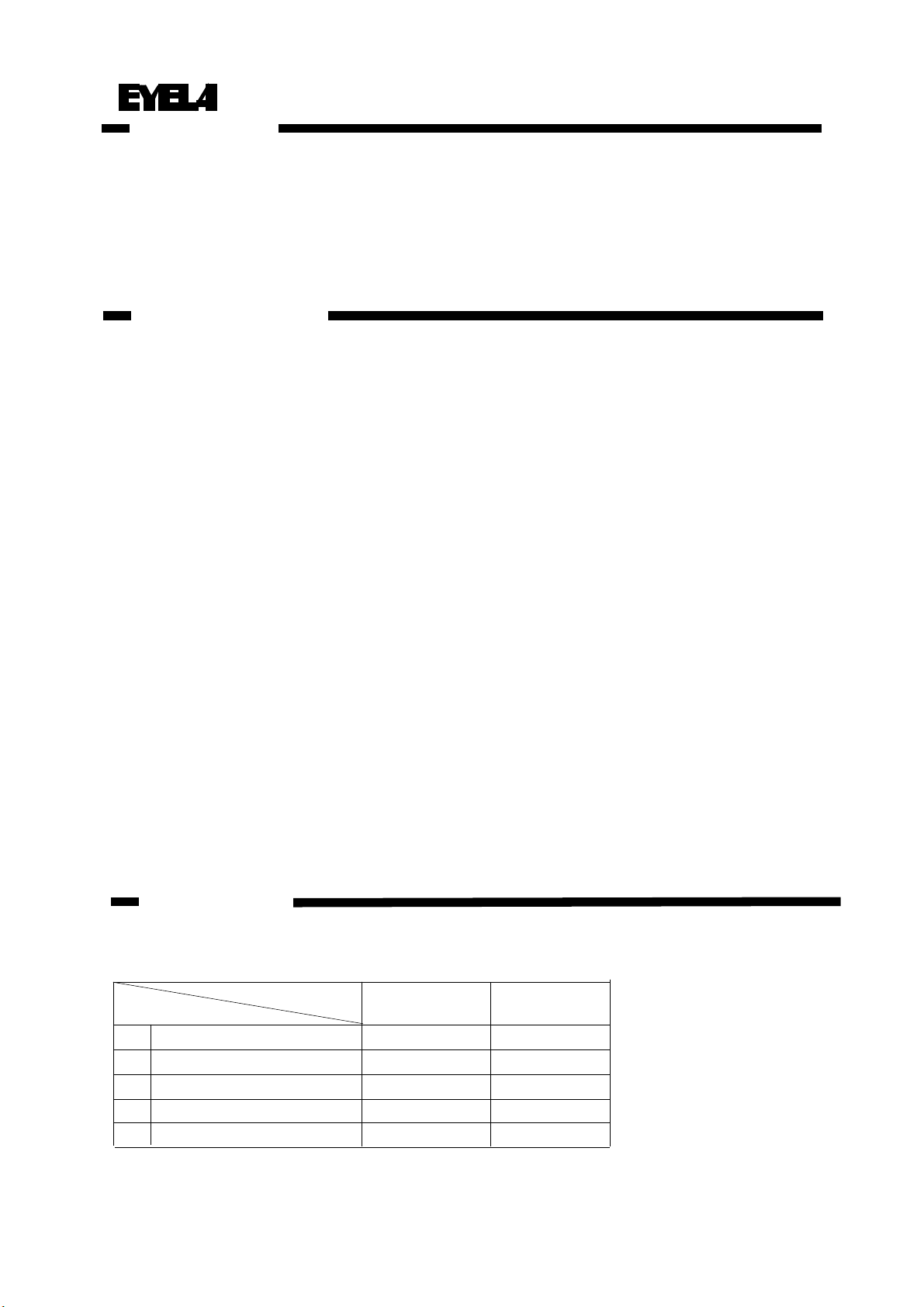

± 0.05 ~

6A, 0.6kVA

3.5kg

138W x 150D x 312H (Excluding any projection)

5 ~ 35°C

AC-100V 50/60Hz

11A, 1.1kVA

500W (SUS316L) 1kW (SUS316L)

7L / min

(50 / 60 Hz / water / high circulation)

1.2m / 1.5m

(50 / 60 Hz / water / high circulation)

± 0.1 ~

2

Outline

Warning

Do not remodel.

Do not use out of applications.

Remodeling or use out of applications may

cause an electric shock or mechanical troubles.

This unit is applicable for wide variety of

experiments / examinations of reaction,

crystallization, synthesis, deposition of organic

steel, environmental tests of materials,

breakdown tests, endurance test, and such.

Room Temperature (RT) +5℃〜80℃(If you use a supplied bath, Max.

70°C) * 1 (If you use this with a cooling bath, -20〜RT+5℃)

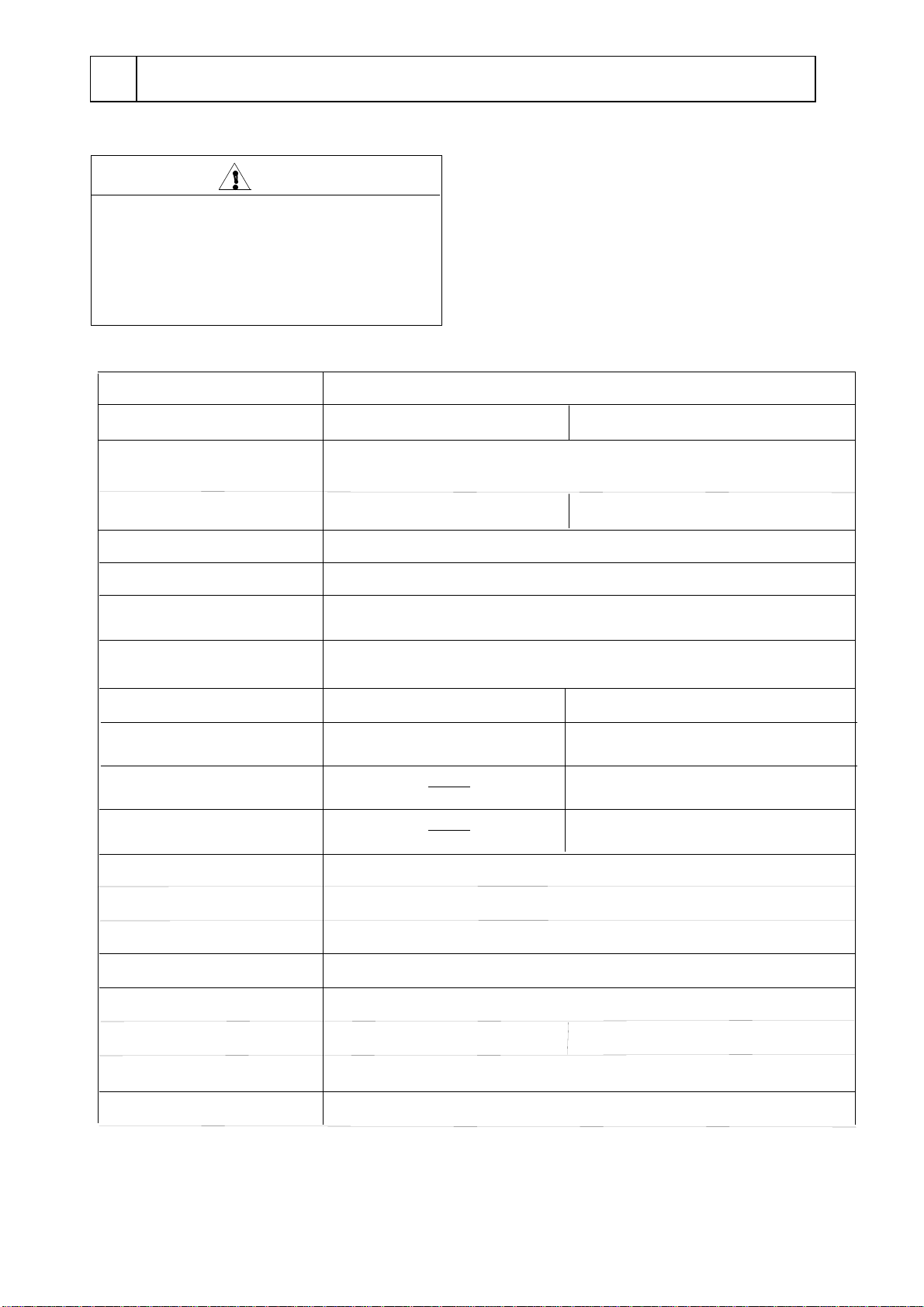

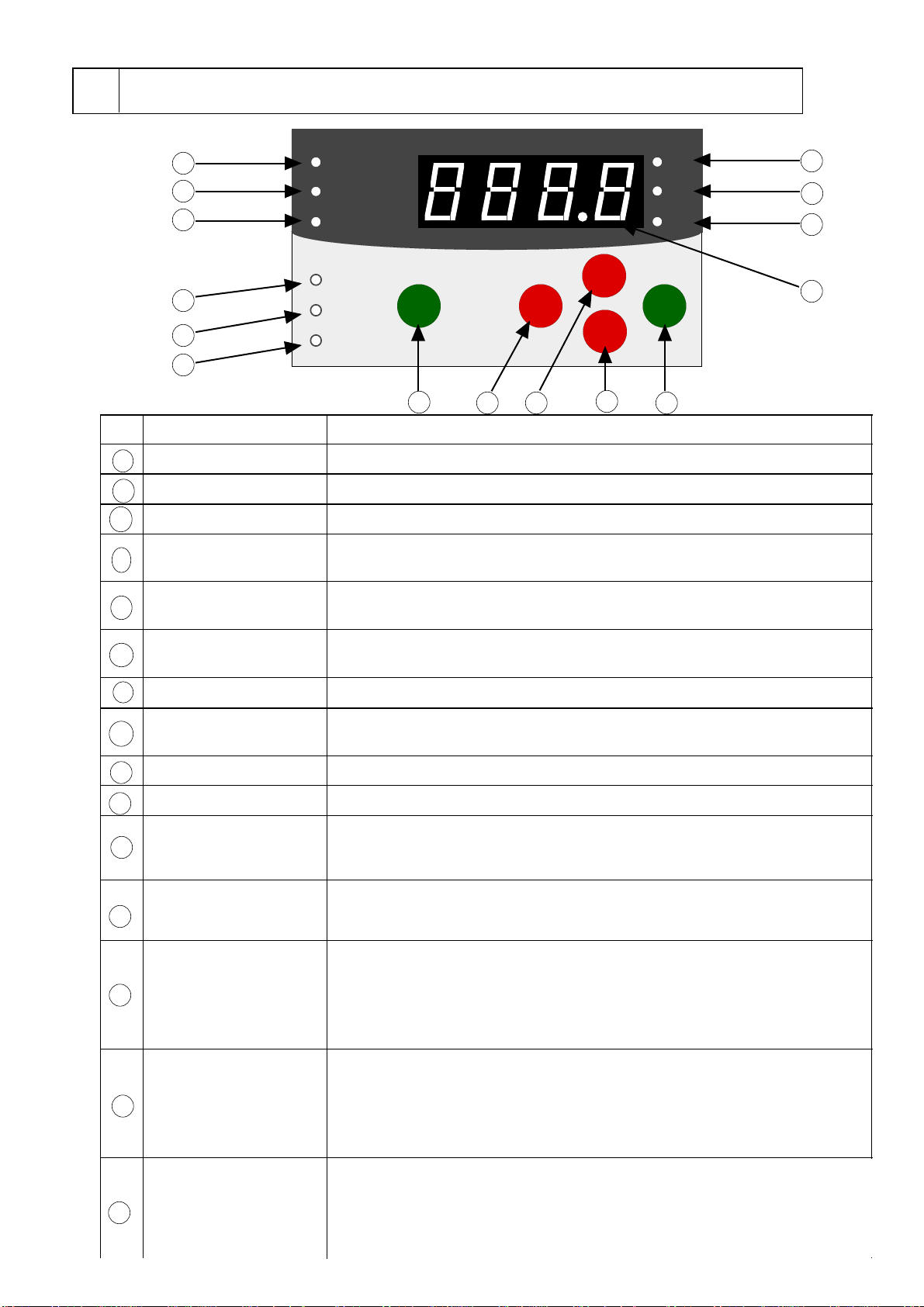

Alarm function (Low water level, Over shoot, Control, Sensor),

Variable independent over temperature protector, Circuit protector

Changeable jet flow

Thermistor

Auto-tuning, Temperature calibration, Auto-stop 1, Auto-stop 2,

Auto-start, Selectable operation after power failure

Digital setting by membrane switch, digital read-out by 0.1°C

PID microprocessor control, SSR output

Model

Name of product

Heater output

Safety features

Temperature control

Temp. settings / indication

Additional functions

Temp. control accuracy

Temp. control range

Temperature sensor

Stirring method

Max. flow rate of

Max. head of circulation pump

circulation pump

Applicable ambient temp. range

Overall dimensions

Net weight

Power source input

Rated power source

(Possible external circulation)

Protection cover

Water bath

Anti-bacterial stainless steel-made

Self-extinguishing resin (Max. 70°C) 9L capacity

* 1 Use an anti-freeze solution when the temperature is 10°C or lower.

If you use at Room temperature + 5°C or lower, combine with other cooling unit such as an immersion

cooler or a cooling water circulator, etc.

* 2 The performance is shown at room temperature 20°C , 100V, 50Hz, using a supplied water bath filled

with 7L water without lid.

*2

Immersion type Thermo regulating bath

Propeller by stirring speed control