Gasket for top lid and junction box shall be replaced at

intervals of one year. (Part No. 5001 0040 and 5001 0041).

Gaskets shall be of same type as originals. One set of

replacement gaskets are included in shipment.

The navigation light should be inspected according to

Company routines. The manufacturer suggests regular

check for water intrusion / condensation which should

be removed immediately. When cleaning, use only mild

detergents. Alcohol or petroleum based products may

damage lens, paint or plastic components.

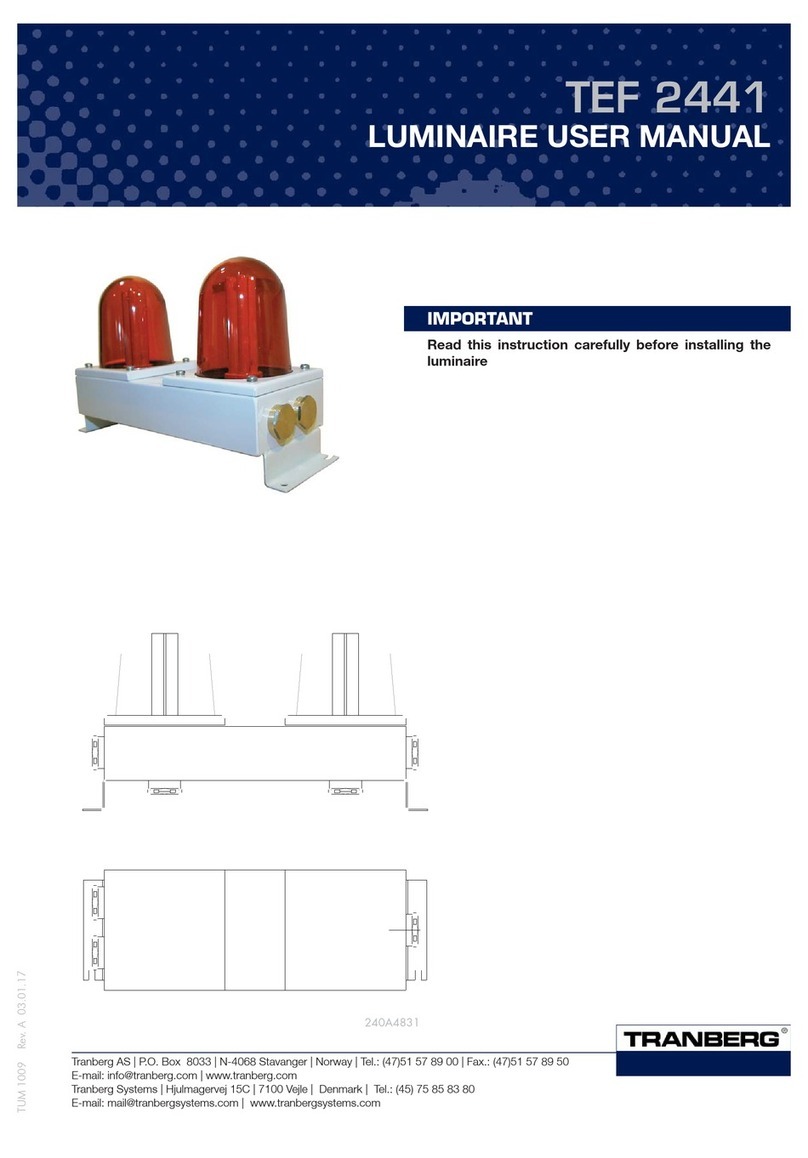

TEF 2850 Ex NAVIGATION LIGHT USER MANUAL

TOOLS REQUIRED

Thank you for purchasing this product!

For installation, maintenance and assurance of a long life

of this product, please follow this manual.

CONTENT IN BOX

The product is fully assembled, and ready for installation.

SAFETY PRECAUTIONS

Note that changes made to the product and/or installation

of components which do not conform to the approval,

may be a safety violation. The manufacturer will in no

circumstance be held responsible for such activity. For

your health and safety, always use safety gear suited for

the task. Be certain to follow codes, regulations and/or

specific procedures that are related to the installation.

INTRODUCTION

Regular tools required for installation.

• Wrench(es) suitable for selected M10 bolts for fixing

navigation light to mast / ships structure.

• Flat screwdriver for opening junction box.

• 27mm wrench for installing of cable gland.

• 19 mm wrench for opening top lid.

• Small flat screwdriver for terminating wires.

IMPORTANT INFORMATION

The navigation lights are supplied with galvanic isolators.

These should be placed between the navigation lights and

the wall, thus preventing corrosion to either. There should

be used acid resistant stainless steel fixing screws/bolts.

Never paint the navigation light or any of its components.

Use only spare parts as described.

MAINTENANCE INSTRUCTIONS

INSTALLATION INSTRUCTIONS

The navigation light should be installed according to IMO reg-

ulations and other relevant rules and regulations for electrical

installations onboard ships.

Consider the difference in material between the navigation

light (seawater resistant brass) and the wall/mast it is to be

installed on. Use galvanic isolators whenever there is a risk of

corrosion.

• Fix navigation light to mast / ships structure using M10

bolts (not supplied). Use acid resistant screws/bolts.

Tight firmly, max. 25 Nm.

• Open junction box to install and secure electrical cable.

The cable must be clamped near up to the navigation

light according to relevant rules and regulations for

electrical installations onboard ships.

• Connect electrical wires. Max. 2.5mm2. Strip length

8mm. Tightening force 0.6-0.8nm. Connect ground wire

to M5 earth screw in junction box.

• Screw on junction box lid. Max. tightening force: 5 Nm.

Make sure that gasket is centered and covering the

whole perimeter.

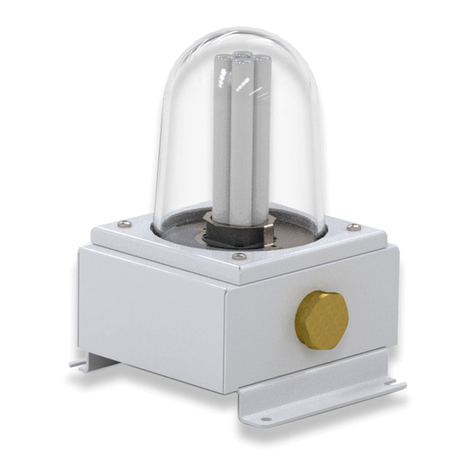

• External bonding conductor. Connect bonding wire to

point shown in illustration below.

At intervals according to company routines, the restricted

breathing properties should be verified. Remove stopping

plug at test port (M20). See illustration below. Connect

pressure meter / vacuum pump and conduct test according

to IEC 60079-15(2010) 23.2.3.2.1.1. Note: M20 gland for

connection of Ø5-10mm hose is included in shipment.

Note: According to approval, test of restricted breathing

properties is not required.

Allround Navigation Light Sector Navigation Light