113237-15 www.adclaundry.com 9

Dryers may be positioned sidewall to sidewall. However, a

1/16” (1.5875 mm) minimum allowance must be made for

the opening and closing of the control door. It is suggested

that the dryer be positioned about 2 feet (0.61 meters) away

from the nearest obstruction for ease of installation,

maintenance, and service (to be measured from the back

guard). Refer to the illustration on the previous page for

details.

Fresh Air Supply Requirements _______

This appliance may only be installed in a room that meets

the appropriate ventilation requirements specified in the

national installation regulations.

The air supply (make-up air) must be given careful

consideration to ensure proper performance of each dryer.

An unrestricted source of air is necessary for each dryer. An

airflow of 460 cfm (cubic feet per minute) (13 cmm [cubic

meters per minute]) must be supplied to each dryer. As a

general rule, an unrestricted air entrance from the outdoors

(atmosphere) of a minimum of 1 square foot (0.093 square

meters) is required for each dryer. If registers or louvers are

installed over the openings, then the area must be increased.

It is not necessary to have a separate make-up air opening

for each dryer. Common make-up air openings are

acceptable. However, they must be set up in such a manner

that the make-up air is distributed equally to the dryers. The

dryer must be installed with provisions for adequate

combustion and make-up air supply.

EXAMPLE: For a bank of eight dryers, two unrestricted

openings measuring 2 feet by 2 feet (0.61 meters by 0.61

meters) (4 square feet [0.372 square meters]) are

acceptable.

Exhaust Requirements ________________

Exhaust ductwork should be designed and installed by a

qualified professional. Improperly sized ductwork will create

excessive back pressure, which results in slow drying,

increased use of energy, and shutdown of the burner by the

airflow (sail) switch, burner hi-limit, or lint chamber hi-heat

protectorthermostat. Thedryermust be installed with aproper

exhaust duct connection to the outside.

When possible, it is suggested to provide a separate (single)

exhaust duct for each dryer.

The design of the flue system shall be such that any

condensate formed when operating the appliance from cold

shall either be retained and subsequently re-evaporated or

discharged.

CAUTION: This dryer produces combustible lint and

must be exhausted to the outdoors.

Improperly sized or installed exhaust ductwork can

create a potential fire hazard.

The exhaust ductwork should be laid out in such a way that

the ductwork travels as directly as possible to the outdoors

with as few turns as possible. The shape of the ductwork is

not critical as long as the minimum cross section area is

provided. Single or independent dryer venting is

recommended.

It is suggested that the use of 90° turns be avoided; use 30°

or 45° angles instead.

The ductwork should be smooth inside with no projections

from sheet metal screws or other obstructions, which will

collect lint. When adding ducts, the ducts to be added should

overlap the duct to which it is connected. All ductwork joints

must be taped to prevent moisture and lint from escaping

into the building. Additionally, inspection doors should be

installed at strategic points in the exhaust ductwork for

periodic inspection and cleaning.

IMPORTANT: When connecting ductwork to the dryer

exhaust duct, be sure that when screws are used they do

not restrict the operation (both opening and closing) of the

damper.

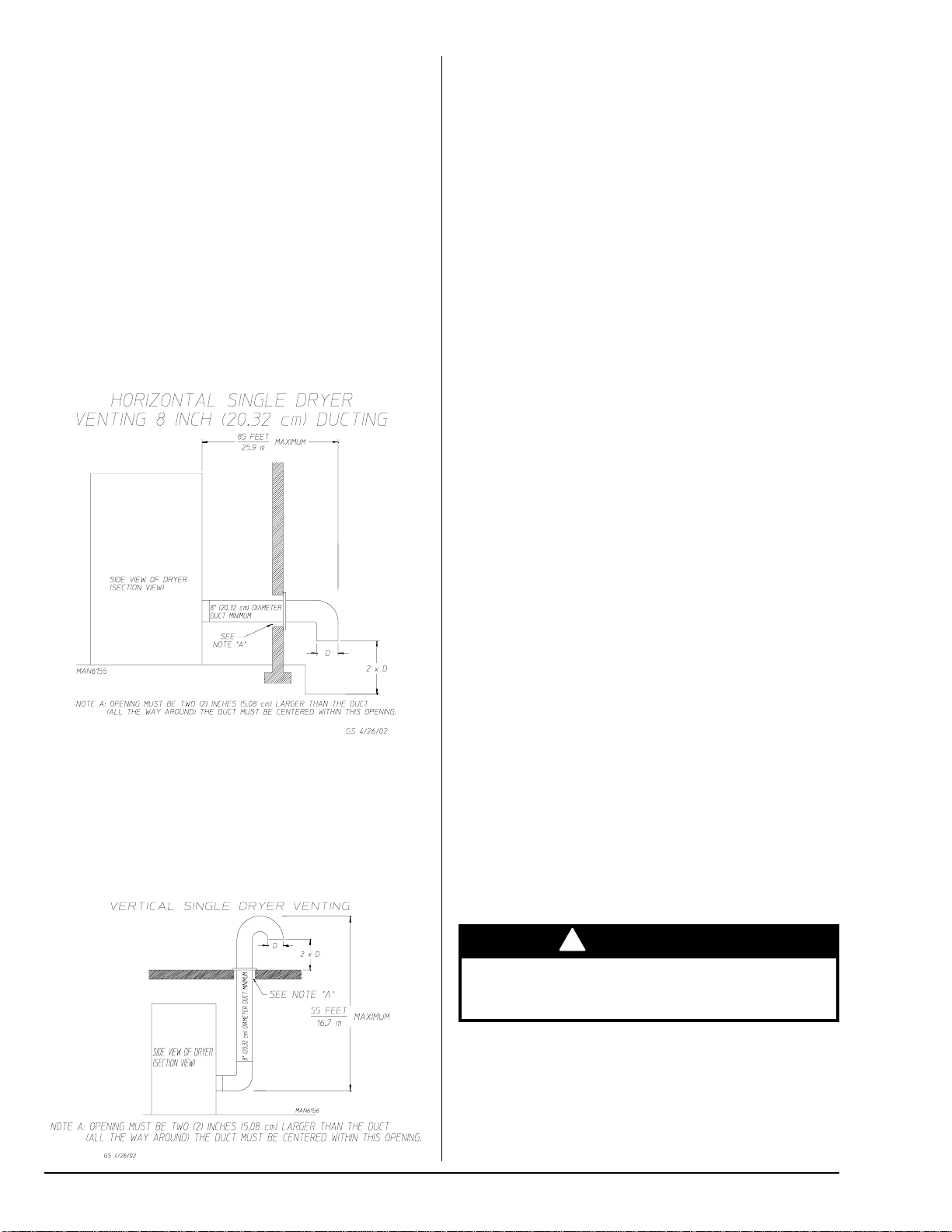

NOTE: When the exhaust ductwork passes through a wall,

ceiling, or roof made of combustible materials, the

opening must be 2-inches (5.08 cm) larger than the duct

(all the way around). The duct must be centered within this

opening.

To protect the outside end of the horizontal ductwork from the

weather, a 90° elbow bent downward should be installed

where the exhaust exits the building. If the ductwork travels

vertically up through the roof, it should be protected from the

weather by using a 180° turn to point the opening downward.

In either case, allow at least twice the diameter of the duct

between the duct opening and the nearest obstruction (i.e.,

roof or ground level).

IMPORTANT: Do not use screens, louvers, or caps on the

outside opening of the exhaust ductwork.

Exhaust back pressure measured by a manometer at the

dryer exhaust duct area must be no less than 0 and must

not exceed 0.3 in WC (0.74 mb).

It is recommended that exhaust or booster fans not be

used in the exhaust ductwork system.

IMPORTANT: Make-up air openings should not be located

in an area directly near where exhaust vents exit the

building.

Allowances must be made for remote or constricting

passageways or where dryers are located at excessive

altitudes or predominantly low-pressure areas.

IMPORTANT: Make-up air must be provided from a source

free of dry cleaning solvent fumes. Make-up air that is

contaminated by dry cleaning solvent fumes will result in

irreparable damage to the motors and other dryer

components.

NOTE: Component failure due to dry cleaning solvent

fumes will void the warranty.