ntr l/calibrat r/standard vial presence - the barcode reader reads the barcode on

the vial;

c) reagent or control/calibrator/standard vial wrong positioning - the barcode reader gives no reading.

Reagents rack specifications

Capacity

12 positi

ons for standards and controls

5 positions for reagents

Reagents and controls/calibrators/

standards loading holes diameter

Customizable

Prediluted controls/calibrators/

standards minimum volume

50 µL

+ volume to be aspirated

Concentrated controls/calib

rators/

standards minimum volume

50 µL

+ volume to be aspirated

Reagents minimum volume in a 60 mL vial

4

000

µL

+ volume to be aspirated

Reagents minimum volume in a 15 mL vial

8

00

µL

+ volume to be aspirated

WARNING

:

The reagents vials have to be hand

led and disposed of as potentially contaminated

material.

NEXgen User’s Manual

General information

18

2.1.5 M

ICROPLATES HOLDER

Image 9 - Micr plate h lder

NEXgen is supplied with 6 micr plate h lders, each for a 96 well microplate.

2.1.6 IFA

SLIDES RACK

Image 10 - IFA slides rack

NEXgen is supplied with 2 IFA slide racks, 4 slides each. NEXgen can contain up to 7 IFA slide racks.

NEXgen User’s Manual

General information

19

2.1.7 R

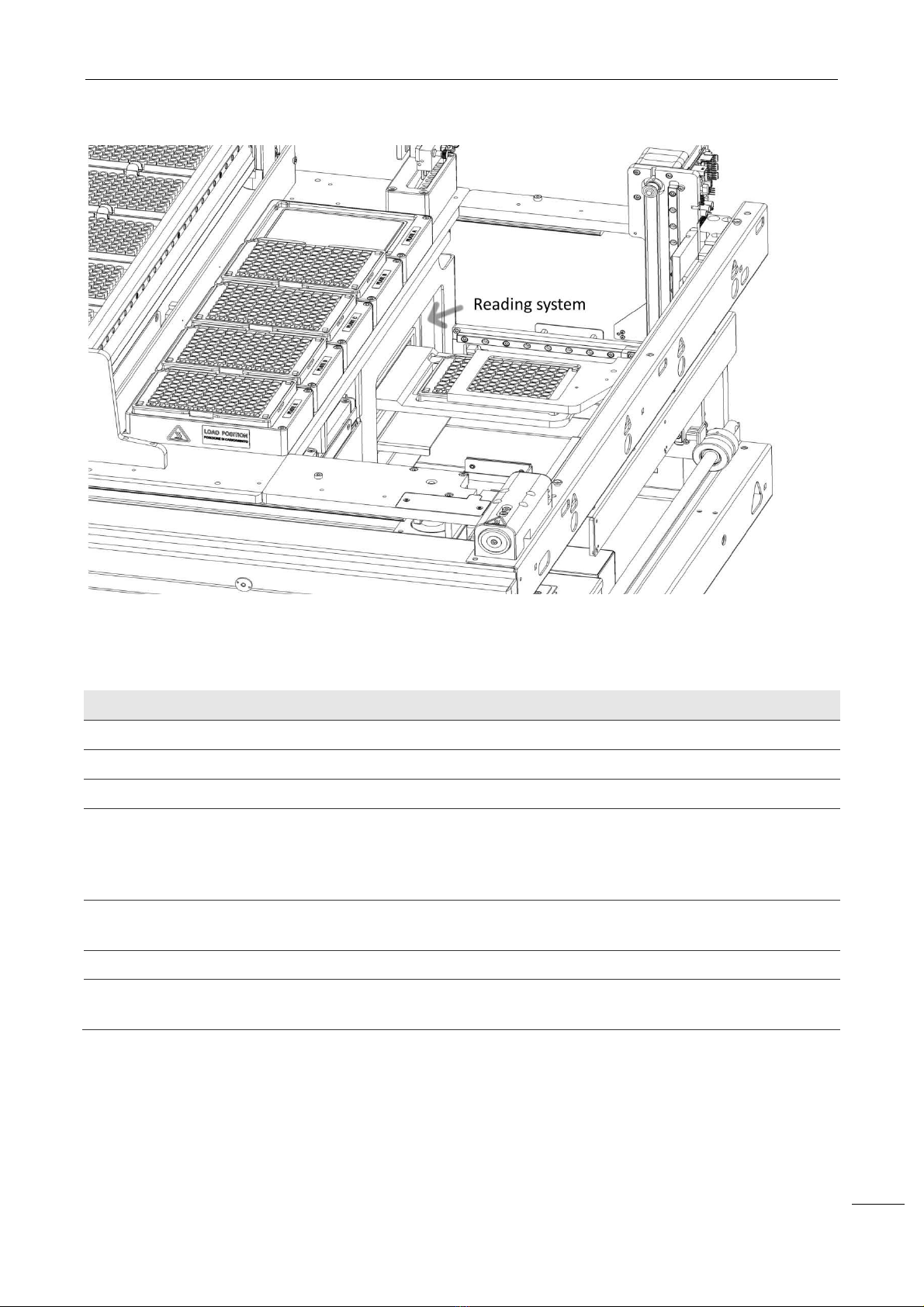

EADING SYSTEM

Image 11 - Reading system

The reading system is located in the lower part of NEXgen. The microplate robotic arm moves the

microplate from the working area to the retractable cart of the reader.

Reading system specifications

Dynamic

0

-

3.

3

OD

Spectrum

400

-

700 nm

Loadable filters number

8

Precision

0,01

SD

(0,000

-

0,500

OD

)

≤1% CV (0,501-2,000 OD)

≤1,5% CV (2,001-2,500 OD)

≤2% CV (≥2,501 OD)

Linearity

< ± 0.75% (at 0.100 to 3.000 OD)

< ± 1.50% (at 3.000 to 3.300 OD)

Accuracy

< ± 0.50% (1.0 OD at 492 nm)

Reading time

5 seconds

per

single wavelength

8 seconds per dual wavelength

NEXgen User’s Manual

General information

20

2.1.8 B

ARCODE READER

Image 12 - Barc de reader

The barc de reader is on the external upright of the y-axis. Any resource loaded on NEXgen is identified by

the barcode reader.

Barcode reader specifications

Type

High Speed Laser Sca

n

Scanning mode

Single line

Scanning speed

500 scans/sec

Minimum code width

0.127 mm (5 mil)

Configured barcodes

EAN/UPC; Code 39; ITF 2 di 5; Code 93; Code 128

Interface

RS232C (baud rate 115200)

Table of contents

Popular Laboratory Equipment manuals by other brands

MLT

MLT FS-16-25 Instructions for use

Waters

Waters Xevo TQ MS Operator's, overview and maintenance guide

REPLIGEN

REPLIGEN TangenX PRO PD user guide

Ample Scientific

Ample Scientific Champion S-33 manual

Ecowell

Ecowell Homeguard manual

Molecular Devices

Molecular Devices FilterMax F3 Unpacking and setup guide