– 2 –

–+

J1

XL1

J2

+

-

NC

TAMP.

TAMP.

U1

TEST

MODE

PADS

SW3 (SENS1

AND SENS2

SWITCHES)

COVER

TAMPER

SWITCH

ENROLL

SWITCH

ENROLL

SWITCH

5852-003-V0

LED ENABLE

SWITCH

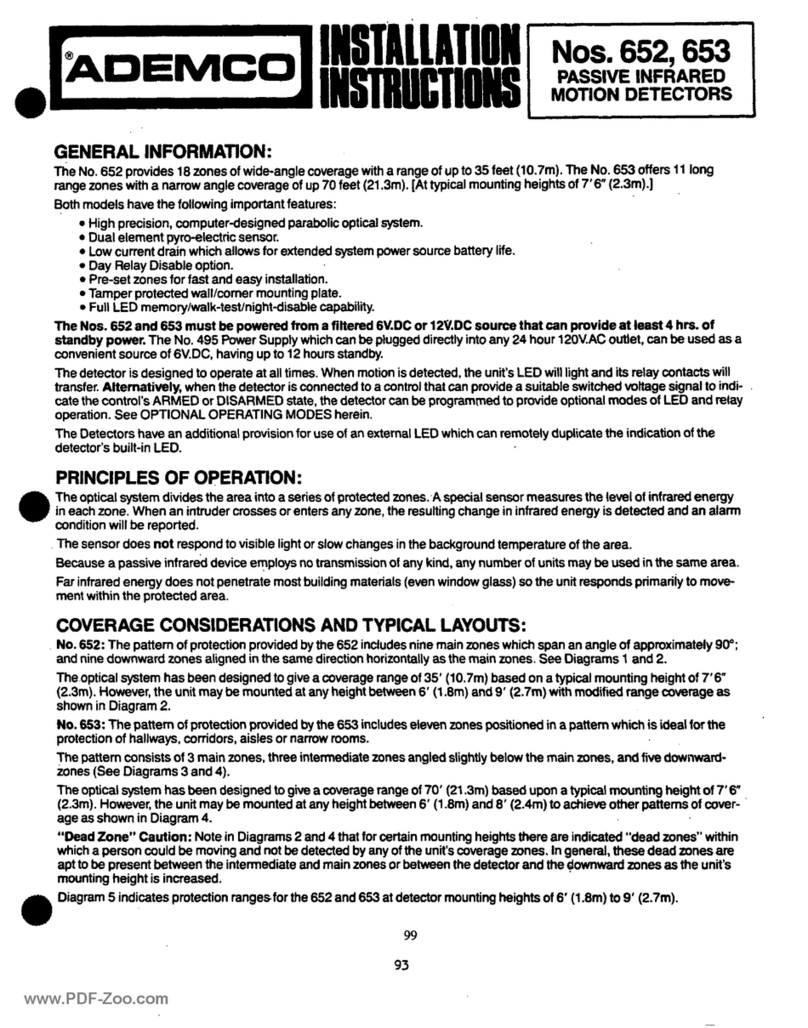

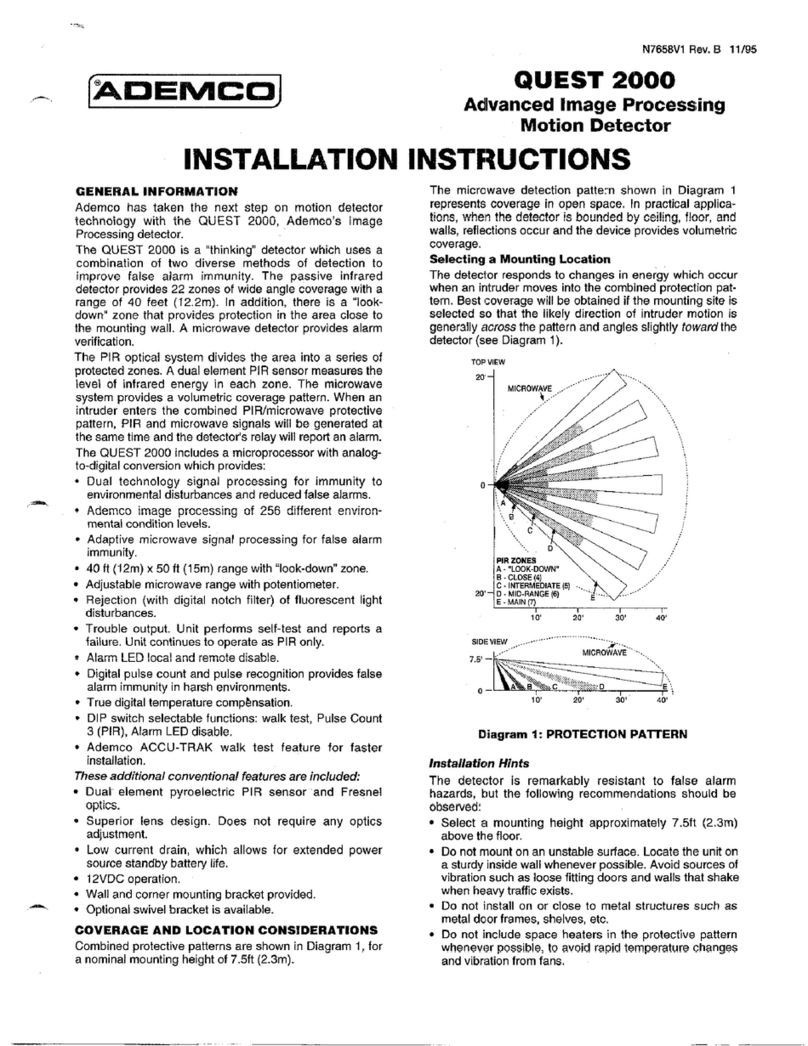

Figure 3. 5852 with Cover Assembly Removed

1. With the sensor in the approximate mounting location, carefully

open cover door. Avoid opening door too far or too fast.

2. Enable LEDs for test purposes by sliding the LED Enable

switch in the direction of the printed arrow (an orange tab will

protrude from the side of the sensor). See Figure 2, or use

procedure for entering the Remote LED Enable/Disable Mode

provided in this document.

3. Use a small screwdriver (or similar tool) to move the SENS1

and SENS2 switches to the desired positions (see table below).

ON OFF

SENS1

SENS2

SENSITIVITY

SENS1

SENS2 APPROX.

RANGE*

Max OFF OFF 25 ft (7.6 m)

Med ON OFF 15 ft (4.6 m)

LowOFFON10 ft (3m)

Lowest ON ON 5 ft (1.5 m)

*Verify range with the Intellisense Model FG-701 or Ademco

GBS7 Glassbreak Simulator.

4. Turn on any heating/air conditioning systems and other

equipment in the sensor's vicinity.

5. Observe the green Event LED for about one minute. If the

green LED flashes, the sensor should be relocated.

6. After adjustment, disable LEDs and close cover door.

REMOTE LED ENABLE/DISABLE MODE

The sensor’s Remote LED Enable/Disable mode allows you to

enable or disable the sensor’s LEDs with the FG-701 Glassbreak

Simulator. To enable or disable LEDs with the FG-701,

proceed as follows:

1. Set LED switch S4, position 4 to OFF.

2. Set the FG-701 switches to the ACTIVATE and MANUAL

positions.

3. Stand within 15 feet (4.6 m) of the sensor, point front of

FG-701 at sensor, and press red START button. The

simulator generates an audio activation signal, and the

sensor’s green LED flashes once per second.

4. Repeat step 3, and the sensor’s green LED will stop

flashing.

5. Within 2 seconds, repeat step 3 to send another activation

code. If disabling LEDs, the sensor’s green LED will flash

once. If enabling LEDs, the green LED will flash two or

three times.

6. Clap your hands to test LEDs. If LEDs are enabled, the

green LED will flicker. If LEDs are disabled, the green

LED will remain off.

"ENROLLING" THE 5852 SERIAL NUMBER

The 5852's serial number must be "enrolled" by the control

panel prior to use in the system. The control panel's installation

instructions provide detailed programming instructions for

"enrolling" transmitter serial numbers. Before programming,

proceed as follows:

1. Install battery (if not installed). Observe polarity!

2. Remove cover assembly.

3. When programming the transmitter, note the following:

• Input Type = 3 (Supervised RF)

• Loop Number = 1

When prompted, transmit from the sensor (momentarily

press the enroll switch located on the exposed transmitter

PC board, press the tamper switch, etc.). You can also

manually enter the sensor’s serial number.

4. Test the sensor after "enrolling" the serial number in the

system. Refer to the Testing the 5852 section.

MOUNTING

1. Determine the optimum mounting location, noting the

following (see Figure 4):

•Mount on ceiling or wall, at least 7 feet from floor.

•Ensure that the sensor has a direct, unobstructed line-of-

sight to the protected glass.

•Mount no more than 25 feet from the farthest protected

glass.

•Make sure there are no intervening partitions, curtains,

etc. that could block the transfer of shock or sound

waves.

NOTE: If window dressing is present, it will absorb

sound energy from breaking glass. In such cases, the

sensor should be mounted between the protected glass

and the window dressing.

•Avoid locating the sensor near sources of ambient

vibration or sound, such as air conditioners, fans,

blowers, air ducts, or loudspeakers.

•Avoid locations where furniture can be moved so that it

blocks the sensor's line-of sight to the glass.

•Avoid locations where a door can be opened or closed

such that it blocks the sensor's line of sight to the glass.

•Avoid locations near doors or windows that may be

slammed.

2. Before permanently mounting the 5852, conduct tests to

verify adequate signal strength (refer to control panel

instructions), and, if necessary, relocate the 5852 (pressing

the sensor's test switch will send a transmission). It is also

recommended that, before mounting permanently, the

sensor should be tested to ensure it is within reliable audio

and flex range from the protected glass. Refer to the

Testing the 5852 section for the procedure.

3. If not already removed, remove the sensor's cover assembly

by removing the screw located near the LED Enable

switch. Carefully pull cover assembly away from case.

4. Mark the mounting hole locations on the ceiling or wall

using the case as a template.

SW3

www.PDF-Zoo.com