ADB PVL IP54 User manual

AM.04.265e Edition 1.1

Instruction Manual

Guidance Sign

Type PVL IP54

2

© ADB

This manual or parts thereof may not be reproduced, stored in a retrieval system, or transmitted,

in any form or by any means, electronic, mechanical, photocopying, recording, nor otherwise,

without ADBs prior written consent.

This manual could contain technical inaccuracies or typographical errors.

ADB reserves the right to revise this manual from time to time in the contents thereof without

obligation of ADB to notify any person of such revision or change.

Details and values given in this manual are average values and have been compiled with care.

They are not binding, however, and ADB disclaims any liability for damages or detriments

suffered as a result of reliance on the information given herein or the use of products, processes

or equipment to which this manual refers. No warranty is made that the use of the information or

of the products, processes or equipment to which this manual refers will not infringe any third

party’s patents or rights. The information given does not release the buyer from making their own

experiments and tests.

ADB Address: Leuvensesteenweg 585, B-1930 Zaventem, Belgium

Tel.: +32 2 722 17 11, Fax: +32 2 722 17 64

Email: marketing@adb-air.com

Internet: www.adb-air.com

AM.04.265e - Edition 1.1 3

Table of contents

1. About this manual

1.1. How to work with the manual ..............................................................................................................5

1.2. Record of changes..............................................................................................................................5

1.3. Abbreviations and terms .....................................................................................................................6

1.4. Icons used in the manual ....................................................................................................................6

2. Safety

2.1. Use......................................................................................................................................................7

2.2. Safety symbols....................................................................................................................................7

2.3. Skilled personnel.................................................................................................................................8

2.4. Liability ................................................................................................................................................8

2.5. Installation...........................................................................................................................................8

2.6. Fasteners ............................................................................................................................................9

2.7. Operation ............................................................................................................................................9

2.8. Action in the event of an equipment malfunction ................................................................................9

2.9. Maintenance and repair ....................................................................................................................10

2.10. Breakable coupling ...........................................................................................................................10

2.11. CE certification..................................................................................................................................10

2.12. Guarantee .........................................................................................................................................10

3. Description

3.1. Overview ........................................................................................................................................... 11

3.2. Intended use ..................................................................................................................................... 11

3.3. Variants of equipment ....................................................................................................................... 11

4. Installation

4.1. Inspect on delivery ............................................................................................................................13

4.2. Store..................................................................................................................................................13

4.3. Install according to standards ...........................................................................................................13

4.4. Overview of components required for installation .............................................................................13

4.5. Installation examples ........................................................................................................................14

4.6. Determine location of equipment ......................................................................................................16

4.7. Install concrete foundation ................................................................................................................16

4.8. Install transformer housing (series circuit only).................................................................................16

4.9. Install equipment...............................................................................................................................18

4.10. Install the tether (Option) ..................................................................................................................18

4.11. Electrical connection through leg (option).........................................................................................19

4.12. Install electrical connection ...............................................................................................................20

4.13. Install anti-bird deterrent (option) ......................................................................................................21

5. Maintenance

5.1. Preventive maintenance schedule ....................................................................................................23

5.2. Open equipment ...............................................................................................................................24

5.3. Close equipment ...............................................................................................................................24

5.4. Part replacement...............................................................................................................................25

6. Troubleshooting

6.1. Troubleshooting guide.......................................................................................................................31

4AM.04.265e - Edition 1.1

7. Technical data

7.1. Specifications ....................................................................................................................................33

7.2. Electrical wiring and PCB settings ....................................................................................................40

7.3. Exploded view and components .......................................................................................................43

7.4. Possible hardware for installation .....................................................................................................45

7.5. Possible tools for installation.............................................................................................................46

7.6. Ambient conditions............................................................................................................................46

AM.04.265e - Edition 1.1 5

About this manual

1 About this manual

The manual shows the information necessary to:

-install

- carry out maintenance

- carry out troubleshooting

on the PVL guidance sign, in the manual referred to as the equipment.

1.1 How to work with the manual

1. Familiarize yourself with the structure and content.

2. Carry out the actions completely and in the given sequence.

1.2 Record of changes

Edition Editor Check Date Description

1.0 MR WGR,

TWE,

THA,

MA,

01/2014 New manual IP54 version

1.1 TWE WGR,

NBU

10/2015 Update for new parts and minor changes.

6AM.04.265e - Edition 1.1

About this manual

1.3 Abbreviations and terms

1.4 Icons used in the manual

For all WARNING symbols, see § 2.2.

Term or abbreviation Description

AGL Airfield Ground Lighting

CCR Constant Current Regulator

FAA Federal Aviation Administration

Fastener Generic term for an item that holds the equipment together or that

holds the equipment on its mounting support, e.g. nut, bolt, washer

FOD Foreign Object Debris

ICAO International Civil Aviation Organisation

IEC International Electrical Committee

IP Ingress protection

ISO International Standardization Organisation

Light source This can be a LED, a fluorescent lamp or an halogen lamp. The type

depends on the type of equipment.

LED Light Emitting Diode

Mounting support Any mounting interface for elevated lights. It can be a piece of

equipment permanently installed in or on the ground, on which the

light is installed. It can be a shallow or deep base. It can be with or

without adapter ring.

PCB Printed Circuit Board

UNC Unified Thread Standard

VOR check-point Very high Frequency Omni directional Range check-point. A point

on the aerodrome where there is sufficient signal strength from a

VOR to check the VOR equipment on the aircraft.

CAUTION

Can cause damage to the

equipment.

NOTE

Gives further information.

TIP

Gives information on how to carry

out or to understand the

instruction or information more

easily.

AM.04.265e - Edition 1.1 7

Safety

2 Safety

Read all warnings carefully. Failure to do so may result in personal injury, death, or property

damage.

2.1 Use

To use the equipment safely:

Refer to the International Standard IEC 61820, Electrical installation for lighting and

beaconing of aerodromes - Constant current series circuits for aeronautical ground lighting -

System design and installation requirements, and to the International Standard IEC 61821,

Electrical installations for lighting and beaconing of aerodromes - Maintenance of

aeronautical ground lighting circuits for instructions on safety precautions.

See FAA Advisory Circular AC 150/5340-26, Maintenance of Airport Visual Aids Facilities,

for additional instructions on safety precautions.

Observe all safety regulations. To avoid injuries, always remove power prior to making any

wire connections and touching any live part. Refer to the International Standards IEC 61820

and IEC 61821.

In addition for a parallel power supply also take into account the International Standard IEC

60598 (for class I equipment).

Read and become familiar with the general safety instructions provided in this chapter

before you install, operate, maintain or repair the equipment.

Read and carefully follow the instructions given throughout this manual before installing,

operating, maintaining, or repairing the equipment.

Store this manual within easy reach of personnel installing, operating, maintaining or

repairing the equipment.

Follow all applicable safety procedures required by your company, industry standards, and

government or other regulatory agencies.

Obtain and read Material Safety Data Sheets (MSDS) for all materials used.

2.2 Safety symbols

Become familiar with the safety symbols presented in this chapter. These symbols will alert you

to safety hazards and conditions that may result in personal injury, death, or property and

equipment damage.

WARNING 1: Failure to observe this warning may result in personal injury, death, or

equipment damage.

WARNING 2: Risk of electrical shock. Disconnect equipment from line voltage.

Failure to observe this warning may result in personal injury, death, or equipment

damages.

WARNING 3: Wear personal protective equipment. Failure to observe may result in

serious injury.

WARNING 4: Do not touch. Failure to observe this warning may result in personal

injury, death, or equipment damage.

8AM.04.265e - Edition 1.1

Safety

2.3 Skilled personnel

The term skilled personnel is defined here as individual who thoroughly understand the

equipment and its safe operation, maintenance, and repair. Skilled personnel are physically

capable of performing the required tasks, familiar with all relevant safety rules and regulations

and have been trained to safely install, operate, maintain, and repair the equipment. It is the

responsibility of the company operating the equipment to see that its personnel meet these

requirements.

2.4 Liability

ADB cannot be held responsible for injuries or damages resulting from non-standard, unintended

uses of its equipment. The equipment is designed and intended only for the purpose described in

the manual. Uses not described in the manual are considered unintended uses and may result in

serious personal injury, death or property damage.

Unintended uses includes the following actions:

Making changes to equipment that have not been recommended or described in this

manual or using parts that are not genuine ADB replacement parts or accessories.

Failing to make sure that auxiliary equipment complies with approval agency requirements,

local codes, and all applicable safety standards if not in contradiction with the general rules.

Using materials or auxiliary equipment that are inappropriate or incompatible with your ADB

equipment.

Allowing unskilled personnel to perform any task on or with the equipment.

2.5 Installation

Read the installation section of all system component manuals before installing your equipment.

A thorough understanding of system components and their requirements will help you install the

equipment safely and efficiently.

Allow only skilled personnel to install ADB and auxiliary equipment. Use only approved

equipment. Using unapproved equipment in an approved system may void agency

approvals and will void the warranty.

Make sure all equipment is rated and approved for the environment in which you are using

it.

Follow all instructions for installing components and accessories.

Install all electrical connections to local code provided they are not in contradiction with the

general rules.

Use only electrical wire of sufficient gauge and insulation to handle the rated current and

voltage demand. All wiring must meet local codes.

Route electrical wiring along a protected path. Make sure they will not be damaged by

moving equipment and animals (e.g. rodents).

Protect components from damage, wear, and harsh environment conditions.

Allow ample room for maintenance, panel accessibility (power products), and cover removal

(power products).

Protect equipment with safety devices as specified by applicable safety regulations.

If safety devices must be removed for installation, install them immediately after the work is

completed and check them for proper functioning.

WARNING

Use of the equipment in ways other than described in the catalogue leaflet

and the manual may result in personal injury, death, or property and

equipment damage. Use this equipment only as described in the manual.

WARNING

Failure to follow these safety procedures can result in personal injury or

death.

AM.04.265e - Edition 1.1 9

Safety

2.6 Fasteners

Example It is possible to insert a 3/8” UNC screw in a M10 threaded hole. However, such a combination

damages the female thread and does not ensure a correct fastening. The screw could loosen

under the influence of aircrafts that roll over. The use of incorrect screws can lead to either

damage to the thread in the mounting support or to an incorrect fixation of the equipment.

2.7 Operation

Only skilled personnel, physically capable of operating the equipment and with no impairments in

their judgment or reaction times, should operate this equipment.

Read all system component manuals before operating the equipment. A thorough understanding

of system components and their operation will help you operate the equipment safely and

efficiently.

Before starting this equipment, check all safety interlocks and protective devices such as

panels and covers. Make sure all devices are fully functional. Do not operate the equipment

if these devices are not working properly. Do not deactivate or bypass automatic safety

interlocks or locked-out electrical disconnects or pneumatic valves.

Never operate equipment with a known malfunction.

Do not attempt to operate or service electrical equipment if standing water is present.

Use the equipment only in the environments for which it is rated. Do not operate the

equipment in humid, flammable, or explosive environments unless it has been rated for safe

operation in these environments.

Never touch exposed electrical connections on equipment while the power is ON. Make

sure the exposed electrical connections are proven to be dead.

2.8 Action in the event of an equipment malfunction

Do not operate a system that contains malfunctioning components. If a component malfunctions,

turn the system OFF immediately.

1. Disconnect and lock out electrical power.

2. Allow only skilled personnel to make repairs. Repair or replace the malfunctioning

component according to instructions provided in its manual.

WARNING

Only use fasteners of the same type as the one originally supplied with

the equipment.

Always tighten the fasteners to the recommended torque. Use a

calibrated torque wrench and apply the recommended adhesive type.

Obey the instructions of the adhesives necessary for the fasteners.

If this is not the case, this may cause the fasteners to loosen, damage the

equipment, potentially to loosen the equipment. This can lead to a highly

dangerous situation of FOD, with potential lethal consequences.

10 AM.04.265e - Edition 1.1

Safety

2.9 Maintenance and repair

Allow only skilled personnel to perform maintenance, troubleshooting, and repair tasks. Only

persons who are properly trained and familiar with ADB equipment are permitted to service the

equipment.

Always use safety devices when working on the equipment.

Follow the recommended maintenance procedures in your equipment manuals.

Do not service or adjust any equipment unless another person trained in first aid and Cardio

Pulmonary Resuscitation (CPR) is present.

Connect all disconnected equipment ground cables and wires after servicing equipment.

Ground all conductive equipment.

Use only approved ADB replacement parts. Using unapproved parts or making unapproved

modifications to equipment may void agency approvals, impair specified performance and

create safety hazards.

Check interlock systems periodically to ensure their effectiveness.

Do not attempt to service electrical equipment if standing water is present. Use caution

when servicing electrical equipment in a high-humidity environment.

Use tools with insulated handles when working with electrical equipment.

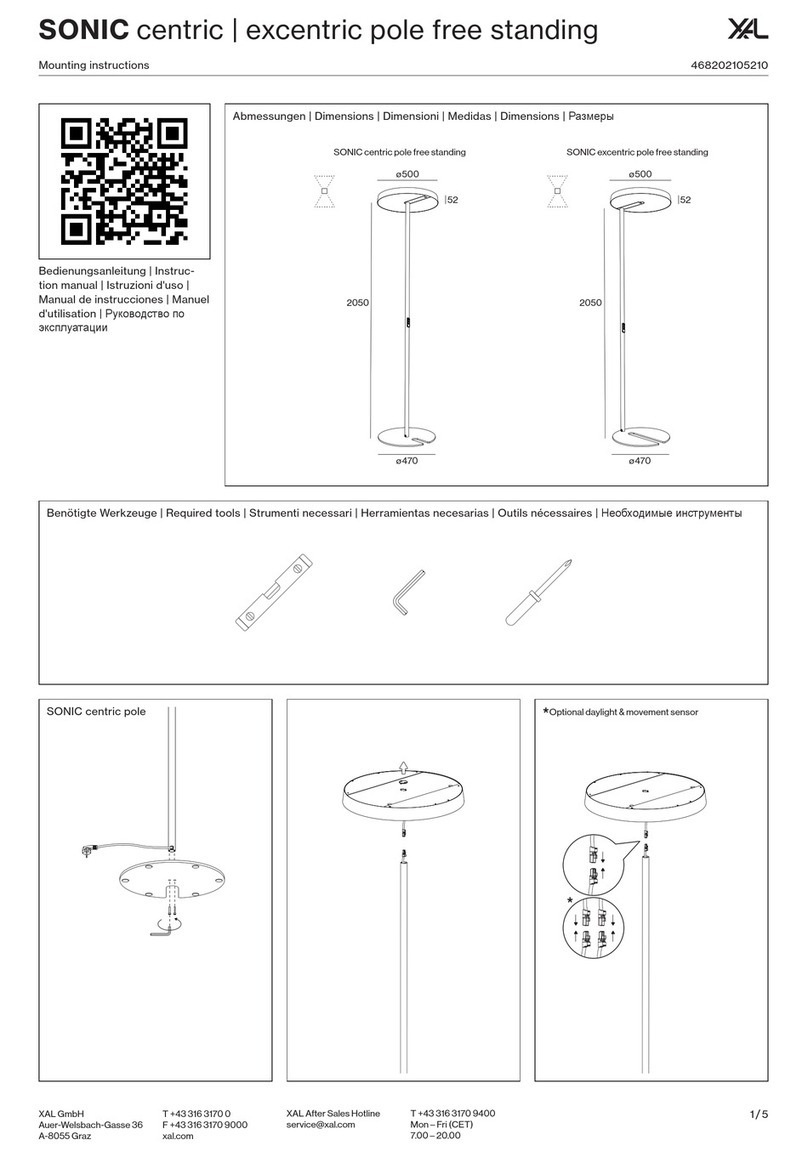

2.10 Breakable coupling

A: Mounting leg

B: Weakening groove

C: Mounting flange

The equipment is mounted on mounting legs.

The mounting legs have a weakening groove,

which serves as a breakable coupling.

Expansion bolts secure the mounting flanges to

the foundation.

2.11 CE certification

The equipment is CE certified. It means that the product complies with the essential

requirements concerning health and safety. The directives that have been taken into

consideration in the design are available on written request to ADB.

2.12 Guarantee

LED Products of ADB Airfield Solutions manufactured and sold by ADB or its licensed

representatives, meet the corresponding requirements of FAA, ICAO and IEC.

Refer to the document ‘General Conditions for Deliveries and Services by ADB’.

C

B

A

AM.04.265e - Edition 1.1 11

Description

3 Description

3.1 Overview

You can find a complete overview of the equipment in all available versions in the chapter 7.

3.2 Intended use

On civil aerodromes:

- Mandatory instruction signs

- Information signs

- VOR check-point sign

3.3 Variants of equipment

The equipment can be also supplied with these options:

- An additional safety switch. The safety switch allows safe servicing on the equipment when

the safety switch is set to the OFF position. The safety switch is mainly used for equipments

that are supplied directly from the mains supply with 230 V AC.

- Supply cables that go through the mounting legs.

- A tether to secure the equipment.

The manual does not show these variants in detail.

12 AM.04.265e - Edition 1.1

Description

AM.04.265e - Edition 1.1 13

Installation

4 Installation

4.1 Inspect on delivery

1. Inspect all packings for visible damage.

2. Open every damaged box and inspect the contents for damage.

3. Immediately fill a claim form with the carrier if any equipment is damaged.

4. Store the equipment in its original packing in a protected area.

4.2 Store

1. Store the equipment in its original packing in a protected area.

4.3 Install according to standards

1. See these standards:

- ICAO Annex 14, volume 1;

- ICAO Airport Design Manual, parts 4 and 6, section that refer to signs;

- ICAO Airport Design Manual, part 5 ‘Electrical Systems’;

- IEC 61820 and 61821.

2. For a parallel power supply, see also:

- IEC 61950 (low voltage directive);

- IEC 60598-1 (class I equipment).

4.4 Overview of components required for installation

- Assembled equipment;

- Secondary cable(s) and possibly a flexible conduit.

- Series circuit: 2-core cable with FAA plug (supplied with the equipment);

- Parallel circuit: 2-core cable with earthing wire (not supplied with the equipment);

- Hardware for installation. See § 7.4.

- Tools for installation. See § 7.5.

- Series transformers. See § 7.1. Series circuit only.

- Optional: security cable or tether.

WARNING

The equipment meets IEC 60598-1. Make sure that you make all electrical

connections accordingly.

Note

- The figures show a typical connection that uses an ADB conduit elbow.

- The procedures in this chapter show the complete information for a

series power supply. For a parallel power supply, the procedures are

similar. The difference is that there is no series transformer necessary.

The power supply cable that comes from a derivation box or connection

box is directly connected to the power adaptor within the equipment.

WARNING

Do not damage the cable insulation.

CAUTION

Do not unpack the equipment before it is at the installation site to avoid

damage due to transportation and handling.

Installation

Installation AM.04.265e - Edition 1.1

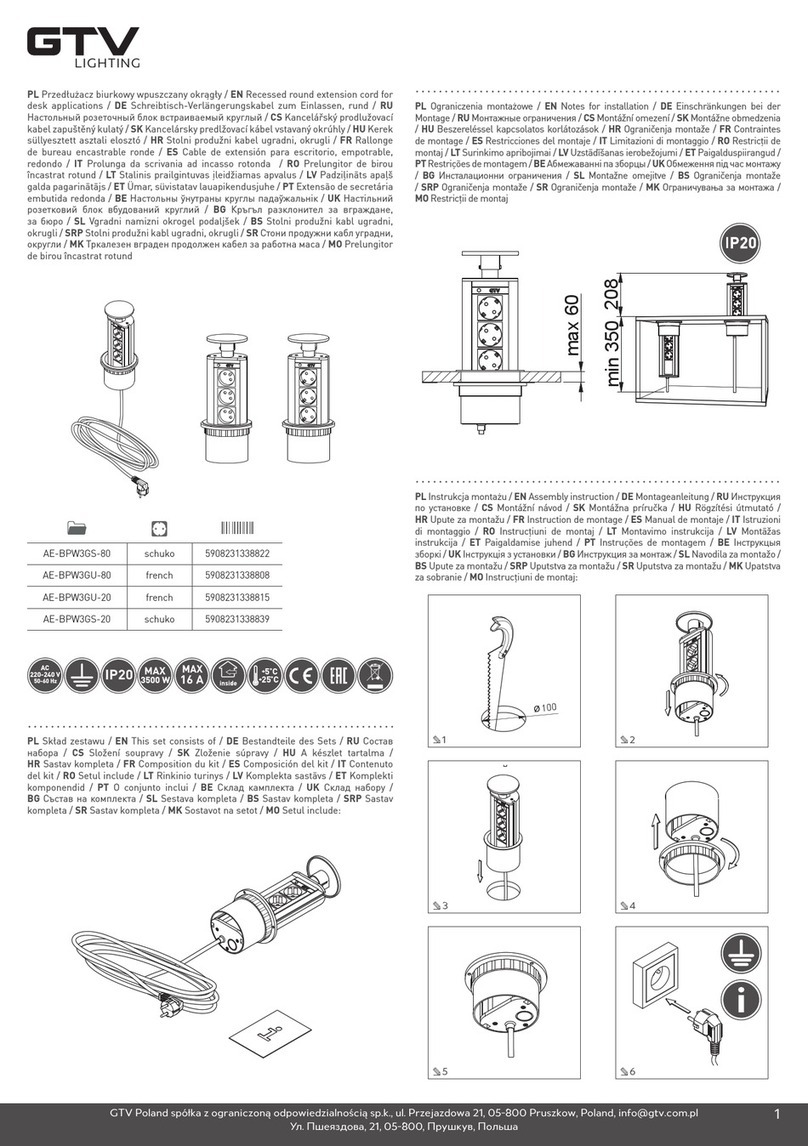

4.5 Installation examples

Example 1

Items: A: Ground level

B: Primary series loop

C: Transformer pit or housing with drainage

to ground or drain

D: Weather proof sealing and filling

E: Conduit elbow

F: M10 expansion bolt (3 per flange)

G: Concrete block

H: Sign

I: Message

J: Frost line

Measurements: X1: 748 mm

X2: 700 mm

X3: minimum 300 mm

X4: 100 mm

X5: 644 mm

Y1: 640 mm

Y2: 600 mm

Y3: 25 mm

Y4: minimum 575 mm

Y5: minimum 100 mm

Z1: 230 mm horizontal

Z2: minimum 830 mm

Z3: minimum 300 mm

Z4: 230 mm

Z5: minimum 300 mm

Z6: 50 mm

V1: diameter 145 mm

V2: angle 120 degrees

V3: 2 cm per 1 m

Note

These examples show general installation details. The drawings are for

instructional use only, do not use them as construction drawings for specific

projects.

6048

A

Y1

Y1

Z1

X1

V1

V2

X3

X4

X5 X3

V2

V1

Z6 Z4

Z5

Z3

Z2

G

Y4

J

Y5

V3

A

Y3

Y2

X1

X2

I

C

B

A

H

D

E

F

NOTE

- Depending on the type of power supply (series or parallel), the

transformer pit contains the series transformer or a derivation box.

- You must install one transformer per series power supply. Refer to

section 7.1.3 Power consumption series supply to choose the size of the

transformer.

Installation

AM.04.265e - Edition 1.1 15

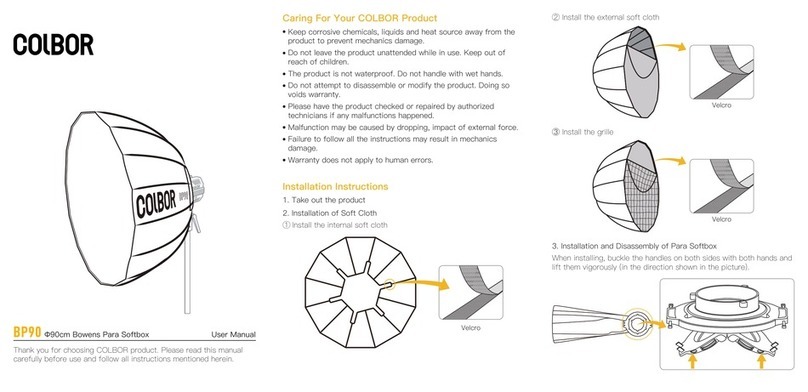

Example 2

Items: A: Base L-867B or transformer pit

B: Weather proof sealing and filling

C: M10 expansion bolt (3 per flange)

D: Conduit elbow

E: Concrete block

F: Ground level

G: Frost line

H: Sign

I: Message

J: Electrical connection through leg (option)

Measurements: X1: 2100 mm

X2: 36 mm

X3: 1900 mm

X4: 750 mm

X5: 500 mm

X6: 1023 mm

X7: 1023 mm

X8: 140 mm

X9: 923 mm

X10: 923 mm

X11: 300 mm

X12: 100 mm

X13: 140 mm

X14: 36 mm

Y1: 840 mm

Y2: minimum 575 mm

Y3: minimum 100 mm

Z1: 50 mm

V1: diameter 60 mm

V2: diameter 145 mm

V3: angle 120 degrees

07-25

CAT II

X13

V2

V3

V2

X14 I

3 x M10

X8 X9 X10 X11

X4 X5

X12

Z1

H

V1

X6

X12

H

X7

Z1 II

F

X3

X2

X1

H

Y2

Y1

Y3

A

I

B

C

DJ

E

G

NOTE

- Depending on the type of power supply (series or parallel), the

transformer pit contains the series transformer or a derivation box.

- You must install one transformer per series power supply. Refer to

section 7.1.3 Power consumption series supply to choose the size of the

transformer.

16 AM.04.265e - Edition 1.1

Installation

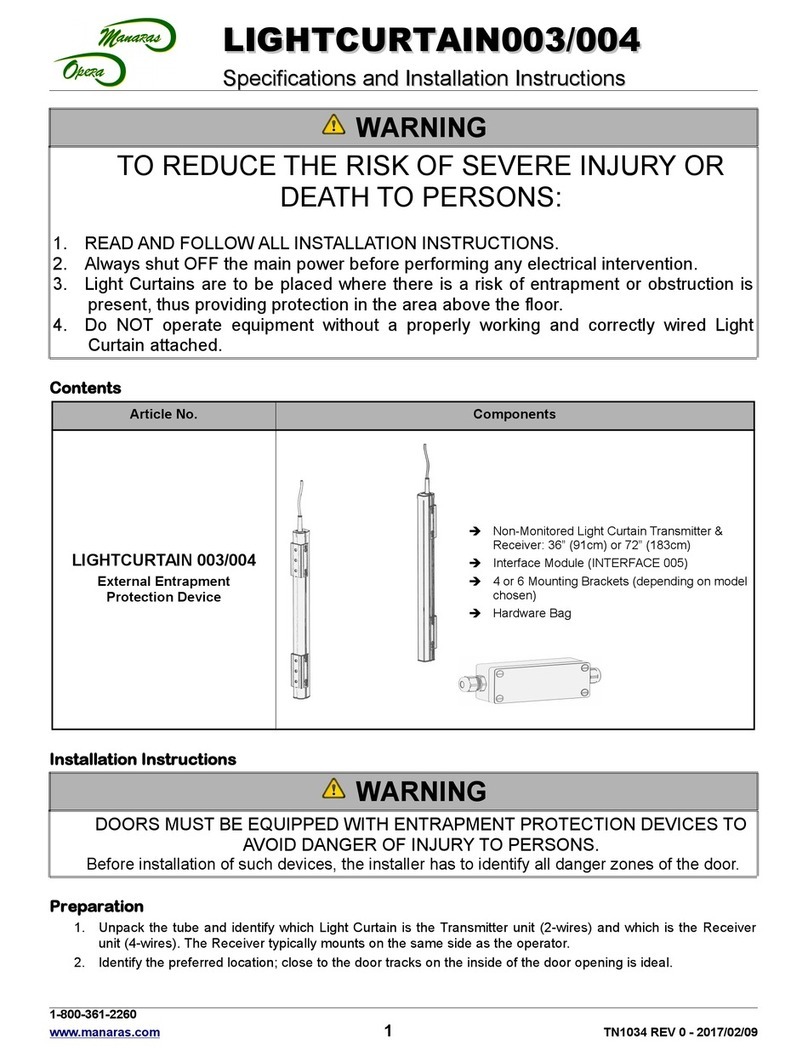

4.6 Determine location of equipment

1. Determine the perpendicular distance for

the defined taxiway or runway pavement

edge to the nearest edge of the equipment.

Use table 5-5 of ICAO Annex 14, Volume 1.

2. In the case of adjacent equipment, make

sure that:

- The equipment is separated with a

distance X = 36 mm;

- The centre lines of adjacent mounting

legs are separated with a distance Y

= 140 mm.

3. Determine the exact location and

orientation on site.

4. Make sure that the Airport Authority approves the exact location.

4.7 Install concrete foundation

Prepare 1. Define the dimensions of the concrete foundation block, based on several factors among

which:

- The length of the equipment;

- The height of the equipment;

- The bearing of the soil;

- The stability of the soil;

- The frost line: the depth of the foundation must be more than the depth of the frost line.

2. Use one-piece concrete block for adjacent equipment.

Choose casting

method

1. Choose between:

- Cast the concrete blocks in situ;

- Use pre-fabricated concrete blocks.

2. Accurately level and smoothen the top surface of the concrete foundation.

4.8 Install transformer housing (series circuit only)

Each equipment requires one to three series transformers. See § 7.1. A series transformer must

be installed in a transformer housing, adjacent to the sign foundation.

Note

Also take into consideration the unobstructed equipment legibility and

the protection from direct exhaust blast.

Y

X

Note

The drawings in § 4.6 show typical examples.

CAUTION

If this is not the case, the concrete can crack under the pressure of the

expansion bolts of the adjacent (outer) legs.

AM.04.265e - Edition 1.1 17

Installation

Define location of

transformer

housing

A Equipment

B Transformer housing location

C Primary cable

1. Make sure the transformer housing is

adjacent to the sign foundation. The figure

shows some possible arrangements.

2. Make sure that you can easily access the

transformer and do not need to remove the

equipment.

Choose

transformer

housing type

1. Choose between:

- Transformer pit;

- FAA steel base.

Install

transformer pit A Load bearing cover

B Equipment

C Conduit elbow

D Typical water drainage hole

E Series transformer

F Ground level

1. Install the transformer pit. The figure shows

a possible installation layout.

2. Make sure that the space between the

centres of the conduit elbow and the

adjacent mounting leg (X) is minimum 185

mm.

3. Make sure the space between the side of

the base and the adjacent expansion bolts

of the equipment is large enough (recommended minimum 100 mm).

Install FAA steel

base A Bolted steel cover, 10 mm thickness

B Conduit coupling

C Equipment

D Flexible conduit

E 2” or 3” diameter entry for primary cables

F Water drainage pipe (optional)

G FAA L867 base, diameter 12, depth 400 or

610 mm

H Ground level

1. Install the FAA steel can. The figure shows

a possible installation layout.

2. Make sure the space between the side of

the base and the adjacent expansion bolts

of the equipment is large enough

(recommended minimum 100 mm).

BA

I

II

III

AAA

BB B

A

BC

C

C

AA

25

E

AF B

D

C

X

25-

G

BAH

C

D

F

E

18 AM.04.265e - Edition 1.1

Installation

4.9 Install equipment

Prepare 1. Put the equipment on the concrete foundation.

2. Align the equipment, especially in the case of adjacent equipments.

3. Mark the position of the fixation holes. Use the drill template. See § 7.5.

4. Remove the equipment.

5. Drill the fixation holes.

Install 1. Put the equipment above the fixation holes.

2. Tighten the expansion bolts (A) with a torque

of 27 Nm.

3. Install the tether (B) (Option).

4. Remove the protection film from the legend

panel.

4.10 Install the tether (Option)

1. Put the fastener (A) through these items:

- Hole (B)

- Washer (C)

-Nut(D)

2. Tighten the nut (D).

3. Install these parts:

- Bracket (E)

- washer (F)

-Nut(G)

4. Tighten the nut (G) with a torque of 27 Nm.

Note

If you do not use the drill template, the figure in § 7.1.2 shows the

dimensions.

Note

This procedure describes the use of expansion bolts. You can also use

bent anchor bolts or resin bolts. Refer to your bolt supplier for

installation instructions.

B

A

BA

E

F

G

DC

AM.04.265e - Edition 1.1 19

Installation

4.11 Electrical connection through leg (option)

1. Prepare a hole (A) with a diameter of

63 mm.

2. Pull the secondary cable (B) through the

leg (C).

Note

The secondary cable is not

supplied with the equipment

C

A

B

20 AM.04.265e - Edition 1.1

Installation

4.12 Install electrical connection

Enter cable into

the equipment

1. Open the equipment. See § 5.2.

2. Slip the flexible conduit over the cable, if used.

3. Enter the supply cable(s) into the equipment through the compression gland(s) or the

nipple(s) at the bottom of the equipment or through the compression gland in the leg, see §

4.11.

Connect cable to

equipment

For an overview of the location of the input terminals and glands, see § 7.2.3.

Parallel power supply

1. Connect the cables (A) to the input

terminals 1 and 5 of the connector (C).

Connect the earth cable (B) to input

terminal 3 of the connector (C).

Series power supply

1. Connect the cables (A) to the left

receptable (B) and the right receptable (C)

of the connector.

Note

We recommend to run the cable either through a flexible conduit or

through the left outer leg for protection against damage caused by

rodents and UV-radiation.

1

2

3

4

5

6

CA

B A

A

A

B

C

This manual suits for next models

1

Table of contents

Other ADB Lighting Equipment manuals