Adam Equipment QBW Series User manual

Other Adam Equipment Scale manuals

Adam Equipment

Adam Equipment ABK Series User manual

Adam Equipment

Adam Equipment NBL 84 e/i User manual

Adam Equipment

Adam Equipment WBZ Series User manual

Adam Equipment

Adam Equipment ACBplus Series User manual

Adam Equipment

Adam Equipment HIGHLAND HCB123 User manual

Adam Equipment

Adam Equipment GK series User manual

Adam Equipment

Adam Equipment Nimbus NBL Serie User manual

Adam Equipment

Adam Equipment MUW 300L User manual

Adam Equipment

Adam Equipment ACB-600H User manual

Adam Equipment

Adam Equipment SHS Series User manual

Adam Equipment

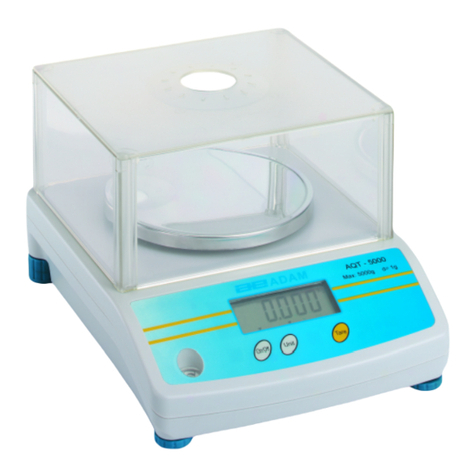

Adam Equipment AQT Series User manual

Adam Equipment

Adam Equipment AZplus Series User manual

Adam Equipment

Adam Equipment Gladiator GGS 8 User manual

Adam Equipment

Adam Equipment CQT 202 Assembly instructions

Adam Equipment

Adam Equipment LBX 12 User manual

Adam Equipment

Adam Equipment WBW 3M User manual

Adam Equipment

Adam Equipment MDW-250L User manual

Adam Equipment

Adam Equipment pgw series User manual

Adam Equipment

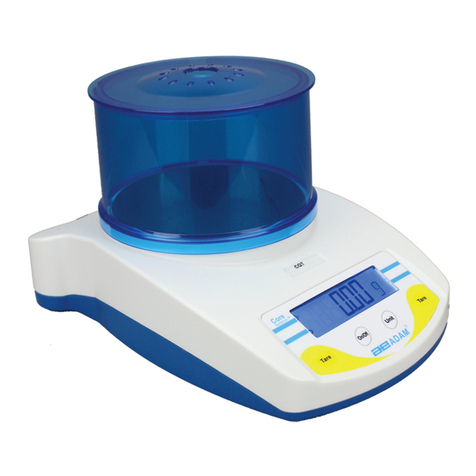

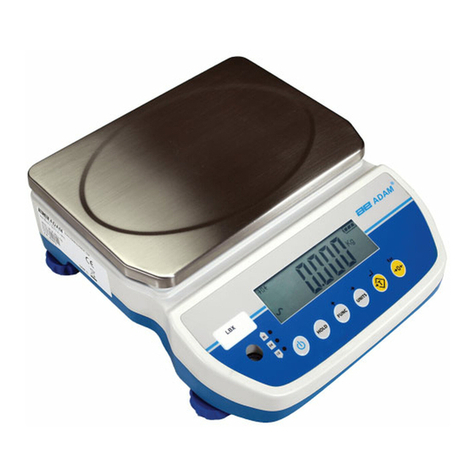

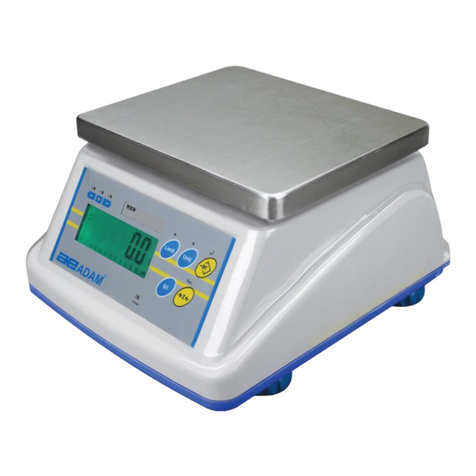

Adam Equipment CBW Series User manual

Adam Equipment

Adam Equipment ASC User manual