IF.PUG.003 R7

PRODUCT CONTENTS

Package includes the following:

1. TangenX™ PRO PD -0.01 m2(0.1 ft2), 0.02 m2(0.2 ft2), 0.1 m2(1 ft2) membrane

filtration cassettes

2. Silicone* or EPDM** Gaskets (*A01,W01 / **AP1,AP2,WP1,WP2)

IMPORTANT INFORMATION BEFORE YOU BEGIN

CASSETTES

•Cassettes may be stacked to increase filtration surface area; however, use only

one type of membrane molecular weight cutoff at one time. Do not install a

mixture of cassettes with different pore sizes in the hardware.

•Cassettes must be flushed with deionized (DI) water or water for injection

(WFI) to ensure removal of storage agents and preservatives from the

membrane filter. It is critical to use the highest quality water possible to avoid

fouling the membrane or introducing contaminants into the system that could

affect membrane performance and product recovery.

GASKETS

•Gaskets lose their resiliency over time. Repligen recommends that you replace

gaskets a minimum of every six months. Repligen supplies two gaskets per

cassette. Installation of the first cassette requires two gaskets; stacking

additional cassettes requires only one gasket. Extra gaskets should be saved to

replace worn or damaged gaskets.

PUMP

•When using TangenX™ cassettes, select a pump with adequate capacity;

crossflow rate ranges (see Table 3) are feed channel type and process fluid

dependent.

MEMBRANE CASSETTE INSTALLATION

1. Lift the end plate off the manifold.

2. Rinse the silicone gaskets with deionized water or WFI. Place a rinsed gasket

flat against the bottom manifold; ensure that the holes in the gasket line up

with the holes in the manifold.

3. Using scissors carefully open the cassette bag to remove cassette.

WARNING: Each cassette is stored in an aqueous solution containing

15-20% glycerin and 0.1% sodium azide, pH 7 - 10. Follow standard

safety procedures for handling aqueous glycerin/sodium azide,

including the use of gloves, safety goggles, and lab coat.

4. Place the cassette into the holder flat against the gasket. Place another gasket

on top of the cassette. Ensure that the holes in the manifold, gaskets, and

cassette are completely aligned. If you are using multiple cassettes, continue

the same gasket/cassette/gasket pattern, ending with a gasket between the

last cassette and the end plate.

5. Place the end plate on top of the last gasket of the cassette or cassette stack.

6. Install the tie-rod spacers (if used) and washers on each bolt leaving a

minimum of 18 mm (0.75 inch) of thread exposed on the rod. By hand, screw

the nut on each bolt and hand tighten evenly by alternating from one nut to

the other. Bolts must be further tightened to within the recommended torque

values shown in Table 1 using a calibrated manual torque wrench.

Table 1 Recommended Torque Values

Holder Type Torque Range (in-lbs)

Torque Range (nm)

TangenX™ PRO PD 120 – 180 14 – 20

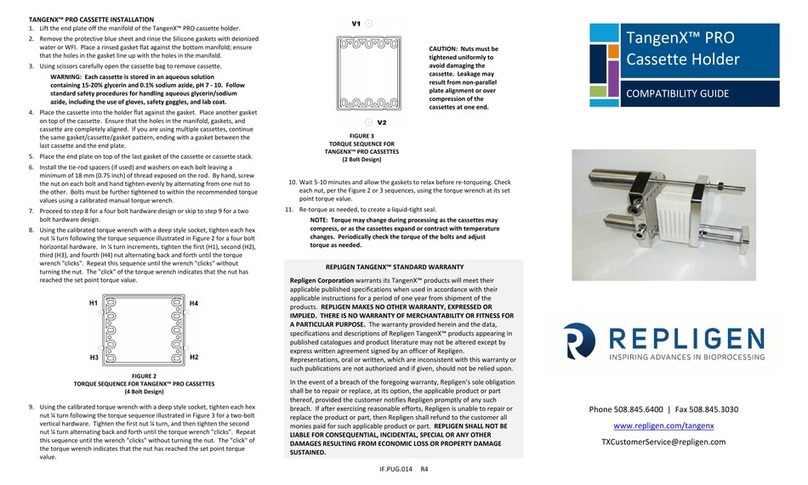

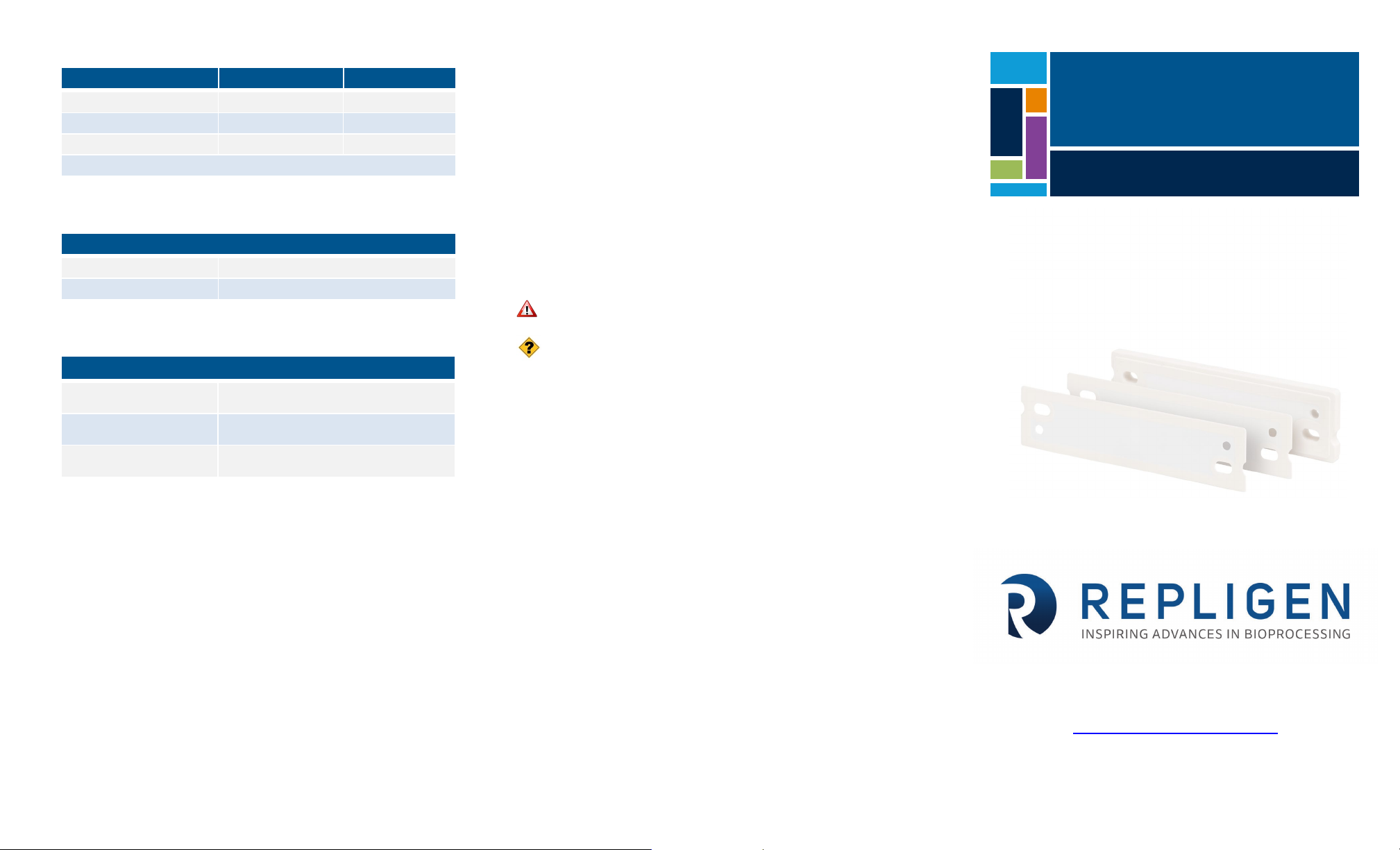

7. Using the calibrated torque wrench with an 11/16” deep socket, tighten each

hex nut ¼ turn following the torque sequence illustrated in Figure 1. Tighten

the first nut ¼ turn, and then tighten the second nut ¼ turn alternating back

and forth until the torque wrench "clicks". Repeat this sequence until the

wrench "clicks" without turning the nut. The "click" of the torque wrench

indicates that the nut has reached the set point torque value.

CAUTION: Nuts must be tightened uniformly to avoid damaging the

cassette. Leakage may result from non-parallel plate alignment or

over compression of the cassettes at one end.

8. Wait 5-10 minutes and

allow the gaskets to relax

before re-torqueing.

Check each nut, per the

Figure 1 sequence, using

the torque wrench at its

set point torque value (see

step 7 above).

9. Re-torque to a maximum

of 180 inch-pounds, as

needed, to create a liquid-tight seal.

NOTE: Torque may change during processing as the cassettes may

compress, or as the cassettes expand or contract with temperature

changes. Periodically check the torque of the bolts and adjust torque

as needed.

FIRST TIME USE OF MEMBRANE CASSETTE

Cassettes should be flushed with DI water or WFI to ensure removal of storage and

preservative agents from the membrane filter and to minimize any possible

interaction with your particular application. The recommended volume of water to

flush the cassettes prior to use is 20 to 40 L/m². For some applications, further

sanitization is required.

CASSETTE INTEGRITY TEST

The integrity testing is a non-destructive method to verify the integrity of a

Tangential Flow Filtration (TFF) cassette. Each cassette manufactured by Repligen

undergoes strict release testing, including an air integrity test. This release test

verifies the integrity of the cassette prior to shipment; however it can't guarantee

the integrity of the cassette's installation in the holder at the time of use. In the

rare case there is an integrity issue, it can be a result of shipping damage or

improper installation.

Therefore, a pre-use integrity test should be conducted on site and can easily be

performed following the cassette installation and flush. Integrity test specifications

are shown in Table 5 of this guide. A detailed procedure (AN1002) for the

measurement of air integrity can be obtained by contacting Repligen or your local

sales representative.

CLEANING OF MEMBRANE CASSETTES

Cassettes can be reused if cleaned and stored properly. To clean, flush each

cassette (or cassette stack) with a recommended cleaning solution from Table 2.

Use 2 liters of cleaning solution per 1 m2of membrane area. Upon completion of

the cleaning cycle, flush each cassette (or stack) with buffer, WFI, or DI water prior

to storing.

Table 2 Recommended Cleaning Solutions

Cleaning Agent Cleaning Conditions

0.1n to 0.5N Sodium Hydroxide

Contact Time = 30 – 60 minutes

Temperature = 35°C (95°F)

1.5% Alconox® Detergent

Contact Time = 30 – 60 minutes

Temperature = 40°C (104°F)

STORAGE OF MEMBRANE CASSETTES

Membrane cassettes must be stored wet to maintain their characteristics and

integrity and prevent microbial growth. Below are critical factors to remember

when storing include the following:

•Cassettes stored greater than 2-4 weeks should be removed from the holder.

•Cassettes left in the holder should be flushed with fresh storage agent about

every 2 weeks. Contact the membrane manufacturer for a list of appropriate

storage agents.

•Recommended PH ranges:

o2 - 13, long term (storage)

o1 - 14, short term (cleaning)

•Recommended storage temperature:

o4°C - 25°C long term (>7 Days)

o50°C short term (<7 Days)

oDo not freeze cassettes

MEMBRANE OPERATING CHARACTERISTICS

Take care to use the membrane at the lowest pressure possible while still

producing consistent permeate flow. Although higher operating pressures initially

improve flow rate, they also promote increased concentration polarization and

membrane compaction, which ultimately limits flow. With very low NMWL

membranes, lower operating pressure may also reduce the retention of salts and

very low molecular weight species.

FIGURE 1

TORQUE SEQUENCE FOR TANGENX™ PRO PD