113403-17 www.amdry.com 3

IMPORTANT

You must disconnect and lockout the electric supply

and the gas supply or the steam supply before any

covers or guards are removed from the machine to

allow access for cleaning, adjusting, installation, or

testing of any equipment per OSHA standards.

Please observe all safety precautions displayed on

the equipment and/or specified in the installation

manual included with the dryer.

Before installation, check that the local distribution

conditions, nature of gas and pressure, and

adjustment of the appliances are compatible.

CAUTION

Dryer(s) should never be left unattended while in

operation.

When discarding or storing your old clothes dryer,

remove the door.

Lorsque vous entreposez ou mettez votre

sécheuse au rebut, enlevez-en la porte.

“Caution: Label all wires prior to disconnection when

servicing controls. Wiring errors can cause improper

operation.”

«Attention:Au moment de l’entretien des commandes,

étiquetez tous les fils avant de les débrancher. Des

erreurs de câblage peuvent entraîner un

fonctionnement inadéquat et dangereux.»

FOR YOUR SAFETY

Do not dry mop heads in the dryer. Do not use

dryer in the presence of dry cleaning fumes.

The dryers must not be installed or stored in an area

where it will be exposed to water and/or weather.

The wiring diagram for the dryer is located behind the

control panel.

Table of Contents __________________

In the State of Massachusetts, the following installation

instructions apply:

■Installations and repairs must be performed by a

qualified or licensed contractor, plumber, or gasfitter

qualified or licensed by the State of Massachusetts.

■If using a ball valve, it shall be a T-handle type.

■A flexible gas connector, when used, must not exceed 3

feet.

WARNING

Children should not be allowed to play on or near

the dryer(s). Children should be supervised if

near dryer(s) in operation.

Under no circumstances should the dryer door

switch(es), lint door/drawer switch(es), or heat

safety circuit(s) ever be disabled.

Do not modify this appliance.

The dryer must never be operated with any of

the back guards, outer tops, or service panels

removed. Personal injury or fire could result.

The dryer must never be operated without the

lint filter/screen in place, even if an external lint

collection system is used.

If the hi-limit switch trips, a service call is

required to investigate the reason and resolve

the issue.

Proposition 65

Use of this product could expose you to substances

from fuel combustion that contain chemicals

known to the State of California to cause cancer,

birth defects and other reproductive harm.

!WARNING

List of Acronyms _________________________

HVAC Heating, Ventilating, and Air-Conditioning

in WC Inches of Water Column

L.C.D. Liquid Crystal Display

L.P. Liquid Propane

OSHA Occupational Safety and Health Administration

R.M.A. Return Material Authorization

UL Underwriters Laboratory

Safety Precautions ................................................................ 4

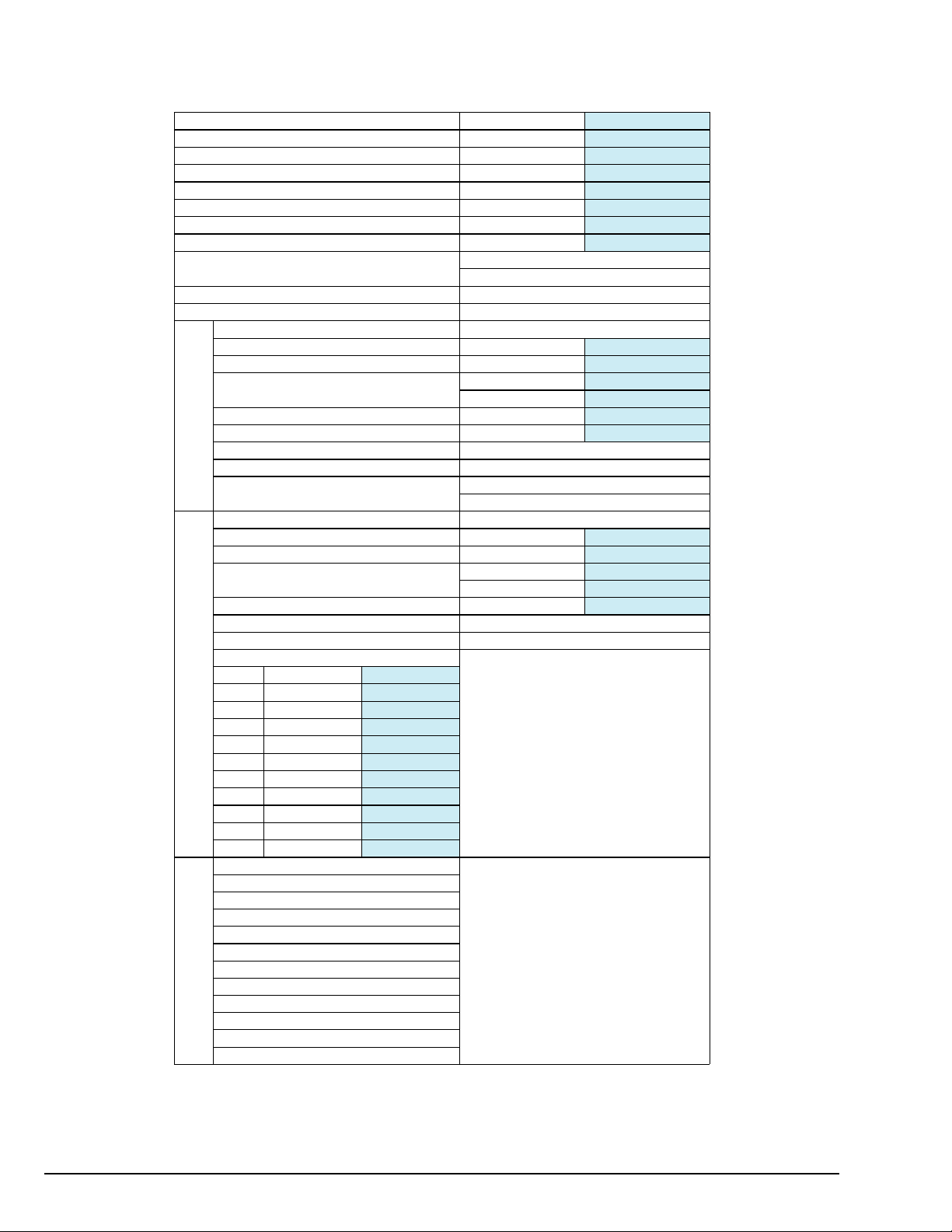

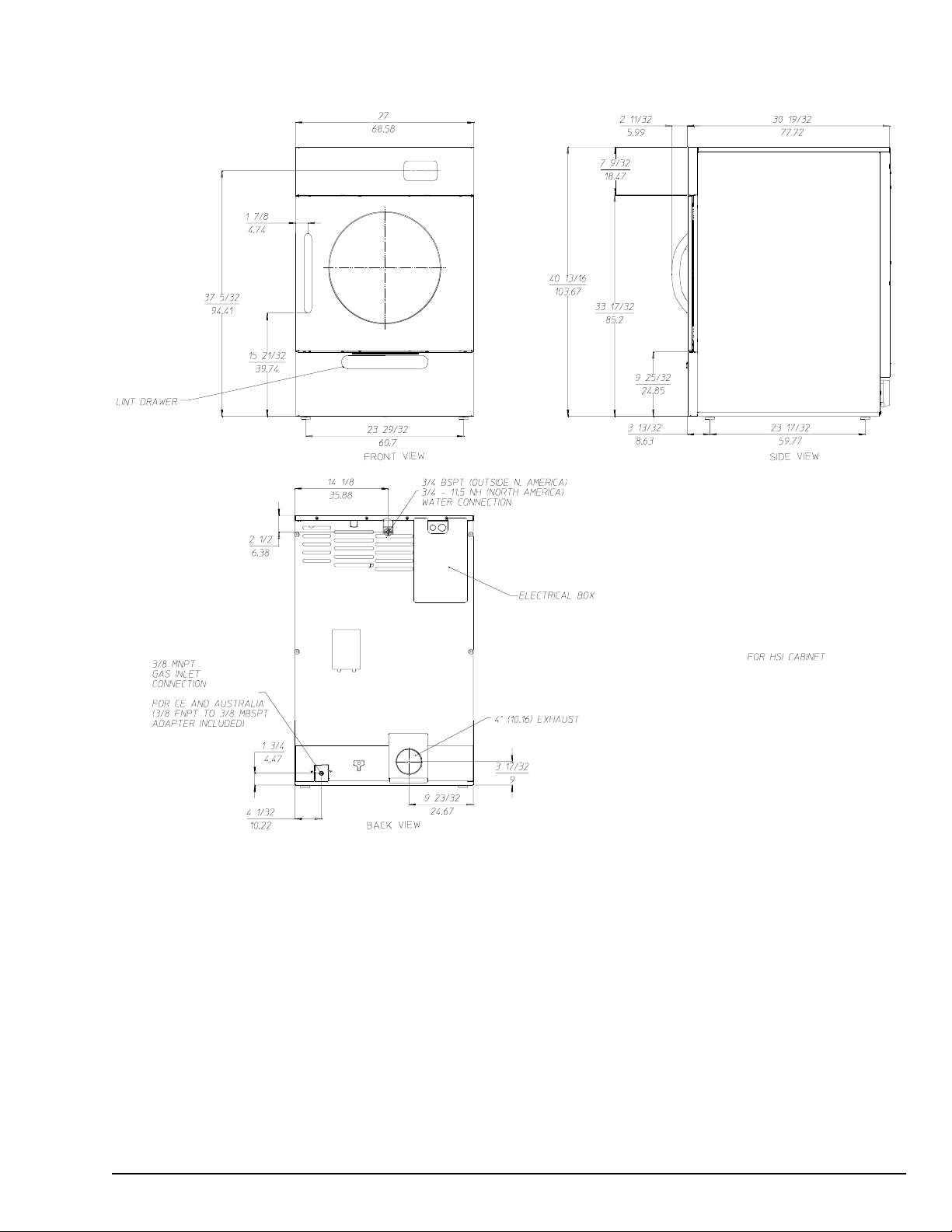

SL20 Specifications ............................................................... 6

SL31 Specifications ............................................................... 8

SL50 Specifications ............................................................. 10

SL75 Specifications ............................................................. 12

Installation Procedures ...................................................... 14

Location Requirements ........................................................ 14

Unpacking / Setting Up ......................................................... 14

Dryer Enclosure Requirements ........................................... 14

Fresh Air Supply Requirements .......................................... 15

Exhaust Requirements ......................................................... 15

Electrical Information ............................................................ 17

Gas Information.................................................................... 20

Steam Information ................................................................ 25

Water Information ................................................................ 26

Preparation for Operation / Start-Up ................................... 27

Preoperational Test .............................................................. 27

Preoperational Instructions ................................................. 28

Shutdown Instructions ........................................................ 28

Service / Parts Information ............................................... 29

Service ................................................................................. 29

Parts ...................................................................................... 29

Warranty Information .......................................................... 29

Returning Warranty Cards .................................................. 29

Warranty .............................................................................. 29

Returning Warranty Parts ................................................... 29

Routine Maintenance .......................................................... 30

Data Label Information ....................................................... 31

Programming........................................................................ 32