TurboVap®96 Dual Installation and Safety | © Biotage 2021

Safety

Safety Requirements

You must observe all safety requirements when installing and

operating the system. Failure to install or use the system in

a manner specified by Biotage may result in personal injury

and/or equipment damage.

If the system has been damaged or does not function properly,

turn it off immediately and contact Biotage®1-Point Support™

(www.biotage.com).

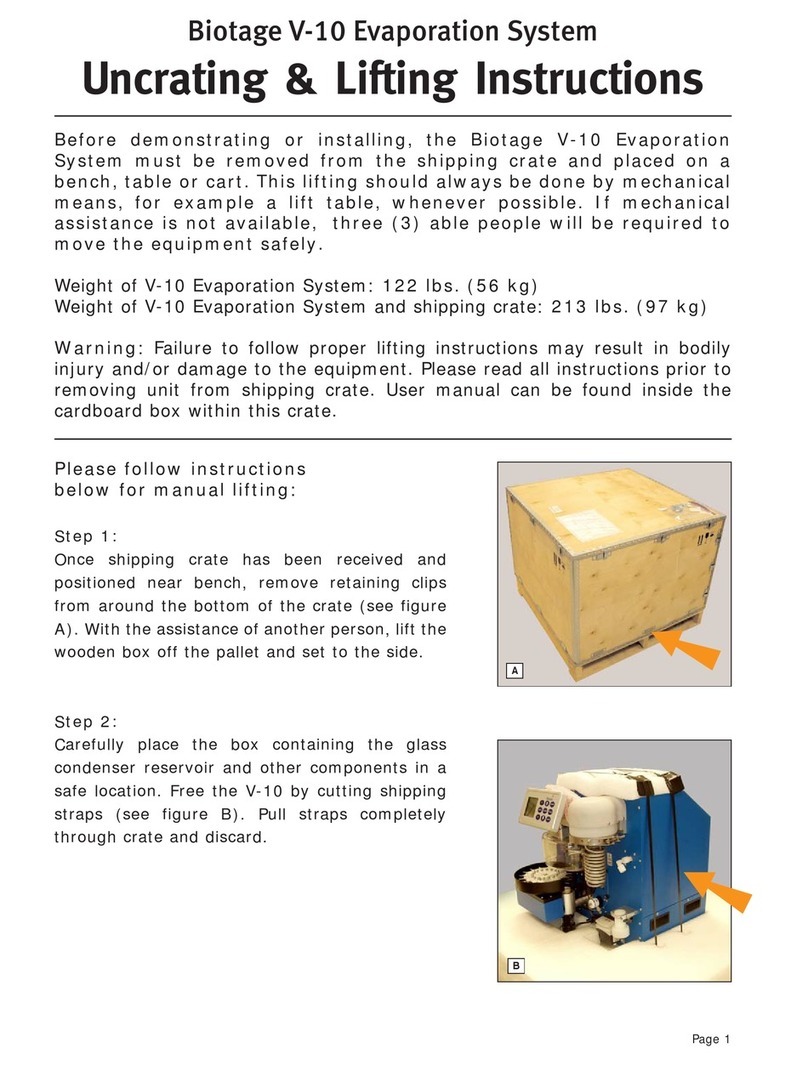

Installation

»

The system must be unpacked and installed

as described in this document.

»

Follow regional safety practices when handling

and moving shipping boxes and containers,

and when moving the system.

»

The total weight of the package including the

system is 24 kg (52.8 lbs). Use suitable lifting

equipment when moving the package.

»

The system must be either connected to a ventilation system

using the exhaust outlet at the rear of the system or placed

in a well-ventilated fume hood or an equivalent enclosure

to reduce the risk of exposure to harmful solvent vapors.

»

The ventilation system or fume hood must be capable

of exhausting 1 m3/min (35.3 ft3/min). Insufficient

flow can cause concentrations of solvents in the

exhaust system. Risk of explosion and fire.

»

Use only an exhaust hose supplied by Biotage.

To avoid excessive increase in pressure, it is

important to use an exhaust hose with the

appropriate length and internal diameter.

»

Do not connect the system to an electrical supply that is not

in accordance with the system’s electrical specifications;

see the rating plate located at the rear of the system.

»

To avoid the risk of fire or electrical shock, the system must

be electrically grounded (earthed). Use only a power cord

supplied by Biotage. The plug should only be connected

to a grounded outlet as per local and national regulations.

Keep the mains plug easily accessible in case the system

needs to be disconnected quickly from mains power.

»

To avoid injury to person or damage to the

system, do not exceed the maximum inlet

pressure of 6.5 bar (0.65 MPa, 94PSI).

»

Only connect nitrogen gas to the N2port.

»

Ensure that the power cord and any cables, hoses,

and tubing connected to the system cannot come

in contact with chemicals. Corrosives and solvents

can degrade the cord/cable insulation and dissolve

the hoses and tubing. There is a risk of electric

shock, fire, and/or equipment damage.

»

Do not place any equipment or bottles

on top of or above the system.

»

Ensure that no hoses or tubing connected to the

nitrogen supply or ventilation are misshaped

and that the flow is not blocked.

»

Ensure that the exhaust hose is properly installed. If it

is not, solvents might gather and grow into salts in the

exhaust outlet and in the hose. These salts blocks the

exhaust flow which can lead to exposure to harmful vapors.

»

External fire protection should be installed according to

local regulations for equipment operating unattended.

»

Ensure to follow the described procedure to

disconnect the nitrogen inlet tube. Failure to

do so can cause damage to the N2port.

Operation

»

Use the system only for its intended purpose, as described

in the user documentation delivered with the system and

user documentation available at www.biotage.com. If the

system is used in a manner not specified by Biotage,

the safety features of the system may be impaired.

»

The surface temperatures of the gas heater

and the plate heater can be very hot. Avoid

contact, potential risk for burn damage.

»

Never operate a damaged system.

»

When using flammable solvents, read and follow

your local static discharge codes of practice and

available national recommended procedures for the

avoidance of hazards due to static electricity.

»

If flammable solvents have been spilled into the

plate heater, they must be cleaned according to local

SOPs for solvent spills or biological samples.

»

If not in contradiction with your local practices and

procedures, wear antistatic protective clothing and

footwear, or stand on an anti-static floor mat when using

flammable solvents. If you cannot take the usual anti-static

measures, touch a grounded (earthed) metal object before

opening the lid on the system to discharge any static

electricity that may have accumulated on your body.

»

The nozzles may have come into contact with

hazardous samples. Avoid contact.

»

Ensure not to bend any of the nozzles. If a nozzle is bent,

it is recommended that the manifold is replaced.