ADB EURODIM TWIN TECH User manual

Installation Manual

V 1.2

EURODIM Twin Tech

M 3213 1106.03.213

Lighting Technologies

EURODIM TWIN TECH

www.adblighting.com

Installation manual - Page 1

Version 1.2

INDEX

1. DELIVERY - UNPACKING ........................................................................................................... 3

2. DESCRIPTION.............................................................................................................................. 4

3. INSTALLATION............................................................................................................................ 5

3.1 Dimmer room......................................................................................................................... 5

3.1.1 Preparation ........................................................................................................................ 5

3.2 Ventilation of the dimmer room.............................................................................................. 6

3.2.1 Example No. 1 ................................................................................................................... 6

3.3 Installation of the cabinets..................................................................................................... 7

3.3.1 Tools for commissioning.................................................................................................... 7

3.3.2 Packaging .......................................................................................................................... 8

3.3.3 Lifting Eyes (Optional Accessory)...................................................................................... 8

3.3.4 Junction Plate (optional part)............................................................................................. 8

4. CONTRACTOR'S COMPARTMENT –SUPPLY ....................................................................... 10

4.1 Controller Electronics - CPU/ PSU crate............................................................................. 11

4.2 Supply voltage..................................................................................................................... 11

4.3 Supply busbar...................................................................................................................... 12

4.3.1 Protected Earth (PE)........................................................................................................ 13

4.4 Connecting power supply cables......................................................................................... 13

4.5 Ground and Earth Connections........................................................................................... 14

5. SEQUENTIAL DIAGNOSTICS (Optional)................................................................................. 15

5.1 Hardware installation........................................................................................................... 16

5.2 Mounting Procedure ............................................................................................................ 17

5.3 Finished installation............................................................................................................. 17

5.4 Software Installation ............................................................................................................ 18

5.5 Overview of the User Interface Menu items........................................................................ 20

5.6 TTD Management SOFTWARE.......................................................................................... 21

5.7 References and Element Codes ......................................................................................... 22

6. CONTRACTOR’S COMPARTMENT – OUTPUTS .................................................................... 23

6.1 Outputs to the loads ............................................................................................................ 24

6.2 Identification of the dimmers................................................................................................ 24

6.3 Load terminals for 4 x 2.5 / 3 kW modules.......................................................................... 24

6.4 Load terminals for 3 x 5 kW modules.................................................................................. 24

6.5 Load terminals for 2 x 3 kW fluo modules ........................................................................... 24

6.6 Load terminals for 10kW modules....................................................................................... 25

DMX and Ethernet terminals............................................................................................................. 26

6.6.1 DMX Connection –type of cable..................................................................................... 26

6.6.2 Pin numbering.................................................................................................................. 27

6.6.3 DIP switches SW1 –termination of the DMX data lines.................................................. 27

6.7 Local / Remote Controller selector switch CPU1 –CPU2 –Automatic .............................. 28

7. TTD HUMAN INTERFACE ......................................................................................................... 29

8. PLUG IN MODULES................................................................................................................... 31

8.1 DimSwitch - Thyristor Technology....................................................................................... 31

8.2 Sine Wave Technology........................................................................................................ 31

8.3 NON-DIM (Feed Through) modules.................................................................................... 31

8.4 Blank Panels........................................................................................................................ 31

8.5 Distribution of the dimmers over the phases....................................................................... 31

8.6 Protections –types, number of poles.................................................................................. 31

8.7 Dimmer module protection by HRC fuse............................................................................. 32

EURODIM TWIN TECH

www.adblighting.com

Installation manual - Page 2

Version 1.2

8.8 Dimmer protection by MCB ................................................................................................. 32

8.9 Residual Current Devices (RCD Ground Fault Protection)................................................. 32

8.10 Installing Dimmer Modules.................................................................................................. 33

8.11 CONTROLLER UNIT (CPU) - POWER SUPPLY UNIT (PSU)........................................... 34

8.12 BLANK MODULES.............................................................................................................. 35

8.13 MODULE LOCKS................................................................................................................ 36

9. CHARACTERISTICS.................................................................................................................. 37

9.1 Electrical characteristics...................................................................................................... 37

9.2 Physical characteristics....................................................................................................... 38

10. DMX NETWORK AND INTERCONNETCIONS ......................................................................... 39

10.1 Example 1: One DMX lighting desk, one CPU per EURODIM cabinet............................... 39

10.2 Example 2: One DMX lighting desk, two CPU’s per EURODIM cabinet............................. 39

10.3 Example 3: Two DMX lighting desks, one CPU per EURODIM cabinet ............................. 39

10.4 Example 4: Two DMX lighting desks, two CPU’s per EURODIM cabinet (case A) ........... 40

10.5 Example 5: Two DMX lighting desks, two CPU’S per EURODIM cabinet (case B)............ 40

11. Appendix B –Drawings............................................................................................................ 41

11.1 5000-35-650 EURODIM Twin Tech –Vertical Packaging (standard)................................. 41

11.2 3500.01.650 Power Modules 1 - 8 ...................................................................................... 42

11.3 3500.01.660 Power Modules 9 - 16 .................................................................................... 43

11.4 3500.01.670 Power Modules 17 - 24 .................................................................................. 44

11.5 3500.01.680 Power Modules 25 - 32 .................................................................................. 45

11.6 10 kW Module Connection .................................................................................................. 46

11.7 3650.00.311 PCB3031 DMX512 Connection...................................................................... 47

11.8 3650.00.311 PCB3031 Selector with Wiring....................................................................... 48

11.9 3500.01.710 OUTPUT TERMINALS FOR FLUO Modules................................................. 49

11.10 CE Certificate for EURODIM Twin Tech ............................................................................. 50

12. Appendix C–Power Supply for Thyristor Dimmers –Basic Principles for Safe Electrical

Design................................................................................................................................................... 51

12.1 Phase-control dimmers........................................................................................................ 51

12.2 Use ‘true rms’ voltmeters only ............................................................................................. 51

12.3 Current in the Neutral –Sine Wave..................................................................................... 51

12.4 Current in the Neutral –Dimmer Systems........................................................................... 52

12.5 Practical implications........................................................................................................... 52

12.5.1 Example No. 1............................................................................................................. 52

12.5.2 Example No. 2............................................................................................................. 52

12.5.3 Example No. 3............................................................................................................. 52

12.6 Main transformer, cables, switchgear, busbar systems ...................................................... 53

12.7 Voltage distortion and 'short-circuit voltage' of the main transformer.................................. 53

13. Appendix D: Specification of Magnetic Circuit Breakers (MCB).......................................... 54

14. CONFIGURATION TABLES ...................................................................................................... 55

EURODIM TWIN TECH

www.adblighting.com

Installation manual - Page 3

Version 1.2

1. DELIVERY - UNPACKING

Thank you for purchasing our EURODIM Twin Tech installation dimmer. We have designed

this installation dimmer to provide you with a superior professional dimmer in design and

engineering. We are confident that it will perform to our expectations for many years to come.

Upon delivery of your equipment, open the packaging carefully and examine the device. If

you observe any damage, contact the shipping company immediately and have your

complaint duly recorded. Please take pictures in order to prevent further misunderstandings.

The plug-in dimmer modules, Human (User) Interface and controller(s) are shipped

separately from the cabinet. You may rest assured that your equipment left our factory in

perfect condition. Check whether what you have received is in conformity with the delivery

notice and whether the notice is in conformity with your order.

In the event of any error, contact your shipper immediately to clarify the situation and receive

full satisfaction.

If you find nothing wrong, replace the material in the packing and store it in a warm place,

away from dust, humidity and mechanical hazards, while awaiting final installation.

Never leave the material unprotected on the work site.

Programming and setting up the cabinet (configuration) is described in a separate manual.

CAUTION!

Installation is entirely at your own risk. Read this installation manual from cover to cover

before attempting installation. Do not attempt installation unless you are suitably qualified.

Installation errors may endanger operators and cause system damage and failure. If you do

not understand a point in this manual, don’t guess. Contact ADB or one of our authorised

distribution partners for advice.

We recommend ordering commissioning through ADB or one of our authorised partners prior

energizing the system. Not following this recommendation may result in equipment damage

that may not be covered by your warranty!

EURODIM TWIN TECH

www.adblighting.com

Installation manual - Page 5

Version 1.2

3. INSTALLATION

3.1 Dimmer room

3.1.1 Preparation

Determine the dimensions of the dimmer room so as to place all EURODIM Twin Tech

cabinets easily. Provide for an open space of approximately 90 cm in front of the cabinets to

facilitate maintenance. Before attempting to move the rack(s) into the final position, check

access routes to the dimmer room for space to manoeuvre through doorways and around

corridor corners. The cabinets can be placed against a wall, side by side or back to back.

The supply cables and the load cables can enter the wiring compartment either from the top

or bottom of the cabinet. See drawing for size and location of cable entries.

Dimmer Room Requirements

A clean (not dusty) temperature-controlled environment.

Restricted public access to prevent any unauthorised tampering with the

dimmer settings.

Soundproofing or performance area separation to muffle ventilation fan noise.

Acoustic measurements are available from ADB Lighting Technologies.

Provide for a free space, minimum 30 cm above the EURODIM Twin Tech so

as to facilitate the exhaust airflow. If an optional “Silencer” is used, then more

space may be necessary. The dimensions and weight of the cabinets are

included in the Chapter “Characteristics”. Plan for fire extinguishers in

compliance with local regulations. The lighting of the area should be sufficient

for maintenance and inspection. A level of 300 lux is considered satisfactory.

Plan for mains outlets in the room, independent of the supply of the dimmers.

Plan for an Ethernet network to the control room and a cable for remote “CPU1 - CPU2”

selection (if applicable).

EURODIM Twin Tech cabinets are professional equipment and relevant safety rules are

applicable. EURODIM Twin Tech cabinets should be placed in areas that are accessible only

to persons responsible for maintenance, surveillance or repair of the equipment.

Please refer to local regulations and requirements.

Such an area should be located as close as possible to the stage or studio, in order to

reduce the length of the electrical cables, and therefore, the cost of installation. At the time of

installation of the cabinets in the area, it should be completely unobstructed; that is, that all

engineering work, wall or floor covering work, painting, electric lighting work, drilling, welding,

etc., must be completed.

Do not install the plug-in modules until all wiring installation is completed.

EURODIM Twin Tech has been designed to European standards for electrical switchgear

EN60439. It is CE marked. See chapter 11.10 CE Declaration Document for EURODIM Twin

Tech.

EURODIM TWIN TECH

www.adblighting.com

Installation manual - Page 6

Version 1.2

3.2 Ventilation of the dimmer room

The dimmer room should be dry at all times, free from dust and ventilated in such a manner

as to comply with the following:

-Relative humidity: 5% to 90% without condensation.

-Temperature between + 5 °C and + 35 °C (ideal: + 20 °C).

In order to size the air-conditioning equipment required for the dimmer room, refer to the

following dissipations:

-Cabinet electronics including 150 W global value for CPU(s), PSU and fans

-Thyristor modules:

o4 x 3 kW modules : 37 W per dimmer (worst case)

o3 x 5 kW modules : 69 W per dimmer (worst case)

o1 x 10 kW modules : 170 W per dimmer (worst case)

-Sinewave modules:

o4 x 2.5 kW modules : 60 W per dimmer (worst case)

-No-load losses of sine wave dimmers:

oSine wave dimmers have a no-load loss of approximately 4 W per dimmer.

In practice, you may consider a utility factor of 0.6: that is, on the average, 60% of the

dimmers are at full load, while 40% are off.

3.2.1 Example No. 1

A dimmer room with a EURODIM Twin Tech cabinet equipped with 128 thyristor dimmers of

3 kW and a second cabinet with 96 thyristor dimmers of 5 kW. The cabinets are fitted with a

back-up power supply for the processor unit. Utility factor = 0.6

1) Cabinet N°1

Electronics: 1 x 150 W

Dimmers 128 x 37 W x 0.6 = 2841 W

2) Cabinet N°2

Electronics: 1 x 150 W

Dimmers 96 x 69 W x 0.6 = 3974 W

ROOM TOTAL: 7115 W (1 W = 0.86 kcal/hour) or 6119 kcal/hour.

In this example, it will be necessary to evacuate approximately 7115 W of losses.

EURODIM TWIN TECH

www.adblighting.com

Installation manual - Page 7

Version 1.2

3.3 Installation of the cabinets

3.3.1 Tools for commissioning

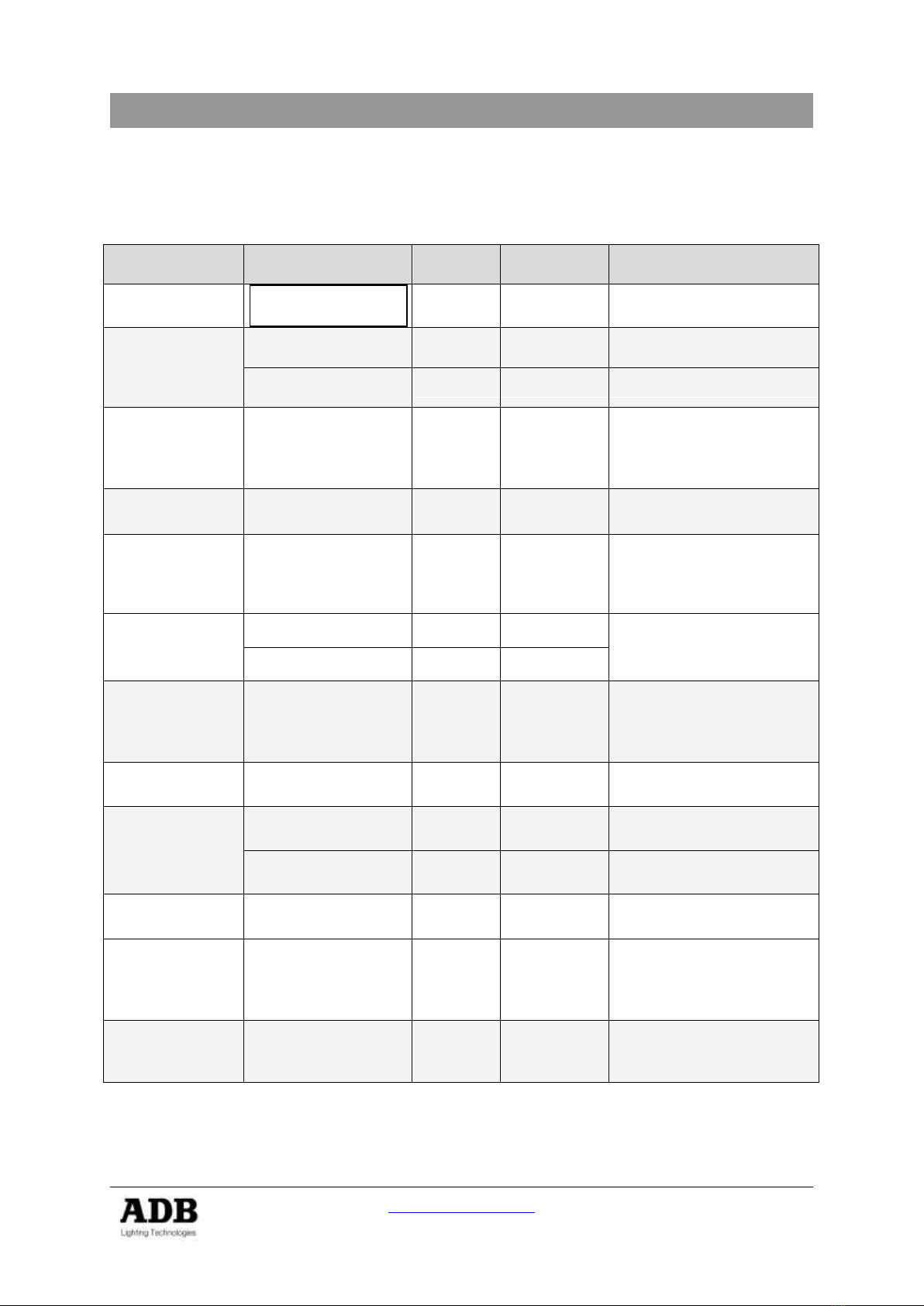

Operation

Connection

Designation

Qty

Torque

Tools

Remove Doors

Pan Head Screw

M4x12 PZ

1

1,5 Nm

Screw Driver PZ2

Remove Card

Cage Dimmers

Pan Head Screw

M4x12 PZ

5

2 Nm

Screw Driver PZ2

Slotted Flat Head

Screw M4 x 12 PZ

16

1,5 Nm

Screw Driver PZ 2

Open Cables

aperture

In & Out

Pan Head Screw

M4x12 PZ

8

2 Nm

Screw Driver PZ 2

PE Connection

Power In

Nut M10

1

8 to 10 Nm

Metric Wrenches 17

Sequential

Diagnostics

(Optional)

Nut M 5 / Flat

Washers M 5 /

Helical Spring Lock

Washers M 5

2 of each

1,5 Nm

Metric Wrench 8

Input

Connection

(Bus Bar)

Nut M12

4

8 to 10 Nm

2 x Metric Wrenches 19

Bolt M12

4

8 to10 Nm

Output

Connection

(Output)

Terminal

Connection

Free Drive Screw

256

1,5 Nm

Flat Screw Driver 1 x 6, 5

(do not use power tools!)

PE connection

(Output)

Screws M4 x 8

128

1,5 Nm

Screw driver PZ 1

DMX

Connection

RJ 45

1

Phoenix MSTBVA

2,5 –6

6

0,5 Nm

Flat ScrewDriver 0,5 x3, 5

Ethernet

Connection

RJ 45

1

TTD Human

Interface

Nut M 4 / Flat

Washers M 4 /

Helical Spring Lock

Washers M 4

X4 (of

each)

1,5 Nm

Metric Wrench 7

Junction Plate

(Accessory)

Hex Cap Screw

M 16 x 25

4

3 Nm

Metric Wrenches 24

ADB recommend using Insulated Screwdriver.

EURODIM TWIN TECH

www.adblighting.com

Installation manual - Page 8

Version 1.2

3.3.2 Packaging

The cabinets are shipped on a wooden pallet (see attached drawing in Chapter 12:

5000-35-650).

Standard transport position is vertical; First open the top panel after removing the screws of

the side panels.

The control processors, TTD Human Interface and dimmer modules are packed separately.

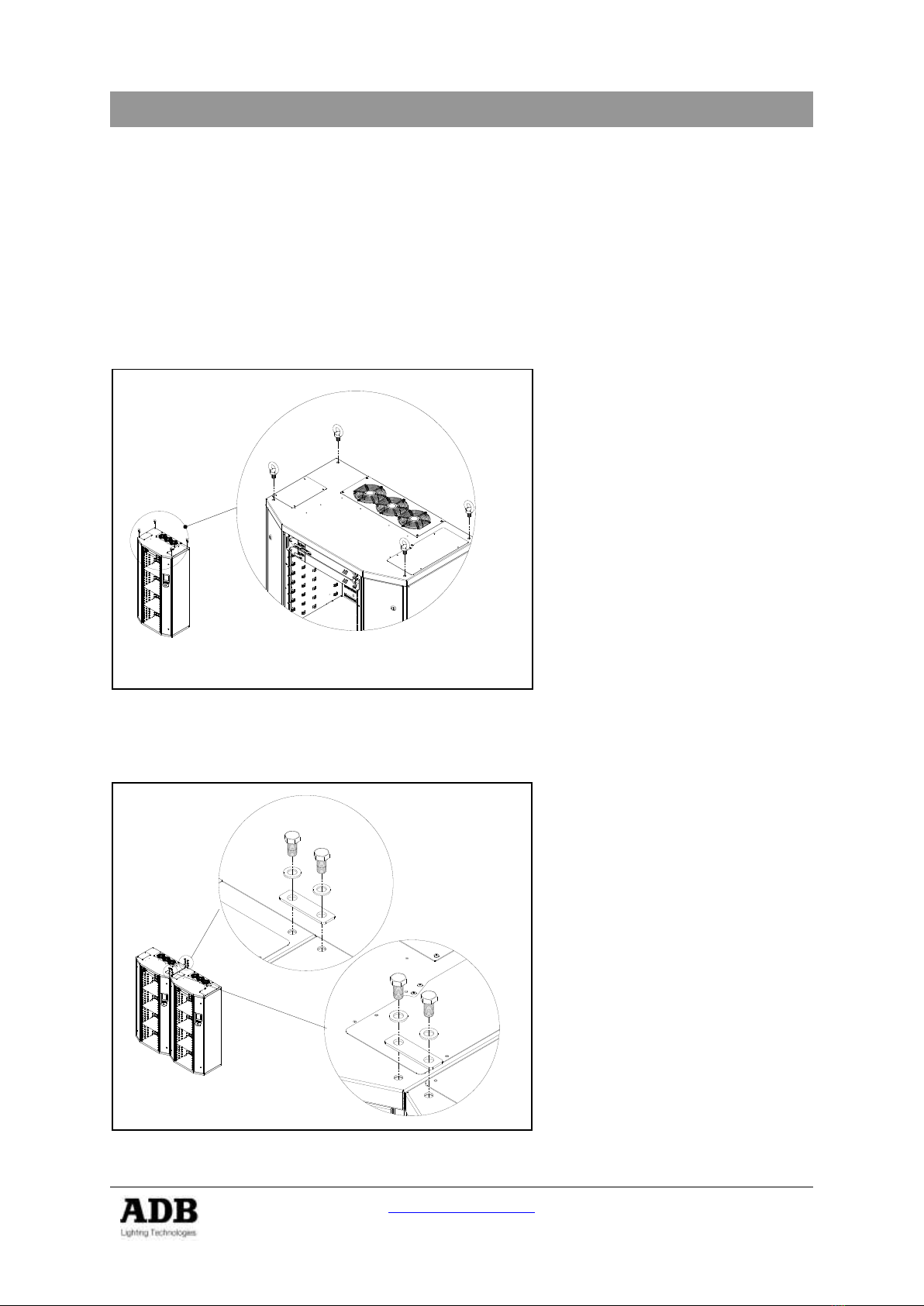

3.3.3 Lifting Eyes (Optional Accessory)

If the cabinet must be elevated with a crane, use 4 lifting eyes

TTD/CAB/LIFT kit including 4 Lifting Eyes.

3.3.4 Junction Plate (optional part)

With the optional junction plate two cabinets can be connected to guarantee permanent

fixation.

EURODIM TWIN TECH

www.adblighting.com

Installation manual - Page 9

Version 1.2

The weight and dimensions of the cabinets are included in Chapter “Characteristics”. Prior to

positioning each cabinet, ensure that the floor is flat and horizontal to ensure a good weight

distribution.

It is the responsibility of the system integrator or installer to check if the cabinet weight load

can be supported by the building structure!

After you have positioned the cabinets:

-Do not remove the plastic, so as to keep a protection during the cabling works.

-Cut the plastic to have an access to the cabling areas.

-Remove the doors of the contractor's areas by simply opening the door hinges.

CAUTION! The doors are grounded / earthed.

Gently remove this grounding connection WHICH MUST BE

RESTORED when the door is eventually put back in place.

During the cabling works, leave the doors in a clean area and covered

with a protection.

EURODIM TWIN TECH

www.adblighting.com

Installation manual - Page 10

Version 1.2

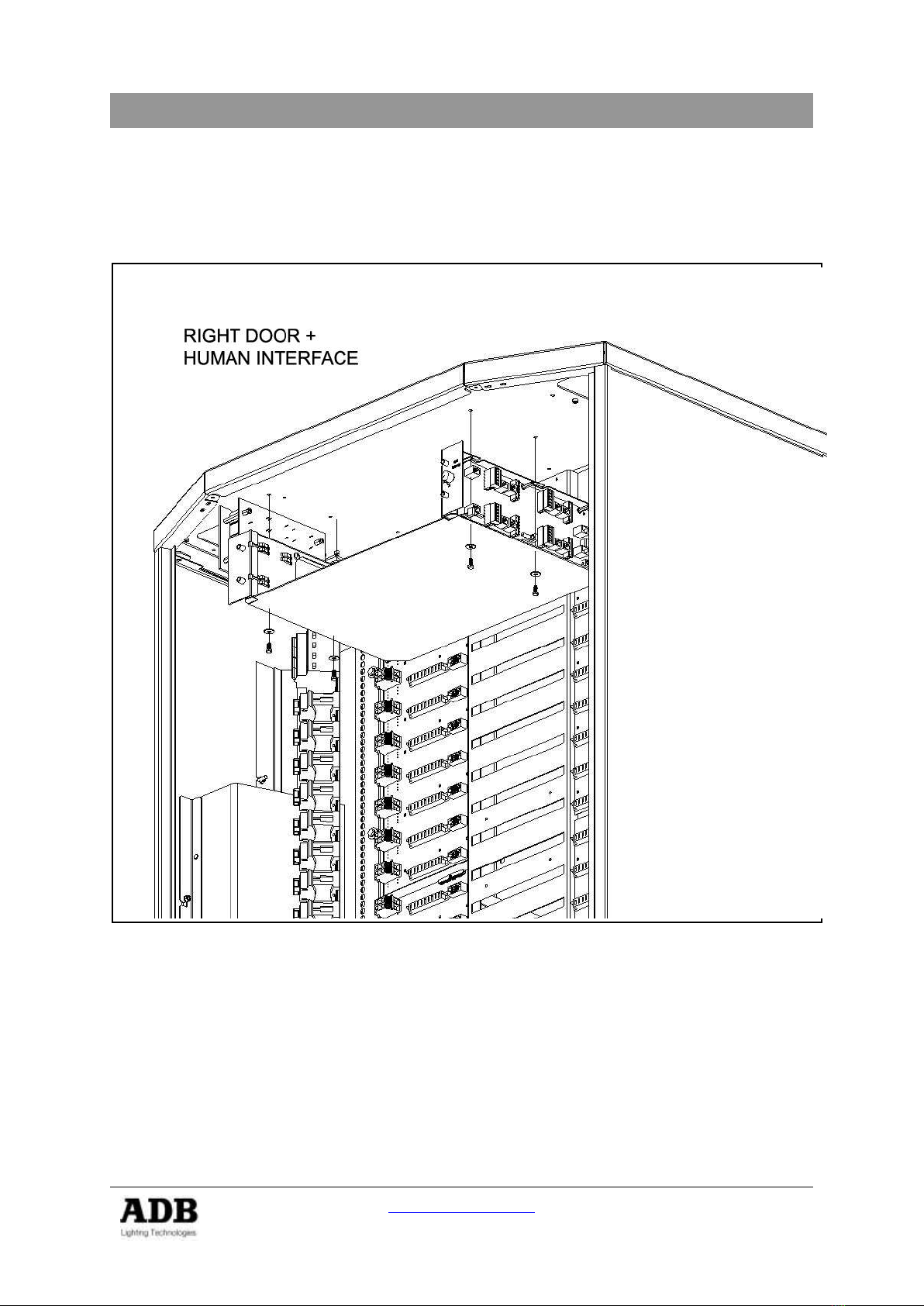

4. CONTRACTOR'S COMPARTMENT –SUPPLY

Front access only is required. Cable entry is possible through bottom and top of the cabinet.

Cover panels for the unused cable entry/ exit apertures are supplied.

In order to gain maximum space to access the

cabinet for installation and maintenance

purposes, remove the two doors, loosen the 16

crosshead screws in the back and 3 left + right

at the bottom and dismount the entire card

cage in one piece.

Mounting the cabinet, first insert the card cage,

enter two dimmer modules to align the rack

and fasten the 16 screws. Put the doors in

place and reconnect the doors earth

connection.

EURODIM TWIN TECH

www.adblighting.com

Installation manual - Page 11

Version 1.2

4.1 Controller Electronics - CPU/ PSU crate

The CPU/ PSU crate is already mounted in our factory. If a removal is required, loosen the 4

screws and remove the complete crate gently. Replace the connected flat cables with

caution.

4.2 Supply voltage

The high voltage/low voltage power transformer MUST ABSOLUTELY provide a three phase

star system with available neutral (3NPE-400), and rated line voltage 380 V to 415 V

between phases and 220 V to 240 V rated voltage between each phase and neutral. See

“Protections” for more details.

The supply cable must have the four current-carrying power conductors (not necessarily the

PE conductor) twisted under the same sleeve, in order to reduce the electrical noise induced

by large dimmed currents.

The neutral conductor must be of equal or larger size than the phase conductors.

See the Appendix to this manual for more details about power supply systems for dimmer

systems.

EURODIM TWIN TECH

www.adblighting.com

Installation manual - Page 12

Version 1.2

4.3 Supply busbar

The three phase connection points are labelled L1 (phase No. 1, phase R), L2 (phase No. 2,

phase S) and L3 (phase No. 3, phase T).

The Neutral is labelled N and the colour code for the Neutral is blue, as per IEC

Recommendation 446.

The Phase and Neutral connection bars have 2 holes of Ø 13 mm, with 22 mm distance

between centres. Connections are suitable for size M 12 bolts and nuts, for connection of up

to four supply conductors. The conductors must be fitted with cable lugs.

EURODIM TWIN TECH

www.adblighting.com

Installation manual - Page 13

Version 1.2

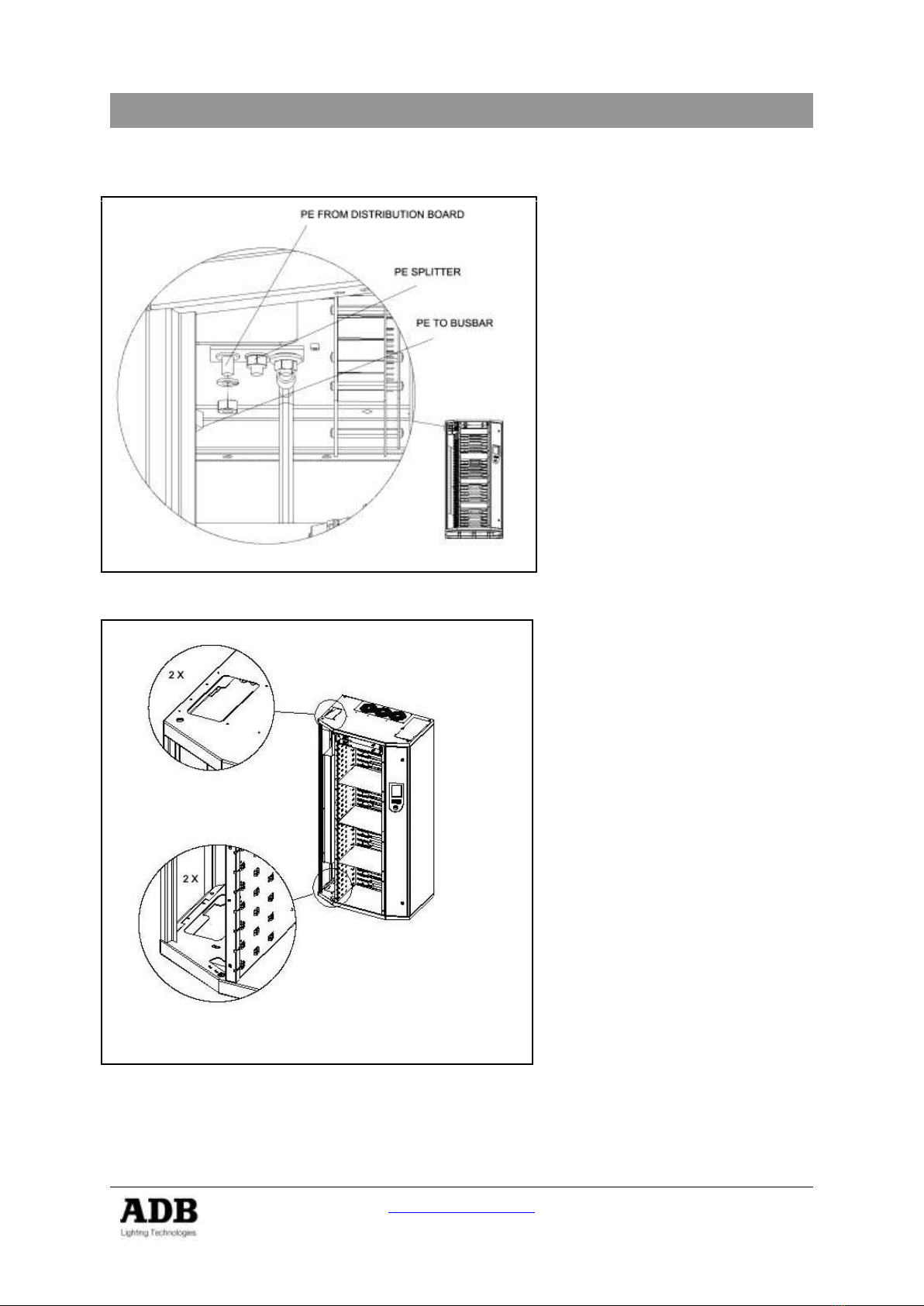

4.3.1 Protected Earth (PE) The Protective Earth (PE) on the

busbar connection is a bolt and

nut, size M10. Colour code:

green/yellow. The equipotential

connection, connecting the metal

frame, is provided at the top of the

supply cabling compartment. This

connection is already wired to the

busbar PE. An additional PE

connection is provided on the

cabinet’s bottom of the supply

compartment. All necessary nuts

and washers are included.

4.4 Connecting power supply cables.

Supply cables can be wired in

parallel, whilst each of these

cables must contain the three

phases and the Neutral under the

same sleeve. This cable must be

protected in the switchboard. The

total size of the conductors must

be chosen depending on the total

power of the dimmers, the utility

factor, the general protection on

the supply side, the voltage drop in

the line and local regulations. We

suggest the use of several cables

placed in parallel, to facilitate the

work of the contractor: the cables

usually have a bending radius of

min. 15 times their external

diameter. Respect an angle of 30

degree to connect the supply cable

in order to achieve necessary

distance between the cables and

busbar. Use the wholes on bottom

and top to connect the cable wraps

for stress relief.

EURODIM TWIN TECH

www.adblighting.com

Installation manual - Page 14

Version 1.2

4.5 Ground and Earth Connections

The sound or video earth should be separated from the dimmer earth. The distance between

the dimmer earth and the others should be as large as possible. Refer to local regulations for

grounding.

Regarding the Protection Earth (PE) local and international rules and regulations apply. If in

doubt about the correct please consult a local approved electrical engineer specialists for

advice in your particular case.

EURODIM TWIN TECH

www.adblighting.com

Installation manual - Page 15

Version 1.2

5. SEQUENTIAL DIAGNOSTICS (Optional)

In case the client has ordered the option:

One Sequential Diagnostics kit must be installed for each dimmer cabinet in the installation.

The sequential diagnostics function is similar in function to the diagnostics already used in

the EURODIM 3. The dimmer channels are examined one after the other (sequential) and

the value is reported either to the local Human Interface or a remote program running the

TTD Management Software.

The communication to a single remote reporting pc is done via the proprietary ADB ADN

protocol based on an Ethernet Network to a Personal Computer with the Windows Operating

System running the TTD Management Software. The Ethernet information is generated by

each EURODIM Twin Tech controller and physically available for each individual controller

on dedicated RJ45 connectors (Two possible per cabinet if double controller options are

used).

The TTD Management Software and the necessary hardware are available as option for the

EURODIM Twin Tech cabinet, which shall be ordered separately installation.

Standard functions include

Presence of Mains and DMX signal

Processor (active) check

Over Temperature

Fan Failure (Information per FAN!)

DMX Control Levels

Local test of a dimmer (steady, flash or chaser)

Automatic self-test of control electronics.

Error messages and all events/parameters are available for display locally on the EURODIM

Twin Tech Human Interface Controller and/or remotely on the TT Dimmer Manager PC

connected via an Ethernet Network. (use of ADN protocol)

Scan Load and the related functions are pre-show

1

test routines providing additional

information on the status of each dimmer, i.e.

Value of the dimmer load (kW)

Deviation from reference load

No load, overload warnings

Short-Circuit

The necessary hardware to perform Sequential Diagnostic measurements is an option and

which shall be installed at the client’s site.

1

Sequential Diagnostics cannot be used during a show, since control is disabled and the dimmers

system runs through a test routine.

EURODIM TWIN TECH

www.adblighting.com

Installation manual - Page 16

Version 1.2

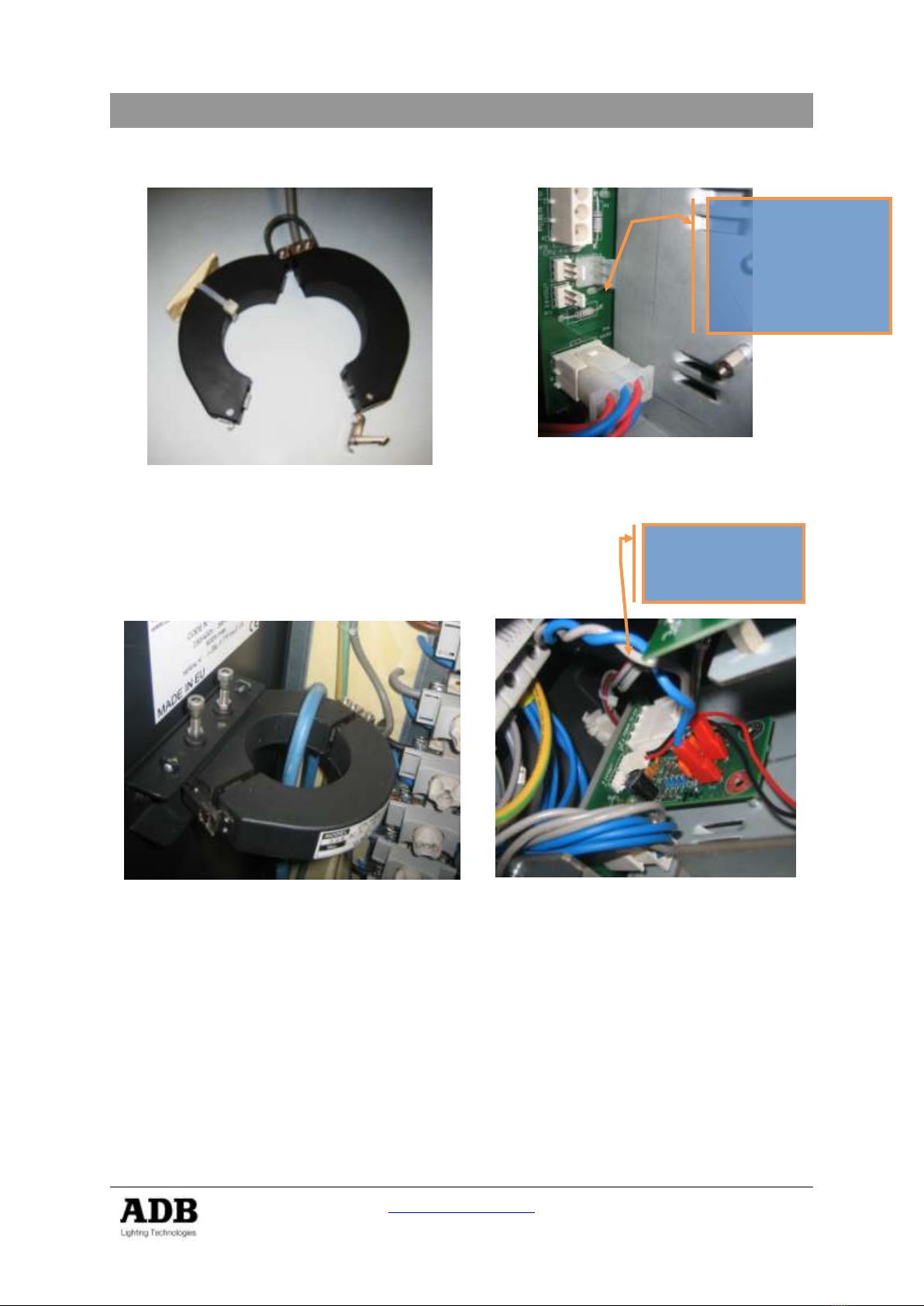

5.1 Hardware installation

Overview of EDTT cabinet - Supply Compartment

All the hardware installations are to be performed in the left hand contractor department. This

is where the EURODIM Twin Tech cabinet receives the power supply. It is advisable to

mount the hardware before you introduce the power supply cables, because there is more

space for the installation left.

The only cable which shall pass through the TI (power coil) is the neutral cable (blue) - the

other supply lines pass on the outside of the TI. The TI coil has a latching mechanics

allowing to open the coil and to pass the (large) neutral cable through it. There is a cable

(approx. 150 cm) with grey and blue wire. This cable is to be brought to the upper right hand

side of the cabinet, where the PCB 3015 is to be mounted.

PCB 3015 for communication

to Processor Unit.

TI –Measuring Coil. The

NEUTRAL (blue) cable from

the cabinet power supply must

pass through.

EURODIM TWIN TECH

www.adblighting.com

Installation manual - Page 17

Version 1.2

5.2 Mounting Procedure

Figure 1: open TI before mounting

(Cable for connection to PCB 3015)

Detail of Mounting Place for PCB 3015

5.3 Finished installation

Detail of TI with mounting Kit

Detail of PCB 3015 connected

The PCB 3015 is fixed with 2 provided screws to the central controller housing.

PCB 3015

Connector

(the other

connectors remain

as they are for fan

power).

Cables from TI

(Grey/Blue)

EURODIM TWIN TECH

www.adblighting.com

Installation manual - Page 18

Version 1.2

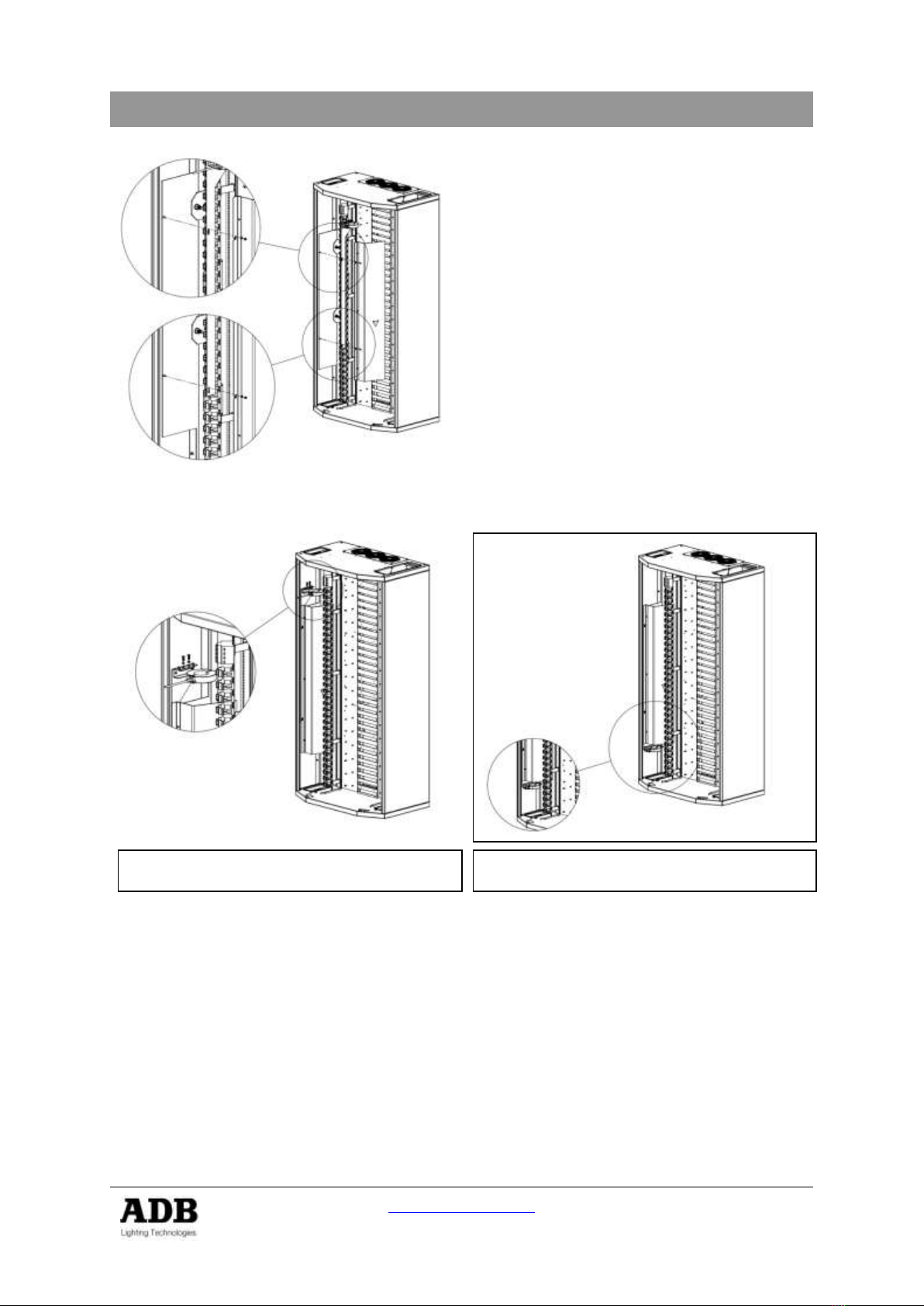

Installation of TI –Measurement device

1.) Remove the Bus-Bar protection (2

Screws).

2.) Install the TI-Holder (long metal

plate) –Direction depends if the

cable entry is from the top or bottom

of cabinet.

3.) Connect Phase and Ground Cable to

the Bus-Bar with suitable screws.

4.) Bring the NEUTRAL (blue) cable

through the TI (the TI can be opened

for easier installation.

5.) Connect the NEUTRAL to the bus

bar.

6.) Place the Bus-Bar protection back in

the cabinet –and attach with the two

screws.

Mounting of the TI for supply cable entry

from the top of the cabinet

Mounting of the TI for supply cable entry

from the bottom of the cabinet

5.4 Software Installation

The black lines are ETHERNET connections between the EURODIM Twin Tech, Switch and

PC running the TTD Management Software. This software must only be installed one time.

At the same time a lighting control desk (which must support ArtNET communications

protocol) may be connected to the ETHERNET Switch. To simplify the image the control

desk has not been included in the drawing. Both the PC running TTD Management Software

and the lighting control desk (e.g. ADB LIBERTY, FREEDOM or MENTOR desks) may

operate simultaneously and there is no influence, since both systems work with different

protocols. Alternatively the control desk may be connected to one of the DMX inputs of the

EURODIM Twin Tech cabinet. (Instead of using ArtNET protocol). The ETHERNET switch is

connected with suitable communication cables (e.g. CAT5) to handle the dimmer information

as well as the ArtNET communication.

Other manuals for EURODIM TWIN TECH

1

Table of contents

Other ADB Lighting Equipment manuals