6American Dryer Corp. 113390-5

NOTE: ADCreservestheright tomake changesinspecifications atany timewithoutnotice or

obligation.

SECTIONII

SPECIFICATIONS / COMPONENTIDENTIFICATION

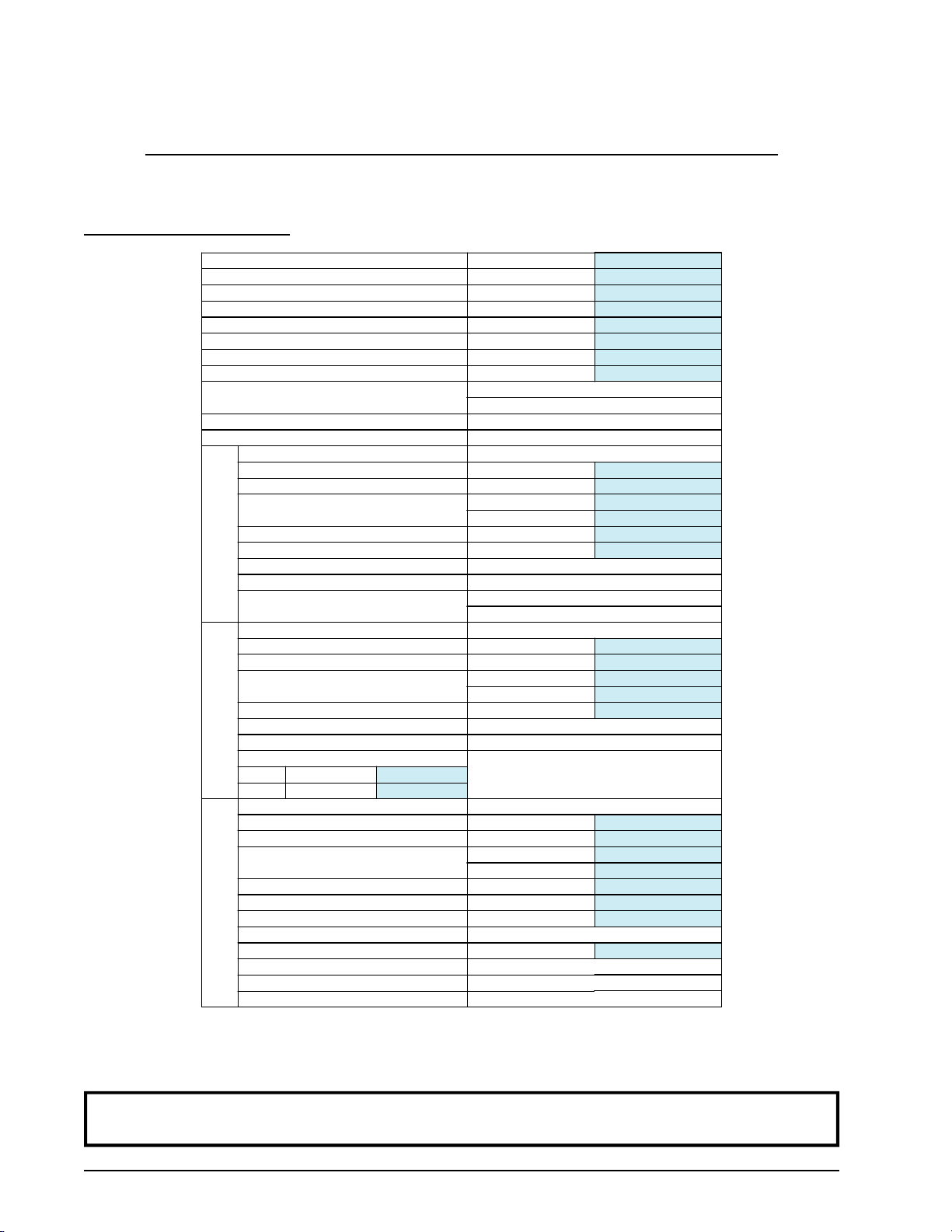

A. SPECIFICATIONS

MAXIMUM CAPACITY (DRY WEIGHT) 75 lb 34.02 kg

TUMBLER DIAMETER 36-1/4” 92.08 cm

TUMBLER DEPTH 36” 91.44 cm

TUMBLER VOLUME 21.50 cu ft 608.81 L

TUMBLER (DRIVE) MOTOR Non-Reversing / Reversing 1 hp / 1/2 hp*0.75 kW / 0.37 kW

BLOWER (FAN) MOTOR Non-Reversing / Reversing — / 1 hp*— / 0.75 kW

DOOR OPENING (DIAMETER) 31-3/8” 79.69 cm

DOOR SILL HEIGHT 28” 71.12 cm

WATER CONNECTION 3/4”-11.5 NH (North America)

3/4” B.S.P.T. (Outside North America)

DRYERS PER 20’/40’ CONTAINER 10 / 20

DRYERS PER 48’/53’ TRUCK 24 / 26

VOLTAGE AVAILABLE 120-575V 1,3ø 2,3,4w 50/60 Hz

APPROXIMATE NET WEIGHT 721 lb 327.04 kg

APPROXIMATE SHIPPING WEIGHT 773 lb 350.63 kg

AIRFLOW 60 Hz 1,000 cfm 28.32 cmm

50 Hz 833 cfm 23.60 cmm

HEAT INPUT 175,000 Btu/hr 44,099 kcal/hr

EXHAUST CONNECTION (DIAMETER) 8” 20.32 cm

COMPRESSED AIR CONNECTION N / A

COMPRESSED AIR VOLUME N / A

INLET PIPE CONNECTION 3/4” F.N.P.T.

3/4” B.S.P.T. (CE and Australia Only)

VOLTAGE AVAILABLE 208-575V 3ø 3,4w 50/60 Hz

APPROXIMATE NET WEIGHT 721 lb 327.04 kg

APPROXIMATE SHIPPING WEIGHT 773 lb 350.63 kg

AIRFLOW 60 Hz 1,000 cfm 28.32 cmm

50 Hz 833 cfm 23.60 cmm

EXHAUST CONNECTION (DIAMETER) 8” 20.32 cm

COMPRESSED AIR CONNECTION N / A

COMPRESSED AIR VOLUME N / A

OVEN SIZE

kW Btu/hr kcal/hr

30 102,400 25,800

VOLTAGE AVAILABLE 120-575V 1,3ø 2,3,4w 50/60 Hz

APPROXIMATE NET WEIGHT 816 lb 370.13 kg

APPROXIMATE SHIPPING WEIGHT 868 lb 393.72 kg

AIRFLOW 60 Hz 1,200 cfm 33.98 cmm

50 Hz 1,000 cfm 28.32 cmm

STEAM CONSUMPTION 275 lb/hr 124.7 kg/hr

OPERATING STEAM PRESSURE 125 psi max 8.62 bar

EXHAUST CONNECTION (DIAMETER) 8” 20.32 cm

COMPRESSED AIR CONNECTION 1/8” F.N.P.T.

COMPRESSED AIR VOLUME 0.75 cfh 0.02 cmh

BOILER HORSEPOWER (NORMAL LOAD) 7.2 Bhp

SUPPLY CONNECTIONS (2) 1-1/4” M.N.P.T.

RETURN CONNECTIONS (2) 1” M.N.P.T.

GAS

Shaded areas are stated in metric equivalents 2/19/09

*Reversing dryers use 3-phase (3ø) motors.

ELECTRICSTEAM